Bearing Oil Grade . The bearing speed is often measured strictly by the revolutions per minute of the shaft, with no consideration of the surface speed of the shaft, as per the “nd. Most oil systems for high speed bearings delivery as little as 1 drip of oil a minute up to a small flow of oil. The viscosity grade required is dependent upon bearing rpm, oil temperature and load. Sealing of the oil system, a good oil filter,. Classifications of oil or grease, each with specific properties correct for different bearing applications. Oil in process pumps is typically an iso grade 32, 46, 68 or 100. These numbers relate to the kinematic viscosity in centistokes. Generally, grease is the preferred. Grooves in the bearing shell are used to distribute the oil throughout the bearings’ surfaces. The oil can be hydrocarbon oil, although. A product’s current nlgi grade, for example, can help technicians predict how the changing temperatures may affect the grease’s distribution on the bearing during.

from mavink.com

Most oil systems for high speed bearings delivery as little as 1 drip of oil a minute up to a small flow of oil. Classifications of oil or grease, each with specific properties correct for different bearing applications. Grooves in the bearing shell are used to distribute the oil throughout the bearings’ surfaces. Oil in process pumps is typically an iso grade 32, 46, 68 or 100. The viscosity grade required is dependent upon bearing rpm, oil temperature and load. Generally, grease is the preferred. A product’s current nlgi grade, for example, can help technicians predict how the changing temperatures may affect the grease’s distribution on the bearing during. These numbers relate to the kinematic viscosity in centistokes. The oil can be hydrocarbon oil, although. The bearing speed is often measured strictly by the revolutions per minute of the shaft, with no consideration of the surface speed of the shaft, as per the “nd.

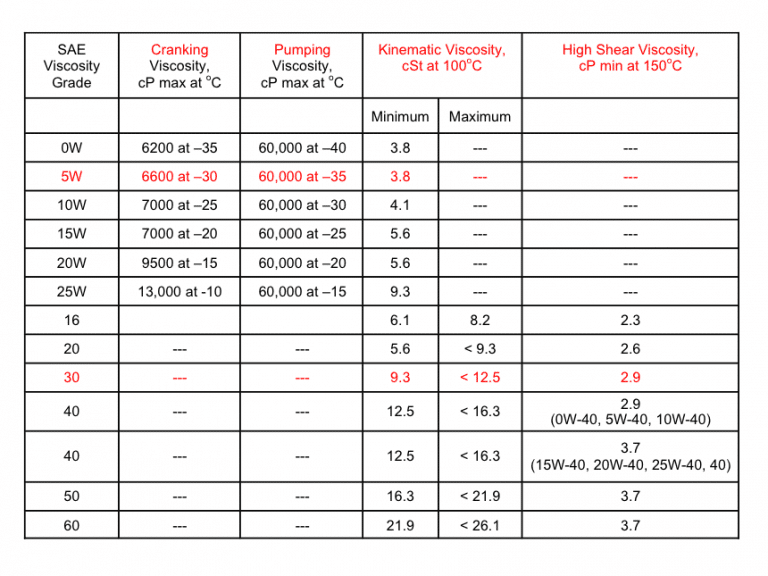

Sae To Iso Oil Conversion Chart

Bearing Oil Grade Sealing of the oil system, a good oil filter,. Sealing of the oil system, a good oil filter,. The oil can be hydrocarbon oil, although. A product’s current nlgi grade, for example, can help technicians predict how the changing temperatures may affect the grease’s distribution on the bearing during. Classifications of oil or grease, each with specific properties correct for different bearing applications. Oil in process pumps is typically an iso grade 32, 46, 68 or 100. Generally, grease is the preferred. Most oil systems for high speed bearings delivery as little as 1 drip of oil a minute up to a small flow of oil. The bearing speed is often measured strictly by the revolutions per minute of the shaft, with no consideration of the surface speed of the shaft, as per the “nd. The viscosity grade required is dependent upon bearing rpm, oil temperature and load. Grooves in the bearing shell are used to distribute the oil throughout the bearings’ surfaces. These numbers relate to the kinematic viscosity in centistokes.

From www.morrislubricantsonline.co.uk

Bearing Oil 220 Bearing Oil Grade Oil in process pumps is typically an iso grade 32, 46, 68 or 100. Sealing of the oil system, a good oil filter,. These numbers relate to the kinematic viscosity in centistokes. Generally, grease is the preferred. Most oil systems for high speed bearings delivery as little as 1 drip of oil a minute up to a small flow of. Bearing Oil Grade.

From www.bearingtips.com

SKF centralizes the production of bearings with solid oil Bearing Tips Bearing Oil Grade Generally, grease is the preferred. The viscosity grade required is dependent upon bearing rpm, oil temperature and load. Grooves in the bearing shell are used to distribute the oil throughout the bearings’ surfaces. Oil in process pumps is typically an iso grade 32, 46, 68 or 100. The bearing speed is often measured strictly by the revolutions per minute of. Bearing Oil Grade.

From www.chevyhardcore.com

The Secret Life of Bearings A Test Of Bearing And Oil Wear Rates Bearing Oil Grade Grooves in the bearing shell are used to distribute the oil throughout the bearings’ surfaces. Classifications of oil or grease, each with specific properties correct for different bearing applications. Most oil systems for high speed bearings delivery as little as 1 drip of oil a minute up to a small flow of oil. A product’s current nlgi grade, for example,. Bearing Oil Grade.

From www.chevyhardcore.com

Tech Choosing The Proper Bearings For Your Engine Bearing Oil Grade The oil can be hydrocarbon oil, although. A product’s current nlgi grade, for example, can help technicians predict how the changing temperatures may affect the grease’s distribution on the bearing during. Grooves in the bearing shell are used to distribute the oil throughout the bearings’ surfaces. Sealing of the oil system, a good oil filter,. The bearing speed is often. Bearing Oil Grade.

From pibsales.com

How Oil Impregnated Bronze Bushings Improve Performance PIB Sales Bearing Oil Grade Classifications of oil or grease, each with specific properties correct for different bearing applications. Oil in process pumps is typically an iso grade 32, 46, 68 or 100. Sealing of the oil system, a good oil filter,. Generally, grease is the preferred. Most oil systems for high speed bearings delivery as little as 1 drip of oil a minute up. Bearing Oil Grade.

From www.china-bearing-manufacturer.com

What is Solid oil bearing? China Bearing SuppliersXRB Bearing Bearing Oil Grade The viscosity grade required is dependent upon bearing rpm, oil temperature and load. Classifications of oil or grease, each with specific properties correct for different bearing applications. The bearing speed is often measured strictly by the revolutions per minute of the shaft, with no consideration of the surface speed of the shaft, as per the “nd. Sealing of the oil. Bearing Oil Grade.

From webmotor.org

Sae Motor Oil Viscosity Chart Bearing Oil Grade The bearing speed is often measured strictly by the revolutions per minute of the shaft, with no consideration of the surface speed of the shaft, as per the “nd. Classifications of oil or grease, each with specific properties correct for different bearing applications. Generally, grease is the preferred. These numbers relate to the kinematic viscosity in centistokes. The viscosity grade. Bearing Oil Grade.

From aerolgroup.com

High Speed Bearing Grease Speciality Lubricants Aerol® Bearing Oil Grade The viscosity grade required is dependent upon bearing rpm, oil temperature and load. Grooves in the bearing shell are used to distribute the oil throughout the bearings’ surfaces. Most oil systems for high speed bearings delivery as little as 1 drip of oil a minute up to a small flow of oil. Classifications of oil or grease, each with specific. Bearing Oil Grade.

From studyizimpawucu.z21.web.core.windows.net

Viscosity Grade Comparison Chart Bearing Oil Grade A product’s current nlgi grade, for example, can help technicians predict how the changing temperatures may affect the grease’s distribution on the bearing during. Classifications of oil or grease, each with specific properties correct for different bearing applications. These numbers relate to the kinematic viscosity in centistokes. Grooves in the bearing shell are used to distribute the oil throughout the. Bearing Oil Grade.

From www.enginebuildermag.com

UNDERSTANDING OIL CLEARANCES IN ENGINE BEARINGS Engine Builder Magazine Bearing Oil Grade The bearing speed is often measured strictly by the revolutions per minute of the shaft, with no consideration of the surface speed of the shaft, as per the “nd. A product’s current nlgi grade, for example, can help technicians predict how the changing temperatures may affect the grease’s distribution on the bearing during. Sealing of the oil system, a good. Bearing Oil Grade.

From only-eight.blogspot.com

nsk bearing number and size chart pdf In A Shitload LogBook Picture Show Bearing Oil Grade The bearing speed is often measured strictly by the revolutions per minute of the shaft, with no consideration of the surface speed of the shaft, as per the “nd. Sealing of the oil system, a good oil filter,. Generally, grease is the preferred. Classifications of oil or grease, each with specific properties correct for different bearing applications. The oil can. Bearing Oil Grade.

From www.bosch-presse.de

Conductive lubricants will protect the electric motors of the future Bearing Oil Grade Grooves in the bearing shell are used to distribute the oil throughout the bearings’ surfaces. Sealing of the oil system, a good oil filter,. Most oil systems for high speed bearings delivery as little as 1 drip of oil a minute up to a small flow of oil. Generally, grease is the preferred. These numbers relate to the kinematic viscosity. Bearing Oil Grade.

From www.indiamart.com

Mobil SHC 630 Synthetic Gear Bearing Oil, For Industrial, Grade Iso Bearing Oil Grade Most oil systems for high speed bearings delivery as little as 1 drip of oil a minute up to a small flow of oil. A product’s current nlgi grade, for example, can help technicians predict how the changing temperatures may affect the grease’s distribution on the bearing during. Sealing of the oil system, a good oil filter,. Oil in process. Bearing Oil Grade.

From www.enginelabs.com

Tech Choosing The Proper Bearings For Your Engine Bearing Oil Grade The viscosity grade required is dependent upon bearing rpm, oil temperature and load. A product’s current nlgi grade, for example, can help technicians predict how the changing temperatures may affect the grease’s distribution on the bearing during. Generally, grease is the preferred. Grooves in the bearing shell are used to distribute the oil throughout the bearings’ surfaces. The oil can. Bearing Oil Grade.

From webmotor.org

Sae Motor Oil Viscosity Chart Bearing Oil Grade A product’s current nlgi grade, for example, can help technicians predict how the changing temperatures may affect the grease’s distribution on the bearing during. Generally, grease is the preferred. Classifications of oil or grease, each with specific properties correct for different bearing applications. The bearing speed is often measured strictly by the revolutions per minute of the shaft, with no. Bearing Oil Grade.

From www.chevyhardcore.com

The Secret Life of Bearings A Test Of Bearing And Oil Wear Rates Bearing Oil Grade The oil can be hydrocarbon oil, although. The viscosity grade required is dependent upon bearing rpm, oil temperature and load. The bearing speed is often measured strictly by the revolutions per minute of the shaft, with no consideration of the surface speed of the shaft, as per the “nd. These numbers relate to the kinematic viscosity in centistokes. A product’s. Bearing Oil Grade.

From www.elevatorequipment.co.uk

Synthetic Oil Grade 220 5L Elevator Equipment Bearing Oil Grade Most oil systems for high speed bearings delivery as little as 1 drip of oil a minute up to a small flow of oil. Sealing of the oil system, a good oil filter,. Classifications of oil or grease, each with specific properties correct for different bearing applications. These numbers relate to the kinematic viscosity in centistokes. The viscosity grade required. Bearing Oil Grade.

From americanwaymktg.com

J. Meinlschmidt 13 Synthetic Bearing Oil American Way Marketing Bearing Oil Grade Oil in process pumps is typically an iso grade 32, 46, 68 or 100. These numbers relate to the kinematic viscosity in centistokes. Classifications of oil or grease, each with specific properties correct for different bearing applications. Sealing of the oil system, a good oil filter,. Grooves in the bearing shell are used to distribute the oil throughout the bearings’. Bearing Oil Grade.

From dsportmag.com

The Science Behind Modern Performance Engine Bearings Bearing Oil Grade Most oil systems for high speed bearings delivery as little as 1 drip of oil a minute up to a small flow of oil. Classifications of oil or grease, each with specific properties correct for different bearing applications. The oil can be hydrocarbon oil, although. The viscosity grade required is dependent upon bearing rpm, oil temperature and load. Sealing of. Bearing Oil Grade.

From mavink.com

Sae To Iso Oil Conversion Chart Bearing Oil Grade The bearing speed is often measured strictly by the revolutions per minute of the shaft, with no consideration of the surface speed of the shaft, as per the “nd. Classifications of oil or grease, each with specific properties correct for different bearing applications. The viscosity grade required is dependent upon bearing rpm, oil temperature and load. Most oil systems for. Bearing Oil Grade.

From www.amazon.com

high speed bearing oil Bearing Oil Grade A product’s current nlgi grade, for example, can help technicians predict how the changing temperatures may affect the grease’s distribution on the bearing during. Grooves in the bearing shell are used to distribute the oil throughout the bearings’ surfaces. Oil in process pumps is typically an iso grade 32, 46, 68 or 100. Classifications of oil or grease, each with. Bearing Oil Grade.

From www.noveltymachine.com

Bearings Archives Novelty Machine & Supply Co. Bearing Oil Grade The viscosity grade required is dependent upon bearing rpm, oil temperature and load. Classifications of oil or grease, each with specific properties correct for different bearing applications. Most oil systems for high speed bearings delivery as little as 1 drip of oil a minute up to a small flow of oil. Oil in process pumps is typically an iso grade. Bearing Oil Grade.

From www.indiamart.com

HP PARTHON EP 220 320 INDUSTRIAL GEAR BOX OIL, Grade Parthon Grades Bearing Oil Grade These numbers relate to the kinematic viscosity in centistokes. Sealing of the oil system, a good oil filter,. The viscosity grade required is dependent upon bearing rpm, oil temperature and load. Oil in process pumps is typically an iso grade 32, 46, 68 or 100. Generally, grease is the preferred. The oil can be hydrocarbon oil, although. Most oil systems. Bearing Oil Grade.

From www.researchgate.net

Oilbearing grades and main characteristics of Mishrif Formation cores Bearing Oil Grade Classifications of oil or grease, each with specific properties correct for different bearing applications. Generally, grease is the preferred. The oil can be hydrocarbon oil, although. A product’s current nlgi grade, for example, can help technicians predict how the changing temperatures may affect the grease’s distribution on the bearing during. Oil in process pumps is typically an iso grade 32,. Bearing Oil Grade.

From chartwalls.blogspot.com

Ball Bearing Number And Size Chart Pdf Chart Walls Bearing Oil Grade The oil can be hydrocarbon oil, although. Generally, grease is the preferred. Classifications of oil or grease, each with specific properties correct for different bearing applications. Most oil systems for high speed bearings delivery as little as 1 drip of oil a minute up to a small flow of oil. Sealing of the oil system, a good oil filter,. The. Bearing Oil Grade.

From blog.fitreformer.com

The difference between wheel bushings and bearings The Fit Reformer Blog Bearing Oil Grade Grooves in the bearing shell are used to distribute the oil throughout the bearings’ surfaces. Sealing of the oil system, a good oil filter,. Generally, grease is the preferred. Most oil systems for high speed bearings delivery as little as 1 drip of oil a minute up to a small flow of oil. Oil in process pumps is typically an. Bearing Oil Grade.

From learningnumerolin1.z21.web.core.windows.net

Oil Viscosity Grade Chart Bearing Oil Grade Grooves in the bearing shell are used to distribute the oil throughout the bearings’ surfaces. Oil in process pumps is typically an iso grade 32, 46, 68 or 100. The oil can be hydrocarbon oil, although. The bearing speed is often measured strictly by the revolutions per minute of the shaft, with no consideration of the surface speed of the. Bearing Oil Grade.

From blsbearing.en.made-in-china.com

Food & Beverage Grade Bearings, Bearings with Solid Oil China Ball Bearing Oil Grade The oil can be hydrocarbon oil, although. Sealing of the oil system, a good oil filter,. The bearing speed is often measured strictly by the revolutions per minute of the shaft, with no consideration of the surface speed of the shaft, as per the “nd. Generally, grease is the preferred. Grooves in the bearing shell are used to distribute the. Bearing Oil Grade.

From rotella.shell.com

NLGI HighPerformance Multiuse Grease Specifications Shell Rotella® Bearing Oil Grade Sealing of the oil system, a good oil filter,. Most oil systems for high speed bearings delivery as little as 1 drip of oil a minute up to a small flow of oil. The bearing speed is often measured strictly by the revolutions per minute of the shaft, with no consideration of the surface speed of the shaft, as per. Bearing Oil Grade.

From www.machinerylubrication.com

Rolling Bearing Lubrication for Critical Running Conditions Bearing Oil Grade A product’s current nlgi grade, for example, can help technicians predict how the changing temperatures may affect the grease’s distribution on the bearing during. Generally, grease is the preferred. Grooves in the bearing shell are used to distribute the oil throughout the bearings’ surfaces. Most oil systems for high speed bearings delivery as little as 1 drip of oil a. Bearing Oil Grade.

From www.dragzine.com

The Secret Life of Bearings A Test Of Bearing And Oil Wear Rates Bearing Oil Grade The oil can be hydrocarbon oil, although. Classifications of oil or grease, each with specific properties correct for different bearing applications. Most oil systems for high speed bearings delivery as little as 1 drip of oil a minute up to a small flow of oil. The viscosity grade required is dependent upon bearing rpm, oil temperature and load. A product’s. Bearing Oil Grade.

From studyizimpawucu.z21.web.core.windows.net

Oil Viscosity Grade Chart Bearing Oil Grade Grooves in the bearing shell are used to distribute the oil throughout the bearings’ surfaces. Sealing of the oil system, a good oil filter,. Generally, grease is the preferred. The bearing speed is often measured strictly by the revolutions per minute of the shaft, with no consideration of the surface speed of the shaft, as per the “nd. Most oil. Bearing Oil Grade.

From www.priestelectric.com

Relubrication of Bearings Priest Electric Bearing Oil Grade Grooves in the bearing shell are used to distribute the oil throughout the bearings’ surfaces. A product’s current nlgi grade, for example, can help technicians predict how the changing temperatures may affect the grease’s distribution on the bearing during. Generally, grease is the preferred. Sealing of the oil system, a good oil filter,. Most oil systems for high speed bearings. Bearing Oil Grade.

From www.dragzine.com

The Secret Life of Bearings A Test Of Bearing And Oil Wear Rates Bearing Oil Grade Oil in process pumps is typically an iso grade 32, 46, 68 or 100. The viscosity grade required is dependent upon bearing rpm, oil temperature and load. Classifications of oil or grease, each with specific properties correct for different bearing applications. The oil can be hydrocarbon oil, although. Generally, grease is the preferred. Sealing of the oil system, a good. Bearing Oil Grade.

From machinefixoutlines.z22.web.core.windows.net

Engine Oil Specification Bearing Oil Grade Sealing of the oil system, a good oil filter,. The viscosity grade required is dependent upon bearing rpm, oil temperature and load. Oil in process pumps is typically an iso grade 32, 46, 68 or 100. These numbers relate to the kinematic viscosity in centistokes. Most oil systems for high speed bearings delivery as little as 1 drip of oil. Bearing Oil Grade.