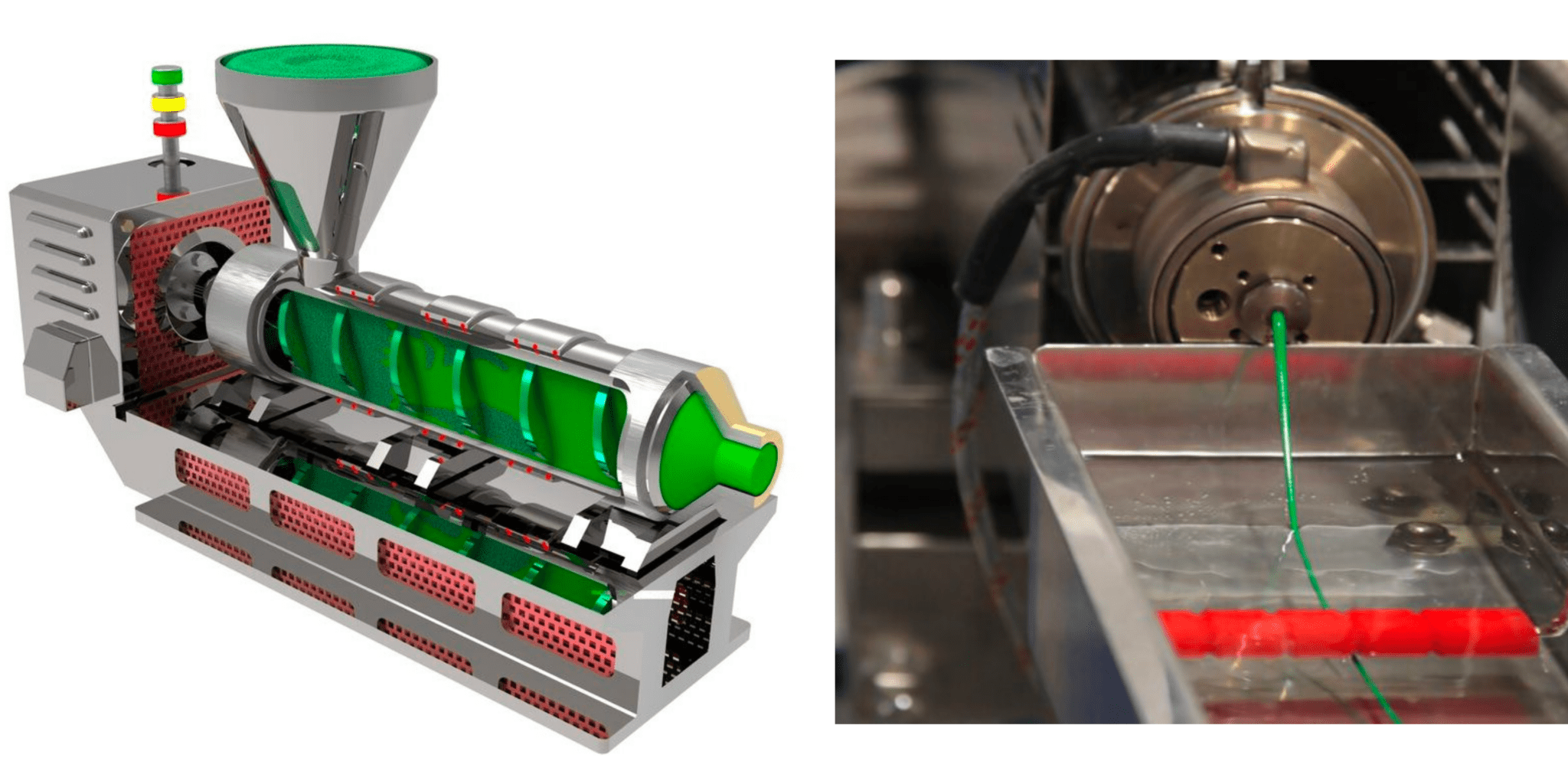

Cold Feed Extruder Working . Cold feed type extruders are constructed with specially designed screws best suited for cold feeding. Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. It discusses common screw nomenclature and sections including flighted length, diameter, feed, transition, and metering. The elimination of the warm up mill before. In this video, we showcase a 120 mm cold feed rubber extruder machine, powered by a robust 132 kw motor. Key concepts covered include length to diameter. Cold rubber compounds are fed to the extruder by a slab feeder. The extruder heats and homogenizes the material and conveys the material into the pork chop head by means of a screw. Hot extrusion is a process that involves using high temperatures to force metal through a die. Cold extrusion is a process that involves using lower temperatures to force metal. In almost all fields of rubber extrusion, the cold feed extruders are fast replacing the conventional hot feed extruders. The primary components of each machine are an extruder unit, a temperature.

from www.rainbowbelts.com

Cold rubber compounds are fed to the extruder by a slab feeder. Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. The primary components of each machine are an extruder unit, a temperature. It discusses common screw nomenclature and sections including flighted length, diameter, feed, transition, and metering. Key concepts covered include length to diameter. In this video, we showcase a 120 mm cold feed rubber extruder machine, powered by a robust 132 kw motor. The extruder heats and homogenizes the material and conveys the material into the pork chop head by means of a screw. The elimination of the warm up mill before. Cold extrusion is a process that involves using lower temperatures to force metal. Hot extrusion is a process that involves using high temperatures to force metal through a die.

What Is The Profile Extrusion Process?

Cold Feed Extruder Working Key concepts covered include length to diameter. In this video, we showcase a 120 mm cold feed rubber extruder machine, powered by a robust 132 kw motor. In almost all fields of rubber extrusion, the cold feed extruders are fast replacing the conventional hot feed extruders. The elimination of the warm up mill before. The extruder heats and homogenizes the material and conveys the material into the pork chop head by means of a screw. Cold rubber compounds are fed to the extruder by a slab feeder. Hot extrusion is a process that involves using high temperatures to force metal through a die. Key concepts covered include length to diameter. The primary components of each machine are an extruder unit, a temperature. Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. Cold feed type extruders are constructed with specially designed screws best suited for cold feeding. Cold extrusion is a process that involves using lower temperatures to force metal. It discusses common screw nomenclature and sections including flighted length, diameter, feed, transition, and metering.

From www.rainbowbelts.com

What Is The Profile Extrusion Process? Cold Feed Extruder Working Cold rubber compounds are fed to the extruder by a slab feeder. In almost all fields of rubber extrusion, the cold feed extruders are fast replacing the conventional hot feed extruders. The elimination of the warm up mill before. Cold extrusion is a process that involves using lower temperatures to force metal. The primary components of each machine are an. Cold Feed Extruder Working.

From www.indiamart.com

90 mm Pin Type Cold Feed Rubber Extruder Machine, 75 kW at best price Cold Feed Extruder Working The elimination of the warm up mill before. The extruder heats and homogenizes the material and conveys the material into the pork chop head by means of a screw. The primary components of each machine are an extruder unit, a temperature. Hot extrusion is a process that involves using high temperatures to force metal through a die. Cold feed extruders. Cold Feed Extruder Working.

From www.tradeindia.com

Automatic Electric Cold Feed Rubber Extruder Machine at Best Price in Cold Feed Extruder Working It discusses common screw nomenclature and sections including flighted length, diameter, feed, transition, and metering. Cold extrusion is a process that involves using lower temperatures to force metal. Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. Hot extrusion is a process that involves using high temperatures to force metal through a die.. Cold Feed Extruder Working.

From www.tradeindia.com

Automatic Cold Feed Vacuum Rubber Extrudercold Feed Rubber Extruder Cold Feed Extruder Working The extruder heats and homogenizes the material and conveys the material into the pork chop head by means of a screw. Cold feed type extruders are constructed with specially designed screws best suited for cold feeding. Hot extrusion is a process that involves using high temperatures to force metal through a die. Cold extrusion is a process that involves using. Cold Feed Extruder Working.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Cold Feed Extruder Working Cold extrusion is a process that involves using lower temperatures to force metal. Cold rubber compounds are fed to the extruder by a slab feeder. It discusses common screw nomenclature and sections including flighted length, diameter, feed, transition, and metering. Hot extrusion is a process that involves using high temperatures to force metal through a die. In this video, we. Cold Feed Extruder Working.

From exobdhbqy.blob.core.windows.net

Pasta Extrusion Process at Flores blog Cold Feed Extruder Working In almost all fields of rubber extrusion, the cold feed extruders are fast replacing the conventional hot feed extruders. Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. It discusses common screw nomenclature and sections including flighted length, diameter, feed, transition, and metering. Cold extrusion is a process that involves using lower temperatures. Cold Feed Extruder Working.

From www.globalseafood.org

Extrusion production of aquatic feeds Responsible Seafood Advocate Cold Feed Extruder Working Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. In this video, we showcase a 120 mm cold feed rubber extruder machine, powered by a robust 132 kw motor. It discusses common screw nomenclature and sections including flighted length, diameter, feed, transition, and metering. Cold extrusion is a process that involves using lower. Cold Feed Extruder Working.

From www.alibaba.com

Pin Barrel Cold Feed Vacuum Extruder Silicone Rubber Extruder Machine Cold Feed Extruder Working The primary components of each machine are an extruder unit, a temperature. Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. In almost all fields of rubber extrusion, the cold feed extruders are fast replacing the conventional hot feed extruders. Key concepts covered include length to diameter. Cold rubber compounds are fed to. Cold Feed Extruder Working.

From dir.indiamart.com

Cold Feed Rubber Extruders Cold Feed Extruder Machines Latest Price Cold Feed Extruder Working Hot extrusion is a process that involves using high temperatures to force metal through a die. The primary components of each machine are an extruder unit, a temperature. Cold extrusion is a process that involves using lower temperatures to force metal. Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. In almost all. Cold Feed Extruder Working.

From vatsntecnic.com

Used Cold Feed Rubber Extruder EPDM Rubber Making Machine VatsnTecnic Cold Feed Extruder Working In almost all fields of rubber extrusion, the cold feed extruders are fast replacing the conventional hot feed extruders. Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. Cold feed type extruders are constructed with specially designed screws best suited for cold feeding. Cold rubber compounds are fed to the extruder by a. Cold Feed Extruder Working.

From www.alibaba.com

Pin Barrel Cold Feed Vacuum Extruder Silicone Rubber Extruder Machine Cold Feed Extruder Working Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. In almost all fields of rubber extrusion, the cold feed extruders are fast replacing the conventional hot feed extruders. The extruder heats and homogenizes the material and conveys the material into the pork chop head by means of a screw. The elimination of the. Cold Feed Extruder Working.

From www.globalsources.com

150mm Cold Feed Rubber Extruder Rubber Strip Extruder Production Line Cold Feed Extruder Working Cold extrusion is a process that involves using lower temperatures to force metal. The elimination of the warm up mill before. The extruder heats and homogenizes the material and conveys the material into the pork chop head by means of a screw. Hot extrusion is a process that involves using high temperatures to force metal through a die. The primary. Cold Feed Extruder Working.

From www.deguma.com

Extruders DEGUMASCHÜTZ GmbH Cold Feed Extruder Working Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. Cold extrusion is a process that involves using lower temperatures to force metal. It discusses common screw nomenclature and sections including flighted length, diameter, feed, transition, and metering. The elimination of the warm up mill before. Key concepts covered include length to diameter. Hot. Cold Feed Extruder Working.

From www.indiamart.com

90 Mm Cold Feed Rubber Extruder Machine, 120 Hp at best price in Navi Cold Feed Extruder Working The primary components of each machine are an extruder unit, a temperature. Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. Key concepts covered include length to diameter. The extruder heats and homogenizes the material and conveys the material into the pork chop head by means of a screw. Cold feed type extruders. Cold Feed Extruder Working.

From www.indiamart.com

100 MM Cold Feed Rubber Extruders, 60 HP at Rs 3500000 in New Delhi Cold Feed Extruder Working Hot extrusion is a process that involves using high temperatures to force metal through a die. The elimination of the warm up mill before. In almost all fields of rubber extrusion, the cold feed extruders are fast replacing the conventional hot feed extruders. It discusses common screw nomenclature and sections including flighted length, diameter, feed, transition, and metering. Key concepts. Cold Feed Extruder Working.

From www.alibaba.com

Pin Barrel Cold Feed Vacuum Extruder Silicone Rubber Extruder Machine Cold Feed Extruder Working Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. In almost all fields of rubber extrusion, the cold feed extruders are fast replacing the conventional hot feed extruders. The elimination of the warm up mill before. The primary components of each machine are an extruder unit, a temperature. Hot extrusion is a process. Cold Feed Extruder Working.

From www.mdpi.com

Polymers Free FullText Squeezing Mechanical Analysis and Model Cold Feed Extruder Working In this video, we showcase a 120 mm cold feed rubber extruder machine, powered by a robust 132 kw motor. Hot extrusion is a process that involves using high temperatures to force metal through a die. Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. The elimination of the warm up mill before.. Cold Feed Extruder Working.

From www.globalsources.com

150mm Cold Feed Rubber Extruder Rubber Strip Extruder Production Line Cold Feed Extruder Working Cold rubber compounds are fed to the extruder by a slab feeder. The elimination of the warm up mill before. In almost all fields of rubber extrusion, the cold feed extruders are fast replacing the conventional hot feed extruders. In this video, we showcase a 120 mm cold feed rubber extruder machine, powered by a robust 132 kw motor. Cold. Cold Feed Extruder Working.

From shengxinze.en.made-in-china.com

Cold Feed Extruder/ Rubber Extruder/ Extruder Machine (XJW) China Cold Feed Extruder Working Hot extrusion is a process that involves using high temperatures to force metal through a die. Key concepts covered include length to diameter. Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. Cold feed type extruders are constructed with specially designed screws best suited for cold feeding. Cold extrusion is a process that. Cold Feed Extruder Working.

From bainasb.en.made-in-china.com

90mm20d Cold Feed Rubber Extrude Machine Rubber Extrusion Machine Cold Feed Extruder Working It discusses common screw nomenclature and sections including flighted length, diameter, feed, transition, and metering. The primary components of each machine are an extruder unit, a temperature. Hot extrusion is a process that involves using high temperatures to force metal through a die. Key concepts covered include length to diameter. Cold feed extruders are a type of machinery used primarily. Cold Feed Extruder Working.

From www.alibaba.com

Xjd120 Cold Feed Rubber Extruder Machine / Butyl Tape Making Machine Cold Feed Extruder Working Cold feed type extruders are constructed with specially designed screws best suited for cold feeding. Key concepts covered include length to diameter. Hot extrusion is a process that involves using high temperatures to force metal through a die. Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. In this video, we showcase a. Cold Feed Extruder Working.

From www.rubber-machineries.com

Cold Feed Rubber Extruder Machine Single Screw Rubber Cable Extruder Cold Feed Extruder Working Cold rubber compounds are fed to the extruder by a slab feeder. It discusses common screw nomenclature and sections including flighted length, diameter, feed, transition, and metering. The elimination of the warm up mill before. In this video, we showcase a 120 mm cold feed rubber extruder machine, powered by a robust 132 kw motor. The extruder heats and homogenizes. Cold Feed Extruder Working.

From www.eventalways.com

Cold Feed Rubber Extruder, INR 400000.00 Per Unit, JRD RUBBER & PLASTIC Cold Feed Extruder Working In almost all fields of rubber extrusion, the cold feed extruders are fast replacing the conventional hot feed extruders. The elimination of the warm up mill before. Cold feed type extruders are constructed with specially designed screws best suited for cold feeding. The primary components of each machine are an extruder unit, a temperature. Cold rubber compounds are fed to. Cold Feed Extruder Working.

From shengxinze.en.made-in-china.com

Cold Feed Rubber Extruder Machine Xj120 China Rubber Extruder and Cold Feed Extruder Working Cold extrusion is a process that involves using lower temperatures to force metal. Cold feed type extruders are constructed with specially designed screws best suited for cold feeding. Hot extrusion is a process that involves using high temperatures to force metal through a die. In almost all fields of rubber extrusion, the cold feed extruders are fast replacing the conventional. Cold Feed Extruder Working.

From qdboria.en.made-in-china.com

Cold Feeding Rubber Extruder, Rubber Strip Extrusion Line China Cold Feed Extruder Working It discusses common screw nomenclature and sections including flighted length, diameter, feed, transition, and metering. In this video, we showcase a 120 mm cold feed rubber extruder machine, powered by a robust 132 kw motor. The primary components of each machine are an extruder unit, a temperature. Key concepts covered include length to diameter. Cold extrusion is a process that. Cold Feed Extruder Working.

From www.tradeindia.com

Automatic Cold Feed Rubber Extruder Machine at Best Price in Dongguan Cold Feed Extruder Working Cold extrusion is a process that involves using lower temperatures to force metal. The elimination of the warm up mill before. Hot extrusion is a process that involves using high temperatures to force metal through a die. Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. It discusses common screw nomenclature and sections. Cold Feed Extruder Working.

From www.elastron.com

What is Extrusion? Plastic Extrusion Process Elastron TPE Cold Feed Extruder Working The primary components of each machine are an extruder unit, a temperature. Cold feed type extruders are constructed with specially designed screws best suited for cold feeding. Cold extrusion is a process that involves using lower temperatures to force metal. In this video, we showcase a 120 mm cold feed rubber extruder machine, powered by a robust 132 kw motor.. Cold Feed Extruder Working.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Cold Feed Extruder Working Hot extrusion is a process that involves using high temperatures to force metal through a die. Key concepts covered include length to diameter. The extruder heats and homogenizes the material and conveys the material into the pork chop head by means of a screw. The primary components of each machine are an extruder unit, a temperature. Cold feed type extruders. Cold Feed Extruder Working.

From www.globalsources.com

150mm Cold Feed Rubber Extruder Rubber Strip Extruder Production Line Cold Feed Extruder Working In this video, we showcase a 120 mm cold feed rubber extruder machine, powered by a robust 132 kw motor. Cold feed extruders are a type of machinery used primarily in the rubber and plastics industries. The extruder heats and homogenizes the material and conveys the material into the pork chop head by means of a screw. Cold rubber compounds. Cold Feed Extruder Working.

From www.alibaba.com

Pin Barrel Cold Feed Vacuum Extruder Silicone Rubber Extruder Machine Cold Feed Extruder Working Cold rubber compounds are fed to the extruder by a slab feeder. It discusses common screw nomenclature and sections including flighted length, diameter, feed, transition, and metering. The elimination of the warm up mill before. Cold feed type extruders are constructed with specially designed screws best suited for cold feeding. The primary components of each machine are an extruder unit,. Cold Feed Extruder Working.

From www.youtube.com

The Bonnot Company Cooking Extruder, Cold Forming Extruder (Pet Food Cold Feed Extruder Working The primary components of each machine are an extruder unit, a temperature. In almost all fields of rubber extrusion, the cold feed extruders are fast replacing the conventional hot feed extruders. Cold feed type extruders are constructed with specially designed screws best suited for cold feeding. Cold rubber compounds are fed to the extruder by a slab feeder. Key concepts. Cold Feed Extruder Working.

From www.youtube.com

Extrusion Processes Hot Extrusion and Cold Extrusion Process Working Cold Feed Extruder Working In this video, we showcase a 120 mm cold feed rubber extruder machine, powered by a robust 132 kw motor. In almost all fields of rubber extrusion, the cold feed extruders are fast replacing the conventional hot feed extruders. The primary components of each machine are an extruder unit, a temperature. Cold extrusion is a process that involves using lower. Cold Feed Extruder Working.

From www.indiamart.com

250 mm Pin Type Cold Feed Rubber Extruder Machine, 500 kW at best price Cold Feed Extruder Working The elimination of the warm up mill before. Cold feed type extruders are constructed with specially designed screws best suited for cold feeding. The primary components of each machine are an extruder unit, a temperature. Hot extrusion is a process that involves using high temperatures to force metal through a die. Key concepts covered include length to diameter. In this. Cold Feed Extruder Working.

From www.deguma.com

Cold Feed Extruder GE 120 KS x 14 D DEGUMASCHÜTZ GmbH Cold Feed Extruder Working The extruder heats and homogenizes the material and conveys the material into the pork chop head by means of a screw. In this video, we showcase a 120 mm cold feed rubber extruder machine, powered by a robust 132 kw motor. Cold feed type extruders are constructed with specially designed screws best suited for cold feeding. Cold rubber compounds are. Cold Feed Extruder Working.

From www.azom.com

An Introduction to Single Screw Extrusion Cold Feed Extruder Working Cold rubber compounds are fed to the extruder by a slab feeder. Key concepts covered include length to diameter. Cold extrusion is a process that involves using lower temperatures to force metal. In almost all fields of rubber extrusion, the cold feed extruders are fast replacing the conventional hot feed extruders. It discusses common screw nomenclature and sections including flighted. Cold Feed Extruder Working.