Brass Solder Joints . In this case i’m soldering a copper reducer to a piece of copper pipe. Cool your pieces, and clean them. The goal is to get the brass hot enough so that the solder will flow freely, but not so hot that it burns the flux. But soldering brass can be tricky due to its high thermal conductivity and low melting point. Next, you will need to heat both pieces of brass with a soldering iron. The solder will stick better as a result, but don’t allow any globs of flux to remain, or they may cause pitting of the pipe. Once you know it is cooled off, you’ll need to rinse the brass pieces in your sink to get rid of any excess flux. Now you’ll need to let the solder cool for a few minutes. Now that you’ve prepared the solder, start soldering the brass. Now, dry your piece and clean it, so you don’t have any extra solder. Place the 2 pieces of copper/brass you want to solder on a hard surface. Brass is a popular alloy used in various applications, including jewelry making, plumbing, and electrical work. Soldering brass is a rewarding and satisfying task that requires proper techniques and tools to achieve a strong and durable solder joint. Hold the iron vertically and move it back and forth to.

from www.cruxweld.com

Cool your pieces, and clean them. Once you know it is cooled off, you’ll need to rinse the brass pieces in your sink to get rid of any excess flux. Place the 2 pieces of copper/brass you want to solder on a hard surface. Brass is a popular alloy used in various applications, including jewelry making, plumbing, and electrical work. Now that you’ve prepared the solder, start soldering the brass. But soldering brass can be tricky due to its high thermal conductivity and low melting point. The solder will stick better as a result, but don’t allow any globs of flux to remain, or they may cause pitting of the pipe. Now you’ll need to let the solder cool for a few minutes. Hold the iron vertically and move it back and forth to. Soldering brass is a rewarding and satisfying task that requires proper techniques and tools to achieve a strong and durable solder joint.

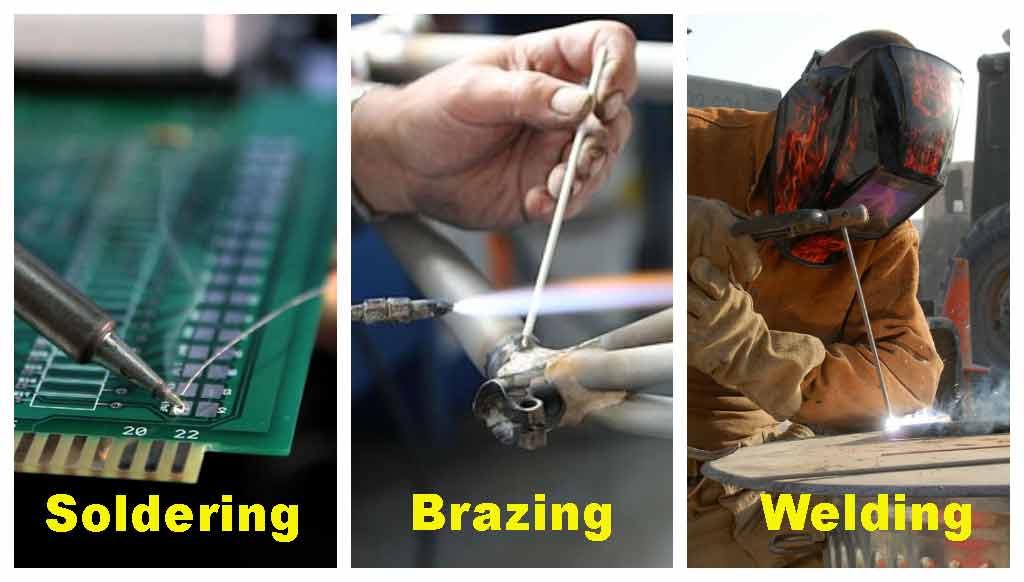

The Difference between Soldering and Brazing with Welding [The

Brass Solder Joints The goal is to get the brass hot enough so that the solder will flow freely, but not so hot that it burns the flux. Hold the iron vertically and move it back and forth to. Soldering brass is a rewarding and satisfying task that requires proper techniques and tools to achieve a strong and durable solder joint. Now, dry your piece and clean it, so you don’t have any extra solder. Now you’ll need to let the solder cool for a few minutes. In this case i’m soldering a copper reducer to a piece of copper pipe. Brass is a popular alloy used in various applications, including jewelry making, plumbing, and electrical work. Now that you’ve prepared the solder, start soldering the brass. The goal is to get the brass hot enough so that the solder will flow freely, but not so hot that it burns the flux. Place the 2 pieces of copper/brass you want to solder on a hard surface. But soldering brass can be tricky due to its high thermal conductivity and low melting point. The solder will stick better as a result, but don’t allow any globs of flux to remain, or they may cause pitting of the pipe. Once you know it is cooled off, you’ll need to rinse the brass pieces in your sink to get rid of any excess flux. Cool your pieces, and clean them. Next, you will need to heat both pieces of brass with a soldering iron.

From www.youtube.com

Silver Soldering Demo YouTube Brass Solder Joints Now, dry your piece and clean it, so you don’t have any extra solder. Place the 2 pieces of copper/brass you want to solder on a hard surface. Now that you’ve prepared the solder, start soldering the brass. The solder will stick better as a result, but don’t allow any globs of flux to remain, or they may cause pitting. Brass Solder Joints.

From www.cruxweld.com

The Difference between Soldering and Brazing with Welding [The Brass Solder Joints The goal is to get the brass hot enough so that the solder will flow freely, but not so hot that it burns the flux. Next, you will need to heat both pieces of brass with a soldering iron. Now you’ll need to let the solder cool for a few minutes. Hold the iron vertically and move it back and. Brass Solder Joints.

From exyugfjts.blob.core.windows.net

How To Solder A Copper Pipe Joint at Roger Criddle blog Brass Solder Joints Cool your pieces, and clean them. Once you know it is cooled off, you’ll need to rinse the brass pieces in your sink to get rid of any excess flux. Brass is a popular alloy used in various applications, including jewelry making, plumbing, and electrical work. Now, dry your piece and clean it, so you don’t have any extra solder.. Brass Solder Joints.

From www.pmmag.com

Soldering vs. brazing when piping is involved 20160928 Plumbing Brass Solder Joints Once you know it is cooled off, you’ll need to rinse the brass pieces in your sink to get rid of any excess flux. Cool your pieces, and clean them. Next, you will need to heat both pieces of brass with a soldering iron. The solder will stick better as a result, but don’t allow any globs of flux to. Brass Solder Joints.

From www.protoexpress.com

IPC JSTD001 Standard for Soldering Sierra Circuits Brass Solder Joints Brass is a popular alloy used in various applications, including jewelry making, plumbing, and electrical work. Soldering brass is a rewarding and satisfying task that requires proper techniques and tools to achieve a strong and durable solder joint. But soldering brass can be tricky due to its high thermal conductivity and low melting point. Hold the iron vertically and move. Brass Solder Joints.

From hobbyrcbd.com

M3 Metal Ball Joints for RC Car/ Model Airplane HobbyRC BD Brass Solder Joints The solder will stick better as a result, but don’t allow any globs of flux to remain, or they may cause pitting of the pipe. Soldering brass is a rewarding and satisfying task that requires proper techniques and tools to achieve a strong and durable solder joint. In this case i’m soldering a copper reducer to a piece of copper. Brass Solder Joints.

From www.pinterest.com

Learn How to Solder Copper Pipe Yourself Welding Classes, Welding Jobs Brass Solder Joints The solder will stick better as a result, but don’t allow any globs of flux to remain, or they may cause pitting of the pipe. Hold the iron vertically and move it back and forth to. The goal is to get the brass hot enough so that the solder will flow freely, but not so hot that it burns the. Brass Solder Joints.

From www.youtube.com

How to Solder Wires like A Pro Wire Soldering Techniques YouTube Brass Solder Joints The solder will stick better as a result, but don’t allow any globs of flux to remain, or they may cause pitting of the pipe. Now, dry your piece and clean it, so you don’t have any extra solder. Once you know it is cooled off, you’ll need to rinse the brass pieces in your sink to get rid of. Brass Solder Joints.

From partdiagrampalisadae.z14.web.core.windows.net

How To Solder Electric Wire Brass Solder Joints Next, you will need to heat both pieces of brass with a soldering iron. Soldering brass is a rewarding and satisfying task that requires proper techniques and tools to achieve a strong and durable solder joint. Now that you’ve prepared the solder, start soldering the brass. The goal is to get the brass hot enough so that the solder will. Brass Solder Joints.

From www.youtube.com

Soldering vertical joint YouTube Brass Solder Joints Hold the iron vertically and move it back and forth to. Once you know it is cooled off, you’ll need to rinse the brass pieces in your sink to get rid of any excess flux. Now you’ll need to let the solder cool for a few minutes. In this case i’m soldering a copper reducer to a piece of copper. Brass Solder Joints.

From slide-elements.blogspot.com

How To Solder Copper Pipe Slide Elements Brass Solder Joints But soldering brass can be tricky due to its high thermal conductivity and low melting point. In this case i’m soldering a copper reducer to a piece of copper pipe. The goal is to get the brass hot enough so that the solder will flow freely, but not so hot that it burns the flux. Hold the iron vertically and. Brass Solder Joints.

From www.diynetwork.com

How to Solder Copper Pipe Using a Propane Torch howtos DIY Brass Solder Joints Cool your pieces, and clean them. Now you’ll need to let the solder cool for a few minutes. But soldering brass can be tricky due to its high thermal conductivity and low melting point. Next, you will need to heat both pieces of brass with a soldering iron. Soldering brass is a rewarding and satisfying task that requires proper techniques. Brass Solder Joints.

From www.thespruce.com

How to Solder Copper Pipe Brass Solder Joints Now you’ll need to let the solder cool for a few minutes. In this case i’m soldering a copper reducer to a piece of copper pipe. But soldering brass can be tricky due to its high thermal conductivity and low melting point. Brass is a popular alloy used in various applications, including jewelry making, plumbing, and electrical work. Cool your. Brass Solder Joints.

From www.skillcatapp.com

The Soldering Process in 5 Simple Steps Brass Solder Joints Hold the iron vertically and move it back and forth to. But soldering brass can be tricky due to its high thermal conductivity and low melting point. Soldering brass is a rewarding and satisfying task that requires proper techniques and tools to achieve a strong and durable solder joint. Now, dry your piece and clean it, so you don’t have. Brass Solder Joints.

From blog.thepipingmart.com

Brazing Copper vs Soldering Copper What's the Difference Brass Solder Joints The solder will stick better as a result, but don’t allow any globs of flux to remain, or they may cause pitting of the pipe. Place the 2 pieces of copper/brass you want to solder on a hard surface. Cool your pieces, and clean them. Hold the iron vertically and move it back and forth to. Now that you’ve prepared. Brass Solder Joints.

From manuallistcantabank.z21.web.core.windows.net

Electrical Wire Connection Brass Solder Joints Soldering brass is a rewarding and satisfying task that requires proper techniques and tools to achieve a strong and durable solder joint. Next, you will need to heat both pieces of brass with a soldering iron. Brass is a popular alloy used in various applications, including jewelry making, plumbing, and electrical work. Hold the iron vertically and move it back. Brass Solder Joints.

From www.youtube.com

Skillful Copper Soldering YouTube Brass Solder Joints In this case i’m soldering a copper reducer to a piece of copper pipe. Brass is a popular alloy used in various applications, including jewelry making, plumbing, and electrical work. The goal is to get the brass hot enough so that the solder will flow freely, but not so hot that it burns the flux. Cool your pieces, and clean. Brass Solder Joints.

From exyugfjts.blob.core.windows.net

How To Solder A Copper Pipe Joint at Roger Criddle blog Brass Solder Joints Brass is a popular alloy used in various applications, including jewelry making, plumbing, and electrical work. Soldering brass is a rewarding and satisfying task that requires proper techniques and tools to achieve a strong and durable solder joint. In this case i’m soldering a copper reducer to a piece of copper pipe. Next, you will need to heat both pieces. Brass Solder Joints.

From gionlfuyu.blob.core.windows.net

Solder For Copper Pipe Lead Free at Rosalina Lazzaro blog Brass Solder Joints Hold the iron vertically and move it back and forth to. Now, dry your piece and clean it, so you don’t have any extra solder. The goal is to get the brass hot enough so that the solder will flow freely, but not so hot that it burns the flux. In this case i’m soldering a copper reducer to a. Brass Solder Joints.

From www.protoexpress.com

IPC JSTD001 Standard for Soldering Sierra Circuits Brass Solder Joints Once you know it is cooled off, you’ll need to rinse the brass pieces in your sink to get rid of any excess flux. Now that you’ve prepared the solder, start soldering the brass. Now, dry your piece and clean it, so you don’t have any extra solder. In this case i’m soldering a copper reducer to a piece of. Brass Solder Joints.

From www.youtube.com

Symbols Used for WELDING, BRAZING & SOLDERING JOINTS in Engineering Brass Solder Joints The goal is to get the brass hot enough so that the solder will flow freely, but not so hot that it burns the flux. Brass is a popular alloy used in various applications, including jewelry making, plumbing, and electrical work. In this case i’m soldering a copper reducer to a piece of copper pipe. Cool your pieces, and clean. Brass Solder Joints.

From www.electronicsandyou.com

Hand Soldering Tutorial How to Solder Electronic Components Brass Solder Joints The solder will stick better as a result, but don’t allow any globs of flux to remain, or they may cause pitting of the pipe. Now, dry your piece and clean it, so you don’t have any extra solder. Place the 2 pieces of copper/brass you want to solder on a hard surface. In this case i’m soldering a copper. Brass Solder Joints.

From www.pinterest.com

⭐⭐ Basics of proper soldering work 😊 Share this with your friends and Brass Solder Joints Next, you will need to heat both pieces of brass with a soldering iron. The solder will stick better as a result, but don’t allow any globs of flux to remain, or they may cause pitting of the pipe. Brass is a popular alloy used in various applications, including jewelry making, plumbing, and electrical work. Once you know it is. Brass Solder Joints.

From blog.thepipingmart.com

Brazing vs Silver Soldering What's the Difference Brass Solder Joints Soldering brass is a rewarding and satisfying task that requires proper techniques and tools to achieve a strong and durable solder joint. Next, you will need to heat both pieces of brass with a soldering iron. Place the 2 pieces of copper/brass you want to solder on a hard surface. Now, dry your piece and clean it, so you don’t. Brass Solder Joints.

From www.youtube.com

How To Solder Copper Pipe The CORRECT Way YouTube Brass Solder Joints Place the 2 pieces of copper/brass you want to solder on a hard surface. Soldering brass is a rewarding and satisfying task that requires proper techniques and tools to achieve a strong and durable solder joint. Cool your pieces, and clean them. Now, dry your piece and clean it, so you don’t have any extra solder. Brass is a popular. Brass Solder Joints.

From www.indiamart.com

Siron Si90t 90w Soldering Iron With Temperature Control at Rs 755.00 Brass Solder Joints Next, you will need to heat both pieces of brass with a soldering iron. Hold the iron vertically and move it back and forth to. But soldering brass can be tricky due to its high thermal conductivity and low melting point. Soldering brass is a rewarding and satisfying task that requires proper techniques and tools to achieve a strong and. Brass Solder Joints.

From www.dreamstime.com

Soldering of Brass Fittings on Copper Pipe Stock Photo Image of Brass Solder Joints Soldering brass is a rewarding and satisfying task that requires proper techniques and tools to achieve a strong and durable solder joint. Once you know it is cooled off, you’ll need to rinse the brass pieces in your sink to get rid of any excess flux. Place the 2 pieces of copper/brass you want to solder on a hard surface.. Brass Solder Joints.

From www.youtube.com

How to solder flat seam joint by franklincustomcopperworks llc Brass Solder Joints Soldering brass is a rewarding and satisfying task that requires proper techniques and tools to achieve a strong and durable solder joint. Once you know it is cooled off, you’ll need to rinse the brass pieces in your sink to get rid of any excess flux. Brass is a popular alloy used in various applications, including jewelry making, plumbing, and. Brass Solder Joints.

From manuallistcantabank.z21.web.core.windows.net

How To Splice Small Gauge Wire Brass Solder Joints The goal is to get the brass hot enough so that the solder will flow freely, but not so hot that it burns the flux. Next, you will need to heat both pieces of brass with a soldering iron. Now you’ll need to let the solder cool for a few minutes. Place the 2 pieces of copper/brass you want to. Brass Solder Joints.

From stellartechnical.com

Sheet Metal Solder & Soldering Equipment Stellar Technical Products Brass Solder Joints Hold the iron vertically and move it back and forth to. Next, you will need to heat both pieces of brass with a soldering iron. Brass is a popular alloy used in various applications, including jewelry making, plumbing, and electrical work. Cool your pieces, and clean them. Once you know it is cooled off, you’ll need to rinse the brass. Brass Solder Joints.

From www.circuitbasics.com

How to Solder Circuit Basics Brass Solder Joints Hold the iron vertically and move it back and forth to. The solder will stick better as a result, but don’t allow any globs of flux to remain, or they may cause pitting of the pipe. Place the 2 pieces of copper/brass you want to solder on a hard surface. Next, you will need to heat both pieces of brass. Brass Solder Joints.

From www.mokotechnology.com

What Is Solder Wetting and How to Prevent Poor Wetting? Brass Solder Joints Next, you will need to heat both pieces of brass with a soldering iron. In this case i’m soldering a copper reducer to a piece of copper pipe. Place the 2 pieces of copper/brass you want to solder on a hard surface. Once you know it is cooled off, you’ll need to rinse the brass pieces in your sink to. Brass Solder Joints.

From hobbyrcbd.com

M3 Metal Ball Joints for RC Car/ Model Airplane HobbyRC BD Brass Solder Joints In this case i’m soldering a copper reducer to a piece of copper pipe. The solder will stick better as a result, but don’t allow any globs of flux to remain, or they may cause pitting of the pipe. Next, you will need to heat both pieces of brass with a soldering iron. Brass is a popular alloy used in. Brass Solder Joints.

From www.youtube.com

How to Solder Copper Pipe The CORRECT Way GOT2LEARN YouTube Brass Solder Joints The solder will stick better as a result, but don’t allow any globs of flux to remain, or they may cause pitting of the pipe. But soldering brass can be tricky due to its high thermal conductivity and low melting point. Brass is a popular alloy used in various applications, including jewelry making, plumbing, and electrical work. Now you’ll need. Brass Solder Joints.

From exyugfjts.blob.core.windows.net

How To Solder A Copper Pipe Joint at Roger Criddle blog Brass Solder Joints Brass is a popular alloy used in various applications, including jewelry making, plumbing, and electrical work. The solder will stick better as a result, but don’t allow any globs of flux to remain, or they may cause pitting of the pipe. Now, dry your piece and clean it, so you don’t have any extra solder. In this case i’m soldering. Brass Solder Joints.