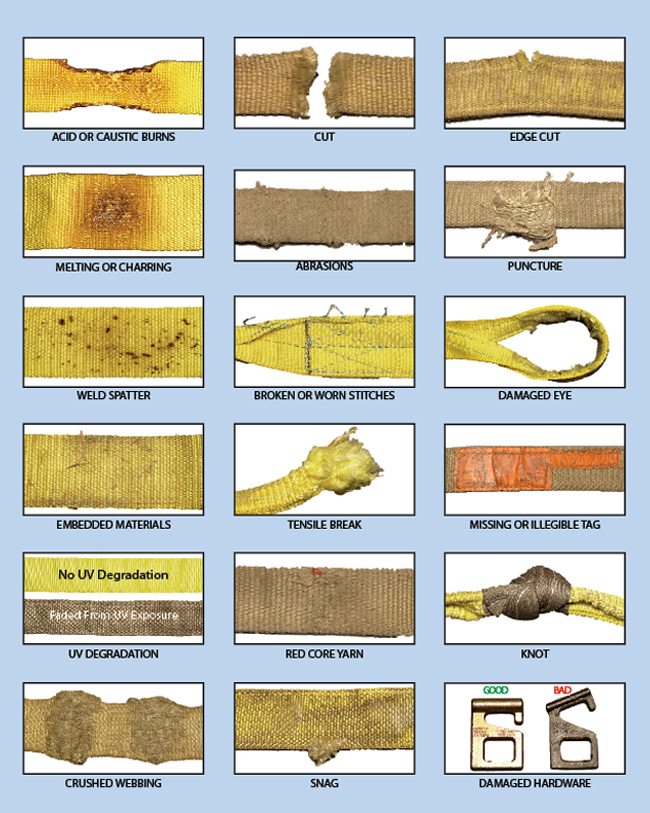

Slings Inspection . Yearly for normal service use,. Make periodic inspections of synthetic web slings at intervals no greater than 12 months. Sling inspection made easy factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Items to look for include: The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. Designate a competent person to inspect synthetic web slings daily—a visual inspection of slings and all fastenings and. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions. A good guide to follow includes: Missing or illegible sling identification. Make a thorough inspection of slings and attachments. Osha regulations require that all chain slings receive a thorough inspection at least once per year by a competent person.

from www.lift-it.com

Yearly for normal service use,. Make periodic inspections of synthetic web slings at intervals no greater than 12 months. A good guide to follow includes: Items to look for include: Sling inspection made easy factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions. Make a thorough inspection of slings and attachments. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. Missing or illegible sling identification. Osha regulations require that all chain slings receive a thorough inspection at least once per year by a competent person.

Sling Inspection Sling Repair Services Sling Replacement Lift

Slings Inspection Missing or illegible sling identification. Sling inspection made easy factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Missing or illegible sling identification. Make periodic inspections of synthetic web slings at intervals no greater than 12 months. A good guide to follow includes: Items to look for include: Yearly for normal service use,. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions. Osha regulations require that all chain slings receive a thorough inspection at least once per year by a competent person. Make a thorough inspection of slings and attachments. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. Designate a competent person to inspect synthetic web slings daily—a visual inspection of slings and all fastenings and.

From www.mazzellacompanies.com

How to Inspect Synthetic Slings to ASME B30.9 Standards Slings Inspection A good guide to follow includes: Items to look for include: Yearly for normal service use,. Designate a competent person to inspect synthetic web slings daily—a visual inspection of slings and all fastenings and. Sling inspection made easy factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Osha 1910.184, asme b30.9, b30.20,. Slings Inspection.

From www.lift-it.com

Sling Inspection Sling Repair Services Sling Replacement Lift Slings Inspection Make periodic inspections of synthetic web slings at intervals no greater than 12 months. Missing or illegible sling identification. Osha regulations require that all chain slings receive a thorough inspection at least once per year by a competent person. Sling inspection made easy factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs.. Slings Inspection.

From www.milessupply.com

Chain Sling Inspection and Repair Services from Miles Supply Slings Inspection Sling inspection made easy factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Items to look for include: Make periodic inspections of synthetic web slings at intervals no greater than 12 months. Make a thorough inspection of slings and attachments. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented. Slings Inspection.

From www.mazzellacompanies.com

Best Practices for Alloy Chain Sling Inspection and Chain Sling Use Slings Inspection Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions. Make periodic inspections of synthetic web slings at intervals no greater than 12 months. Osha regulations require that all chain slings receive a thorough. Slings Inspection.

From www.mazzellacompanies.com

Best Practices for Alloy Chain Sling Inspection and Chain Sling Use Slings Inspection Make a thorough inspection of slings and attachments. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. Make periodic inspections of synthetic web slings at intervals no greater than 12 months. Items to look for include: Designate a competent person to inspect. Slings Inspection.

From www.mazzellacompanies.com

How to Inspect a Synthetic Sling to OSHA and ASME Standards Slings Inspection Make periodic inspections of synthetic web slings at intervals no greater than 12 months. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices,. Slings Inspection.

From www.scribd.com

BR Lifting Sling Inspection Criteria R2 PDF Rope Knot Slings Inspection The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. Make periodic inspections of synthetic web slings at intervals no greater than 12 months. Yearly for normal service use,. Items to look for include: Sling inspection made easy factory trained professionals inspect all. Slings Inspection.

From www.mazzellacompanies.com

How to Inspect Wire Rope Slings According to ASME B30.9 Standards Slings Inspection Missing or illegible sling identification. Osha regulations require that all chain slings receive a thorough inspection at least once per year by a competent person. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. Make periodic inspections of synthetic web slings at. Slings Inspection.

From www.safetyshorts.com

Slings Inspection Care and Storage Safety Video Safetyhub Slings Inspection Make periodic inspections of synthetic web slings at intervals no greater than 12 months. A good guide to follow includes: Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions. Make a thorough inspection. Slings Inspection.

From www.mazzellacompanies.com

How to Inspect a Wire Rope Lifting Sling to OSHA and ASME Standards Slings Inspection Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions. Designate a competent person to inspect synthetic web slings daily—a visual inspection of slings and all fastenings and. Make periodic inspections of synthetic web. Slings Inspection.

From iandisling.com

Inspections I&I Sling, Inc. Comprehensive Rigging Inspection Services Slings Inspection Yearly for normal service use,. Items to look for include: Make periodic inspections of synthetic web slings at intervals no greater than 12 months. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions.. Slings Inspection.

From www.youtube.com

Synthetic Sling Inspection with Mike Parnell YouTube Slings Inspection Make periodic inspections of synthetic web slings at intervals no greater than 12 months. Sling inspection made easy factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Yearly for normal service use,. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the. Slings Inspection.

From www.slideserve.com

PPT Sling Inspection guidance PowerPoint Presentation, free download Slings Inspection Missing or illegible sling identification. A good guide to follow includes: The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. Make a thorough inspection of slings and attachments. Items to look for include: Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359. Slings Inspection.

From www.lift-it.com

Sling Inspection Sling Repair Services Sling Replacement Lift Slings Inspection Make a thorough inspection of slings and attachments. A good guide to follow includes: Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions. Osha regulations require that all chain slings receive a thorough. Slings Inspection.

From www.hhilifting.com

A Guide on Alloy Chain Sling Inspection Holloway Blog Your Gateway Slings Inspection A good guide to follow includes: Make a thorough inspection of slings and attachments. Missing or illegible sling identification. Yearly for normal service use,. Items to look for include: Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly. Slings Inspection.

From www.youtube.com

How to Inspect a Wire Rope Lifting Sling to OSHA and ASME Standards L Slings Inspection Make periodic inspections of synthetic web slings at intervals no greater than 12 months. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions. Make a thorough inspection of slings and attachments. A good. Slings Inspection.

From loeahwnir.blob.core.windows.net

Sling Inspection at Tommy William blog Slings Inspection Make periodic inspections of synthetic web slings at intervals no greater than 12 months. Osha regulations require that all chain slings receive a thorough inspection at least once per year by a competent person. Make a thorough inspection of slings and attachments. Missing or illegible sling identification. The purpose of a sling inspection is to determine if a wire rope. Slings Inspection.

From www.youtube.com

Lifting Slings Inspection Checklist Zip's 360 YouTube Slings Inspection A good guide to follow includes: Items to look for include: Make periodic inspections of synthetic web slings at intervals no greater than 12 months. Yearly for normal service use,. Missing or illegible sling identification. Make a thorough inspection of slings and attachments. Sling inspection made easy factory trained professionals inspect all types of slings, hoists, below the hook lifting. Slings Inspection.

From www.lift-it.com

TwinPath Extra Slings Information LiftIt® Manufacturing Slings Inspection Items to look for include: Yearly for normal service use,. Sling inspection made easy factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Missing or illegible sling identification. Designate a competent person to inspect synthetic web slings daily—a visual inspection of slings and all fastenings and. Osha 1910.184, asme b30.9, b30.20, b30.26,. Slings Inspection.

From www.youtube.com

Sling Inspection 1 YouTube Slings Inspection Yearly for normal service use,. Items to look for include: Missing or illegible sling identification. Designate a competent person to inspect synthetic web slings daily—a visual inspection of slings and all fastenings and. A good guide to follow includes: The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work. Slings Inspection.

From www.hsedocuments.com

Sling Inspection Checklist HSE Documents Slings Inspection Items to look for include: The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. Designate a competent person to inspect synthetic web slings daily—a visual inspection of slings and all fastenings and. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require. Slings Inspection.

From www.scribd.com

014Sling Inspection Checklist PDF Rope Wire Slings Inspection Sling inspection made easy factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions. Items to look. Slings Inspection.

From www.mazzellacompanies.com

Periodic Sling and Rigging Inspection OSHA / ASME Compliance Slings Inspection A good guide to follow includes: Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions. Missing or illegible sling identification. Items to look for include: Designate a competent person to inspect synthetic web. Slings Inspection.

From www.scribd.com

Sling Inspection Checklist General Requirements and Inspection Slings Inspection Missing or illegible sling identification. Yearly for normal service use,. Make periodic inspections of synthetic web slings at intervals no greater than 12 months. Sling inspection made easy factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Make a thorough inspection of slings and attachments. The purpose of a sling inspection is. Slings Inspection.

From www.slideserve.com

PPT Sling Inspection guidance PowerPoint Presentation, free download Slings Inspection Make a thorough inspection of slings and attachments. Osha regulations require that all chain slings receive a thorough inspection at least once per year by a competent person. Designate a competent person to inspect synthetic web slings daily—a visual inspection of slings and all fastenings and. Make periodic inspections of synthetic web slings at intervals no greater than 12 months.. Slings Inspection.

From resources.herculesslr.com

Synthetic Round Slings Inspection Download Guide Hercules SLR Slings Inspection Designate a competent person to inspect synthetic web slings daily—a visual inspection of slings and all fastenings and. Yearly for normal service use,. Items to look for include: A good guide to follow includes: Make periodic inspections of synthetic web slings at intervals no greater than 12 months. Sling inspection made easy factory trained professionals inspect all types of slings,. Slings Inspection.

From www.scribd.com

Sling Belt & Wire Rope Inspection Checklist Slings Inspection Missing or illegible sling identification. A good guide to follow includes: Yearly for normal service use,. Osha regulations require that all chain slings receive a thorough inspection at least once per year by a competent person. Make a thorough inspection of slings and attachments. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient. Slings Inspection.

From www.konecranes.com

OSHA sling inspections Konecranes USA Slings Inspection Osha regulations require that all chain slings receive a thorough inspection at least once per year by a competent person. Missing or illegible sling identification. Make a thorough inspection of slings and attachments. Sling inspection made easy factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Designate a competent person to inspect. Slings Inspection.

From www.iti.com

ASME B30.9 Slings Documented Sling Inspections Slings Inspection Sling inspection made easy factory trained professionals inspect all types of slings, hoists, below the hook lifting equipment and tie downs. Designate a competent person to inspect synthetic web slings daily—a visual inspection of slings and all fastenings and. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work. Slings Inspection.

From www.youtube.com

LiftAll Wire Rope Sling Inspection YouTube Slings Inspection A good guide to follow includes: Designate a competent person to inspect synthetic web slings daily—a visual inspection of slings and all fastenings and. The purpose of a sling inspection is to determine if a wire rope sling retains sufficient capability to perform the work to be done before the next. Missing or illegible sling identification. Yearly for normal service. Slings Inspection.

From www.mazzellacompanies.com

Best Practices for Alloy Chain Sling Inspection and Chain Sling Use Slings Inspection Make periodic inspections of synthetic web slings at intervals no greater than 12 months. Items to look for include: Make a thorough inspection of slings and attachments. Osha regulations require that all chain slings receive a thorough inspection at least once per year by a competent person. Yearly for normal service use,. Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi. Slings Inspection.

From hsseworld.com

chainslingsinspection HSSE WORLD Slings Inspection Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions. Items to look for include: A good guide to follow includes: Missing or illegible sling identification. The purpose of a sling inspection is to. Slings Inspection.

From www.youtube.com

LiftAll Chain Sling Inspection YouTube Slings Inspection Osha 1910.184, asme b30.9, b30.20, b30.26, & ansi z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions. Yearly for normal service use,. Items to look for include: Missing or illegible sling identification. Designate a competent person to inspect synthetic web slings. Slings Inspection.

From www.mazzellacompanies.com

Best Practices for Alloy Chain Sling Inspection and Chain Sling Use Slings Inspection Make periodic inspections of synthetic web slings at intervals no greater than 12 months. Osha regulations require that all chain slings receive a thorough inspection at least once per year by a competent person. Items to look for include: Missing or illegible sling identification. Yearly for normal service use,. Designate a competent person to inspect synthetic web slings daily—a visual. Slings Inspection.

From www.youtube.com

How to Inspect a Synthetic Sling to OSHA and ASME Standards L2 Slings Inspection Missing or illegible sling identification. Items to look for include: A good guide to follow includes: Yearly for normal service use,. Make a thorough inspection of slings and attachments. Designate a competent person to inspect synthetic web slings daily—a visual inspection of slings and all fastenings and. Make periodic inspections of synthetic web slings at intervals no greater than 12. Slings Inspection.