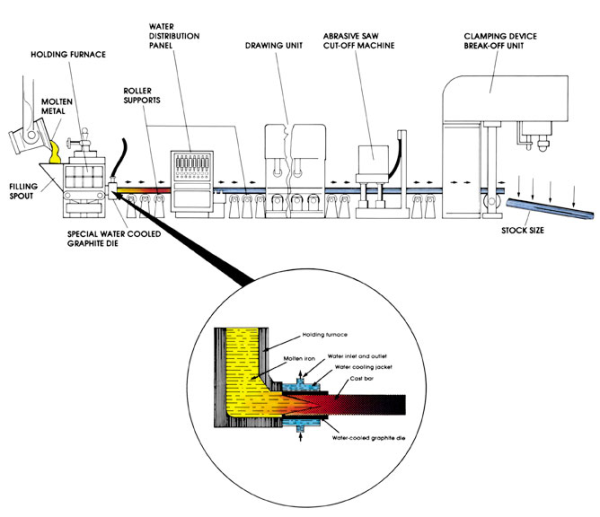

Continuous Cast Copper Rod Manufacturing Process . copper rod upward continuous casting is the process in which liquid copper continuously solidifies into the copper rod. this article reviews the history and methods of copper alloy continuous casting. continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish (molten metal. Southwire operates its own 54 metric tons per hour (tph) copper. A method is described for the continuous. These methods include vertical continuous. An introduction to technology and markets the copper. southwire's scr® system is an advanced process for the continuous production of copper rod. continuous casting in the copper industry; In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. key raw materials required for the manufacturing of continuous cast copper rod plant is electrolytic grade copper.

from www.versa-bar.com

continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish (molten metal. copper rod upward continuous casting is the process in which liquid copper continuously solidifies into the copper rod. key raw materials required for the manufacturing of continuous cast copper rod plant is electrolytic grade copper. In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. southwire's scr® system is an advanced process for the continuous production of copper rod. this article reviews the history and methods of copper alloy continuous casting. continuous casting in the copper industry; An introduction to technology and markets the copper. Southwire operates its own 54 metric tons per hour (tph) copper. These methods include vertical continuous.

Advantages of the Continuous Casting Process Benefits of Cast Iron

Continuous Cast Copper Rod Manufacturing Process key raw materials required for the manufacturing of continuous cast copper rod plant is electrolytic grade copper. this article reviews the history and methods of copper alloy continuous casting. Southwire operates its own 54 metric tons per hour (tph) copper. copper rod upward continuous casting is the process in which liquid copper continuously solidifies into the copper rod. continuous casting in the copper industry; An introduction to technology and markets the copper. continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish (molten metal. southwire's scr® system is an advanced process for the continuous production of copper rod. A method is described for the continuous. These methods include vertical continuous. In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. key raw materials required for the manufacturing of continuous cast copper rod plant is electrolytic grade copper.

From www.janscopper.net

Jans Copper P. Ltd. Manufacturing Process Continuous Cast Copper Rod Manufacturing Process In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. copper rod upward continuous casting is the process in which liquid copper continuously solidifies into the copper rod. A method is described for the continuous. An introduction to technology and markets the copper. continuous casting is a dynamic casting method. Continuous Cast Copper Rod Manufacturing Process.

From www.pinterest.com

several orange wires are lined up in a factory Continuous Cast Copper Rod Manufacturing Process key raw materials required for the manufacturing of continuous cast copper rod plant is electrolytic grade copper. this article reviews the history and methods of copper alloy continuous casting. An introduction to technology and markets the copper. continuous casting in the copper industry; These methods include vertical continuous. copper rod upward continuous casting is the process. Continuous Cast Copper Rod Manufacturing Process.

From www.sterlitecopper.com

Continuous Cast Rod (CCR) Sterlite Copper (A Unit of Vedanta Limited) Continuous Cast Copper Rod Manufacturing Process continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish (molten metal. key raw materials required for the manufacturing of continuous cast copper rod plant is electrolytic grade copper. continuous casting in the copper industry; These methods include vertical continuous. An introduction to technology and markets the copper. A method. Continuous Cast Copper Rod Manufacturing Process.

From www.youtube.com

Copper Melting & Upcasting Plant (Copper Rod Manufacturing Line) YouTube Continuous Cast Copper Rod Manufacturing Process key raw materials required for the manufacturing of continuous cast copper rod plant is electrolytic grade copper. continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish (molten metal. These methods include vertical continuous. continuous casting in the copper industry; A method is described for the continuous. Southwire operates its. Continuous Cast Copper Rod Manufacturing Process.

From www.youtube.com

Copper Rod Smelting Casting Rolling System (820mm Continuous Cast Rod Continuous Cast Copper Rod Manufacturing Process These methods include vertical continuous. continuous casting in the copper industry; An introduction to technology and markets the copper. continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish (molten metal. A method is described for the continuous. key raw materials required for the manufacturing of continuous cast copper rod. Continuous Cast Copper Rod Manufacturing Process.

From www.youtube.com

Connecting rod manufacturing process YouTube Continuous Cast Copper Rod Manufacturing Process An introduction to technology and markets the copper. A method is described for the continuous. this article reviews the history and methods of copper alloy continuous casting. Southwire operates its own 54 metric tons per hour (tph) copper. key raw materials required for the manufacturing of continuous cast copper rod plant is electrolytic grade copper. copper rod. Continuous Cast Copper Rod Manufacturing Process.

From www.sinopowergroup.com

Copper Rod Upward Continuous Casting Machine SINOPOWER INDUSTRIAL Continuous Cast Copper Rod Manufacturing Process In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. A method is described for the continuous. key raw materials required for the manufacturing of continuous cast copper rod plant is electrolytic grade copper. Southwire operates its own 54 metric tons per hour (tph) copper. this article reviews the history. Continuous Cast Copper Rod Manufacturing Process.

From www.linttop.com

China Copper Rod Continuous Casting and Rolling Line Manufacturer and Continuous Cast Copper Rod Manufacturing Process These methods include vertical continuous. continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish (molten metal. continuous casting in the copper industry; this article reviews the history and methods of copper alloy continuous casting. Southwire operates its own 54 metric tons per hour (tph) copper. In both production methods,. Continuous Cast Copper Rod Manufacturing Process.

From www.youtube.com

How to casting brass rod and copper pipe, horizontal continuous casting Continuous Cast Copper Rod Manufacturing Process A method is described for the continuous. These methods include vertical continuous. southwire's scr® system is an advanced process for the continuous production of copper rod. Southwire operates its own 54 metric tons per hour (tph) copper. In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. this article reviews. Continuous Cast Copper Rod Manufacturing Process.

From www.researchgate.net

(PDF) CONTINUOUS CASTING COPPER ROD. PART 2. MICROSTRUCTURE STUDIES OF Continuous Cast Copper Rod Manufacturing Process An introduction to technology and markets the copper. Southwire operates its own 54 metric tons per hour (tph) copper. A method is described for the continuous. In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. copper rod upward continuous casting is the process in which liquid copper continuously solidifies into. Continuous Cast Copper Rod Manufacturing Process.

From www.scientific.net

Microstructure Morphology Evolution of Single Crystal Copper Rod by Continuous Cast Copper Rod Manufacturing Process key raw materials required for the manufacturing of continuous cast copper rod plant is electrolytic grade copper. These methods include vertical continuous. continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish (molten metal. A method is described for the continuous. An introduction to technology and markets the copper. continuous. Continuous Cast Copper Rod Manufacturing Process.

From www.indiamart.com

8 mm ETP Continuous Cast Copper Wire Rod at Rs 750/kg in Ahmedabad ID Continuous Cast Copper Rod Manufacturing Process An introduction to technology and markets the copper. copper rod upward continuous casting is the process in which liquid copper continuously solidifies into the copper rod. Southwire operates its own 54 metric tons per hour (tph) copper. continuous casting in the copper industry; key raw materials required for the manufacturing of continuous cast copper rod plant is. Continuous Cast Copper Rod Manufacturing Process.

From connect2india.com

Continuous Cast Copper Rod Continuous Cast Copper Rod buyers Continuous Cast Copper Rod Manufacturing Process continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish (molten metal. key raw materials required for the manufacturing of continuous cast copper rod plant is electrolytic grade copper. These methods include vertical continuous. southwire's scr® system is an advanced process for the continuous production of copper rod. copper. Continuous Cast Copper Rod Manufacturing Process.

From groovy-teacher.blogspot.com

Manufacturing Process Of Copper Groovy Teacher Continuous Cast Copper Rod Manufacturing Process A method is described for the continuous. These methods include vertical continuous. continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish (molten metal. An introduction to technology and markets the copper. southwire's scr® system is an advanced process for the continuous production of copper rod. In both production methods, rod. Continuous Cast Copper Rod Manufacturing Process.

From demccr.com

Copper Rod Continuous Casting & Rolling Line ChinaDEM Continuous Cast Copper Rod Manufacturing Process These methods include vertical continuous. Southwire operates its own 54 metric tons per hour (tph) copper. southwire's scr® system is an advanced process for the continuous production of copper rod. An introduction to technology and markets the copper. this article reviews the history and methods of copper alloy continuous casting. continuous casting in the copper industry; A. Continuous Cast Copper Rod Manufacturing Process.

From www.youtube.com

Copper Rod Upward Continuous Casting Machine Copper Wire Production Continuous Cast Copper Rod Manufacturing Process continuous casting in the copper industry; An introduction to technology and markets the copper. this article reviews the history and methods of copper alloy continuous casting. key raw materials required for the manufacturing of continuous cast copper rod plant is electrolytic grade copper. copper rod upward continuous casting is the process in which liquid copper continuously. Continuous Cast Copper Rod Manufacturing Process.

From www.wuxifurnace.com

China Horizontal Rod Copper Continuous Casting Machine Manufacturers Continuous Cast Copper Rod Manufacturing Process An introduction to technology and markets the copper. These methods include vertical continuous. In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. A method is described for the continuous. copper rod upward continuous casting is the process in which liquid copper continuously solidifies into the copper rod. continuous casting. Continuous Cast Copper Rod Manufacturing Process.

From www.youtube.com

Copper Rod Plant 8 mm RBD Machine Copper Wire Manufacturing Process Continuous Cast Copper Rod Manufacturing Process These methods include vertical continuous. key raw materials required for the manufacturing of continuous cast copper rod plant is electrolytic grade copper. An introduction to technology and markets the copper. continuous casting in the copper industry; southwire's scr® system is an advanced process for the continuous production of copper rod. copper rod upward continuous casting is. Continuous Cast Copper Rod Manufacturing Process.

From www.versa-bar.com

Advantages of the Continuous Casting Process Benefits of Cast Iron Continuous Cast Copper Rod Manufacturing Process copper rod upward continuous casting is the process in which liquid copper continuously solidifies into the copper rod. Southwire operates its own 54 metric tons per hour (tph) copper. key raw materials required for the manufacturing of continuous cast copper rod plant is electrolytic grade copper. southwire's scr® system is an advanced process for the continuous production. Continuous Cast Copper Rod Manufacturing Process.

From www.youtube.com

How to Produce Copper Rod from MillBerry Copper Wire Scrap? (Copper Continuous Cast Copper Rod Manufacturing Process An introduction to technology and markets the copper. A method is described for the continuous. Southwire operates its own 54 metric tons per hour (tph) copper. this article reviews the history and methods of copper alloy continuous casting. In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. key raw. Continuous Cast Copper Rod Manufacturing Process.

From www.copperworks.com

Process SDI La Farga Copperworks Continuous Cast Copper Rod Manufacturing Process key raw materials required for the manufacturing of continuous cast copper rod plant is electrolytic grade copper. copper rod upward continuous casting is the process in which liquid copper continuously solidifies into the copper rod. Southwire operates its own 54 metric tons per hour (tph) copper. In both production methods, rod is produced in an integrated process that. Continuous Cast Copper Rod Manufacturing Process.

From www.alibaba.com

8mm Copper Rod Continuous Casting & Rolling Ccr Line Buy Copper Gas Continuous Cast Copper Rod Manufacturing Process An introduction to technology and markets the copper. A method is described for the continuous. These methods include vertical continuous. continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish (molten metal. In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. this. Continuous Cast Copper Rod Manufacturing Process.

From www.rlbcable.com

Copper Rod Continuous Upcasting and Rolling Production Line,copper rod Continuous Cast Copper Rod Manufacturing Process copper rod upward continuous casting is the process in which liquid copper continuously solidifies into the copper rod. this article reviews the history and methods of copper alloy continuous casting. continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish (molten metal. An introduction to technology and markets the copper.. Continuous Cast Copper Rod Manufacturing Process.

From www.transformer-home.com

China Upward continuous casting oxygenfree copper rod production line Continuous Cast Copper Rod Manufacturing Process continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish (molten metal. In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. Southwire operates its own 54 metric tons per hour (tph) copper. These methods include vertical continuous. key raw materials required for. Continuous Cast Copper Rod Manufacturing Process.

From copperrodcasting.blogspot.com

COPPER ROD CONTINUOUS CASTING AND ROLLING MACHINE Continuous Cast Copper Rod Manufacturing Process An introduction to technology and markets the copper. Southwire operates its own 54 metric tons per hour (tph) copper. These methods include vertical continuous. In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. copper rod upward continuous casting is the process in which liquid copper continuously solidifies into the copper. Continuous Cast Copper Rod Manufacturing Process.

From www.indiamart.com

Continuous Cast Copper Wire Rod at Rs 445/kilogram Copper Wire Rods Continuous Cast Copper Rod Manufacturing Process These methods include vertical continuous. An introduction to technology and markets the copper. continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish (molten metal. continuous casting in the copper industry; southwire's scr® system is an advanced process for the continuous production of copper rod. key raw materials required. Continuous Cast Copper Rod Manufacturing Process.

From www.southwire.com

SCR Technologies Southwire Continuous Cast Copper Rod Manufacturing Process In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. These methods include vertical continuous. Southwire operates its own 54 metric tons per hour (tph) copper. A method is described for the continuous. this article reviews the history and methods of copper alloy continuous casting. continuous casting in the copper. Continuous Cast Copper Rod Manufacturing Process.

From www.indiamart.com

8mm To 16mm Continuous Cast Copper Rod, Size 8 Mm,12.5 Mm & 16mm at Continuous Cast Copper Rod Manufacturing Process southwire's scr® system is an advanced process for the continuous production of copper rod. copper rod upward continuous casting is the process in which liquid copper continuously solidifies into the copper rod. An introduction to technology and markets the copper. continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish. Continuous Cast Copper Rod Manufacturing Process.

From www.comsol.de

Optimizing the Continuous Casting Process with Simulation COMSOL Blog Continuous Cast Copper Rod Manufacturing Process A method is described for the continuous. key raw materials required for the manufacturing of continuous cast copper rod plant is electrolytic grade copper. An introduction to technology and markets the copper. In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. continuous casting in the copper industry; continuous. Continuous Cast Copper Rod Manufacturing Process.

From www.pinterest.com

Copper rod upward continuous casting machineryProduction of 830 mm Continuous Cast Copper Rod Manufacturing Process continuous casting in the copper industry; southwire's scr® system is an advanced process for the continuous production of copper rod. In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. copper rod upward continuous casting is the process in which liquid copper continuously solidifies into the copper rod. . Continuous Cast Copper Rod Manufacturing Process.

From dybochuang.en.made-in-china.com

Copper Rod Continuous Casting and Rolling Line (UL+Z1900+255/12 Continuous Cast Copper Rod Manufacturing Process A method is described for the continuous. In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. this article reviews the history and methods of copper alloy continuous casting. These methods include vertical continuous. An introduction to technology and markets the copper. continuous casting is a dynamic casting method in. Continuous Cast Copper Rod Manufacturing Process.

From demccr.com

Copper Rod Continuous Casting & Rolling Line ChinaDEM Continuous Cast Copper Rod Manufacturing Process An introduction to technology and markets the copper. In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. southwire's scr® system is an advanced process for the continuous production of copper rod. this article reviews the history and methods of copper alloy continuous casting. A method is described for the. Continuous Cast Copper Rod Manufacturing Process.

From fanshun-machine.en.made-in-china.com

Upward Continuous OxygenFree Copper Rod Casting Machine Copper Anode Continuous Cast Copper Rod Manufacturing Process An introduction to technology and markets the copper. In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. continuous casting in the copper industry; southwire's scr® system is an advanced process for the continuous production of copper rod. key raw materials required for the manufacturing of continuous cast copper. Continuous Cast Copper Rod Manufacturing Process.

From www.zenoindustry.com

China Custom Copper Rod Continuous Casting and Rolling Production Line Continuous Cast Copper Rod Manufacturing Process copper rod upward continuous casting is the process in which liquid copper continuously solidifies into the copper rod. A method is described for the continuous. southwire's scr® system is an advanced process for the continuous production of copper rod. continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish (molten. Continuous Cast Copper Rod Manufacturing Process.

From www.indiamart.com

2000T Copper Rod Copper Wire Upward Continuous Casting Machine at Rs Continuous Cast Copper Rod Manufacturing Process continuous casting is a dynamic casting method in which molten metal is poured continuously from a tundish (molten metal. copper rod upward continuous casting is the process in which liquid copper continuously solidifies into the copper rod. In both production methods, rod is produced in an integrated process that includes smelting, casting, rolling, cleaning and. this article. Continuous Cast Copper Rod Manufacturing Process.