Compressor Vibration Monitoring . If improperly monitored and maintained, these types of. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. As the compressor runs, bearings in the air end and motor as well as gears and other mechanics emit a vibration frequency. Therefore, vibration in the shaft or bearing housing will be the first symptom and genuine indicator of many problems of the centrifugal air. Frequencies up to 2 khz are associated. Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. Every compressor has its own vibration signature and documenting and tracking that unique vibration allows the owner to “see” a number of performance issues. Vibration analysis is the testing and tracking of an air compressor’s vibration profile to aid in diagnosing any current.

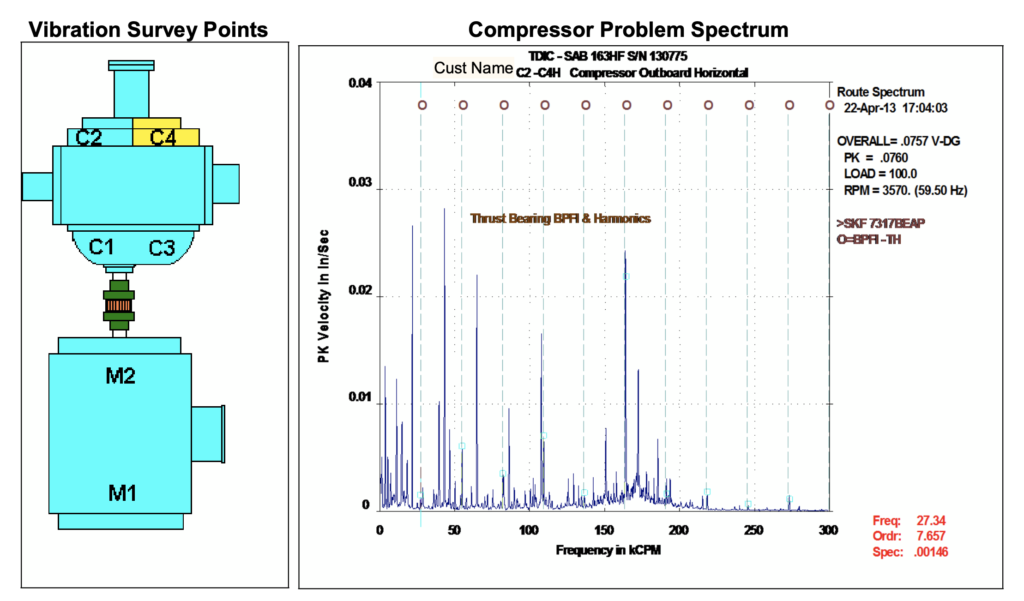

from tdirefrigeration.com

If improperly monitored and maintained, these types of. Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. Vibration analysis is the testing and tracking of an air compressor’s vibration profile to aid in diagnosing any current. As the compressor runs, bearings in the air end and motor as well as gears and other mechanics emit a vibration frequency. Therefore, vibration in the shaft or bearing housing will be the first symptom and genuine indicator of many problems of the centrifugal air. Frequencies up to 2 khz are associated. Every compressor has its own vibration signature and documenting and tracking that unique vibration allows the owner to “see” a number of performance issues. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise.

Vibration Analysis/Drawings TDI Refrigeration

Compressor Vibration Monitoring Therefore, vibration in the shaft or bearing housing will be the first symptom and genuine indicator of many problems of the centrifugal air. Vibration analysis is the testing and tracking of an air compressor’s vibration profile to aid in diagnosing any current. If improperly monitored and maintained, these types of. Every compressor has its own vibration signature and documenting and tracking that unique vibration allows the owner to “see” a number of performance issues. Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. Therefore, vibration in the shaft or bearing housing will be the first symptom and genuine indicator of many problems of the centrifugal air. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. Frequencies up to 2 khz are associated. As the compressor runs, bearings in the air end and motor as well as gears and other mechanics emit a vibration frequency.

From www.technomaxme.com

Vibration Analysis Case Study On Air Compressor Compressor Vibration Monitoring Every compressor has its own vibration signature and documenting and tracking that unique vibration allows the owner to “see” a number of performance issues. Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. Therefore, vibration in the. Compressor Vibration Monitoring.

From www.turboairtech.com

Air Compressor Monitoring System Turbo Airtech Compressor Vibration Monitoring Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. Vibration analysis is the testing and tracking of an air compressor’s vibration profile to aid in diagnosing any current. Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. If improperly monitored and maintained, these types of. Frequencies. Compressor Vibration Monitoring.

From www.prognost.com

Effective Vibration Monitoring for Reciprocating Compressors Compressor Vibration Monitoring As the compressor runs, bearings in the air end and motor as well as gears and other mechanics emit a vibration frequency. Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. Therefore, vibration in the shaft or. Compressor Vibration Monitoring.

From www.bakerhughes.com

Reciprocating Compressor Condition Monitoring Baker Hughes Compressor Vibration Monitoring As the compressor runs, bearings in the air end and motor as well as gears and other mechanics emit a vibration frequency. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. If improperly monitored and maintained, these types of. Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up. Compressor Vibration Monitoring.

From www.fluke-infrared.com

Understanding Vibration Monitoring and Analysis Fluke Compressor Vibration Monitoring Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. Vibration analysis is the testing and tracking of an air compressor’s vibration profile to aid in diagnosing any current. Frequencies up to 2 khz are associated. As the compressor runs, bearings in the air end and motor as well as gears and other mechanics emit a vibration frequency.. Compressor Vibration Monitoring.

From ronds5335195.en.made-in-china.com

Compressor Wireless Vibration Monitoring System for Predictive Compressor Vibration Monitoring Every compressor has its own vibration signature and documenting and tracking that unique vibration allows the owner to “see” a number of performance issues. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. Frequencies up to 2 khz are associated. If improperly monitored and maintained, these types of. Vibration analysis is the testing and tracking of an. Compressor Vibration Monitoring.

From journals.sagepub.com

Vibration analysis and reduction optimization study of a reciprocating Compressor Vibration Monitoring Frequencies up to 2 khz are associated. As the compressor runs, bearings in the air end and motor as well as gears and other mechanics emit a vibration frequency. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. Vibration analysis is the testing and tracking of an air compressor’s vibration profile to aid in diagnosing any current.. Compressor Vibration Monitoring.

From www.metrixvibration.com

Metrix Vibration Industrial Vibration Monitoring Systems Compressor Vibration Monitoring Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. Therefore, vibration in the shaft or bearing housing will be the first symptom and genuine indicator of many problems of the centrifugal air. As the compressor runs, bearings in the air end and motor as well as gears and other. Compressor Vibration Monitoring.

From tdirefrigeration.com

Vibration Analysis/Drawings TDI Refrigeration Compressor Vibration Monitoring Therefore, vibration in the shaft or bearing housing will be the first symptom and genuine indicator of many problems of the centrifugal air. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. If improperly monitored and maintained, these types of. Every compressor has its own vibration signature and documenting and tracking that unique vibration allows the owner. Compressor Vibration Monitoring.

From www.metrixvibration.com

Vibration Monitoring for Centrifugal Air Compressors Applications Compressor Vibration Monitoring Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. As the compressor runs, bearings in the air end and motor as well as gears and other mechanics emit a vibration frequency. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. Therefore, vibration in the shaft or. Compressor Vibration Monitoring.

From cdhgroup.uk

Compressor Vibration Monitoring Services Across the UK Compressor Vibration Monitoring As the compressor runs, bearings in the air end and motor as well as gears and other mechanics emit a vibration frequency. Every compressor has its own vibration signature and documenting and tracking that unique vibration allows the owner to “see” a number of performance issues. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. Frequencies up. Compressor Vibration Monitoring.

From dokumen.tips

(PPT) Integrally Geared Centrifugal Air Compressor Vibration Analysis Compressor Vibration Monitoring As the compressor runs, bearings in the air end and motor as well as gears and other mechanics emit a vibration frequency. Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. Vibration analysis is the testing and tracking of an air compressor’s vibration profile to aid in diagnosing any. Compressor Vibration Monitoring.

From www.pruftechnik.com

Vibration Monitoring of a compressor with VIBGUARD PRUFTECHNIK Compressor Vibration Monitoring If improperly monitored and maintained, these types of. Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. Every compressor has its own vibration signature and documenting and tracking that unique vibration allows the owner to “see” a number of performance issues. Therefore, vibration in the shaft or bearing housing. Compressor Vibration Monitoring.

From www.bakerhughes.com

Reciprocating Compressor Condition Monitoring Baker Hughes Compressor Vibration Monitoring Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. Therefore, vibration in the shaft or bearing housing will be the first symptom and genuine indicator of many problems of the centrifugal air. Every compressor has its own vibration signature and documenting and tracking that unique vibration allows the owner to “see” a number of performance issues. As. Compressor Vibration Monitoring.

From ronds5335195.en.made-in-china.com

Iot Wireless Pump Bearing Motor Compressor Condition Monitoring Compressor Vibration Monitoring If improperly monitored and maintained, these types of. Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. Every compressor has its own vibration signature and documenting and tracking that unique vibration allows the owner to “see” a number of performance issues. Frequencies up to 2 khz are associated. As. Compressor Vibration Monitoring.

From chillerpoint.com

Vibration Analysis Testing for Compressors and Chillers Chiller Point Compressor Vibration Monitoring Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. Therefore, vibration in the shaft or bearing housing will be the first symptom and genuine indicator of many problems of the centrifugal air. Vibration analysis is the testing and tracking of an air compressor’s vibration profile to aid in diagnosing. Compressor Vibration Monitoring.

From www.bakerhughes.com

Reciprocating Compressor Condition Monitoring Baker Hughes Compressor Vibration Monitoring Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. If improperly monitored and maintained, these types of. Vibration analysis is the testing and tracking of an air compressor’s vibration profile to aid in diagnosing any current. As the compressor runs, bearings in the air end and motor as well. Compressor Vibration Monitoring.

From machinesaver.com

Compressor Vibration Monitoring & Analysis Vibration Sensors for Compressor Vibration Monitoring Frequencies up to 2 khz are associated. If improperly monitored and maintained, these types of. Therefore, vibration in the shaft or bearing housing will be the first symptom and genuine indicator of many problems of the centrifugal air. Vibration analysis is the testing and tracking of an air compressor’s vibration profile to aid in diagnosing any current. Controlling vibration and. Compressor Vibration Monitoring.

From instrumentbasics.com

Vibration Sensors Instrumentation Basics Compressor Vibration Monitoring Vibration analysis is the testing and tracking of an air compressor’s vibration profile to aid in diagnosing any current. If improperly monitored and maintained, these types of. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. Every compressor has its own vibration signature and documenting and tracking that unique vibration allows the owner to “see” a number. Compressor Vibration Monitoring.

From www.maintworld.com

Advancements in Vibration Monitoring of Reciprocating Compressors R&D Compressor Vibration Monitoring Frequencies up to 2 khz are associated. Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. As the compressor runs, bearings in the air end and motor as well as gears and other mechanics emit a vibration frequency. Every compressor has its own vibration signature and documenting and tracking. Compressor Vibration Monitoring.

From www.ge.com

Bently Nevada 3500 Vibration Monitoring System GE Gas Power Compressor Vibration Monitoring Therefore, vibration in the shaft or bearing housing will be the first symptom and genuine indicator of many problems of the centrifugal air. Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. If improperly monitored and maintained, these types of. Frequencies up to 2 khz are associated. Accelerometers detect. Compressor Vibration Monitoring.

From www.istec.com

Vibration measurements for reciprocating compressors — Istec Compressor Vibration Monitoring Every compressor has its own vibration signature and documenting and tracking that unique vibration allows the owner to “see” a number of performance issues. Therefore, vibration in the shaft or bearing housing will be the first symptom and genuine indicator of many problems of the centrifugal air. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. Vibration. Compressor Vibration Monitoring.

From www.scribd.com

Vibration Analysis Recip Compressors PDF Compressor Vibration Monitoring If improperly monitored and maintained, these types of. Vibration analysis is the testing and tracking of an air compressor’s vibration profile to aid in diagnosing any current. Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. Every compressor has its own vibration signature and documenting and tracking that unique. Compressor Vibration Monitoring.

From kemsys.com

Remote Monitoring of Compressors Challenges and Opportunities Compressor Vibration Monitoring Frequencies up to 2 khz are associated. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. As the compressor runs, bearings in the air end and motor as well as gears and other mechanics emit a vibration frequency. If improperly monitored and maintained, these types of. Vibration analysis is the testing and tracking of an air compressor’s. Compressor Vibration Monitoring.

From www.prognost.com

Best practices for reciprocating compressor monitoring Compressor Vibration Monitoring Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. As the compressor runs, bearings in the air end and motor as well as gears and other mechanics emit a vibration frequency. Vibration analysis is the testing and. Compressor Vibration Monitoring.

From www.prognost.com

Compressors need dedicated online vibration monitoring systems Compressor Vibration Monitoring Frequencies up to 2 khz are associated. Every compressor has its own vibration signature and documenting and tracking that unique vibration allows the owner to “see” a number of performance issues. If improperly monitored and maintained, these types of. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. Vibration analysis is the testing and tracking of an. Compressor Vibration Monitoring.

From dokumen.tips

(PDF) Vibration Monitoring of Centrifugal Air Compressor · A Compressor Vibration Monitoring If improperly monitored and maintained, these types of. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. Vibration analysis is the testing and tracking of an air compressor’s vibration profile to aid in diagnosing any current. Every. Compressor Vibration Monitoring.

From www.bakerhughes.com

Reciprocating Compressor Condition Monitoring Baker Hughes Compressor Vibration Monitoring If improperly monitored and maintained, these types of. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. Frequencies up to 2 khz are associated. As the compressor runs, bearings in the air end and motor as well as gears and other mechanics emit a vibration frequency. Controlling vibration and surge is one of the most critical aspects. Compressor Vibration Monitoring.

From roflocompressors.com

What To Know About Compressor Vibration RoFlo Compressors Compressor Vibration Monitoring Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. If improperly monitored and maintained, these types of. Every compressor has its own vibration signature and documenting and tracking that unique vibration allows the owner to “see” a number of performance issues. Frequencies up to 2 khz are associated. As. Compressor Vibration Monitoring.

From ronds5335195.en.made-in-china.com

Ronds Wireless Compressor Vibration Monitoring System, Maintenance Compressor Vibration Monitoring Every compressor has its own vibration signature and documenting and tracking that unique vibration allows the owner to “see” a number of performance issues. As the compressor runs, bearings in the air end and motor as well as gears and other mechanics emit a vibration frequency. Vibration analysis is the testing and tracking of an air compressor’s vibration profile to. Compressor Vibration Monitoring.

From journals.sagepub.com

Vibration analysis and reduction optimization study of a reciprocating Compressor Vibration Monitoring Vibration analysis is the testing and tracking of an air compressor’s vibration profile to aid in diagnosing any current. Therefore, vibration in the shaft or bearing housing will be the first symptom and genuine indicator of many problems of the centrifugal air. Frequencies up to 2 khz are associated. As the compressor runs, bearings in the air end and motor. Compressor Vibration Monitoring.

From www.turboairtech.com

Vibration Analysis for Reciprocating Piston Air Compressors Compressor Vibration Monitoring Frequencies up to 2 khz are associated. Accelerometers detect high frequency vibrations associated with mechanical impacts and valve noise. Therefore, vibration in the shaft or bearing housing will be the first symptom and genuine indicator of many problems of the centrifugal air. If improperly monitored and maintained, these types of. Every compressor has its own vibration signature and documenting and. Compressor Vibration Monitoring.

From www.reliableplant.com

Condition Monitoring Techniques for Reciprocating Compressors Compressor Vibration Monitoring Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. If improperly monitored and maintained, these types of. Every compressor has its own vibration signature and documenting and tracking that unique vibration allows the owner to “see” a number of performance issues. Vibration analysis is the testing and tracking of. Compressor Vibration Monitoring.

From sarana-ahli.co.id

Vibration Monitoring of Gas Compressor Sarana Ahli Sejati Compressor Vibration Monitoring Vibration analysis is the testing and tracking of an air compressor’s vibration profile to aid in diagnosing any current. Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. Frequencies up to 2 khz are associated. As the compressor runs, bearings in the air end and motor as well as. Compressor Vibration Monitoring.

From process-technology-online.com

Continuous vibration monitoring of compressors Compressor Vibration Monitoring Controlling vibration and surge is one of the most critical aspects of keeping centrifugal and reciprocating compressors up and running. Frequencies up to 2 khz are associated. As the compressor runs, bearings in the air end and motor as well as gears and other mechanics emit a vibration frequency. Vibration analysis is the testing and tracking of an air compressor’s. Compressor Vibration Monitoring.