How Do Spring Tube Benders Work . Like in press brake forming, tubes experience springback after bending, producing a bend that undergoes radial growth. This process is crucial for creating components that need to fit. This force is applied gradually, reducing the risk of. They exert force externally onto a tube to make it follow the shape of a die set. This is the simplest method of tube bending. It involves using a set of dies to clamp the tube in place and then applying force to the tube to. Tube bending involves deforming a metal tube into a curved shape without compromising its structural integrity. The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. Tube benders work on a simple principle:

from www.youtube.com

It involves using a set of dies to clamp the tube in place and then applying force to the tube to. This is the simplest method of tube bending. They exert force externally onto a tube to make it follow the shape of a die set. Like in press brake forming, tubes experience springback after bending, producing a bend that undergoes radial growth. This force is applied gradually, reducing the risk of. Tube benders work on a simple principle: The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. Tube bending involves deforming a metal tube into a curved shape without compromising its structural integrity. This process is crucial for creating components that need to fit.

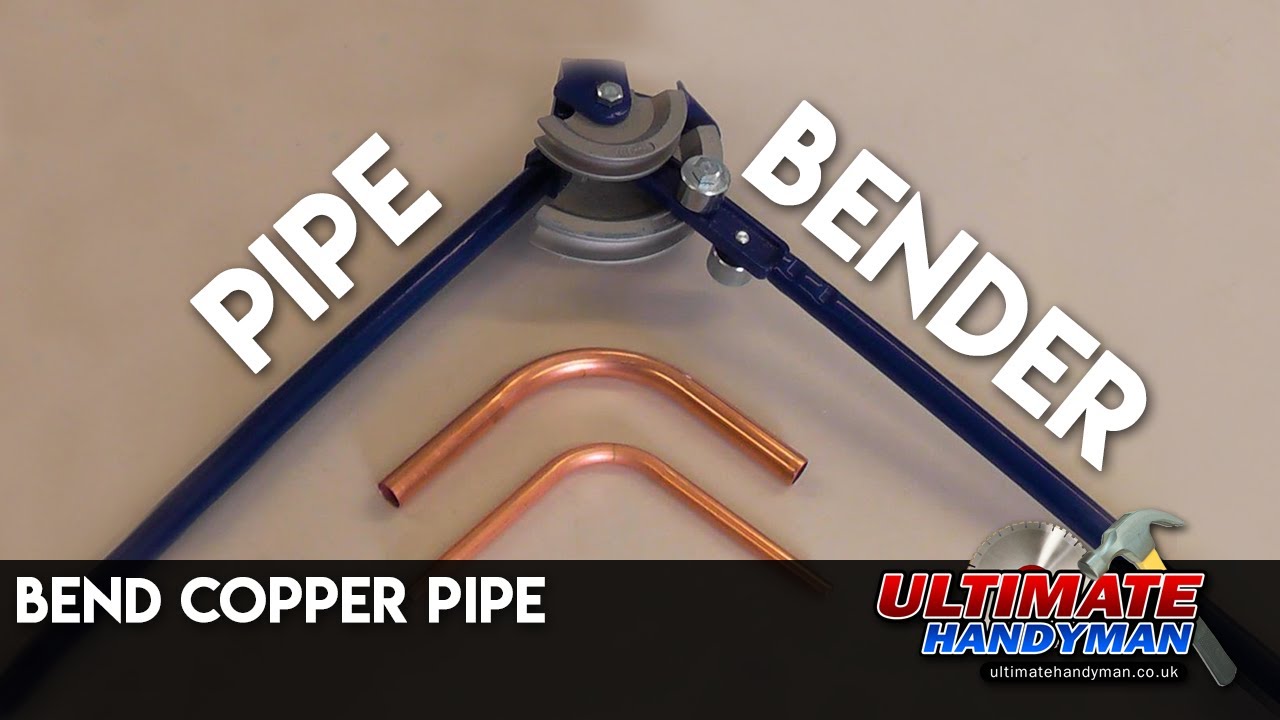

Pipe bender bend copper pipe YouTube

How Do Spring Tube Benders Work This process is crucial for creating components that need to fit. Tube benders work on a simple principle: This force is applied gradually, reducing the risk of. Tube bending involves deforming a metal tube into a curved shape without compromising its structural integrity. The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. Like in press brake forming, tubes experience springback after bending, producing a bend that undergoes radial growth. It involves using a set of dies to clamp the tube in place and then applying force to the tube to. This is the simplest method of tube bending. This process is crucial for creating components that need to fit. They exert force externally onto a tube to make it follow the shape of a die set.

From www.aliexpress.com

FREE SHIPPING Length 500mm diameter 20mm hand out spring pvc tube How Do Spring Tube Benders Work This is the simplest method of tube bending. This force is applied gradually, reducing the risk of. Tube bending involves deforming a metal tube into a curved shape without compromising its structural integrity. This process is crucial for creating components that need to fit. Tube benders work on a simple principle: It involves using a set of dies to clamp. How Do Spring Tube Benders Work.

From huddleston.com.au

Imperial 101F Spring Tube Bender Set Huddleston Australia How Do Spring Tube Benders Work This is the simplest method of tube bending. It involves using a set of dies to clamp the tube in place and then applying force to the tube to. This process is crucial for creating components that need to fit. Tube benders work on a simple principle: The spring provides support during manual bending, which involves securing the tube at. How Do Spring Tube Benders Work.

From www.indiamart.com

Pipe Spring Bender, For Electrical Fittings, Model FBS at Rs 60/piece How Do Spring Tube Benders Work The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. Like in press brake forming, tubes experience springback after bending, producing a bend that undergoes radial growth. They exert force externally onto a tube to make it follow the shape of a die set.. How Do Spring Tube Benders Work.

From ithurukaramu.lk

spring tube bender Ithurukaramu How Do Spring Tube Benders Work They exert force externally onto a tube to make it follow the shape of a die set. This force is applied gradually, reducing the risk of. The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. This process is crucial for creating components that. How Do Spring Tube Benders Work.

From www.grainger.com

WESTWARD Spring Tube Bender Set 6 Pc., 10 1/2 in Overall Lg (In.), 0 How Do Spring Tube Benders Work This is the simplest method of tube bending. Tube benders work on a simple principle: They exert force externally onto a tube to make it follow the shape of a die set. This force is applied gradually, reducing the risk of. This process is crucial for creating components that need to fit. It involves using a set of dies to. How Do Spring Tube Benders Work.

From www.youtube.com

Pipe bender bend copper pipe YouTube How Do Spring Tube Benders Work This force is applied gradually, reducing the risk of. This process is crucial for creating components that need to fit. Tube bending involves deforming a metal tube into a curved shape without compromising its structural integrity. They exert force externally onto a tube to make it follow the shape of a die set. This is the simplest method of tube. How Do Spring Tube Benders Work.

From www.pinterest.com

Uniweld’s Spring Tube Benders allow freeform bending of soft copper How Do Spring Tube Benders Work The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. They exert force externally onto a tube to make it follow the shape of a die set. It involves using a set of dies to clamp the tube in place and then applying force. How Do Spring Tube Benders Work.

From www.dhgate.com

2020 Inner Pvc Pipe Bender House Decoration Spring Tube Bender Bending How Do Spring Tube Benders Work Tube bending involves deforming a metal tube into a curved shape without compromising its structural integrity. The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. This is the simplest method of tube bending. This process is crucial for creating components that need to. How Do Spring Tube Benders Work.

From www.alimranuae.com

Spring Bender (3/8″, 1/2”, 5/8”, 3/4”, 7/8”) HVACR Wholesale Dealer How Do Spring Tube Benders Work Tube benders work on a simple principle: Tube bending involves deforming a metal tube into a curved shape without compromising its structural integrity. This is the simplest method of tube bending. This process is crucial for creating components that need to fit. They exert force externally onto a tube to make it follow the shape of a die set. It. How Do Spring Tube Benders Work.

From www.aliexpress.com

4PCS DN16/20/25/32mmpvc pipe / tube bender spring Length 300mm PVC wire How Do Spring Tube Benders Work It involves using a set of dies to clamp the tube in place and then applying force to the tube to. They exert force externally onto a tube to make it follow the shape of a die set. This is the simplest method of tube bending. Like in press brake forming, tubes experience springback after bending, producing a bend that. How Do Spring Tube Benders Work.

From www.indiamart.com

Spring Bender at best price in Coimbatore by Vishveshwaraiyah How Do Spring Tube Benders Work This process is crucial for creating components that need to fit. Like in press brake forming, tubes experience springback after bending, producing a bend that undergoes radial growth. It involves using a set of dies to clamp the tube in place and then applying force to the tube to. This is the simplest method of tube bending. The spring provides. How Do Spring Tube Benders Work.

From slsmachinery.en.made-in-china.com

How to Make a Useful Tools DIY Mandrel Bender Vs How Does Pipe Tube How Do Spring Tube Benders Work The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. They exert force externally onto a tube to make it follow the shape of a die set. This is the simplest method of tube bending. Tube bending involves deforming a metal tube into a. How Do Spring Tube Benders Work.

From www.aliexpress.com

5pcs Tool Steel Spring Tube Bender Set 1/4" 5/16" 3/8" 1/2" 5/8 How Do Spring Tube Benders Work Like in press brake forming, tubes experience springback after bending, producing a bend that undergoes radial growth. The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. Tube benders work on a simple principle: Tube bending involves deforming a metal tube into a curved. How Do Spring Tube Benders Work.

From www.youtube.com

HVAC Copper Pipe Bending Tips With Spring Bender YouTube How Do Spring Tube Benders Work The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. This is the simplest method of tube bending. Tube benders work on a simple principle: This force is applied gradually, reducing the risk of. They exert force externally onto a tube to make it. How Do Spring Tube Benders Work.

From www.alibaba.com

Spring Tube Bender 1/4" 5/16" 3/8" 1/2" 5/8" For Soft Copper And How Do Spring Tube Benders Work The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. This is the simplest method of tube bending. They exert force externally onto a tube to make it follow the shape of a die set. This process is crucial for creating components that need. How Do Spring Tube Benders Work.

From www.youtube.com

How To Use a Tubing Bender! Making Hoops for a Ladder Rack on a Truck How Do Spring Tube Benders Work Tube benders work on a simple principle: Tube bending involves deforming a metal tube into a curved shape without compromising its structural integrity. This process is crucial for creating components that need to fit. The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend.. How Do Spring Tube Benders Work.

From www.instality.com

Spring pipe bender for multilayer and copper pipes How Do Spring Tube Benders Work This force is applied gradually, reducing the risk of. It involves using a set of dies to clamp the tube in place and then applying force to the tube to. This is the simplest method of tube bending. They exert force externally onto a tube to make it follow the shape of a die set. The spring provides support during. How Do Spring Tube Benders Work.

From www.reece.com.au

Rothenberger Copper Tube External Bending Spring 5/8" from Reece How Do Spring Tube Benders Work Tube benders work on a simple principle: The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. It involves using a set of dies to clamp the tube in place and then applying force to the tube to. They exert force externally onto a. How Do Spring Tube Benders Work.

From hvactools.co.nz

Hilmor 1839031 SB Spring Bender 1/4” TO 5/8” HVACTOOLS New Zealand How Do Spring Tube Benders Work This is the simplest method of tube bending. This process is crucial for creating components that need to fit. They exert force externally onto a tube to make it follow the shape of a die set. Tube benders work on a simple principle: Like in press brake forming, tubes experience springback after bending, producing a bend that undergoes radial growth.. How Do Spring Tube Benders Work.

From www.htc.co.nz

UNI42 Manual Tube Bender For Hire HTC How Do Spring Tube Benders Work They exert force externally onto a tube to make it follow the shape of a die set. Tube benders work on a simple principle: Like in press brake forming, tubes experience springback after bending, producing a bend that undergoes radial growth. The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the. How Do Spring Tube Benders Work.

From www.aliexpress.com

PVC Line Pipe Special pipe Bender Tender Lengthened 16mm 0.5meter How Do Spring Tube Benders Work This process is crucial for creating components that need to fit. Like in press brake forming, tubes experience springback after bending, producing a bend that undergoes radial growth. Tube benders work on a simple principle: The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired. How Do Spring Tube Benders Work.

From www.aliexpress.com

1 Tube Bender+5 Spring Bending Tube 6/8/10mm Adjustable 3 In1 Aluminum How Do Spring Tube Benders Work The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. Tube benders work on a simple principle: This process is crucial for creating components that need to fit. Tube bending involves deforming a metal tube into a curved shape without compromising its structural integrity.. How Do Spring Tube Benders Work.

From www.youtube.com

How to use pipe bender // best copper tube bending with tube spring How Do Spring Tube Benders Work Tube bending involves deforming a metal tube into a curved shape without compromising its structural integrity. It involves using a set of dies to clamp the tube in place and then applying force to the tube to. Like in press brake forming, tubes experience springback after bending, producing a bend that undergoes radial growth. This force is applied gradually, reducing. How Do Spring Tube Benders Work.

From gskhardware.com.sg

Spring Bender GSK Hardware How Do Spring Tube Benders Work This force is applied gradually, reducing the risk of. This process is crucial for creating components that need to fit. The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. Tube bending involves deforming a metal tube into a curved shape without compromising its. How Do Spring Tube Benders Work.

From www.aliexpress.com

5pcs PVC Wire Spring Tube Bender Curve Spring Pipe Bending Device How Do Spring Tube Benders Work The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. It involves using a set of dies to clamp the tube in place and then applying force to the tube to. Tube bending involves deforming a metal tube into a curved shape without compromising. How Do Spring Tube Benders Work.

From www.toolexchange.com.au

Imperial Eastman Spring Tube Benders Tool Exchange How Do Spring Tube Benders Work This force is applied gradually, reducing the risk of. This process is crucial for creating components that need to fit. It involves using a set of dies to clamp the tube in place and then applying force to the tube to. Like in press brake forming, tubes experience springback after bending, producing a bend that undergoes radial growth. Tube bending. How Do Spring Tube Benders Work.

From www.amazon.com

Tanstic 6Pcs Spring Tube Bender Set with Copper Pipe Tube Expander, 1/4 How Do Spring Tube Benders Work They exert force externally onto a tube to make it follow the shape of a die set. It involves using a set of dies to clamp the tube in place and then applying force to the tube to. This is the simplest method of tube bending. This process is crucial for creating components that need to fit. Tube benders work. How Do Spring Tube Benders Work.

From www.aliexpress.com

5pcs New CT 102 L Spring Pipe Bender 21cm Length Spring Tube Bender How Do Spring Tube Benders Work This force is applied gradually, reducing the risk of. The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. Tube benders work on a simple principle: They exert force externally onto a tube to make it follow the shape of a die set. Like. How Do Spring Tube Benders Work.

From www.aliexpress.com

1PCS tension spring 50cm DN32mm manual pvc pipe bender spring tube How Do Spring Tube Benders Work This is the simplest method of tube bending. Like in press brake forming, tubes experience springback after bending, producing a bend that undergoes radial growth. It involves using a set of dies to clamp the tube in place and then applying force to the tube to. Tube bending involves deforming a metal tube into a curved shape without compromising its. How Do Spring Tube Benders Work.

From www.toolexchange.com.au

Imperial Eastman Spring Tube Benders Tool Exchange How Do Spring Tube Benders Work They exert force externally onto a tube to make it follow the shape of a die set. This is the simplest method of tube bending. It involves using a set of dies to clamp the tube in place and then applying force to the tube to. This process is crucial for creating components that need to fit. Like in press. How Do Spring Tube Benders Work.

From www.aliexpress.com

5pcs Manual PVC Wire Spring Pipe Bender Curve Springs Tube Bending How Do Spring Tube Benders Work They exert force externally onto a tube to make it follow the shape of a die set. This is the simplest method of tube bending. Tube benders work on a simple principle: It involves using a set of dies to clamp the tube in place and then applying force to the tube to. Tube bending involves deforming a metal tube. How Do Spring Tube Benders Work.

From www.desertcart.in

Buy Tube Bender, 3 In 1 Copper Pipe Bender, 0180 Degrees Tubing Bender How Do Spring Tube Benders Work The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. They exert force externally onto a tube to make it follow the shape of a die set. It involves using a set of dies to clamp the tube in place and then applying force. How Do Spring Tube Benders Work.

From www.wonkeedonkeetools.co.uk

What is a pipe bender? Wonkee Donkee Tools How Do Spring Tube Benders Work The spring provides support during manual bending, which involves securing the tube at one point and gently pulling the spring’s ends to achieve the desired bend. They exert force externally onto a tube to make it follow the shape of a die set. Tube bending involves deforming a metal tube into a curved shape without compromising its structural integrity. Tube. How Do Spring Tube Benders Work.

From www.sawtoolsguide.com

5 Best Tube Bender Brands to Consider in 2023 Saw Tools Guide How Do Spring Tube Benders Work Tube bending involves deforming a metal tube into a curved shape without compromising its structural integrity. Tube benders work on a simple principle: This is the simplest method of tube bending. They exert force externally onto a tube to make it follow the shape of a die set. This process is crucial for creating components that need to fit. Like. How Do Spring Tube Benders Work.

From www.indiamart.com

Refrigeration Tube Bender at best price in Chennai by Shree Baba How Do Spring Tube Benders Work Tube benders work on a simple principle: Tube bending involves deforming a metal tube into a curved shape without compromising its structural integrity. It involves using a set of dies to clamp the tube in place and then applying force to the tube to. The spring provides support during manual bending, which involves securing the tube at one point and. How Do Spring Tube Benders Work.