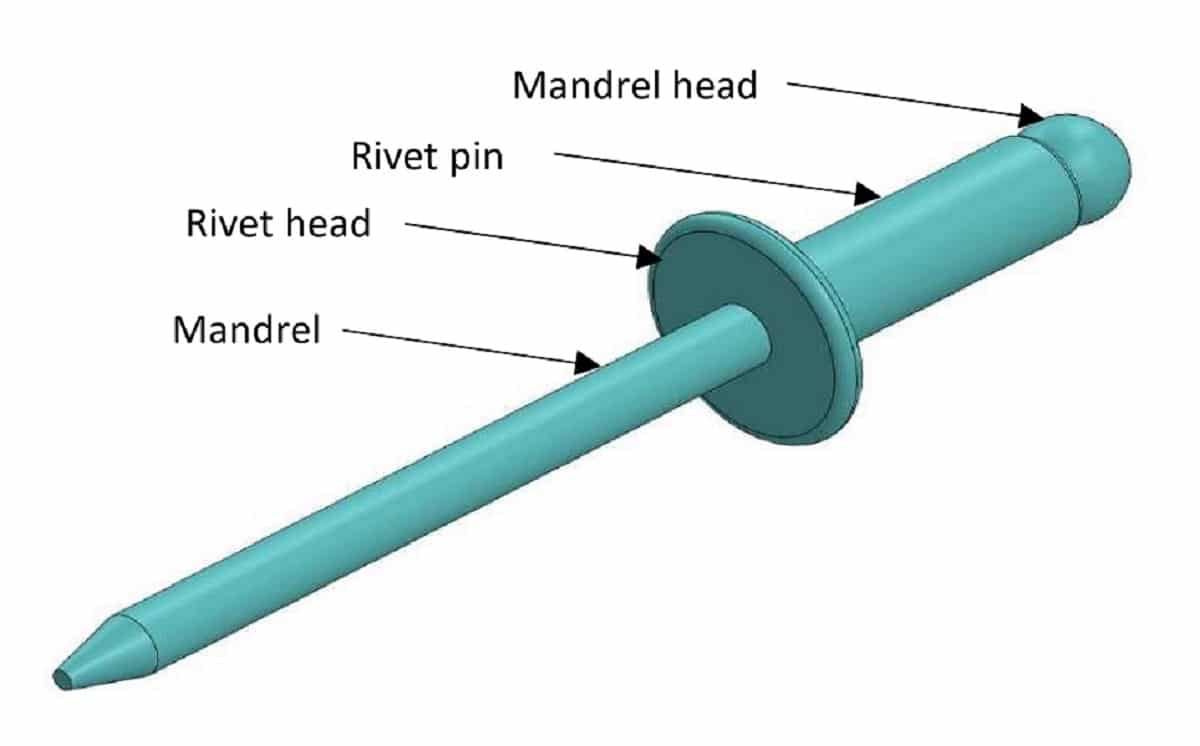

Break Head Vs Break Stem Rivets . The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet sleeve incorporating a protruding. Standard break stem rivets are produced from durable materials and are made up of 2 components: A mandrel with a bulbed head extends from the bottom of the rivet, through the body and out. During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. Key attributes include good clamp and. The body and the mandrel. Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe the desired rivet. Rivets have been used to put things together since the bronze age, but it usually took two workers to set them: One with a hammer to pound the rivet through the hole, the other with a bucking bar.

from slidingmotion.com

A mandrel with a bulbed head extends from the bottom of the rivet, through the body and out. Key attributes include good clamp and. During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. One with a hammer to pound the rivet through the hole, the other with a bucking bar. Rivets have been used to put things together since the bronze age, but it usually took two workers to set them: Standard break stem rivets are produced from durable materials and are made up of 2 components: The body and the mandrel. The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet sleeve incorporating a protruding. Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe the desired rivet.

What is pop rivet How to use Pop Rivet Gun slidingmotion

Break Head Vs Break Stem Rivets During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet sleeve incorporating a protruding. Key attributes include good clamp and. Standard break stem rivets are produced from durable materials and are made up of 2 components: The body and the mandrel. Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe the desired rivet. Rivets have been used to put things together since the bronze age, but it usually took two workers to set them: One with a hammer to pound the rivet through the hole, the other with a bucking bar. A mandrel with a bulbed head extends from the bottom of the rivet, through the body and out.

From www.hardwarefastener.com

Colored Pop Rivets Break Stem Large Dome Head Trifold Aluminum Blind Break Head Vs Break Stem Rivets Rivets have been used to put things together since the bronze age, but it usually took two workers to set them: One with a hammer to pound the rivet through the hole, the other with a bucking bar. A mandrel with a bulbed head extends from the bottom of the rivet, through the body and out. Industrial rivet’s part numbers. Break Head Vs Break Stem Rivets.

From www.jcfasteners.com

Structural Rivets J C Gupta & Sons Break Head Vs Break Stem Rivets Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe the desired rivet. During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. Standard break stem rivets are produced from durable materials and are made up of 2 components: The body and the mandrel. One with. Break Head Vs Break Stem Rivets.

From www.kemikon.com

rivet styles OFF 63 Online Shopping Site for Fashion & Lifestyle. Break Head Vs Break Stem Rivets Rivets have been used to put things together since the bronze age, but it usually took two workers to set them: During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. Key attributes include good clamp and. A mandrel with a bulbed head extends from the bottom of the rivet, through the. Break Head Vs Break Stem Rivets.

From www.all-rivets.com

China Break Head Rivets Manufacturers, Suppliers, Factory Wholesale Break Head Vs Break Stem Rivets A mandrel with a bulbed head extends from the bottom of the rivet, through the body and out. Standard break stem rivets are produced from durable materials and are made up of 2 components: Key attributes include good clamp and. The body and the mandrel. Rivets have been used to put things together since the bronze age, but it usually. Break Head Vs Break Stem Rivets.

From www.hardwarefastener.com

Colored Pop Rivets Break Stem Large Dome Head Trifold Aluminum Blind Break Head Vs Break Stem Rivets The body and the mandrel. The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet sleeve incorporating a protruding. One with a hammer to pound the rivet through the hole, the other with a bucking bar. A mandrel with a bulbed head extends from the bottom of the. Break Head Vs Break Stem Rivets.

From bellazo.en.made-in-china.com

As540 4X10mm Breakstem Rivet Aluminium Dome Head Pulling Core Rivets Break Head Vs Break Stem Rivets Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe the desired rivet. Standard break stem rivets are produced from durable materials and are made up of 2 components: The body and the mandrel. During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. One with. Break Head Vs Break Stem Rivets.

From www.gripwell.com.sg

Avdelmate 2 Piece Breakstem Rivet (Steel) Break Head Vs Break Stem Rivets During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. Standard break stem rivets are produced from durable materials and are made up of 2 components: A mandrel with a bulbed head extends from the bottom of the rivet, through the body and out. Industrial rivet’s part numbers are made up of. Break Head Vs Break Stem Rivets.

From www.dahesds.com

China Aluminum Body/Steel Mandrel Dome Head BreakStem Blind Rivets Break Head Vs Break Stem Rivets Standard break stem rivets are produced from durable materials and are made up of 2 components: During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. One with a hammer to pound the rivet through the hole, the other with a bucking bar. The past decades have seen a proliferation of blind. Break Head Vs Break Stem Rivets.

From www.jcfasteners.com

Structural Rivets J C Gupta & Sons Break Head Vs Break Stem Rivets Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe the desired rivet. The body and the mandrel. Rivets have been used to put things together since the bronze age, but it usually took two workers to set them: Key attributes include good clamp and. One with a hammer to pound the rivet through. Break Head Vs Break Stem Rivets.

From okdor.com

Exploring Different Types of Rivets okdor Break Head Vs Break Stem Rivets During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. Standard break stem rivets are produced from durable materials and are made up of 2 components: Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe the desired rivet. Key attributes include good clamp and. The. Break Head Vs Break Stem Rivets.

From inchbyinch.de

INCH Technical English blind rivet Break Head Vs Break Stem Rivets One with a hammer to pound the rivet through the hole, the other with a bucking bar. The body and the mandrel. Standard break stem rivets are produced from durable materials and are made up of 2 components: The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet. Break Head Vs Break Stem Rivets.

From bellazo.en.made-in-china.com

DIN7337 Stainless Steel Blind Rivets Break Stem Pop Blind Rivets Break Head Vs Break Stem Rivets Standard break stem rivets are produced from durable materials and are made up of 2 components: During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. One with a hammer to pound the rivet through the hole, the other with a bucking bar. A mandrel with a bulbed head extends from the. Break Head Vs Break Stem Rivets.

From www.all-rivets.com

China Break Head Rivets Manufacturers, Suppliers, Factory Wholesale Break Head Vs Break Stem Rivets The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet sleeve incorporating a protruding. A mandrel with a bulbed head extends from the bottom of the rivet, through the body and out. Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe. Break Head Vs Break Stem Rivets.

From www.hardwarefastener.com

Colored Pop Rivets Break Stem Large Dome Head Trifold Aluminum Blind Break Head Vs Break Stem Rivets One with a hammer to pound the rivet through the hole, the other with a bucking bar. During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. Rivets have been used to put things together since the bronze age, but it usually took two workers to set them: The body and the. Break Head Vs Break Stem Rivets.

From www.tjlituo.com

What’s the difference between the rivet and blind rivet? Lituo Break Head Vs Break Stem Rivets During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. Rivets have been used to put things together since the bronze age, but it usually took two workers to set them: One with a hammer to pound the rivet through the hole, the other with a bucking bar. The past decades have. Break Head Vs Break Stem Rivets.

From www.vrogue.co

Pop Rivet Types And Materials Fasteners 101 Youtube vrogue.co Break Head Vs Break Stem Rivets Rivets have been used to put things together since the bronze age, but it usually took two workers to set them: Key attributes include good clamp and. A mandrel with a bulbed head extends from the bottom of the rivet, through the body and out. One with a hammer to pound the rivet through the hole, the other with a. Break Head Vs Break Stem Rivets.

From www.toolhustle.com

What are blind rivets? And how do they work ToolHustle Break Head Vs Break Stem Rivets The body and the mandrel. The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet sleeve incorporating a protruding. Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe the desired rivet. Standard break stem rivets are produced from durable materials and. Break Head Vs Break Stem Rivets.

From www.aliexpress.com

20pcs 304 Stainless Steel Countersunk Head Blind Rivets Flat Head Pop Break Head Vs Break Stem Rivets The body and the mandrel. During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. Standard break stem rivets are produced from durable materials and are made up of 2 components: Rivets have been used to put things together since the bronze age, but it usually took two workers to set them:. Break Head Vs Break Stem Rivets.

From okdor.com

Exploring Different Types of Rivets okdor Break Head Vs Break Stem Rivets One with a hammer to pound the rivet through the hole, the other with a bucking bar. Rivets have been used to put things together since the bronze age, but it usually took two workers to set them: The body and the mandrel. Standard break stem rivets are produced from durable materials and are made up of 2 components: During. Break Head Vs Break Stem Rivets.

From www.alibaba.com

Din7337 Open Type Blind Rivets Black Color Painted Domed Head Aluminum Break Head Vs Break Stem Rivets The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet sleeve incorporating a protruding. Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe the desired rivet. A mandrel with a bulbed head extends from the bottom of the rivet, through the. Break Head Vs Break Stem Rivets.

From coolfastener.en.made-in-china.com

Colored Pop Rivets Break Stem Large Dome Head Trifold Black Exploding Break Head Vs Break Stem Rivets Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe the desired rivet. The body and the mandrel. Rivets have been used to put things together since the bronze age, but it usually took two workers to set them: The past decades have seen a proliferation of blind fastening systems based on the original. Break Head Vs Break Stem Rivets.

From slidingmotion.com

What is pop rivet How to use Pop Rivet Gun slidingmotion Break Head Vs Break Stem Rivets Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe the desired rivet. Rivets have been used to put things together since the bronze age, but it usually took two workers to set them: Key attributes include good clamp and. The past decades have seen a proliferation of blind fastening systems based on the. Break Head Vs Break Stem Rivets.

From fyoancuzt.blob.core.windows.net

Break Mandrel Blind Rivets at Tiffany Sherman blog Break Head Vs Break Stem Rivets Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe the desired rivet. One with a hammer to pound the rivet through the hole, the other with a bucking bar. A mandrel with a bulbed head extends from the bottom of the rivet, through the body and out. The body and the mandrel. Key. Break Head Vs Break Stem Rivets.

From ecommerce.aviationeu.supplies

CHERRY® CHERRYMAX® Blind Rivets SKU CHRYRVTBLDCHERRYMAX Break Head Vs Break Stem Rivets During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. One with a hammer to pound the rivet through the hole, the other with a bucking bar. Standard break stem rivets are produced from durable materials and are made up of 2 components: The body and the mandrel. Rivets have been used. Break Head Vs Break Stem Rivets.

From hainafastener.en.made-in-china.com

ISO 15975 Closed End Blind Rivets with Break Pull Mandrel and Break Head Vs Break Stem Rivets Key attributes include good clamp and. The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet sleeve incorporating a protruding. Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe the desired rivet. A mandrel with a bulbed head extends from the. Break Head Vs Break Stem Rivets.

From mechanicaljungle.com

What Is a Rivet? How Is Riveting Done? Riveting Definition Types Break Head Vs Break Stem Rivets One with a hammer to pound the rivet through the hole, the other with a bucking bar. Standard break stem rivets are produced from durable materials and are made up of 2 components: The body and the mandrel. The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet. Break Head Vs Break Stem Rivets.

From www.fastfixtechnology.com

The benefits of lockbolts Fastener + Fixing Technology Break Head Vs Break Stem Rivets A mandrel with a bulbed head extends from the bottom of the rivet, through the body and out. The body and the mandrel. The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet sleeve incorporating a protruding. Industrial rivet’s part numbers are made up of six elements which,. Break Head Vs Break Stem Rivets.

From www.alamy.com

Blind rivets or break stem rivets are tubular fasteners that can be Break Head Vs Break Stem Rivets Standard break stem rivets are produced from durable materials and are made up of 2 components: Key attributes include good clamp and. One with a hammer to pound the rivet through the hole, the other with a bucking bar. A mandrel with a bulbed head extends from the bottom of the rivet, through the body and out. Industrial rivet’s part. Break Head Vs Break Stem Rivets.

From www.hardwarefastener.com

Colored Pop Rivets Break Stem Large Dome Head Trifold Aluminum Blind Break Head Vs Break Stem Rivets A mandrel with a bulbed head extends from the bottom of the rivet, through the body and out. Key attributes include good clamp and. The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet sleeve incorporating a protruding. Industrial rivet’s part numbers are made up of six elements. Break Head Vs Break Stem Rivets.

From www.jcfasteners.com

CSK Blind Rivets J C Gupta & Sons Break Head Vs Break Stem Rivets The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet sleeve incorporating a protruding. Key attributes include good clamp and. During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. Industrial rivet’s part numbers are made up of six elements. Break Head Vs Break Stem Rivets.

From ar.inspiredpencil.com

Military Call Signs Alphabet Printable Pdf Break Head Vs Break Stem Rivets Key attributes include good clamp and. Standard break stem rivets are produced from durable materials and are made up of 2 components: Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe the desired rivet. During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. Rivets. Break Head Vs Break Stem Rivets.

From www.pbo.co.uk

How to drill out and set rivets mending a broken spinnaker pole Break Head Vs Break Stem Rivets Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe the desired rivet. A mandrel with a bulbed head extends from the bottom of the rivet, through the body and out. The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet sleeve. Break Head Vs Break Stem Rivets.

From www.clarendonsf.com

Rivets Break stem, countersunk, structural, POP, Cherry Break Head Vs Break Stem Rivets Standard break stem rivets are produced from durable materials and are made up of 2 components: Key attributes include good clamp and. The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet sleeve incorporating a protruding. During the setting operation, the mandrel is pulled into or against the. Break Head Vs Break Stem Rivets.

From dksunhoteco.blob.core.windows.net

Solid Rivet Vs Pop Rivets at Richard Lowe blog Break Head Vs Break Stem Rivets During the setting operation, the mandrel is pulled into or against the rivet body and breaks, causing a. The past decades have seen a proliferation of blind fastening systems based on the original concept, which consists of a tubular rivet sleeve incorporating a protruding. Rivets have been used to put things together since the bronze age, but it usually took. Break Head Vs Break Stem Rivets.

From www.iefast.com.au

Breakstem Rivets INFASTECH Break Head Vs Break Stem Rivets The body and the mandrel. Rivets have been used to put things together since the bronze age, but it usually took two workers to set them: Industrial rivet’s part numbers are made up of six elements which, when correctly designated, completely describe the desired rivet. Key attributes include good clamp and. A mandrel with a bulbed head extends from the. Break Head Vs Break Stem Rivets.