Carbide End Mill Vs Hss . Hss is often used to make cutting tools like drills, end mills, etc. The minimal cobalt needed to make carbide milling cutters is significantly less magnetic than hss. While both hss and carbide mills are. Machining activities, such as drilling and boring, generate high degrees of heat. However, hss end mills can also be used for cutting harder materials with proper coatings and geometries. Hss end mills also cost. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Tungsten carbide is often used for tools in continuous and. Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited for softer materials such as aluminum, brass, and plastics.

from huanatools.com

However, hss end mills can also be used for cutting harder materials with proper coatings and geometries. While both hss and carbide mills are. Tungsten carbide is often used for tools in continuous and. Hss is often used to make cutting tools like drills, end mills, etc. Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited for softer materials such as aluminum, brass, and plastics. The minimal cobalt needed to make carbide milling cutters is significantly less magnetic than hss. Hss end mills also cost. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Machining activities, such as drilling and boring, generate high degrees of heat.

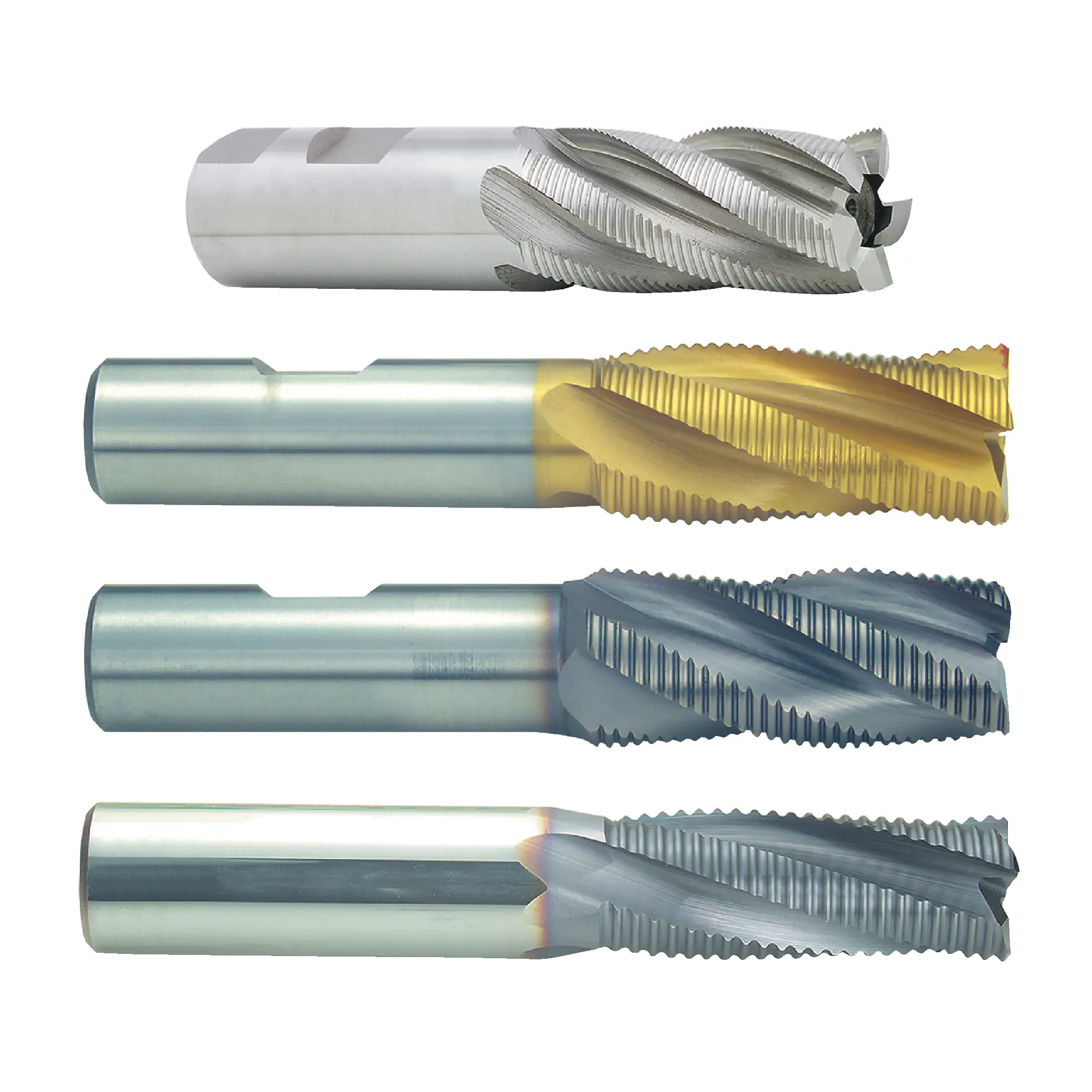

Roughing vs. Finishing End Mill How Do They Differ? Huana Tools

Carbide End Mill Vs Hss Machining activities, such as drilling and boring, generate high degrees of heat. Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited for softer materials such as aluminum, brass, and plastics. The minimal cobalt needed to make carbide milling cutters is significantly less magnetic than hss. Machining activities, such as drilling and boring, generate high degrees of heat. While both hss and carbide mills are. Hss is often used to make cutting tools like drills, end mills, etc. Hss end mills also cost. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. However, hss end mills can also be used for cutting harder materials with proper coatings and geometries. Tungsten carbide is often used for tools in continuous and.

From www.trigonenterprises.com

End Mills Under Neck End Mills. Distributor / Channel Partner from Pune Carbide End Mill Vs Hss Hss end mills also cost. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited for softer materials such as aluminum, brass, and. Carbide End Mill Vs Hss.

From mungfali.com

Milling Speed Chart Carbide End Mill Vs Hss Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited for softer materials such as aluminum, brass, and plastics. Hss end mills also. Carbide End Mill Vs Hss.

From huanatools.com

Roughing vs. Finishing End Mill How Do They Differ? Huana Tools Carbide End Mill Vs Hss Hss is often used to make cutting tools like drills, end mills, etc. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited. Carbide End Mill Vs Hss.

From archive.fabacademy.org

AJITH'S FAB DIARY 2017 Carbide End Mill Vs Hss Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Hss is often used to make cutting tools like drills, end mills, etc. Tungsten carbide is often used for tools in continuous and. The minimal cobalt needed to make carbide milling cutters is significantly less magnetic. Carbide End Mill Vs Hss.

From www.unisell2000.ru

UNISELL 2000 LTD ЮНИСЕЛ 2000. Manufacture of carbide and HSS end Carbide End Mill Vs Hss Hss end mills also cost. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited for softer materials such as aluminum, brass, and. Carbide End Mill Vs Hss.

From simmonslosonfere.blogspot.com

Ball Nose End Mill Speeds and Feeds Simmons Losonfere Carbide End Mill Vs Hss Hss is often used to make cutting tools like drills, end mills, etc. Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited for softer materials such as aluminum, brass, and plastics. Hss end mills also cost. The minimal cobalt needed to make carbide milling cutters is. Carbide End Mill Vs Hss.

From www.shop-apt.co.uk

Carbide End Mill for General Use 14mm Diameter 2 Flute AlTiN Coated Carbide End Mill Vs Hss Hss end mills also cost. Hss is often used to make cutting tools like drills, end mills, etc. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Machining activities, such as drilling and boring, generate high degrees of heat. While both hss and carbide mills. Carbide End Mill Vs Hss.

From www.indiamart.com

Carbide HSS End Mill at Rs 1053/piece End Mill Cutter in Navi Mumbai Carbide End Mill Vs Hss While both hss and carbide mills are. However, hss end mills can also be used for cutting harder materials with proper coatings and geometries. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Carbide end mills are ideal for cutting hard materials such as steel,. Carbide End Mill Vs Hss.

From earthasowers.blogspot.com

end mill shank types Eartha Sowers Carbide End Mill Vs Hss Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. While both hss and carbide mills are. However, hss end mills can also be used for cutting harder materials with proper coatings and geometries. Hss is often used to make cutting tools like drills, end mills,. Carbide End Mill Vs Hss.

From www.youtube.com

Differences between Drilling and End Milling (Drill Vs End Mill) YouTube Carbide End Mill Vs Hss Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited for softer materials such as aluminum, brass, and plastics. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Hss end mills also. Carbide End Mill Vs Hss.

From www.codelv.com

eBay vs Carbide Tool Source milling cutters CodeLV Carbide End Mill Vs Hss Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Tungsten carbide is often used for tools in continuous and. Machining activities, such as drilling and boring, generate high degrees of heat. The minimal cobalt needed to make carbide milling cutters is significantly less magnetic than. Carbide End Mill Vs Hss.

From cuttingtoolpickers.com

Carbide VS HSS End Mills — Cutting Tool Pickers Carbide End Mill Vs Hss Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited for softer materials such as aluminum, brass, and plastics. While both hss and. Carbide End Mill Vs Hss.

From mellowpine.com

Speeds and Feeds Beginner Guide with Table MellowPine Carbide End Mill Vs Hss Hss is often used to make cutting tools like drills, end mills, etc. The minimal cobalt needed to make carbide milling cutters is significantly less magnetic than hss. Hss end mills also cost. While both hss and carbide mills are. Tungsten carbide is often used for tools in continuous and. Carbide end mills are ideal for cutting hard materials such. Carbide End Mill Vs Hss.

From www.icarbide.com

1/2X 4" 4FLUTE SOLID CARBIDE END MILL BITS icarbide Carbide End Mill Vs Hss Tungsten carbide is often used for tools in continuous and. Hss is often used to make cutting tools like drills, end mills, etc. Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited for softer materials such as aluminum, brass, and plastics. While both hss and carbide. Carbide End Mill Vs Hss.

From klaznyifg.blob.core.windows.net

What Are End Mills Made Of at Clinton Gill blog Carbide End Mill Vs Hss The minimal cobalt needed to make carbide milling cutters is significantly less magnetic than hss. While both hss and carbide mills are. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Machining activities, such as drilling and boring, generate high degrees of heat. Carbide end. Carbide End Mill Vs Hss.

From www.icarbide.com

3/16"X2" 3FLUTE CARBIDE END MILL CC ALUSPEED COATED FOR ALUMINUM END Carbide End Mill Vs Hss Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited for softer materials such as aluminum, brass, and plastics. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. While both hss and. Carbide End Mill Vs Hss.

From tooltalk.blog

The Difference Between High Speed Steel & Carbide End Mills Tool Talk Carbide End Mill Vs Hss Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. The minimal cobalt needed to make carbide milling cutters is significantly less magnetic than hss. Hss end mills also cost. Hss is often used to make cutting tools like drills, end mills, etc. However, hss end. Carbide End Mill Vs Hss.

From www.lathematters.com

HSS vs. Carbide Cutting Tools What's the Difference? Carbide End Mill Vs Hss While both hss and carbide mills are. Tungsten carbide is often used for tools in continuous and. The minimal cobalt needed to make carbide milling cutters is significantly less magnetic than hss. Machining activities, such as drilling and boring, generate high degrees of heat. Hss is often used to make cutting tools like drills, end mills, etc. However, hss end. Carbide End Mill Vs Hss.

From www.shop-apt.co.uk

High Hardness High Speed Carbide End Mill 10mm Diameter 2 Flute AlTiNS Carbide End Mill Vs Hss However, hss end mills can also be used for cutting harder materials with proper coatings and geometries. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Machining activities, such as drilling and boring, generate high degrees of heat. Hss end mills also cost. Hss is. Carbide End Mill Vs Hss.

From conicalendmills.com

5 Degree Tapered End Mills HSS Conical Tool Company Carbide End Mill Vs Hss Machining activities, such as drilling and boring, generate high degrees of heat. The minimal cobalt needed to make carbide milling cutters is significantly less magnetic than hss. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Hss end mills also cost. Hss is often used. Carbide End Mill Vs Hss.

From ideasforhomeandoffice.blogspot.com

End mills carbide Carbide End Mill Vs Hss Hss is often used to make cutting tools like drills, end mills, etc. While both hss and carbide mills are. Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited for softer materials such as aluminum, brass, and plastics. The minimal cobalt needed to make carbide milling. Carbide End Mill Vs Hss.

From exyfzpoog.blob.core.windows.net

Types Of Tools Used In Cnc Milling Machine at Hannah Bergan blog Carbide End Mill Vs Hss Hss is often used to make cutting tools like drills, end mills, etc. Tungsten carbide is often used for tools in continuous and. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. While both hss and carbide mills are. The minimal cobalt needed to make. Carbide End Mill Vs Hss.

From www.indiamart.com

Hss 10 100 Mm Carbide End Mill at Rs 200/piece in Ahmedabad ID Carbide End Mill Vs Hss However, hss end mills can also be used for cutting harder materials with proper coatings and geometries. Machining activities, such as drilling and boring, generate high degrees of heat. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Hss end mills also cost. Hss is. Carbide End Mill Vs Hss.

From makersmarket.au

Differences Between Carbide & HSS — Makers Market Carbide End Mill Vs Hss While both hss and carbide mills are. The minimal cobalt needed to make carbide milling cutters is significantly less magnetic than hss. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. However, hss end mills can also be used for cutting harder materials with proper. Carbide End Mill Vs Hss.

From zhenjiangscharptools.en.made-in-china.com

China Solid Carbide End Mill Photos & Pictures Carbide End Mill Vs Hss Hss is often used to make cutting tools like drills, end mills, etc. However, hss end mills can also be used for cutting harder materials with proper coatings and geometries. Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited for softer materials such as aluminum, brass,. Carbide End Mill Vs Hss.

From www.totimetools.com

Carbide End Mill for General Steel Carbide End Mill Vs Hss While both hss and carbide mills are. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Tungsten carbide is often used for tools in continuous and. The minimal cobalt needed to make carbide milling cutters is significantly less magnetic than hss. Carbide end mills are. Carbide End Mill Vs Hss.

From www.qualitytechtool.com

General Purpose End Mills Inch Quality Tech Tool Carbide End Mill Vs Hss The minimal cobalt needed to make carbide milling cutters is significantly less magnetic than hss. Hss is often used to make cutting tools like drills, end mills, etc. However, hss end mills can also be used for cutting harder materials with proper coatings and geometries. Judging between high speed steel (hss) and carbide end mills often boils down to the. Carbide End Mill Vs Hss.

From bamil.lewisburgdistrictumc.org

carbide end mill speed and feed chart Bamil Carbide End Mill Vs Hss Hss end mills also cost. Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited for softer materials such as aluminum, brass, and plastics. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the. Carbide End Mill Vs Hss.

From www.endmills-wotek.com

Development of analytical solid carbide end mill deflection and Carbide End Mill Vs Hss Hss is often used to make cutting tools like drills, end mills, etc. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Tungsten carbide is often used for tools in continuous and. Hss end mills also cost. While both hss and carbide mills are. Machining. Carbide End Mill Vs Hss.

From www.tool-factory.de

HSS end mills Tool Factory Carbide End Mill Vs Hss Tungsten carbide is often used for tools in continuous and. Machining activities, such as drilling and boring, generate high degrees of heat. Hss is often used to make cutting tools like drills, end mills, etc. The minimal cobalt needed to make carbide milling cutters is significantly less magnetic than hss. However, hss end mills can also be used for cutting. Carbide End Mill Vs Hss.

From www.cnccookbook.com

Is Carbide Always Faster? CNCCookbook Be A Better CNC'er Carbide End Mill Vs Hss Hss end mills also cost. Hss is often used to make cutting tools like drills, end mills, etc. Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited for softer materials such as aluminum, brass, and plastics. While both hss and carbide mills are. The minimal cobalt. Carbide End Mill Vs Hss.

From www.cgstool.com

What is End Milling? CGS Tool End Mills Solid Carbide Cutting Tools Carbide End Mill Vs Hss Tungsten carbide is often used for tools in continuous and. Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. While both hss and carbide mills are. Machining activities, such as drilling and boring, generate high degrees of heat. The minimal cobalt needed to make carbide. Carbide End Mill Vs Hss.

From www.shop-apt.co.uk

End Mill for Aluminium 10mm Diameter 2 Flute Uncoated Micrograin Carbide End Mill Vs Hss Hss is often used to make cutting tools like drills, end mills, etc. While both hss and carbide mills are. Carbide end mills are ideal for cutting hard materials such as steel, stainless steel, and titanium, while hss end mills are better suited for softer materials such as aluminum, brass, and plastics. Hss end mills also cost. Judging between high. Carbide End Mill Vs Hss.

From ameliarhamlino.blob.core.windows.net

Hss Drill Speeds And Feeds Chart Metric at ameliarhamlino blog Carbide End Mill Vs Hss Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. Tungsten carbide is often used for tools in continuous and. Hss is often used to make cutting tools like drills, end mills, etc. Hss end mills also cost. Machining activities, such as drilling and boring, generate. Carbide End Mill Vs Hss.

From es.scribd.com

Feeds And Speeds For General Purpose Altin Coated Carbide Endmills Carbide End Mill Vs Hss Judging between high speed steel (hss) and carbide end mills often boils down to the context of use and the priorities of the machining. However, hss end mills can also be used for cutting harder materials with proper coatings and geometries. Tungsten carbide is often used for tools in continuous and. Machining activities, such as drilling and boring, generate high. Carbide End Mill Vs Hss.