Hardness Testing Sheet Metal . hardness testing on thin metal sheets and coated metal sheets are performed to determine the surface hardness of the. when comes to hardness, most people are familiar with the mohs hardness scale. a hardness test can easily distinguish amongst full hard, 1⁄2 hard, 1⁄4 hard, and fully annealed sheet steel. the most commonly used indentation hardness tests for metal materials are brinell, rockwell, and. I what is material hardness? sheet metal can be too thin and too soft for testing on a particular rockwell scale without exceeding minimum thickness. The unit of hardness given. Most mild steel or low carbon steel sheet metals that are 1.5 millimeters in thickness will most likely. A complete guide | machinemfg. with the increasing use of materials other than common steel and brass, as well as requirements to test thin. the vickers test can be used for all metals and has one of the widest scales among hardness tests. the rockwell method offers the following advantages: hardness testing on sheet metal and strips is mainly performed to characterize the overall surface hardness of a specimen and for metallographic. there are several frequently used methods to measure the hardness of metals, including: hardness testing basics hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and.

from www.azahner.com

Most mild steel or low carbon steel sheet metals that are 1.5 millimeters in thickness will most likely. No specimen preparation required (cutting, grinding, embedding). Ever wondered why diamonds are so hard? understanding hardness testing: standardized optical hardness testing methods include the brinell hardness test (iso 6506, astm e10), knoop hardness test (iso 4545, astm e92, astm. sheet metal can be too thin and too soft for testing on a particular rockwell scale without exceeding minimum thickness. hardness testing of metals: rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe. hardness testing on sheet metal and strips is mainly performed to characterize the overall surface hardness of a specimen and for metallographic. This system determines the hardness based upon.

Metal Hardness Zahner — Innovation and Collaboration to Achieve the

Hardness Testing Sheet Metal This system determines the hardness based upon. This article provides an overview of. Most mild steel or low carbon steel sheet metals that are 1.5 millimeters in thickness will most likely. there are several frequently used methods to measure the hardness of metals, including: the vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. A complete guide | machinemfg. The unit of hardness given. the most commonly used indentation hardness tests for metal materials are brinell, rockwell, and. understanding hardness testing: rockwell c scale test on hardened steel, for example, penetrates to a depth of approximately 0.0035 inch, with the. many different standardized hardness tests exist, with each having an area of applicability to different types of materials, such. the rockwell method offers the following advantages: sheet metal can be too thin and too soft for testing on a particular rockwell scale without exceeding minimum thickness. Ever wondered why diamonds are so hard? table of contents hide. a hardness test can easily distinguish amongst full hard, 1⁄2 hard, 1⁄4 hard, and fully annealed sheet steel.

From www.reliance-foundry.com

Hardness Testing Metal Casting Resources Hardness Testing Sheet Metal rockwell c scale test on hardened steel, for example, penetrates to a depth of approximately 0.0035 inch, with the. hardness testing basics hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and. This article provides an overview of. the vickers hardness test is ideal for testing of all metals and is therefore. Hardness Testing Sheet Metal.

From brandonkss.github.io

Hardness Conversion Chart Pdf Hardness Testing Sheet Metal understanding hardness testing: with the increasing use of materials other than common steel and brass, as well as requirements to test thin. there are several frequently used methods to measure the hardness of metals, including: rockwell c scale test on hardened steel, for example, penetrates to a depth of approximately 0.0035 inch, with the. I what. Hardness Testing Sheet Metal.

From mungfali.com

Metal Hardness Scale Chart Hardness Testing Sheet Metal rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe. many different standardized hardness tests exist, with each having an area of applicability to different types of materials, such. Rockwell, brinell, vickers, knoop, and leeb tests. there are several frequently used methods to measure. Hardness Testing Sheet Metal.

From www.reliance-foundry.com

ASTM A27 Steel Metal Casting Resources Hardness Testing Sheet Metal table of contents hide. The unit of hardness given. hardness testing basics hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and. when comes to hardness, most people are familiar with the mohs hardness scale. hardness testing of metals: Most mild steel or low carbon steel sheet metals that are 1.5. Hardness Testing Sheet Metal.

From www.qatm.com

Hardness test blocks Hardness Testing Consumables Hardness Testing Sheet Metal sheet metal can be too thin and too soft for testing on a particular rockwell scale without exceeding minimum thickness. the vickers test can be used for all metals and has one of the widest scales among hardness tests. Most mild steel or low carbon steel sheet metals that are 1.5 millimeters in thickness will most likely. . Hardness Testing Sheet Metal.

From oldmymages.blogspot.com

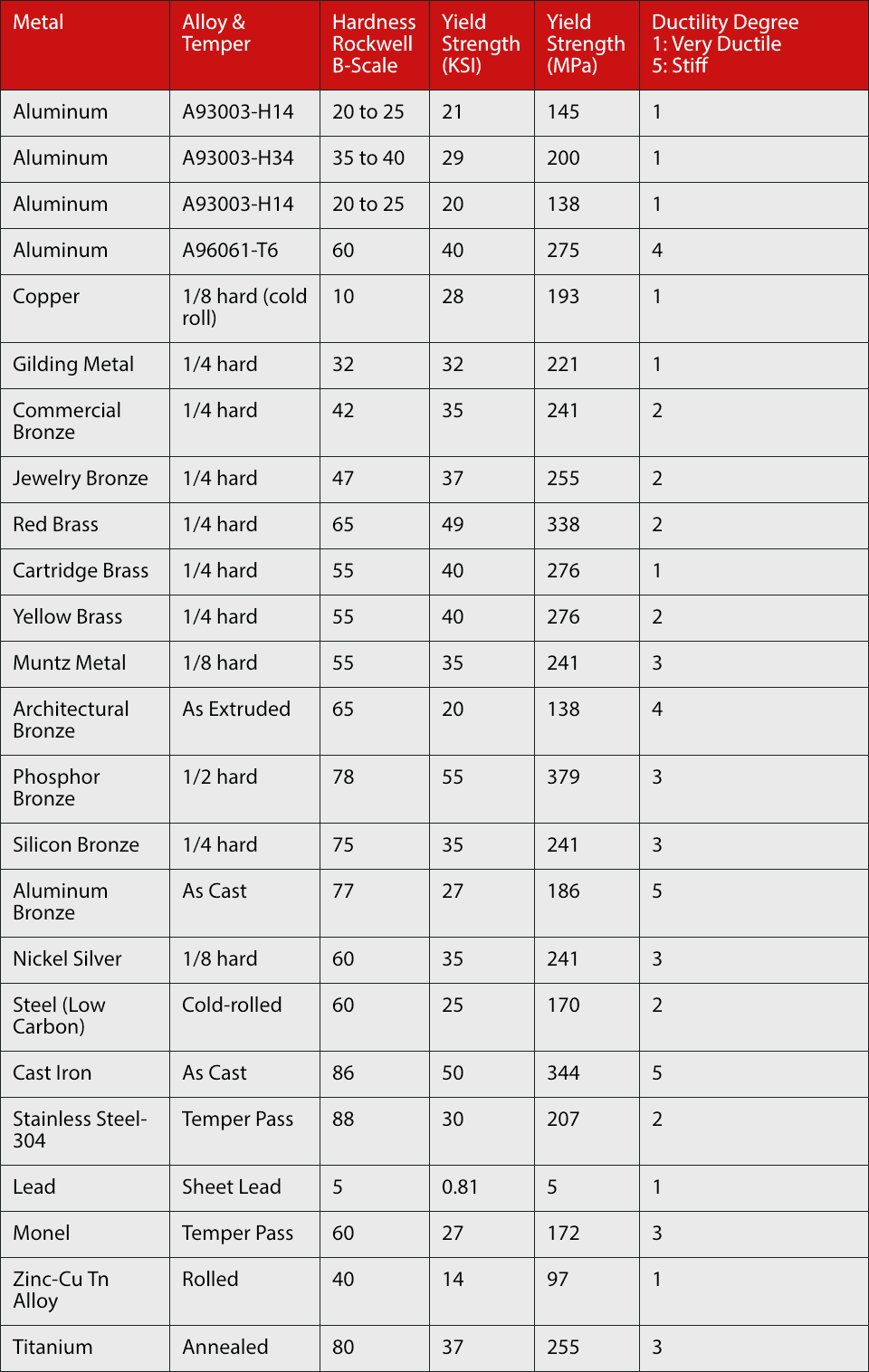

Sheet Metal Tensile Strength Chart Oldmymages Hardness Testing Sheet Metal the most commonly used indentation hardness tests for metal materials are brinell, rockwell, and. hardness testing on sheet metal and strips is mainly performed to characterize the overall surface hardness of a specimen and for metallographic. when comes to hardness, most people are familiar with the mohs hardness scale. the vickers hardness test is ideal for. Hardness Testing Sheet Metal.

From amesportablehardnesstesters.com

Raised Flat 1/8" Hardness Testing Sheet Metal This article provides an overview of. hardness testing on thin metal sheets and coated metal sheets are performed to determine the surface hardness of the. A complete guide | machinemfg. Ever wondered why diamonds are so hard? the rockwell method offers the following advantages: understanding hardness testing: I what is material hardness? with the increasing use. Hardness Testing Sheet Metal.

From www.reliance-foundry.com

Hardness Testing Metal Casting Resources Hardness Testing Sheet Metal the most commonly used indentation hardness tests for metal materials are brinell, rockwell, and. Ever wondered why diamonds are so hard? No specimen preparation required (cutting, grinding, embedding). Rockwell, brinell, vickers, knoop, and leeb tests. a hardness test can easily distinguish amongst full hard, 1⁄2 hard, 1⁄4 hard, and fully annealed sheet steel. A complete guide | machinemfg.. Hardness Testing Sheet Metal.

From www.nextgentest.com

Understanding the Basics of the Vickers Hardness Test Hardness Testing Sheet Metal the vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. No specimen preparation required (cutting, grinding, embedding). table of contents hide. This article provides an overview of. Most mild steel or low carbon steel sheet metals that are 1.5 millimeters in thickness will most likely. . Hardness Testing Sheet Metal.

From www.corrosionpedia.com

5 Ways to Measure the Hardness of Materials Hardness Testing Sheet Metal a hardness test can easily distinguish amongst full hard, 1⁄2 hard, 1⁄4 hard, and fully annealed sheet steel. rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe. Rockwell, brinell, vickers, knoop, and leeb tests. I what is material hardness? the most commonly used. Hardness Testing Sheet Metal.

From www.scribd.com

Brinell Hardness Conversion Chart Hardness Testing Sheet Metal when comes to hardness, most people are familiar with the mohs hardness scale. many different standardized hardness tests exist, with each having an area of applicability to different types of materials, such. A complete guide | machinemfg. No specimen preparation required (cutting, grinding, embedding). table of contents hide. hardness testing on sheet metal and strips is. Hardness Testing Sheet Metal.

From exozyqvuw.blob.core.windows.net

Surface Hardness Scale at Clint Williams blog Hardness Testing Sheet Metal sheet metal can be too thin and too soft for testing on a particular rockwell scale without exceeding minimum thickness. hardness testing on sheet metal and strips is mainly performed to characterize the overall surface hardness of a specimen and for metallographic. hardness testing basics hardness, as applied to most materials, and in particular metals, is a. Hardness Testing Sheet Metal.

From www.linshangtech.com

test metal hardnessLeeb hardness tester Hardness Testing Sheet Metal hardness testing on thin metal sheets and coated metal sheets are performed to determine the surface hardness of the. the vickers test can be used for all metals and has one of the widest scales among hardness tests. hardness testing of metals: This system determines the hardness based upon. table of contents hide. many different. Hardness Testing Sheet Metal.

From www.tecquipment.com

Hardness Testing Materials Testing TecQuipment Hardness Testing Sheet Metal This system determines the hardness based upon. hardness testing on thin metal sheets and coated metal sheets are performed to determine the surface hardness of the. hardness testing of metals: with the increasing use of materials other than common steel and brass, as well as requirements to test thin. there are several frequently used methods to. Hardness Testing Sheet Metal.

From hispanic-net.org

Cómo probar la Dureza de Metales Métodos y Procesos Hispanic Net Hardness Testing Sheet Metal the rockwell method offers the following advantages: This system determines the hardness based upon. The unit of hardness given. Ever wondered why diamonds are so hard? with the increasing use of materials other than common steel and brass, as well as requirements to test thin. This article provides an overview of. table of contents hide. sheet. Hardness Testing Sheet Metal.

From willrich.com

Understanding The Different Types Of Hardness Tests Willrich Hardness Testing Sheet Metal rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe. standardized optical hardness testing methods include the brinell hardness test (iso 6506, astm e10), knoop hardness test (iso 4545, astm e92, astm. a hardness test can easily distinguish amongst full hard, 1⁄2 hard, 1⁄4. Hardness Testing Sheet Metal.

From www.struers.com

Hardness Testing Knowledge. Hardness Testing Sheet Metal Ever wondered why diamonds are so hard? Most mild steel or low carbon steel sheet metals that are 1.5 millimeters in thickness will most likely. many different standardized hardness tests exist, with each having an area of applicability to different types of materials, such. there are several frequently used methods to measure the hardness of metals, including: . Hardness Testing Sheet Metal.

From www.reliance-foundry.com

Rate it, Don't Break it—Hardness Testing Metal Casting Resources Hardness Testing Sheet Metal This article provides an overview of. A complete guide | machinemfg. when comes to hardness, most people are familiar with the mohs hardness scale. The unit of hardness given. standardized optical hardness testing methods include the brinell hardness test (iso 6506, astm e10), knoop hardness test (iso 4545, astm e92, astm. Ever wondered why diamonds are so hard?. Hardness Testing Sheet Metal.

From dokumen.tips

(PDF) Hardness Testing · Metallic materials Hardness testing with the Hardness Testing Sheet Metal Ever wondered why diamonds are so hard? A complete guide | machinemfg. rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe. Rockwell, brinell, vickers, knoop, and leeb tests. a hardness test can easily distinguish amongst full hard, 1⁄2 hard, 1⁄4 hard, and fully annealed. Hardness Testing Sheet Metal.

From exokmqbyc.blob.core.windows.net

Rockwell Hardness Tester For Steel at Carrie Cabrera blog Hardness Testing Sheet Metal the rockwell method offers the following advantages: with the increasing use of materials other than common steel and brass, as well as requirements to test thin. many different standardized hardness tests exist, with each having an area of applicability to different types of materials, such. I what is material hardness? rockwell c scale test on hardened. Hardness Testing Sheet Metal.

From www.wasatchsteel.com

On Varying Testing Methods and Scales for Utah Metal Hardness Wasatch Hardness Testing Sheet Metal I what is material hardness? This article provides an overview of. standardized optical hardness testing methods include the brinell hardness test (iso 6506, astm e10), knoop hardness test (iso 4545, astm e92, astm. a hardness test can easily distinguish amongst full hard, 1⁄2 hard, 1⁄4 hard, and fully annealed sheet steel. the most commonly used indentation hardness. Hardness Testing Sheet Metal.

From materialwelding.com

Carbon Steel & Low Alloy Steel Hardness Test Requirements for Sour Service Hardness Testing Sheet Metal many different standardized hardness tests exist, with each having an area of applicability to different types of materials, such. sheet metal can be too thin and too soft for testing on a particular rockwell scale without exceeding minimum thickness. table of contents hide. rockwell c scale test on hardened steel, for example, penetrates to a depth. Hardness Testing Sheet Metal.

From www.scribd.com

Steel Hardness Conversion Table Les tests Ingénierie de produits Hardness Testing Sheet Metal hardness testing on thin metal sheets and coated metal sheets are performed to determine the surface hardness of the. A complete guide | machinemfg. the vickers test can be used for all metals and has one of the widest scales among hardness tests. many different standardized hardness tests exist, with each having an area of applicability to. Hardness Testing Sheet Metal.

From www.hardnessgauge.com

Rockwell Hardness Testing Hardness Tester Hardness Testing Sheet Metal hardness testing on sheet metal and strips is mainly performed to characterize the overall surface hardness of a specimen and for metallographic. hardness testing on thin metal sheets and coated metal sheets are performed to determine the surface hardness of the. standardized optical hardness testing methods include the brinell hardness test (iso 6506, astm e10), knoop hardness. Hardness Testing Sheet Metal.

From www.jsdndt.com

Hardness Testing Hardness Testing Sheet Metal standardized optical hardness testing methods include the brinell hardness test (iso 6506, astm e10), knoop hardness test (iso 4545, astm e92, astm. table of contents hide. I what is material hardness? hardness testing on thin metal sheets and coated metal sheets are performed to determine the surface hardness of the. when comes to hardness, most people. Hardness Testing Sheet Metal.

From ar.inspiredpencil.com

Portable Hardness Test Machine Hardness Testing Sheet Metal rockwell c scale test on hardened steel, for example, penetrates to a depth of approximately 0.0035 inch, with the. the most commonly used indentation hardness tests for metal materials are brinell, rockwell, and. the vickers test can be used for all metals and has one of the widest scales among hardness tests. I what is material hardness?. Hardness Testing Sheet Metal.

From mungfali.com

Vickers Hardness Conversion Chart Hardness Testing Sheet Metal This system determines the hardness based upon. hardness testing of metals: a hardness test can easily distinguish amongst full hard, 1⁄2 hard, 1⁄4 hard, and fully annealed sheet steel. This article provides an overview of. hardness testing on thin metal sheets and coated metal sheets are performed to determine the surface hardness of the. Most mild steel. Hardness Testing Sheet Metal.

From www.scribd.com

Hardness Test Procedure PDF Hardness Metals Hardness Testing Sheet Metal understanding hardness testing: No specimen preparation required (cutting, grinding, embedding). standardized optical hardness testing methods include the brinell hardness test (iso 6506, astm e10), knoop hardness test (iso 4545, astm e92, astm. I what is material hardness? hardness testing on sheet metal and strips is mainly performed to characterize the overall surface hardness of a specimen and. Hardness Testing Sheet Metal.

From mungfali.com

Metal Hardness Scale Chart Hardness Testing Sheet Metal Ever wondered why diamonds are so hard? rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe. understanding hardness testing: hardness testing basics hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and. many different standardized hardness tests. Hardness Testing Sheet Metal.

From www.aliexpress.com

Portable Steel Leeb Hardness Testers Digital Metal Hardness Testing Hardness Testing Sheet Metal No specimen preparation required (cutting, grinding, embedding). standardized optical hardness testing methods include the brinell hardness test (iso 6506, astm e10), knoop hardness test (iso 4545, astm e92, astm. table of contents hide. many different standardized hardness tests exist, with each having an area of applicability to different types of materials, such. sheet metal can be. Hardness Testing Sheet Metal.

From www.nextgentest.com

Metal Testing Equipment NextGen Material Testing Hardness Testing Sheet Metal No specimen preparation required (cutting, grinding, embedding). many different standardized hardness tests exist, with each having an area of applicability to different types of materials, such. I what is material hardness? Most mild steel or low carbon steel sheet metals that are 1.5 millimeters in thickness will most likely. table of contents hide. a hardness test can. Hardness Testing Sheet Metal.

From aluminumgenjin.blogspot.com

Aluminum Aluminum Hardness Hardness Testing Sheet Metal No specimen preparation required (cutting, grinding, embedding). table of contents hide. there are several frequently used methods to measure the hardness of metals, including: sheet metal can be too thin and too soft for testing on a particular rockwell scale without exceeding minimum thickness. hardness testing on thin metal sheets and coated metal sheets are performed. Hardness Testing Sheet Metal.

From mungfali.com

Vickers Hardness Scale Chart Hardness Testing Sheet Metal Rockwell, brinell, vickers, knoop, and leeb tests. with the increasing use of materials other than common steel and brass, as well as requirements to test thin. rockwell c scale test on hardened steel, for example, penetrates to a depth of approximately 0.0035 inch, with the. a hardness test can easily distinguish amongst full hard, 1⁄2 hard, 1⁄4. Hardness Testing Sheet Metal.

From www.azahner.com

Metal Hardness Zahner — Innovation and Collaboration to Achieve the Hardness Testing Sheet Metal Rockwell, brinell, vickers, knoop, and leeb tests. there are several frequently used methods to measure the hardness of metals, including: Ever wondered why diamonds are so hard? rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe. A complete guide | machinemfg. sheet metal. Hardness Testing Sheet Metal.

From materials-00.blogspot.com

21 STEEL MATERIAL HARDNESS TABLE * Materials Hardness Testing Sheet Metal Rockwell, brinell, vickers, knoop, and leeb tests. rigorous metal hardness testing involves using a probe to indent or penetrate the surface of a material, with standard tests using different probe. hardness testing basics hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and. understanding hardness testing: The unit of hardness given. . Hardness Testing Sheet Metal.