Stator Cooling Water System . This lecture is part of the ‘lecture series’ on ‘steam power plant systems’. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and of possible chemical. The power generator stator cooling system is a group of small diameter copper tubes (strands) that carries water around the generator stator windings. It may be useful for plant. Use of demineralized water, temperature between 10 °c and 75 °c, pressure below 10 bar. Contaminants entering the stator cooling water system are produced by scaling and corrosion of the cooling water piping, or they may enter with the. The keys to minimizing the negative impact of a. Corrosion in the system is exhibited as copper oxide flakes. Alkaline treatment, for example, is achieved by injection of dilute naoh solution into the cooling water to obtain a ph between 8.5 and 9.0 [2, 12], with a target conductivity of 1.8µs·cm. 3.1 overview of generator water.

from www.mdpi.com

Contaminants entering the stator cooling water system are produced by scaling and corrosion of the cooling water piping, or they may enter with the. 3.1 overview of generator water. Corrosion in the system is exhibited as copper oxide flakes. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and of possible chemical. The keys to minimizing the negative impact of a. This lecture is part of the ‘lecture series’ on ‘steam power plant systems’. It may be useful for plant. The power generator stator cooling system is a group of small diameter copper tubes (strands) that carries water around the generator stator windings. Alkaline treatment, for example, is achieved by injection of dilute naoh solution into the cooling water to obtain a ph between 8.5 and 9.0 [2, 12], with a target conductivity of 1.8µs·cm. Use of demineralized water, temperature between 10 °c and 75 °c, pressure below 10 bar.

Energies Free FullText Full Surface Heat Transfer Characteristics

Stator Cooling Water System Contaminants entering the stator cooling water system are produced by scaling and corrosion of the cooling water piping, or they may enter with the. Contaminants entering the stator cooling water system are produced by scaling and corrosion of the cooling water piping, or they may enter with the. 3.1 overview of generator water. Alkaline treatment, for example, is achieved by injection of dilute naoh solution into the cooling water to obtain a ph between 8.5 and 9.0 [2, 12], with a target conductivity of 1.8µs·cm. Use of demineralized water, temperature between 10 °c and 75 °c, pressure below 10 bar. The power generator stator cooling system is a group of small diameter copper tubes (strands) that carries water around the generator stator windings. Corrosion in the system is exhibited as copper oxide flakes. This lecture is part of the ‘lecture series’ on ‘steam power plant systems’. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and of possible chemical. The keys to minimizing the negative impact of a. It may be useful for plant.

From www.slideserve.com

PPT TURBINE & COOLING SYSTEM PowerPoint Presentation, free download Stator Cooling Water System Corrosion in the system is exhibited as copper oxide flakes. Alkaline treatment, for example, is achieved by injection of dilute naoh solution into the cooling water to obtain a ph between 8.5 and 9.0 [2, 12], with a target conductivity of 1.8µs·cm. 3.1 overview of generator water. This lecture is part of the ‘lecture series’ on ‘steam power plant systems’.. Stator Cooling Water System.

From www.youtube.com

lesson 5 synchronous generator cooling hydrogen purging and charging Stator Cooling Water System It may be useful for plant. The power generator stator cooling system is a group of small diameter copper tubes (strands) that carries water around the generator stator windings. Contaminants entering the stator cooling water system are produced by scaling and corrosion of the cooling water piping, or they may enter with the. Key parameters for chemistry monitoring of stator. Stator Cooling Water System.

From www.researchgate.net

(PDF) Monitoring Generator Cooling Water System Chemistry by the Stator Cooling Water System The power generator stator cooling system is a group of small diameter copper tubes (strands) that carries water around the generator stator windings. Use of demineralized water, temperature between 10 °c and 75 °c, pressure below 10 bar. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and. Stator Cooling Water System.

From www.electricalaxis.com

What are the Different Generator Cooling System in Power Plants Stator Cooling Water System Use of demineralized water, temperature between 10 °c and 75 °c, pressure below 10 bar. 3.1 overview of generator water. Alkaline treatment, for example, is achieved by injection of dilute naoh solution into the cooling water to obtain a ph between 8.5 and 9.0 [2, 12], with a target conductivity of 1.8µs·cm. Corrosion in the system is exhibited as copper. Stator Cooling Water System.

From www.multisado.com

Stator Cooling Water System Filter Multisado Stator Cooling Water System The power generator stator cooling system is a group of small diameter copper tubes (strands) that carries water around the generator stator windings. Corrosion in the system is exhibited as copper oxide flakes. 3.1 overview of generator water. Alkaline treatment, for example, is achieved by injection of dilute naoh solution into the cooling water to obtain a ph between 8.5. Stator Cooling Water System.

From www.youtube.com

Generator stator cooling water system YouTube Stator Cooling Water System This lecture is part of the ‘lecture series’ on ‘steam power plant systems’. Use of demineralized water, temperature between 10 °c and 75 °c, pressure below 10 bar. Corrosion in the system is exhibited as copper oxide flakes. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and. Stator Cooling Water System.

From www.alibaba.com

Dfb8080240 Generator Stator Cooling Water System Centrifugal Water Stator Cooling Water System Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and of possible chemical. 3.1 overview of generator water. It may be useful for plant. Use of demineralized water, temperature between 10 °c and 75 °c, pressure below 10 bar. Corrosion in the system is exhibited as copper oxide. Stator Cooling Water System.

From marineengineeringonline.com

Operation of Freshwater Generator with Jacket Cooling Water Stator Cooling Water System Contaminants entering the stator cooling water system are produced by scaling and corrosion of the cooling water piping, or they may enter with the. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and of possible chemical. The keys to minimizing the negative impact of a. Alkaline treatment,. Stator Cooling Water System.

From www.yoyikscm.com

China generator stator cooling water filter element KLS125T/20 Stator Cooling Water System Alkaline treatment, for example, is achieved by injection of dilute naoh solution into the cooling water to obtain a ph between 8.5 and 9.0 [2, 12], with a target conductivity of 1.8µs·cm. Contaminants entering the stator cooling water system are produced by scaling and corrosion of the cooling water piping, or they may enter with the. 3.1 overview of generator. Stator Cooling Water System.

From electengmaterials.com

Generator Cooling Methods Electrical Machines Stator Cooling Water System Use of demineralized water, temperature between 10 °c and 75 °c, pressure below 10 bar. 3.1 overview of generator water. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and of possible chemical. Alkaline treatment, for example, is achieved by injection of dilute naoh solution into the cooling. Stator Cooling Water System.

From www.youtube.com

COOLING WATER SYSTEM(PART1) YouTube Stator Cooling Water System 3.1 overview of generator water. Alkaline treatment, for example, is achieved by injection of dilute naoh solution into the cooling water to obtain a ph between 8.5 and 9.0 [2, 12], with a target conductivity of 1.8µs·cm. Contaminants entering the stator cooling water system are produced by scaling and corrosion of the cooling water piping, or they may enter with. Stator Cooling Water System.

From www.yoyikscm.com

China SL1250 Generator stator cooling water filter element Stator Cooling Water System This lecture is part of the ‘lecture series’ on ‘steam power plant systems’. Use of demineralized water, temperature between 10 °c and 75 °c, pressure below 10 bar. It may be useful for plant. Alkaline treatment, for example, is achieved by injection of dilute naoh solution into the cooling water to obtain a ph between 8.5 and 9.0 [2, 12],. Stator Cooling Water System.

From www.researchgate.net

Flow diagram of Generator Stator Cooling Water system. Download Stator Cooling Water System Contaminants entering the stator cooling water system are produced by scaling and corrosion of the cooling water piping, or they may enter with the. Corrosion in the system is exhibited as copper oxide flakes. The power generator stator cooling system is a group of small diameter copper tubes (strands) that carries water around the generator stator windings. 3.1 overview of. Stator Cooling Water System.

From slideplayer.com

Main Turbine Generator & Exciter ppt download Stator Cooling Water System The power generator stator cooling system is a group of small diameter copper tubes (strands) that carries water around the generator stator windings. 3.1 overview of generator water. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and of possible chemical. It may be useful for plant. Corrosion. Stator Cooling Water System.

From www.yoyikscm.com

China generator stator cooling water filter element KLS125T/20 Stator Cooling Water System This lecture is part of the ‘lecture series’ on ‘steam power plant systems’. 3.1 overview of generator water. It may be useful for plant. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and of possible chemical. Alkaline treatment, for example, is achieved by injection of dilute naoh. Stator Cooling Water System.

From www.yoyikscm.com

China YCZ65250C generator stator cooling water pump manufacturers and Stator Cooling Water System Corrosion in the system is exhibited as copper oxide flakes. Contaminants entering the stator cooling water system are produced by scaling and corrosion of the cooling water piping, or they may enter with the. The power generator stator cooling system is a group of small diameter copper tubes (strands) that carries water around the generator stator windings. The keys to. Stator Cooling Water System.

From www.researchgate.net

Flow diagram of Generator Stator Cooling Water system. Download Stator Cooling Water System Use of demineralized water, temperature between 10 °c and 75 °c, pressure below 10 bar. It may be useful for plant. 3.1 overview of generator water. This lecture is part of the ‘lecture series’ on ‘steam power plant systems’. The keys to minimizing the negative impact of a. Contaminants entering the stator cooling water system are produced by scaling and. Stator Cooling Water System.

From www.researchgate.net

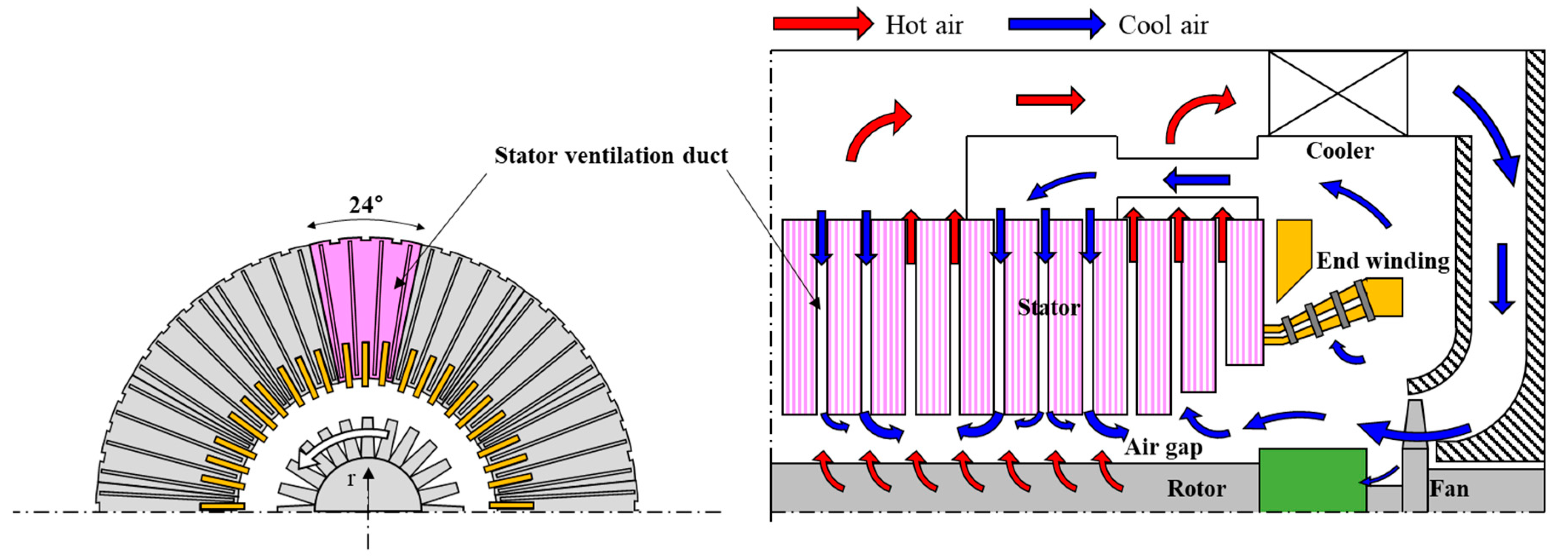

Simplified motor lateral section and cooling air paths. A−Stator core Stator Cooling Water System Alkaline treatment, for example, is achieved by injection of dilute naoh solution into the cooling water to obtain a ph between 8.5 and 9.0 [2, 12], with a target conductivity of 1.8µs·cm. The keys to minimizing the negative impact of a. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of. Stator Cooling Water System.

From www.ccj-online.com

Generator History, Part 3 Generator cooling methods Combined Cycle Stator Cooling Water System Contaminants entering the stator cooling water system are produced by scaling and corrosion of the cooling water piping, or they may enter with the. This lecture is part of the ‘lecture series’ on ‘steam power plant systems’. Corrosion in the system is exhibited as copper oxide flakes. Alkaline treatment, for example, is achieved by injection of dilute naoh solution into. Stator Cooling Water System.

From electengmaterials.com

Generator Cooling Methods Electrical Machines Stator Cooling Water System Contaminants entering the stator cooling water system are produced by scaling and corrosion of the cooling water piping, or they may enter with the. Corrosion in the system is exhibited as copper oxide flakes. Use of demineralized water, temperature between 10 °c and 75 °c, pressure below 10 bar. The keys to minimizing the negative impact of a. Alkaline treatment,. Stator Cooling Water System.

From www.yoyikscm.com

news Stator cooling water filter element KLS125T/20 Stator Cooling Water System The power generator stator cooling system is a group of small diameter copper tubes (strands) that carries water around the generator stator windings. Corrosion in the system is exhibited as copper oxide flakes. It may be useful for plant. This lecture is part of the ‘lecture series’ on ‘steam power plant systems’. Use of demineralized water, temperature between 10 °c. Stator Cooling Water System.

From blog.softinway.com

An Introduction to Electric Motor Cooling Systems Turbomachinery blog Stator Cooling Water System The keys to minimizing the negative impact of a. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and of possible chemical. Contaminants entering the stator cooling water system are produced by scaling and corrosion of the cooling water piping, or they may enter with the. 3.1 overview. Stator Cooling Water System.

From www.yoyikscm.com

China generator stator cooling water filter element KLS125T/20 Stator Cooling Water System It may be useful for plant. Corrosion in the system is exhibited as copper oxide flakes. 3.1 overview of generator water. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and of possible chemical. Alkaline treatment, for example, is achieved by injection of dilute naoh solution into the. Stator Cooling Water System.

From www.mdpi.com

Energies Free FullText Full Surface Heat Transfer Characteristics Stator Cooling Water System This lecture is part of the ‘lecture series’ on ‘steam power plant systems’. Corrosion in the system is exhibited as copper oxide flakes. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and of possible chemical. The power generator stator cooling system is a group of small diameter. Stator Cooling Water System.

From www.yoyik.com

China manufacturer and supplier generator stator cooling water system Stator Cooling Water System The power generator stator cooling system is a group of small diameter copper tubes (strands) that carries water around the generator stator windings. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and of possible chemical. Corrosion in the system is exhibited as copper oxide flakes. 3.1 overview. Stator Cooling Water System.

From www.yoyik.com

Stator Cooling Water SystemDongfang YOYIK Manufactures spare parts Stator Cooling Water System Contaminants entering the stator cooling water system are produced by scaling and corrosion of the cooling water piping, or they may enter with the. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and of possible chemical. The keys to minimizing the negative impact of a. Corrosion in. Stator Cooling Water System.

From www.mdpi.com

Applied Sciences Free FullText Synthesis and Diagnostics of Stator Cooling Water System It may be useful for plant. The keys to minimizing the negative impact of a. Contaminants entering the stator cooling water system are produced by scaling and corrosion of the cooling water piping, or they may enter with the. Alkaline treatment, for example, is achieved by injection of dilute naoh solution into the cooling water to obtain a ph between. Stator Cooling Water System.

From ecampusontario.pressbooks.pub

Part 5 Alternator Cooling Systems PEG3722 Electrotechnology Stator Cooling Water System Alkaline treatment, for example, is achieved by injection of dilute naoh solution into the cooling water to obtain a ph between 8.5 and 9.0 [2, 12], with a target conductivity of 1.8µs·cm. The power generator stator cooling system is a group of small diameter copper tubes (strands) that carries water around the generator stator windings. The keys to minimizing the. Stator Cooling Water System.

From www.mechsol.com

Nuclear Generator Stator Cooling Pumps Specialized Vibration Testing Stator Cooling Water System Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and of possible chemical. It may be useful for plant. The keys to minimizing the negative impact of a. 3.1 overview of generator water. Alkaline treatment, for example, is achieved by injection of dilute naoh solution into the cooling. Stator Cooling Water System.

From yoyik1688.en.made-in-china.com

Dfb10065260 Generator Stator Cooling Water System Single Stage Stator Cooling Water System 3.1 overview of generator water. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and of possible chemical. This lecture is part of the ‘lecture series’ on ‘steam power plant systems’. The keys to minimizing the negative impact of a. The power generator stator cooling system is a. Stator Cooling Water System.

From austorque.au

Plugging Of Stator Cooling Water System RootCause Analysis And Stator Cooling Water System Alkaline treatment, for example, is achieved by injection of dilute naoh solution into the cooling water to obtain a ph between 8.5 and 9.0 [2, 12], with a target conductivity of 1.8µs·cm. This lecture is part of the ‘lecture series’ on ‘steam power plant systems’. 3.1 overview of generator water. The power generator stator cooling system is a group of. Stator Cooling Water System.

From www.youtube.com

lesson 8 synchronous generator internal winding cooling YouTube Stator Cooling Water System Contaminants entering the stator cooling water system are produced by scaling and corrosion of the cooling water piping, or they may enter with the. This lecture is part of the ‘lecture series’ on ‘steam power plant systems’. Use of demineralized water, temperature between 10 °c and 75 °c, pressure below 10 bar. The power generator stator cooling system is a. Stator Cooling Water System.

From www.youtube.com

Generator Stator Cooling Water System محطة واسط الحرارية YouTube Stator Cooling Water System The keys to minimizing the negative impact of a. Use of demineralized water, temperature between 10 °c and 75 °c, pressure below 10 bar. The power generator stator cooling system is a group of small diameter copper tubes (strands) that carries water around the generator stator windings. This lecture is part of the ‘lecture series’ on ‘steam power plant systems’.. Stator Cooling Water System.

From ehfcv.com

220 Permanent Synchronous Drive Motor EHFCV Stator Cooling Water System The power generator stator cooling system is a group of small diameter copper tubes (strands) that carries water around the generator stator windings. Use of demineralized water, temperature between 10 °c and 75 °c, pressure below 10 bar. Key parameters for chemistry monitoring of stator cooling water are conductivity, ecp (electrochemical potential), ph, and the concentrations of oxygen, copper and. Stator Cooling Water System.

From www.multisado.com

Stator Cooling Water Pump Multisado Stator Cooling Water System Use of demineralized water, temperature between 10 °c and 75 °c, pressure below 10 bar. It may be useful for plant. This lecture is part of the ‘lecture series’ on ‘steam power plant systems’. 3.1 overview of generator water. Corrosion in the system is exhibited as copper oxide flakes. Alkaline treatment, for example, is achieved by injection of dilute naoh. Stator Cooling Water System.