How To Operate Wire Cut Machine . The standard operating procedures document outlines the 9 step process for operating an edm wire cut machine. Wire edm technology yields a number of benefits through its specialized machining approach. Wire edm machining is an electrothermal production process that uses electric discharges to remove material from a workpiece. What is edm wire cutting machine and how it works? Benefits and limitations of wire edm cutting. It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. Turn on the main power switch on the machine host. For those who know, the process of cutting, stripping, and feruling wire in electric panels can become tedious, especially when running wire to plcs. Ultimate wire edm guide that explains the working principle, type of material that can be cut, pros & cons. 1) closing the wire cutter to the workpiece, 2) adjusting. To solve this problem, at least cutting.

from www.cliffeng.com

For those who know, the process of cutting, stripping, and feruling wire in electric panels can become tedious, especially when running wire to plcs. Benefits and limitations of wire edm cutting. What is edm wire cutting machine and how it works? Ultimate wire edm guide that explains the working principle, type of material that can be cut, pros & cons. It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. To solve this problem, at least cutting. Turn on the main power switch on the machine host. Wire edm machining is an electrothermal production process that uses electric discharges to remove material from a workpiece. The standard operating procedures document outlines the 9 step process for operating an edm wire cut machine. 1) closing the wire cutter to the workpiece, 2) adjusting.

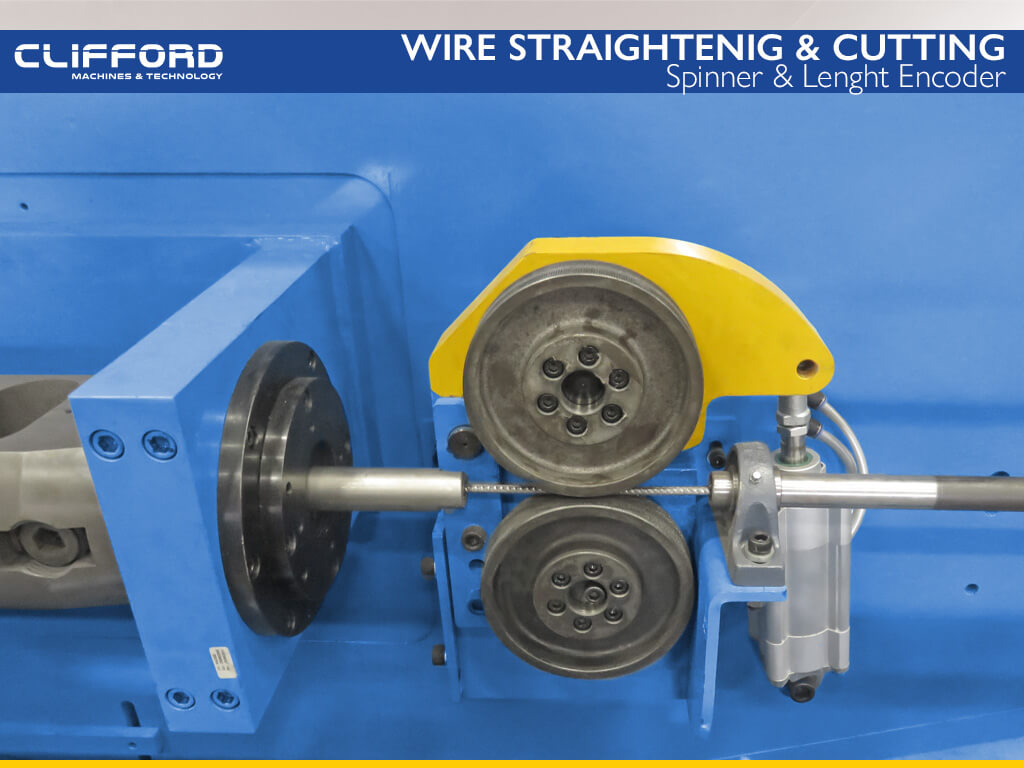

Wire Straightening & Cutting Clifford Machines & Technology

How To Operate Wire Cut Machine Wire edm technology yields a number of benefits through its specialized machining approach. Wire edm machining is an electrothermal production process that uses electric discharges to remove material from a workpiece. Ultimate wire edm guide that explains the working principle, type of material that can be cut, pros & cons. Wire edm technology yields a number of benefits through its specialized machining approach. For those who know, the process of cutting, stripping, and feruling wire in electric panels can become tedious, especially when running wire to plcs. Turn on the main power switch on the machine host. The standard operating procedures document outlines the 9 step process for operating an edm wire cut machine. What is edm wire cutting machine and how it works? 1) closing the wire cutter to the workpiece, 2) adjusting. To solve this problem, at least cutting. Benefits and limitations of wire edm cutting. It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes.

From www.cliffeng.com

Wire Straightening & Cutting Clifford Machines & Technology How To Operate Wire Cut Machine Benefits and limitations of wire edm cutting. Wire edm technology yields a number of benefits through its specialized machining approach. The standard operating procedures document outlines the 9 step process for operating an edm wire cut machine. For those who know, the process of cutting, stripping, and feruling wire in electric panels can become tedious, especially when running wire to. How To Operate Wire Cut Machine.

From blog.hackster.io

Automatic Cable Cutting Machine Hackster Blog How To Operate Wire Cut Machine Wire edm machining is an electrothermal production process that uses electric discharges to remove material from a workpiece. Ultimate wire edm guide that explains the working principle, type of material that can be cut, pros & cons. Benefits and limitations of wire edm cutting. It is an improvement to the conventional edm method, compatible with almost all conductive materials, and. How To Operate Wire Cut Machine.

From www.leussink.com.au

CNC Machining Services Leussink Engineering How To Operate Wire Cut Machine What is edm wire cutting machine and how it works? It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. Wire edm technology yields a number of benefits through its specialized machining approach. For those who know, the process of cutting, stripping, and feruling wire in electric panels. How To Operate Wire Cut Machine.

From www.youtube.com

Wire Cutting Machine for Multi Strand Wire YouTube How To Operate Wire Cut Machine Wire edm technology yields a number of benefits through its specialized machining approach. It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. The standard operating procedures document outlines the 9 step process for operating an edm wire cut machine. Turn on the main power switch on the. How To Operate Wire Cut Machine.

From www.sodick.co.th

Sodick Test How To Operate Wire Cut Machine Benefits and limitations of wire edm cutting. Turn on the main power switch on the machine host. To solve this problem, at least cutting. 1) closing the wire cutter to the workpiece, 2) adjusting. It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. The standard operating procedures. How To Operate Wire Cut Machine.

From www.researchgate.net

CNC wire cut machine Download Scientific Diagram How To Operate Wire Cut Machine Turn on the main power switch on the machine host. For those who know, the process of cutting, stripping, and feruling wire in electric panels can become tedious, especially when running wire to plcs. What is edm wire cutting machine and how it works? To solve this problem, at least cutting. Benefits and limitations of wire edm cutting. Wire edm. How To Operate Wire Cut Machine.

From www.instructables.com

WIRE CUTTING MACHINE 4 Steps (with Pictures) Instructables How To Operate Wire Cut Machine Turn on the main power switch on the machine host. The standard operating procedures document outlines the 9 step process for operating an edm wire cut machine. Wire edm machining is an electrothermal production process that uses electric discharges to remove material from a workpiece. To solve this problem, at least cutting. Ultimate wire edm guide that explains the working. How To Operate Wire Cut Machine.

From www.youtube.com

SODICK AG600L CNC 5AXIS WIRE CUT ELECTRICAL DISCHARGE MACHINE (EDM How To Operate Wire Cut Machine Wire edm technology yields a number of benefits through its specialized machining approach. To solve this problem, at least cutting. Wire edm machining is an electrothermal production process that uses electric discharges to remove material from a workpiece. Ultimate wire edm guide that explains the working principle, type of material that can be cut, pros & cons. It is an. How To Operate Wire Cut Machine.

From www.planetarduino.org

Wire Cutting Machine How To Operate Wire Cut Machine 1) closing the wire cutter to the workpiece, 2) adjusting. Wire edm technology yields a number of benefits through its specialized machining approach. Ultimate wire edm guide that explains the working principle, type of material that can be cut, pros & cons. For those who know, the process of cutting, stripping, and feruling wire in electric panels can become tedious,. How To Operate Wire Cut Machine.

From www.talentcnc.com

Advantages of electric wire cutting machine How To Operate Wire Cut Machine Wire edm technology yields a number of benefits through its specialized machining approach. It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. Benefits and limitations of wire edm cutting. Turn on the main power switch on the machine host. For those who know, the process of cutting,. How To Operate Wire Cut Machine.

From www.youtube.com

DIY Automatic Wire cutting Machine Arduino project YouTube How To Operate Wire Cut Machine Benefits and limitations of wire edm cutting. It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. Turn on the main power switch on the machine host. What is edm wire cutting machine and how it works? Ultimate wire edm guide that explains the working principle, type of. How To Operate Wire Cut Machine.

From fyoscdfae.blob.core.windows.net

Which Tool Is Used To Cut Wires at Tony Bonner blog How To Operate Wire Cut Machine Benefits and limitations of wire edm cutting. The standard operating procedures document outlines the 9 step process for operating an edm wire cut machine. 1) closing the wire cutter to the workpiece, 2) adjusting. For those who know, the process of cutting, stripping, and feruling wire in electric panels can become tedious, especially when running wire to plcs. Wire edm. How To Operate Wire Cut Machine.

From enggkatta.com

WireCut Electrical Discharge Machining (WEDM) EnggKatta How To Operate Wire Cut Machine Wire edm machining is an electrothermal production process that uses electric discharges to remove material from a workpiece. 1) closing the wire cutter to the workpiece, 2) adjusting. For those who know, the process of cutting, stripping, and feruling wire in electric panels can become tedious, especially when running wire to plcs. It is an improvement to the conventional edm. How To Operate Wire Cut Machine.

From www.market-prospects.com

How Does a Wire Cut EDM Machine Work? Market Prospects How To Operate Wire Cut Machine What is edm wire cutting machine and how it works? The standard operating procedures document outlines the 9 step process for operating an edm wire cut machine. To solve this problem, at least cutting. Wire edm technology yields a number of benefits through its specialized machining approach. 1) closing the wire cutter to the workpiece, 2) adjusting. Turn on the. How To Operate Wire Cut Machine.

From www.youtube.com

DIY Wire cutter Machine using Arduino YouTube How To Operate Wire Cut Machine Ultimate wire edm guide that explains the working principle, type of material that can be cut, pros & cons. What is edm wire cutting machine and how it works? 1) closing the wire cutter to the workpiece, 2) adjusting. Wire edm technology yields a number of benefits through its specialized machining approach. It is an improvement to the conventional edm. How To Operate Wire Cut Machine.

From www.researchgate.net

CNC wire cut machine Download Scientific Diagram How To Operate Wire Cut Machine It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. Wire edm machining is an electrothermal production process that uses electric discharges to remove material from a workpiece. Turn on the main power switch on the machine host. Ultimate wire edm guide that explains the working principle, type. How To Operate Wire Cut Machine.

From finemetalworking.com

Wire EDM. Guide to EDM Wirecut Machine, Process & Uses Fine MetalWorking How To Operate Wire Cut Machine Wire edm machining is an electrothermal production process that uses electric discharges to remove material from a workpiece. Wire edm technology yields a number of benefits through its specialized machining approach. Turn on the main power switch on the machine host. The standard operating procedures document outlines the 9 step process for operating an edm wire cut machine. 1) closing. How To Operate Wire Cut Machine.

From www.mmsonline.com

Sodick Adds Functions to Cut EDM Wire Consumption Modern Machine Shop How To Operate Wire Cut Machine Wire edm technology yields a number of benefits through its specialized machining approach. Wire edm machining is an electrothermal production process that uses electric discharges to remove material from a workpiece. To solve this problem, at least cutting. Turn on the main power switch on the machine host. The standard operating procedures document outlines the 9 step process for operating. How To Operate Wire Cut Machine.

From www.youtube.com

Automatic Wire Straightening and cutting machine YouTube How To Operate Wire Cut Machine Ultimate wire edm guide that explains the working principle, type of material that can be cut, pros & cons. For those who know, the process of cutting, stripping, and feruling wire in electric panels can become tedious, especially when running wire to plcs. The standard operating procedures document outlines the 9 step process for operating an edm wire cut machine.. How To Operate Wire Cut Machine.

From www.youtube.com

Detailed operation manual and installation of CNC Wire cutting machine How To Operate Wire Cut Machine It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. For those who know, the process of cutting, stripping, and feruling wire in electric panels can become tedious, especially when running wire to plcs. Ultimate wire edm guide that explains the working principle, type of material that can. How To Operate Wire Cut Machine.

From www.youtube.com

Automatic Wire Straightening and Cutting Machine YouTube How To Operate Wire Cut Machine Benefits and limitations of wire edm cutting. Turn on the main power switch on the machine host. What is edm wire cutting machine and how it works? It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. Wire edm technology yields a number of benefits through its specialized. How To Operate Wire Cut Machine.

From www.dreamstime.com

Cnc Wirecut Machine Fostex Edm Stock Photo Image of working, machine How To Operate Wire Cut Machine It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. Turn on the main power switch on the machine host. Wire edm machining is an electrothermal production process that uses electric discharges to remove material from a workpiece. Wire edm technology yields a number of benefits through its. How To Operate Wire Cut Machine.

From www.bidspotter.com

CARPENTER COMPUSTRIP 97A WIRE CUTTING MACHINE, S/N 970594, DIGITAL How To Operate Wire Cut Machine For those who know, the process of cutting, stripping, and feruling wire in electric panels can become tedious, especially when running wire to plcs. It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. Wire edm machining is an electrothermal production process that uses electric discharges to remove. How To Operate Wire Cut Machine.

From www.youtube.com

Automatic Wire Straightening and Cutting Machine 5 to 10 mm Steel How To Operate Wire Cut Machine Wire edm machining is an electrothermal production process that uses electric discharges to remove material from a workpiece. It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. Turn on the main power switch on the machine host. Ultimate wire edm guide that explains the working principle, type. How To Operate Wire Cut Machine.

From alenaoden.blogspot.com

wire edm machine working principle Alena Oden How To Operate Wire Cut Machine Ultimate wire edm guide that explains the working principle, type of material that can be cut, pros & cons. Wire edm technology yields a number of benefits through its specialized machining approach. To solve this problem, at least cutting. Turn on the main power switch on the machine host. Wire edm machining is an electrothermal production process that uses electric. How To Operate Wire Cut Machine.

From www.dreamstime.com

Operation of Wire Cut Machine Stock Photo Image of mechanical How To Operate Wire Cut Machine Wire edm technology yields a number of benefits through its specialized machining approach. Turn on the main power switch on the machine host. The standard operating procedures document outlines the 9 step process for operating an edm wire cut machine. To solve this problem, at least cutting. It is an improvement to the conventional edm method, compatible with almost all. How To Operate Wire Cut Machine.

From www.youtube.com

AUTOMATIC WIRE CUTTING AND STRIPPING MACHINE (HSE 142) YouTube How To Operate Wire Cut Machine The standard operating procedures document outlines the 9 step process for operating an edm wire cut machine. Turn on the main power switch on the machine host. Wire edm technology yields a number of benefits through its specialized machining approach. Benefits and limitations of wire edm cutting. For those who know, the process of cutting, stripping, and feruling wire in. How To Operate Wire Cut Machine.

From www.xecnc.com

CNC Wire Cut EDM basic operation XECNC How To Operate Wire Cut Machine Wire edm technology yields a number of benefits through its specialized machining approach. Wire edm machining is an electrothermal production process that uses electric discharges to remove material from a workpiece. It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. For those who know, the process of. How To Operate Wire Cut Machine.

From finemetalworking.com

Wire EDM. Guide to EDM Wirecut Machine, Process & Uses Fine MetalWorking How To Operate Wire Cut Machine Wire edm technology yields a number of benefits through its specialized machining approach. The standard operating procedures document outlines the 9 step process for operating an edm wire cut machine. To solve this problem, at least cutting. Ultimate wire edm guide that explains the working principle, type of material that can be cut, pros & cons. Wire edm machining is. How To Operate Wire Cut Machine.

From www.prl.res.in

WireCutEDM Thaltej W/s How To Operate Wire Cut Machine What is edm wire cutting machine and how it works? Turn on the main power switch on the machine host. To solve this problem, at least cutting. The standard operating procedures document outlines the 9 step process for operating an edm wire cut machine. Wire edm machining is an electrothermal production process that uses electric discharges to remove material from. How To Operate Wire Cut Machine.

From www.wjcncmachine.com

Wire Cutting Machine Operation Detailed How To Operate Wire Cut Machine Wire edm technology yields a number of benefits through its specialized machining approach. Ultimate wire edm guide that explains the working principle, type of material that can be cut, pros & cons. It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. 1) closing the wire cutter to. How To Operate Wire Cut Machine.

From www.majujayamachinery.com

CNC WireCut ZF Series Mesin WireCut CNC ZF How To Operate Wire Cut Machine Ultimate wire edm guide that explains the working principle, type of material that can be cut, pros & cons. It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. Turn on the main power switch on the machine host. The standard operating procedures document outlines the 9 step. How To Operate Wire Cut Machine.

From www.hotonmc.com

CNC Wire cutting Machine How To Operate Wire Cut Machine Ultimate wire edm guide that explains the working principle, type of material that can be cut, pros & cons. The standard operating procedures document outlines the 9 step process for operating an edm wire cut machine. Turn on the main power switch on the machine host. To solve this problem, at least cutting. Benefits and limitations of wire edm cutting.. How To Operate Wire Cut Machine.

From www.bindingstore.co.uk

Rilecart TSR 500 Wire Cutting Machine How To Operate Wire Cut Machine It is an improvement to the conventional edm method, compatible with almost all conductive materials, and can create complex designs and shapes. Wire edm technology yields a number of benefits through its specialized machining approach. Benefits and limitations of wire edm cutting. Wire edm machining is an electrothermal production process that uses electric discharges to remove material from a workpiece.. How To Operate Wire Cut Machine.

From www.youtube.com

Cnc Wire Cut Multipass Programme / Wire Cut Machine Programming YouTube How To Operate Wire Cut Machine Ultimate wire edm guide that explains the working principle, type of material that can be cut, pros & cons. The standard operating procedures document outlines the 9 step process for operating an edm wire cut machine. For those who know, the process of cutting, stripping, and feruling wire in electric panels can become tedious, especially when running wire to plcs.. How To Operate Wire Cut Machine.