Rotor Lamination Assembly . Shaft laser cleaning and press fitting; The rotor laminated stack is joined and the bolted together with screws. The rotor manufacturing process can be divided into 6 steps: The rotor’s design depends on the materials used and the engineering. Magnets or conductor bars insertion; The lamination process consistently reduces the loss. A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. Assemble and bolt rotor laminations. Motor lamination stacking and assembly involve assembling individual laminations, which are thin metal sheets, to form the core of an electric motor rotor. • the lamination stack must be electrically as well as mechanically separated from the winding to avoid electrical contact due. Our laminations are used in applications as diverse. We engineer lamination components that deliver optimal performance, efficiency, and reliability in virtually any motor or generator.

from www.alibaba.com

Assemble and bolt rotor laminations. Magnets or conductor bars insertion; Motor lamination stacking and assembly involve assembling individual laminations, which are thin metal sheets, to form the core of an electric motor rotor. The rotor manufacturing process can be divided into 6 steps: The lamination process consistently reduces the loss. Shaft laser cleaning and press fitting; A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. The rotor’s design depends on the materials used and the engineering. • the lamination stack must be electrically as well as mechanically separated from the winding to avoid electrical contact due. The rotor laminated stack is joined and the bolted together with screws.

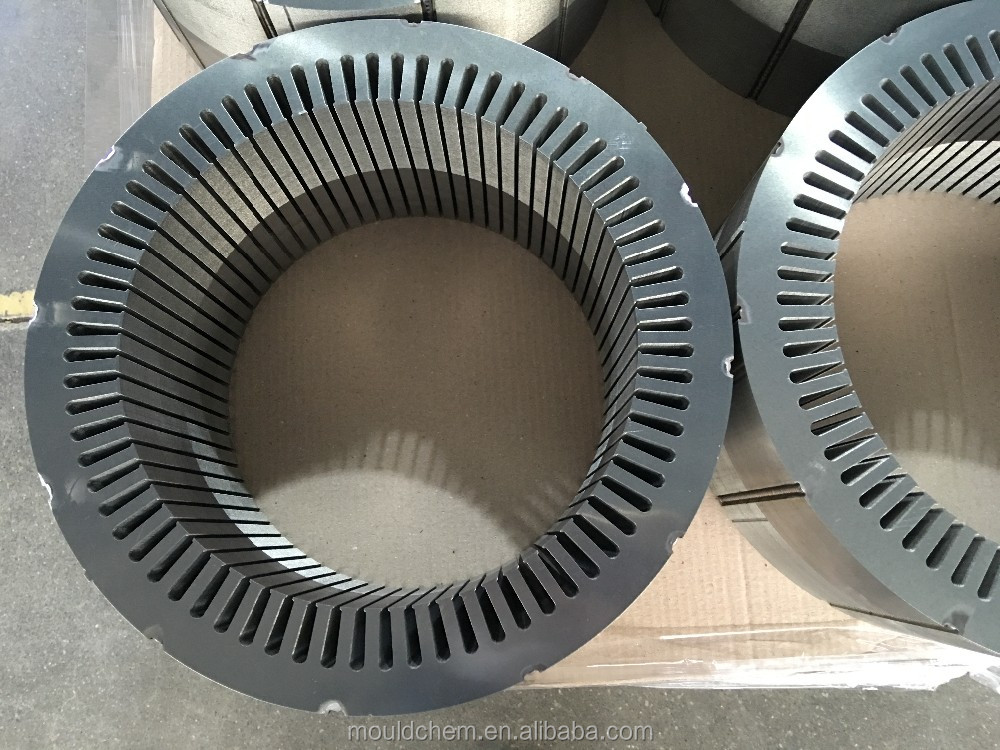

0.35mm Stator And Rotor Lamination Stack For Serve Motor Buy 0.35mm

Rotor Lamination Assembly Motor lamination stacking and assembly involve assembling individual laminations, which are thin metal sheets, to form the core of an electric motor rotor. Assemble and bolt rotor laminations. The rotor manufacturing process can be divided into 6 steps: The rotor’s design depends on the materials used and the engineering. • the lamination stack must be electrically as well as mechanically separated from the winding to avoid electrical contact due. A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. The rotor laminated stack is joined and the bolted together with screws. We engineer lamination components that deliver optimal performance, efficiency, and reliability in virtually any motor or generator. The lamination process consistently reduces the loss. Our laminations are used in applications as diverse. Magnets or conductor bars insertion; Motor lamination stacking and assembly involve assembling individual laminations, which are thin metal sheets, to form the core of an electric motor rotor. Shaft laser cleaning and press fitting;

From www.eng-tips.com

ROTOR STACK LAMINATIONS ROTATIONIN ELECTRO MOTOR LOW VOLTAGE Rotor Lamination Assembly A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. We engineer lamination components that deliver optimal performance, efficiency, and reliability in virtually any motor or generator. The rotor laminated stack is joined and the bolted together with screws. The. Rotor Lamination Assembly.

From laserlaminations.com

Rotor Laminations Laser Laminations Inc. Rotor Lamination Assembly The lamination process consistently reduces the loss. Motor lamination stacking and assembly involve assembling individual laminations, which are thin metal sheets, to form the core of an electric motor rotor. Shaft laser cleaning and press fitting; The rotor manufacturing process can be divided into 6 steps: Assemble and bolt rotor laminations. Magnets or conductor bars insertion; The rotor laminated stack. Rotor Lamination Assembly.

From www.researchgate.net

Rotor core design (a) lamination with cutoff on the qaxis (b Rotor Lamination Assembly We engineer lamination components that deliver optimal performance, efficiency, and reliability in virtually any motor or generator. A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. • the lamination stack must be electrically as well as mechanically separated from. Rotor Lamination Assembly.

From www.alibaba.com

0.35mm Stator And Rotor Lamination Stack For Serve Motor Buy 0.35mm Rotor Lamination Assembly Shaft laser cleaning and press fitting; The rotor laminated stack is joined and the bolted together with screws. Assemble and bolt rotor laminations. The lamination process consistently reduces the loss. • the lamination stack must be electrically as well as mechanically separated from the winding to avoid electrical contact due. Our laminations are used in applications as diverse. The rotor’s. Rotor Lamination Assembly.

From www.backlack.com

Rotor core laminations with Bonding varnish/Backlack Technology Rotor Lamination Assembly • the lamination stack must be electrically as well as mechanically separated from the winding to avoid electrical contact due. The lamination process consistently reduces the loss. A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. Assemble and bolt. Rotor Lamination Assembly.

From tymagnets.com

Stator Assembly Winding & Lamination Supplier Rotor Lamination Assembly The lamination process consistently reduces the loss. Our laminations are used in applications as diverse. Shaft laser cleaning and press fitting; The rotor laminated stack is joined and the bolted together with screws. A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or. Rotor Lamination Assembly.

From www.backlack.com

Rotor core laminations with Bonding varnish/Backlack Technology Rotor Lamination Assembly The rotor laminated stack is joined and the bolted together with screws. Motor lamination stacking and assembly involve assembling individual laminations, which are thin metal sheets, to form the core of an electric motor rotor. A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even. Rotor Lamination Assembly.

From www.emobility-engineering.com

Motor laminations EMobility Engineering Rotor Lamination Assembly The rotor manufacturing process can be divided into 6 steps: The rotor laminated stack is joined and the bolted together with screws. A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. The rotor’s design depends on the materials used. Rotor Lamination Assembly.

From www.researchgate.net

Stator and rotor lamination Download Scientific Diagram Rotor Lamination Assembly A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. The rotor’s design depends on the materials used and the engineering. The lamination process consistently reduces the loss. Assemble and bolt rotor laminations. • the lamination stack must be electrically. Rotor Lamination Assembly.

From baspartsales.com

8678401 Rotor And Lamination Assembly (NEW OLD STOCK) (SA) Rotor Lamination Assembly We engineer lamination components that deliver optimal performance, efficiency, and reliability in virtually any motor or generator. Our laminations are used in applications as diverse. Assemble and bolt rotor laminations. The lamination process consistently reduces the loss. A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6,. Rotor Lamination Assembly.

From www.hsmagnets.com

AC/DC Tubular Motor Stator and Rotor Lamination Core By HSMAG Rotor Lamination Assembly The lamination process consistently reduces the loss. We engineer lamination components that deliver optimal performance, efficiency, and reliability in virtually any motor or generator. Magnets or conductor bars insertion; Motor lamination stacking and assembly involve assembling individual laminations, which are thin metal sheets, to form the core of an electric motor rotor. The rotor’s design depends on the materials used. Rotor Lamination Assembly.

From motorneo.com

What Is Rotor Core Laminations? Motorneo Rotor Lamination Assembly Motor lamination stacking and assembly involve assembling individual laminations, which are thin metal sheets, to form the core of an electric motor rotor. The rotor’s design depends on the materials used and the engineering. • the lamination stack must be electrically as well as mechanically separated from the winding to avoid electrical contact due. Magnets or conductor bars insertion; Assemble. Rotor Lamination Assembly.

From www.rbourgeois.com

Rotor and Stator lamination assemblies Rotor Lamination Assembly The lamination process consistently reduces the loss. A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. Assemble and bolt rotor laminations. Magnets or conductor bars insertion; The rotor manufacturing process can be divided into 6 steps: Our laminations are. Rotor Lamination Assembly.

From webmotor.org

Electric Motor Stator Laminations Rotor Lamination Assembly The lamination process consistently reduces the loss. A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. Assemble and bolt rotor laminations. Shaft laser cleaning and press fitting; The rotor laminated stack is joined and the bolted together with screws.. Rotor Lamination Assembly.

From studylib.net

ROTOR LAMINATION 450 2P 1150KW 690V Rotor Lamination Assembly Shaft laser cleaning and press fitting; Assemble and bolt rotor laminations. Magnets or conductor bars insertion; A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. We engineer lamination components that deliver optimal performance, efficiency, and reliability in virtually any. Rotor Lamination Assembly.

From yunloongsb.com

Motor Stator & Rotor Lamination Core Rebuild Malaysia Yun Loong Rotor Lamination Assembly The lamination process consistently reduces the loss. Magnets or conductor bars insertion; We engineer lamination components that deliver optimal performance, efficiency, and reliability in virtually any motor or generator. A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. The. Rotor Lamination Assembly.

From laserlaminations.com

Rotor Laminations Laser Laminations Inc. Rotor Lamination Assembly Shaft laser cleaning and press fitting; • the lamination stack must be electrically as well as mechanically separated from the winding to avoid electrical contact due. Magnets or conductor bars insertion; The rotor manufacturing process can be divided into 6 steps: We engineer lamination components that deliver optimal performance, efficiency, and reliability in virtually any motor or generator. The lamination. Rotor Lamination Assembly.

From www.researchgate.net

3 Design of the rotor lamination for a 36 kW spinner motor fitted with Rotor Lamination Assembly The rotor manufacturing process can be divided into 6 steps: Magnets or conductor bars insertion; A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. The lamination process consistently reduces the loss. We engineer lamination components that deliver optimal performance,. Rotor Lamination Assembly.

From advrotors.com

Laminations Advanced Rotors Rotor Lamination Assembly • the lamination stack must be electrically as well as mechanically separated from the winding to avoid electrical contact due. The rotor manufacturing process can be divided into 6 steps: Our laminations are used in applications as diverse. Motor lamination stacking and assembly involve assembling individual laminations, which are thin metal sheets, to form the core of an electric motor. Rotor Lamination Assembly.

From www.researchgate.net

Rotor lamination and its parameters Download Scientific Diagram Rotor Lamination Assembly Motor lamination stacking and assembly involve assembling individual laminations, which are thin metal sheets, to form the core of an electric motor rotor. Our laminations are used in applications as diverse. • the lamination stack must be electrically as well as mechanically separated from the winding to avoid electrical contact due. The rotor manufacturing process can be divided into 6. Rotor Lamination Assembly.

From www.polarislaserlaminations.com

Motor Laminations Rotor Lamination Assembly Assemble and bolt rotor laminations. • the lamination stack must be electrically as well as mechanically separated from the winding to avoid electrical contact due. A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. Motor lamination stacking and assembly. Rotor Lamination Assembly.

From www.sotek.com

Stator and Rotor Assembly Lamination Replacement Sotek, inc. Rotor Lamination Assembly A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. The rotor’s design depends on the materials used and the engineering. Our laminations are used in applications as diverse. The rotor laminated stack is joined and the bolted together with. Rotor Lamination Assembly.

From www.alibaba.com

Custom Precision Metal Bldc Core Rotor Stator Lamination Buy Armature Rotor Lamination Assembly Shaft laser cleaning and press fitting; The lamination process consistently reduces the loss. Magnets or conductor bars insertion; We engineer lamination components that deliver optimal performance, efficiency, and reliability in virtually any motor or generator. A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even. Rotor Lamination Assembly.

From travelknowledge.org

The Basics of Stator Core Lamination in Your Equipment Travel Knowledge Rotor Lamination Assembly We engineer lamination components that deliver optimal performance, efficiency, and reliability in virtually any motor or generator. The rotor manufacturing process can be divided into 6 steps: The lamination process consistently reduces the loss. The rotor laminated stack is joined and the bolted together with screws. The rotor’s design depends on the materials used and the engineering. Motor lamination stacking. Rotor Lamination Assembly.

From caetools.wordpress.com

Lamination Sheets CAE Tools Rotor Lamination Assembly A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. Our laminations are used in applications as diverse. The rotor laminated stack is joined and the bolted together with screws. Magnets or conductor bars insertion; The rotor manufacturing process can. Rotor Lamination Assembly.

From www.researchgate.net

18 Stator and rotor laminations of the singlephase IM. Courtesy of Rotor Lamination Assembly Motor lamination stacking and assembly involve assembling individual laminations, which are thin metal sheets, to form the core of an electric motor rotor. Shaft laser cleaning and press fitting; Magnets or conductor bars insertion; • the lamination stack must be electrically as well as mechanically separated from the winding to avoid electrical contact due. Assemble and bolt rotor laminations. The. Rotor Lamination Assembly.

From www.google.ca

Patent US6121709 Rotor assembly having bonded lamination stack Rotor Lamination Assembly Shaft laser cleaning and press fitting; The lamination process consistently reduces the loss. The rotor manufacturing process can be divided into 6 steps: Our laminations are used in applications as diverse. A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial. Rotor Lamination Assembly.

From www.sotek.com

Rotor Lamination Sotek, inc. Rotor Lamination Assembly • the lamination stack must be electrically as well as mechanically separated from the winding to avoid electrical contact due. Motor lamination stacking and assembly involve assembling individual laminations, which are thin metal sheets, to form the core of an electric motor rotor. We engineer lamination components that deliver optimal performance, efficiency, and reliability in virtually any motor or generator.. Rotor Lamination Assembly.

From www.researchgate.net

Stator and rotor assembly. Download Scientific Diagram Rotor Lamination Assembly Motor lamination stacking and assembly involve assembling individual laminations, which are thin metal sheets, to form the core of an electric motor rotor. A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. Shaft laser cleaning and press fitting; Assemble. Rotor Lamination Assembly.

From www.dreamstime.com

Rotor Lamination Sheet Package 3D Rendering Stock Illustration Rotor Lamination Assembly Magnets or conductor bars insertion; • the lamination stack must be electrically as well as mechanically separated from the winding to avoid electrical contact due. Shaft laser cleaning and press fitting; The rotor manufacturing process can be divided into 6 steps: A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3. Rotor Lamination Assembly.

From advrotors.com

Laminations Advanced Rotors Rotor Lamination Assembly • the lamination stack must be electrically as well as mechanically separated from the winding to avoid electrical contact due. Shaft laser cleaning and press fitting; Motor lamination stacking and assembly involve assembling individual laminations, which are thin metal sheets, to form the core of an electric motor rotor. Magnets or conductor bars insertion; The rotor laminated stack is joined. Rotor Lamination Assembly.

From www.ecvv.com

rotor lamination motor stator iron core from China Manufacturer Rotor Lamination Assembly Assemble and bolt rotor laminations. The rotor manufacturing process can be divided into 6 steps: A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or 6, maybe even 18 or more radial prongs. We engineer lamination components that deliver optimal performance, efficiency, and reliability in virtually any motor. Rotor Lamination Assembly.

From www.lasertechnologiesinc.com

Motor Laminations Laser Technologies Rotor Lamination Assembly We engineer lamination components that deliver optimal performance, efficiency, and reliability in virtually any motor or generator. The rotor’s design depends on the materials used and the engineering. The rotor manufacturing process can be divided into 6 steps: A salient pole rotor is built upon a stack of star shaped steel laminations, typically with 2 or 3 or 4 or. Rotor Lamination Assembly.

From www.hsmagnets.com

Silicon Steel Lamination for Motor Stator and Rotor HSMAG Rotor Lamination Assembly Magnets or conductor bars insertion; The rotor manufacturing process can be divided into 6 steps: Our laminations are used in applications as diverse. The rotor laminated stack is joined and the bolted together with screws. The rotor’s design depends on the materials used and the engineering. Assemble and bolt rotor laminations. A salient pole rotor is built upon a stack. Rotor Lamination Assembly.

From www.alibaba.com

Motor Rotor Lamination Assembly Buy Motor Rotor,Rotor Lamination Rotor Lamination Assembly Magnets or conductor bars insertion; Motor lamination stacking and assembly involve assembling individual laminations, which are thin metal sheets, to form the core of an electric motor rotor. Our laminations are used in applications as diverse. We engineer lamination components that deliver optimal performance, efficiency, and reliability in virtually any motor or generator. Assemble and bolt rotor laminations. The lamination. Rotor Lamination Assembly.