Turbine Bearing Temperature High . The culprit for the excessive thrust bearing temperature was discovered and corrected allowing for successful compressor operation. The high temperatures can be. Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that may approach 100. Thrust bearing temperature seems from your note to have a definite relationship to load. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. The drive for higher turbine efficiencies and firing temperatures in gas. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. This is quite normal, but is magnified if. Operating bearings at excessive temperatures continues to be a common cause of damage to bearings.

from www.skf.com

Thrust bearing temperature seems from your note to have a definite relationship to load. Operating bearings at excessive temperatures continues to be a common cause of damage to bearings. The drive for higher turbine efficiencies and firing temperatures in gas. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. The culprit for the excessive thrust bearing temperature was discovered and corrected allowing for successful compressor operation. Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that may approach 100. The high temperatures can be. This is quite normal, but is magnified if.

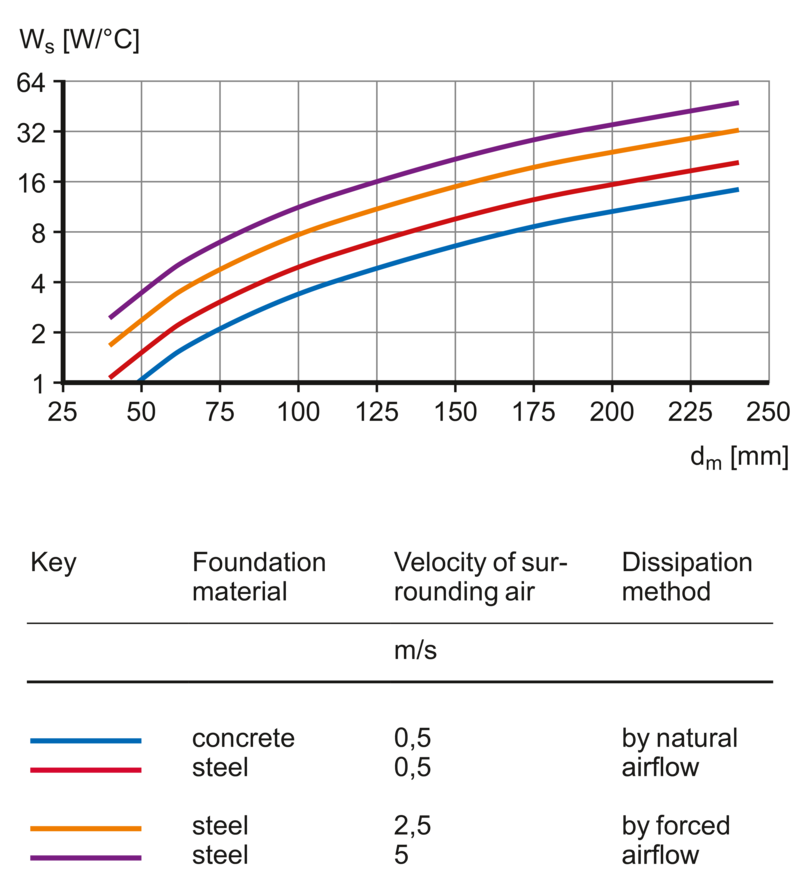

Estimating bearing operating temperature SKF

Turbine Bearing Temperature High The drive for higher turbine efficiencies and firing temperatures in gas. Operating bearings at excessive temperatures continues to be a common cause of damage to bearings. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. The drive for higher turbine efficiencies and firing temperatures in gas. The culprit for the excessive thrust bearing temperature was discovered and corrected allowing for successful compressor operation. Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that may approach 100. This is quite normal, but is magnified if. Thrust bearing temperature seems from your note to have a definite relationship to load. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. The high temperatures can be.

From www.askpowerplant.com

Steam turbine bearings and their function ASKPOWERPLANT Turbine Bearing Temperature High The culprit for the excessive thrust bearing temperature was discovered and corrected allowing for successful compressor operation. The high temperatures can be. The drive for higher turbine efficiencies and firing temperatures in gas. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. Thrust bearing temperature seems from your note to. Turbine Bearing Temperature High.

From www.pinterest.co.uk

High Temperature Bearings Gas turbine, Oil and gas, Bear Turbine Bearing Temperature High Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that may approach 100. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. The drive for higher. Turbine Bearing Temperature High.

From www.skf.com

Estimating bearing operating temperature SKF Turbine Bearing Temperature High Thrust bearing temperature seems from your note to have a definite relationship to load. This is quite normal, but is magnified if. The high temperatures can be. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that. Turbine Bearing Temperature High.

From www.researchgate.net

Bearing temperature rise at different measuring points Download Turbine Bearing Temperature High The drive for higher turbine efficiencies and firing temperatures in gas. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. This is quite normal, but is magnified if. The culprit. Turbine Bearing Temperature High.

From www.researchgate.net

Evolution of turbine inlet temperature and metal operating temperature Turbine Bearing Temperature High Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. Operating bearings at excessive temperatures continues to be a common cause of damage to bearings. Thrust bearing temperature seems from your. Turbine Bearing Temperature High.

From www.researchgate.net

Effect of the turbine inlet temperature on the thermal efficiency of Turbine Bearing Temperature High Operating bearings at excessive temperatures continues to be a common cause of damage to bearings. This is quite normal, but is magnified if. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. The culprit for the excessive thrust bearing temperature was discovered and corrected allowing for successful compressor operation. Cams. Turbine Bearing Temperature High.

From journals.sagepub.com

Methods to improve wind turbine generator bearing temperature imbalance Turbine Bearing Temperature High This is quite normal, but is magnified if. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. The drive for higher turbine efficiencies and firing temperatures in gas. Thrust bearing temperature seems from your note to have a definite relationship to load. The high temperatures can be. Operating bearings. Turbine Bearing Temperature High.

From journals.sagepub.com

Methods to improve wind turbine generator bearing temperature imbalance Turbine Bearing Temperature High For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. The drive for higher turbine efficiencies and firing temperatures in gas. This is quite normal, but is magnified if. The high temperatures can be. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to. Turbine Bearing Temperature High.

From www.researchgate.net

Main bearing temperature and oil supply temperature of the test engine Turbine Bearing Temperature High The high temperatures can be. The drive for higher turbine efficiencies and firing temperatures in gas. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. Operating bearings at excessive temperatures continues to be a common cause of damage to bearings. The culprit for the excessive thrust bearing temperature was. Turbine Bearing Temperature High.

From www.semanticscholar.org

Forecasting Thrust Bearing Temperature of 100 MW Francis Turbine Turbine Bearing Temperature High Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. The drive for higher turbine efficiencies and firing temperatures in gas. This is quite normal, but is magnified if. The culprit for the excessive thrust bearing temperature was discovered and corrected allowing for successful compressor operation. Turbine lubricants must have. Turbine Bearing Temperature High.

From www.alibaba.com

Rc Turbine Jet Engine Bearing High Temperature Ceramic Bearing 6414 Turbine Bearing Temperature High Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that may approach 100. This is quite normal, but is magnified if. The high temperatures can be. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. Operating bearings at excessive temperatures continues to be a common cause. Turbine Bearing Temperature High.

From www.researchgate.net

2 Specific core power with turbine rotor inlet temperature Turbine Bearing Temperature High For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. This is quite normal, but is magnified if. Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that may approach 100. The high temperatures can be. The drive for higher turbine efficiencies and firing temperatures in gas.. Turbine Bearing Temperature High.

From www.researchgate.net

(PDF) High temperature active bearings in industrial steam Turbine Bearing Temperature High This is quite normal, but is magnified if. The high temperatures can be. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. Operating bearings at excessive temperatures continues to be a common cause of damage to bearings. The drive for higher turbine efficiencies and firing temperatures in gas. Thrust. Turbine Bearing Temperature High.

From www.mdpi.com

Machines Free FullText Wind Turbine Bearing Temperature Turbine Bearing Temperature High Thrust bearing temperature seems from your note to have a definite relationship to load. The high temperatures can be. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that may approach 100. For most large gas. Turbine Bearing Temperature High.

From blog.softinway.com

Foil Air Bearings for Turbochargers Turbomachinery blog Turbine Bearing Temperature High Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. Thrust bearing temperature seems from your note to have a definite relationship to load. Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that may approach 100. For most large gas turbine frame units, high operating. Turbine Bearing Temperature High.

From www.grc.nasa.gov

Power Turbine Thermodynamics Turbine Bearing Temperature High The high temperatures can be. The drive for higher turbine efficiencies and firing temperatures in gas. This is quite normal, but is magnified if. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. Operating bearings at excessive temperatures continues to be a common cause of damage to bearings. Turbine lubricants. Turbine Bearing Temperature High.

From journals.sagepub.com

Methods to improve wind turbine generator bearing temperature imbalance Turbine Bearing Temperature High For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. The drive for higher turbine efficiencies and firing temperatures in gas. Thrust bearing temperature seems from your note to have a definite relationship to load. Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that may approach. Turbine Bearing Temperature High.

From www.windsystemsmag.com

The World of Turbine Bearings Wind Systems Magazine Turbine Bearing Temperature High The high temperatures can be. The culprit for the excessive thrust bearing temperature was discovered and corrected allowing for successful compressor operation. Thrust bearing temperature seems from your note to have a definite relationship to load. Operating bearings at excessive temperatures continues to be a common cause of damage to bearings. Cams apm detected a ~10°f increase in the thrust. Turbine Bearing Temperature High.

From www.researchgate.net

Turbine bearing temperature Download Scientific Diagram Turbine Bearing Temperature High This is quite normal, but is magnified if. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. The drive for higher turbine efficiencies and firing temperatures in gas. Operating bearings at excessive temperatures continues to be a common cause of damage to bearings. The culprit for the excessive thrust. Turbine Bearing Temperature High.

From www.mdpi.com

Machines Free FullText Wind Turbine Bearing Temperature Turbine Bearing Temperature High The drive for higher turbine efficiencies and firing temperatures in gas. The culprit for the excessive thrust bearing temperature was discovered and corrected allowing for successful compressor operation. The high temperatures can be. Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that may approach 100. For most large gas turbine frame units, high operating temperature. Turbine Bearing Temperature High.

From www.researchgate.net

(PDF) Wind Turbine Bearing Temperature Forecasting Using a New Data Turbine Bearing Temperature High Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. Thrust bearing temperature seems from your note to have a definite relationship to load. This is quite normal, but is magnified if. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil. Turbine Bearing Temperature High.

From www.researchgate.net

The raw wind turbine bearing temperature series (a) dataset 1 (b Turbine Bearing Temperature High The drive for higher turbine efficiencies and firing temperatures in gas. The high temperatures can be. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. Operating bearings at excessive temperatures continues to be a common cause of damage to bearings. Thrust bearing temperature seems from your note to have. Turbine Bearing Temperature High.

From www.mdaturbines.com

Gas Turbine Exhaust Temperature Spreads MD&A Turbines Turbine Bearing Temperature High This is quite normal, but is magnified if. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. The culprit for the excessive thrust bearing temperature was discovered and corrected allowing for successful compressor operation. The drive for higher turbine efficiencies and firing temperatures in gas. Turbine lubricants must have. Turbine Bearing Temperature High.

From www.researchgate.net

Comparison of bearing temperatures Download Scientific Diagram Turbine Bearing Temperature High Operating bearings at excessive temperatures continues to be a common cause of damage to bearings. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. This is quite normal, but is. Turbine Bearing Temperature High.

From www.mdpi.com

Applied Sciences Free FullText Thermal Characteristics Study of Turbine Bearing Temperature High Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. Thrust bearing temperature seems from your note to have a definite relationship to load. The high temperatures can be. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. This is. Turbine Bearing Temperature High.

From www.mdpi.com

Machines Free FullText Wind Turbine Bearing Temperature Turbine Bearing Temperature High Operating bearings at excessive temperatures continues to be a common cause of damage to bearings. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. The drive for higher turbine efficiencies and firing temperatures in gas. For most large gas turbine frame units, high operating temperature is the leading cause. Turbine Bearing Temperature High.

From www.mdpi.com

Machines Free FullText Wind Turbine Bearing Temperature Turbine Bearing Temperature High Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that may approach 100. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. Thrust bearing temperature seems from your note to have a definite relationship to load. The drive for higher turbine efficiencies and firing temperatures. Turbine Bearing Temperature High.

From www.predictiveengineering.com

ThermalStress Analysis of Reactors, Turbine Generators, Composite Turbine Bearing Temperature High Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. The culprit for the excessive thrust bearing temperature was discovered and corrected allowing for successful compressor operation. This is quite normal, but is magnified if. Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that may. Turbine Bearing Temperature High.

From www.mdpi.com

Machines Free FullText Wind Turbine Bearing Temperature Turbine Bearing Temperature High Thrust bearing temperature seems from your note to have a definite relationship to load. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. The drive for higher turbine efficiencies and firing temperatures in gas. For most large gas turbine frame units, high operating temperature is the leading cause of. Turbine Bearing Temperature High.

From www.alibaba.com

Rc Turbine Jet Engine Bearing High Temperature Ceramic Bearing 608rs Turbine Bearing Temperature High Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. Operating bearings at excessive temperatures continues to be a common cause of damage to bearings. The drive for higher turbine efficiencies and firing temperatures in gas. The high temperatures can be. Thrust bearing temperature seems from your note to have. Turbine Bearing Temperature High.

From www.grc.nasa.gov

Engine Temperature Variation ETR Turbine Bearing Temperature High Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that may approach 100. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. Operating bearings at excessive temperatures continues to be a common cause of damage to bearings. Thrust bearing temperature seems from your note to have. Turbine Bearing Temperature High.

From www.mullerbeltex.com

Bearing temperature monitoring Muller Beltex Turbine Bearing Temperature High Operating bearings at excessive temperatures continues to be a common cause of damage to bearings. The high temperatures can be. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. Thrust bearing temperature seems from your note to have a definite relationship to load. Cams apm detected a ~10°f increase in. Turbine Bearing Temperature High.

From www.projectsmonitor.com

BHEL to establish high temperature turbine rotor test rig for coal Turbine Bearing Temperature High Operating bearings at excessive temperatures continues to be a common cause of damage to bearings. For most large gas turbine frame units, high operating temperature is the leading cause of premature turbine oil failure. The culprit for the excessive thrust bearing temperature was discovered and corrected allowing for successful compressor operation. The high temperatures can be. This is quite normal,. Turbine Bearing Temperature High.

From www.researchgate.net

Siemens steam turbine SST600 with active bearings [1 Turbine Bearing Temperature High The high temperatures can be. The culprit for the excessive thrust bearing temperature was discovered and corrected allowing for successful compressor operation. Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. The drive for higher turbine efficiencies and firing temperatures in gas. Thrust bearing temperature seems from your note. Turbine Bearing Temperature High.

From www.mdpi.com

Machines Free FullText Wind Turbine Bearing Temperature Turbine Bearing Temperature High Cams apm detected a ~10°f increase in the thrust bearing temperature of steam turbine #1 compared to the calculated estimate. The high temperatures can be. Turbine lubricants must have excellent thermal and oxidation resistance at bearing oil temperatures that may approach 100. This is quite normal, but is magnified if. For most large gas turbine frame units, high operating temperature. Turbine Bearing Temperature High.