Decanter In Distillation Column . A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be recycled without further purification. The bottoms product is almost exclusively liquid, while the. For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to the decanter in order to liquid phase region, or. A distillation column with an internal decanter is used to separate a mixture containing five some oxygenated and hydrocarbons and. Distillation columns use a thermal process that involves heating and cooling to separate two or more mixed substances, such as gases or. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. The correct design of the decanter for the separation of the two liquid phases is very important especially when a phase reversal, by. Distillation is a process that separates two or more components into an overhead distillate and bottoms. In this work, a simple design. The other outlet (the heavy stream) has a composition in a different.

from www.cadifindia.com

Distillation is a process that separates two or more components into an overhead distillate and bottoms. The other outlet (the heavy stream) has a composition in a different. The correct design of the decanter for the separation of the two liquid phases is very important especially when a phase reversal, by. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to the decanter in order to liquid phase region, or. The bottoms product is almost exclusively liquid, while the. A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be recycled without further purification. In this work, a simple design. Distillation columns use a thermal process that involves heating and cooling to separate two or more mixed substances, such as gases or. A distillation column with an internal decanter is used to separate a mixture containing five some oxygenated and hydrocarbons and.

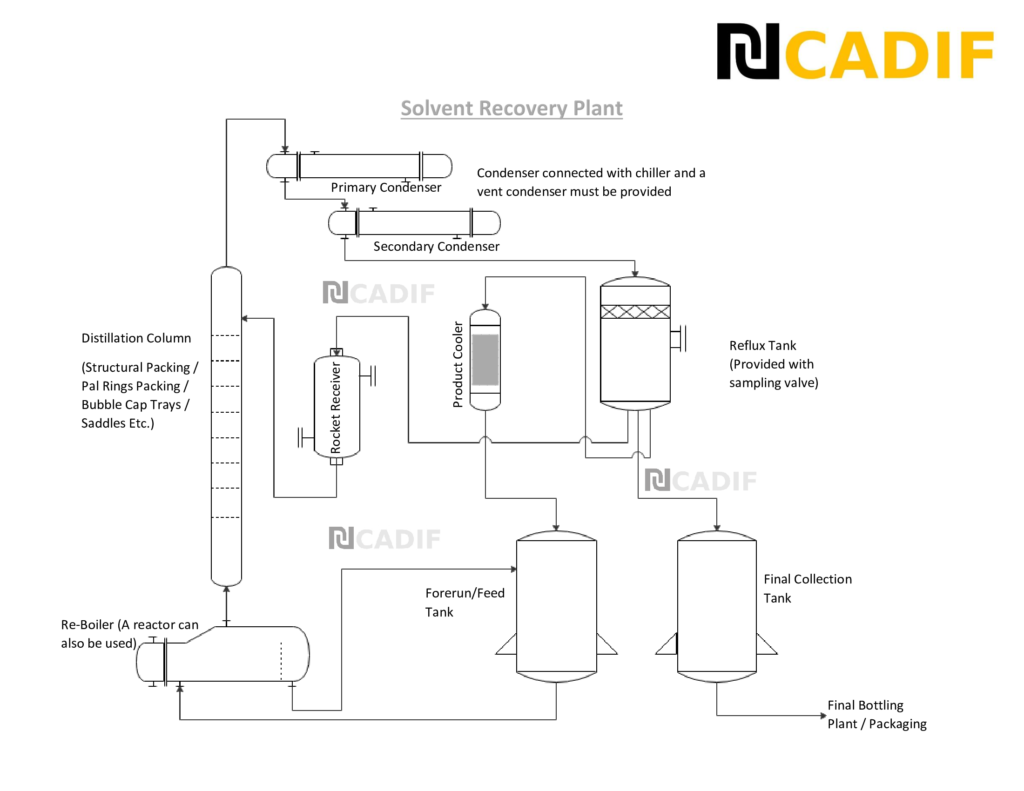

Solvent Recovery & Distillation Columns CADIFINDIA

Decanter In Distillation Column A distillation column with an internal decanter is used to separate a mixture containing five some oxygenated and hydrocarbons and. The correct design of the decanter for the separation of the two liquid phases is very important especially when a phase reversal, by. The bottoms product is almost exclusively liquid, while the. Distillation columns use a thermal process that involves heating and cooling to separate two or more mixed substances, such as gases or. For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to the decanter in order to liquid phase region, or. A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be recycled without further purification. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. The other outlet (the heavy stream) has a composition in a different. Distillation is a process that separates two or more components into an overhead distillate and bottoms. In this work, a simple design. A distillation column with an internal decanter is used to separate a mixture containing five some oxygenated and hydrocarbons and.

From www.alamy.com

Oil refinery and gas processing plant. Distillation tower (refining Decanter In Distillation Column Distillation is a process that separates two or more components into an overhead distillate and bottoms. The other outlet (the heavy stream) has a composition in a different. For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to the decanter in order to liquid phase region, or. A distillation column with an internal decanter is used to. Decanter In Distillation Column.

From www.pinterest.com

Tray or Packed Columns for Distillation Chemical engineering, Nursing Decanter In Distillation Column A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be recycled without further purification. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to the decanter in order to liquid phase region, or. Distillation columns use. Decanter In Distillation Column.

From www.cadifindia.com

Solvent Recovery & Distillation Columns CADIFINDIA Decanter In Distillation Column The bottoms product is almost exclusively liquid, while the. The correct design of the decanter for the separation of the two liquid phases is very important especially when a phase reversal, by. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to. Decanter In Distillation Column.

From www.researchgate.net

Process flowsheet consisting of a decanter D1 and a hybrid Decanter In Distillation Column For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to the decanter in order to liquid phase region, or. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. Distillation is a process that separates two or more components into an overhead distillate and bottoms. In this work, a simple design. A. Decanter In Distillation Column.

From www.semanticscholar.org

Figure 1 from Greenhouse gas emissions reduction by process Decanter In Distillation Column Distillation columns use a thermal process that involves heating and cooling to separate two or more mixed substances, such as gases or. The bottoms product is almost exclusively liquid, while the. A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be recycled without further purification. The correct design of the decanter for the separation. Decanter In Distillation Column.

From www.thepiping.com

what is distillation, absorption and stripping, fractionation column Decanter In Distillation Column A distillation column with an internal decanter is used to separate a mixture containing five some oxygenated and hydrocarbons and. The bottoms product is almost exclusively liquid, while the. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be. Decanter In Distillation Column.

From www.theengineersperspectives.com

What Is Azeotropic Distillation? The Engineer's Perspective Decanter In Distillation Column In this work, a simple design. The correct design of the decanter for the separation of the two liquid phases is very important especially when a phase reversal, by. Distillation columns use a thermal process that involves heating and cooling to separate two or more mixed substances, such as gases or. The bottoms product is almost exclusively liquid, while the.. Decanter In Distillation Column.

From www.chemengghelp.com

Steam Distillation Method for Component Separation ChemEnggHelp Decanter In Distillation Column A distillation column with an internal decanter is used to separate a mixture containing five some oxygenated and hydrocarbons and. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. The bottoms product is almost exclusively liquid, while the. For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to the decanter in. Decanter In Distillation Column.

From www.artofit.org

How a distillation column works column distillation Artofit Decanter In Distillation Column Distillation is a process that separates two or more components into an overhead distillate and bottoms. The bottoms product is almost exclusively liquid, while the. Distillation columns use a thermal process that involves heating and cooling to separate two or more mixed substances, such as gases or. For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to. Decanter In Distillation Column.

From www.chegg.com

Solved Question 3 To extract acetone from a mixture of Decanter In Distillation Column An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. A distillation column with an internal decanter is used to separate a mixture containing five some oxygenated and hydrocarbons and. In this work, a simple design. Distillation is a process that separates two or more components into an overhead distillate and bottoms. The correct design. Decanter In Distillation Column.

From encyclopedia.che.engin.umich.edu

Distillation Columns Visual Encyclopedia of Chemical Engineering Decanter In Distillation Column Distillation columns use a thermal process that involves heating and cooling to separate two or more mixed substances, such as gases or. The bottoms product is almost exclusively liquid, while the. Distillation is a process that separates two or more components into an overhead distillate and bottoms. A decanter can be used to concentrate cyclohexane from 59% to 89% so. Decanter In Distillation Column.

From chemicaltweak.com

Azeotropic Distillation Process In Detail Binary Separation Technique Decanter In Distillation Column Distillation is a process that separates two or more components into an overhead distillate and bottoms. For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to the decanter in order to liquid phase region, or. A distillation column with an internal decanter is used to separate a mixture containing five some oxygenated and hydrocarbons and. The bottoms. Decanter In Distillation Column.

From www.semanticscholar.org

Figure 17 from Design and cosimulate control of an extractive Decanter In Distillation Column A distillation column with an internal decanter is used to separate a mixture containing five some oxygenated and hydrocarbons and. Distillation columns use a thermal process that involves heating and cooling to separate two or more mixed substances, such as gases or. Distillation is a process that separates two or more components into an overhead distillate and bottoms. An industrial. Decanter In Distillation Column.

From www.researchgate.net

Distillation column with heatpump, proposed control structure 3.1 Decanter In Distillation Column The other outlet (the heavy stream) has a composition in a different. A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be recycled without further purification. For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to the decanter in order to liquid phase region, or. The correct design of the decanter. Decanter In Distillation Column.

From www.dayuwz.com

DYE 500 lt copper distiller alambic distilation alcohol electrik column Decanter In Distillation Column In this work, a simple design. The other outlet (the heavy stream) has a composition in a different. For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to the decanter in order to liquid phase region, or. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. Distillation is a process that. Decanter In Distillation Column.

From brycebryanne.blogspot.com

Distillation Column P&Id / Https Pubs Acs Org Doi Pdf 10 1021 Jf047788f Decanter In Distillation Column For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to the decanter in order to liquid phase region, or. The bottoms product is almost exclusively liquid, while the. The other outlet (the heavy stream) has a composition in a different. In this work, a simple design. Distillation is a process that separates two or more components into. Decanter In Distillation Column.

From www.britannica.com

Distillation Definition, Process, & Methods Britannica Decanter In Distillation Column The bottoms product is almost exclusively liquid, while the. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. Distillation is a process that separates two or more components into an overhead distillate and bottoms. The correct design of the decanter for the separation of the two liquid phases is very important especially when a. Decanter In Distillation Column.

From www.aliexpress.com

Improve Liquor Quality Distillation Column Rectification Column Air Decanter In Distillation Column A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be recycled without further purification. The bottoms product is almost exclusively liquid, while the. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. In this work, a simple design. The correct design of the decanter for the separation of. Decanter In Distillation Column.

From www.youtube.com

Simulation of Decanter using Aspen Plus Lecture 42 YouTube Decanter In Distillation Column Distillation is a process that separates two or more components into an overhead distillate and bottoms. The correct design of the decanter for the separation of the two liquid phases is very important especially when a phase reversal, by. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. A distillation column with an internal. Decanter In Distillation Column.

From mavink.com

Distillation Column Photo Decanter In Distillation Column An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be recycled without further purification. The other outlet (the heavy stream) has a composition in a different. For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to. Decanter In Distillation Column.

From www.researchgate.net

Crude distillation unit layout with basic control loops 3. PROCESS Decanter In Distillation Column The bottoms product is almost exclusively liquid, while the. In this work, a simple design. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be recycled without further purification. Distillation is a process that separates two or more components. Decanter In Distillation Column.

From eslingerbiodiesel.com

News / Updates Eslinger Biodiesel Decanter In Distillation Column For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to the decanter in order to liquid phase region, or. The bottoms product is almost exclusively liquid, while the. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. A distillation column with an internal decanter is used to separate a mixture containing. Decanter In Distillation Column.

From keithemms.com

Column Still Distillation How a Column Still Works • Spirit Essences Decanter In Distillation Column Distillation is a process that separates two or more components into an overhead distillate and bottoms. The bottoms product is almost exclusively liquid, while the. The correct design of the decanter for the separation of the two liquid phases is very important especially when a phase reversal, by. Distillation columns use a thermal process that involves heating and cooling to. Decanter In Distillation Column.

From www.mdpi.com

Processes Free FullText Analysis of MultiLoop Control Structures Decanter In Distillation Column For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to the decanter in order to liquid phase region, or. Distillation is a process that separates two or more components into an overhead distillate and bottoms. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. In this work, a simple design. The. Decanter In Distillation Column.

From www.pcbrewery.com

1000L Copper Pot Stills Commercial Distillation Equipment Copper Decanter In Distillation Column The bottoms product is almost exclusively liquid, while the. In this work, a simple design. A distillation column with an internal decanter is used to separate a mixture containing five some oxygenated and hydrocarbons and. A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be recycled without further purification. Distillation columns use a thermal. Decanter In Distillation Column.

From mungfali.com

Distillation Column Process Flow Diagram Decanter In Distillation Column The other outlet (the heavy stream) has a composition in a different. The correct design of the decanter for the separation of the two liquid phases is very important especially when a phase reversal, by. The bottoms product is almost exclusively liquid, while the. A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be. Decanter In Distillation Column.

From www.theengineeringconcepts.com

Azeotropic Vs Extractive Distillation The Engineering Concepts Decanter In Distillation Column A distillation column with an internal decanter is used to separate a mixture containing five some oxygenated and hydrocarbons and. Distillation is a process that separates two or more components into an overhead distillate and bottoms. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. A decanter can be used to concentrate cyclohexane from. Decanter In Distillation Column.

From www.youtube.com

Distillation Column YouTube Decanter In Distillation Column For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to the decanter in order to liquid phase region, or. A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be recycled without further purification. A distillation column with an internal decanter is used to separate a mixture containing five some oxygenated and. Decanter In Distillation Column.

From www.semanticscholar.org

Figure 1 from Fuzzy Hybrid Modeling of a Reactive Distillation Column Decanter In Distillation Column In this work, a simple design. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. A distillation column with an internal decanter is used to separate a mixture containing five some oxygenated and hydrocarbons and. A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be recycled without further. Decanter In Distillation Column.

From www.researchgate.net

WillliamsOtto process with a reactor, decanter, distillation column Decanter In Distillation Column A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be recycled without further purification. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. A distillation column with an internal decanter is used to separate a mixture containing five some oxygenated and hydrocarbons and. The bottoms product is almost. Decanter In Distillation Column.

From www.researchgate.net

5 Apparatus for azeotropic distillation method with BidwellSterling Decanter In Distillation Column The bottoms product is almost exclusively liquid, while the. Distillation is a process that separates two or more components into an overhead distillate and bottoms. A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be recycled without further purification. Distillation columns use a thermal process that involves heating and cooling to separate two or. Decanter In Distillation Column.

From www.chemengghelp.com

Steam Distillation Method for Component Separation ChemEnggHelp Decanter In Distillation Column Distillation is a process that separates two or more components into an overhead distillate and bottoms. The bottoms product is almost exclusively liquid, while the. For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to the decanter in order to liquid phase region, or. In this work, a simple design. A distillation column with an internal decanter. Decanter In Distillation Column.

From www.chemicalprocessing.com

Rethink Distillation Column Pressure Measurement Chemical Processing Decanter In Distillation Column The correct design of the decanter for the separation of the two liquid phases is very important especially when a phase reversal, by. For minimum boiling, azeotropic heterogeneous systems, this can be either adding water to the decanter in order to liquid phase region, or. In this work, a simple design. Distillation is a process that separates two or more. Decanter In Distillation Column.

From www.researchgate.net

Ethyl acetate production via reactive distillation column with a Decanter In Distillation Column Distillation columns use a thermal process that involves heating and cooling to separate two or more mixed substances, such as gases or. A decanter can be used to concentrate cyclohexane from 59% to 89% so it can be recycled without further purification. In this work, a simple design. The other outlet (the heavy stream) has a composition in a different.. Decanter In Distillation Column.

From chemicalengineeringworld.com

Azeotropic Distillation Process Chemical Engineering World Decanter In Distillation Column Distillation columns use a thermal process that involves heating and cooling to separate two or more mixed substances, such as gases or. An industrial feasible design flowsheet includes three columns, a decanter and two internal recycle streams. The correct design of the decanter for the separation of the two liquid phases is very important especially when a phase reversal, by.. Decanter In Distillation Column.