Flap Disc Or Wire Brush . efficiently prepare surfaces for welding with the best tools. confused about wire wheel brushes? flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. for precision work and finishing, flap discs are often the preferred choice, while wire wheels excel in aggressive material removal tasks. Due to changes in the welding processes. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Choose the right brush for the job and get the most out of it. Due to changes in the welding. If achieving a smooth surface finish is crucial, flap discs are more suitable due to their finer abrasive grits and controlled stock removal. make sure the workspace is tidy and has adequate ventilation, and remove any combustible materials. Explore the advantages of using grinding wheels, wire brushes, and flap discs. Learn about the different types of wire wheel brushes, including their uses, safety precautions, and maintenance tips.

from www.toolstation.com

for precision work and finishing, flap discs are often the preferred choice, while wire wheels excel in aggressive material removal tasks. Due to changes in the welding. Explore the advantages of using grinding wheels, wire brushes, and flap discs. Choose the right brush for the job and get the most out of it. make sure the workspace is tidy and has adequate ventilation, and remove any combustible materials. confused about wire wheel brushes? efficiently prepare surfaces for welding with the best tools. If achieving a smooth surface finish is crucial, flap discs are more suitable due to their finer abrasive grits and controlled stock removal. Due to changes in the welding processes. Learn about the different types of wire wheel brushes, including their uses, safety precautions, and maintenance tips.

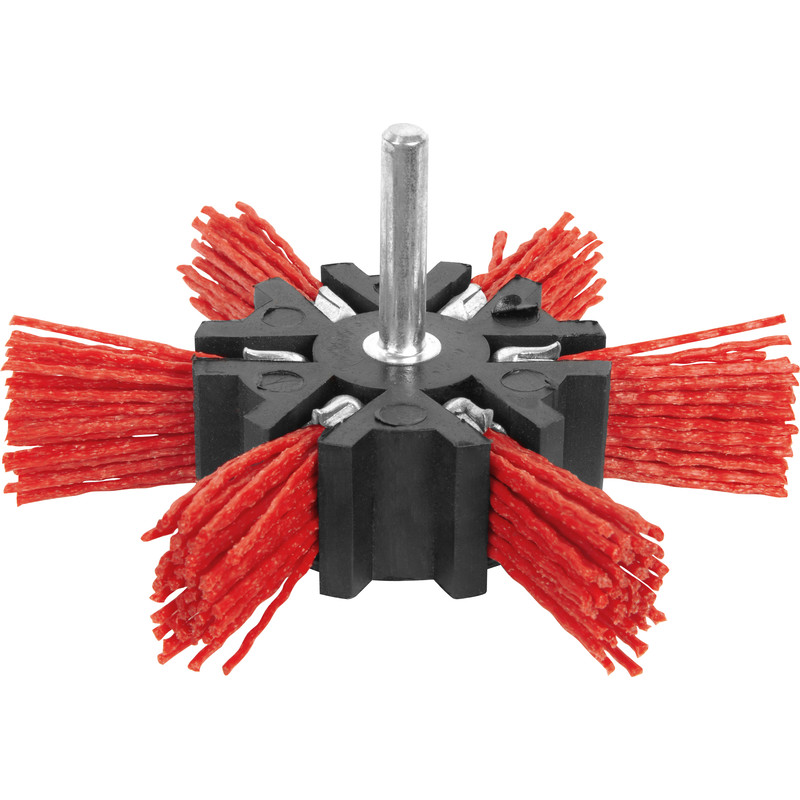

Abracs Nylon Filament Flap Brush 100mm Toolstation

Flap Disc Or Wire Brush Choose the right brush for the job and get the most out of it. efficiently prepare surfaces for welding with the best tools. make sure the workspace is tidy and has adequate ventilation, and remove any combustible materials. Choose the right brush for the job and get the most out of it. Explore the advantages of using grinding wheels, wire brushes, and flap discs. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Due to changes in the welding. Learn about the different types of wire wheel brushes, including their uses, safety precautions, and maintenance tips. If achieving a smooth surface finish is crucial, flap discs are more suitable due to their finer abrasive grits and controlled stock removal. for precision work and finishing, flap discs are often the preferred choice, while wire wheels excel in aggressive material removal tasks. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. confused about wire wheel brushes? Due to changes in the welding processes.

From www.delungrinding.com

flap disc, wire brush, diamond blade supplier Delun Grinding Tools Flap Disc Or Wire Brush Learn about the different types of wire wheel brushes, including their uses, safety precautions, and maintenance tips. Due to changes in the welding processes. If achieving a smooth surface finish is crucial, flap discs are more suitable due to their finer abrasive grits and controlled stock removal. flap discs were developed as an alternative to resin bonded grinding wheels. Flap Disc Or Wire Brush.

From www.ebay.de

10 Pack 3" verpresster Edelstahl Wire Wheel Brush mit 1/4" Schaft eBay Flap Disc Or Wire Brush Due to changes in the welding processes. Choose the right brush for the job and get the most out of it. Learn about the different types of wire wheel brushes, including their uses, safety precautions, and maintenance tips. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. confused about wire wheel brushes?. Flap Disc Or Wire Brush.

From www.abrasivesplus.com

Flap Brush Brass Coated Steel Wire Flap Disc Or Wire Brush Due to changes in the welding. If achieving a smooth surface finish is crucial, flap discs are more suitable due to their finer abrasive grits and controlled stock removal. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Explore the advantages of using grinding wheels, wire brushes, and flap discs. efficiently prepare. Flap Disc Or Wire Brush.

From www.unitedabrasives.com

NonWoven Flap Brushes United Abrasives Flap Disc Or Wire Brush flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Due to changes in the welding processes. confused about wire wheel brushes? for precision work and finishing, flap discs are often the preferred choice, while wire. Flap Disc Or Wire Brush.

From www.cgwabrasives.com

Crimped Wire Wheel Brushes Wire Brushes CGW Abrasives Flap Disc Or Wire Brush Due to changes in the welding processes. If achieving a smooth surface finish is crucial, flap discs are more suitable due to their finer abrasive grits and controlled stock removal. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. confused about wire wheel brushes? make sure the workspace is tidy and. Flap Disc Or Wire Brush.

From www.misterworker.com

BOSCH 2609256543 Flap brush for drills with nylon wire with aluminium Flap Disc Or Wire Brush confused about wire wheel brushes? flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. If achieving a smooth surface finish is crucial, flap discs are more suitable due to their finer abrasive grits and controlled stock removal. flap discs were developed as an alternative to resin bonded grinding wheels and fiber. Flap Disc Or Wire Brush.

From advancedindustrial.com

Flap Brushes Advanced Industrial Supply Flap Disc Or Wire Brush Due to changes in the welding. confused about wire wheel brushes? Explore the advantages of using grinding wheels, wire brushes, and flap discs. Due to changes in the welding processes. Choose the right brush for the job and get the most out of it. Learn about the different types of wire wheel brushes, including their uses, safety precautions, and. Flap Disc Or Wire Brush.

From www.wire-brush.co.uk

Nylon Filament Flap Brush 100mm Wire Brushes from www.WireBrush.co.uk Flap Disc Or Wire Brush for precision work and finishing, flap discs are often the preferred choice, while wire wheels excel in aggressive material removal tasks. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. If achieving a smooth surface finish is crucial, flap discs are more suitable due to their finer abrasive grits and controlled stock. Flap Disc Or Wire Brush.

From www.canadiantire.ca

Mastercraft Assorted Wire & Flap Brush Set, 10pc Canadian Tire Flap Disc Or Wire Brush Learn about the different types of wire wheel brushes, including their uses, safety precautions, and maintenance tips. for precision work and finishing, flap discs are often the preferred choice, while wire wheels excel in aggressive material removal tasks. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. confused about wire wheel. Flap Disc Or Wire Brush.

From www.canadiantire.ca

Mastercraft Assorted Wire & Flap Brush Set, 10pc Canadian Tire Flap Disc Or Wire Brush Due to changes in the welding. for precision work and finishing, flap discs are often the preferred choice, while wire wheels excel in aggressive material removal tasks. Due to changes in the welding processes. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. efficiently prepare surfaces for welding with the best. Flap Disc Or Wire Brush.

From www.walmart.com

Unique Bargains 100mm Diameter Polishing Sanding Flap Disc Wheel Brush Flap Disc Or Wire Brush If achieving a smooth surface finish is crucial, flap discs are more suitable due to their finer abrasive grits and controlled stock removal. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Due to changes in the welding processes. confused about wire wheel brushes? Choose the right brush for the job and. Flap Disc Or Wire Brush.

From www.indiamart.com

4inch Radial Brush SS Wire Flap wheel, For Cleaning, Grit 40 at Rs 170 Flap Disc Or Wire Brush Due to changes in the welding processes. efficiently prepare surfaces for welding with the best tools. confused about wire wheel brushes? Learn about the different types of wire wheel brushes, including their uses, safety precautions, and maintenance tips. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Choose the right brush. Flap Disc Or Wire Brush.

From www.ebay.com

3" Crimped Stainless Steel Wire Wheel Brush with 1/4" Shank Die Grinder Flap Disc Or Wire Brush If achieving a smooth surface finish is crucial, flap discs are more suitable due to their finer abrasive grits and controlled stock removal. Choose the right brush for the job and get the most out of it. for precision work and finishing, flap discs are often the preferred choice, while wire wheels excel in aggressive material removal tasks. Explore. Flap Disc Or Wire Brush.

From www.canadiantire.ca

Mastercraft Assorted Wire & Flap Brush Set, 10pc Canadian Tire Flap Disc Or Wire Brush Explore the advantages of using grinding wheels, wire brushes, and flap discs. make sure the workspace is tidy and has adequate ventilation, and remove any combustible materials. Due to changes in the welding. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. If achieving a smooth surface finish is crucial, flap discs. Flap Disc Or Wire Brush.

From www.tooltime.co.uk

5 PACK FLAP DISC TWIST KNOT SEMI FLAT WIRE WHEEL CUP BRUSH 115MM ANGLE Flap Disc Or Wire Brush Due to changes in the welding. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. confused about wire wheel brushes? If achieving a smooth surface finish is crucial, flap discs are more suitable due to their finer abrasive grits and controlled stock removal. Learn about the different types of wire wheel brushes,. Flap Disc Or Wire Brush.

From www.istockphoto.com

Photo Of Wire Brush And Flap Disc Stock Photo Download Image Now Flap Disc Or Wire Brush Due to changes in the welding processes. efficiently prepare surfaces for welding with the best tools. Choose the right brush for the job and get the most out of it. confused about wire wheel brushes? Learn about the different types of wire wheel brushes, including their uses, safety precautions, and maintenance tips. flap discs were developed as. Flap Disc Or Wire Brush.

From www.dreamstime.com

Different Wire Brush, Spindle Flap Brush, Wire Cup Brush Stock Photo Flap Disc Or Wire Brush confused about wire wheel brushes? efficiently prepare surfaces for welding with the best tools. Choose the right brush for the job and get the most out of it. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. flap discs were developed as an alternative to resin bonded grinding wheels and. Flap Disc Or Wire Brush.

From www.desertcart.in

Buy FEIHU 11 Pcs Wire Brushes Set, Flap Wheels 1/4 Inch Shank, Brass Flap Disc Or Wire Brush flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Due to changes in the welding processes. Explore the advantages of using grinding wheels, wire brushes, and flap discs. efficiently prepare surfaces for welding with the best tools. If achieving a smooth surface finish is crucial, flap discs are more suitable due to. Flap Disc Or Wire Brush.

From www.dreamstime.com

Photo of Wire Brush and Flap Disc Stock Image Image of abrade, works Flap Disc Or Wire Brush Choose the right brush for the job and get the most out of it. Due to changes in the welding processes. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. for precision work and finishing, flap discs are often the preferred choice, while wire wheels excel in aggressive material removal tasks. Learn. Flap Disc Or Wire Brush.

From www.carousell.ph

Wire Brush, Flap Disc, Mounted Wheels, Finishing Stones and others Flap Disc Or Wire Brush flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Explore the advantages of using grinding wheels, wire brushes, and flap discs. make sure the workspace is tidy and has adequate ventilation, and remove any combustible materials. Choose the right brush for the job and get the most out of it. confused. Flap Disc Or Wire Brush.

From www.mscdirect.com

‘Best of Both Worlds’ Norton’s Vortex Flap Disc Shines at Jobs from Flap Disc Or Wire Brush confused about wire wheel brushes? make sure the workspace is tidy and has adequate ventilation, and remove any combustible materials. Choose the right brush for the job and get the most out of it. efficiently prepare surfaces for welding with the best tools. If achieving a smooth surface finish is crucial, flap discs are more suitable due. Flap Disc Or Wire Brush.

From www.empireabrasives.com

4" Nylon Wire Strip Flap Brush 1/4" Hex Shank Flap Disc Or Wire Brush flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. If achieving a smooth surface finish is crucial, flap discs are more suitable due to their finer abrasive grits and controlled stock removal. Due to changes in the welding. flap discs were developed as an alternative to resin bonded grinding wheels and fiber. Flap Disc Or Wire Brush.

From www.toolstation.com

Abracs Nylon Filament Flap Brush 100mm Toolstation Flap Disc Or Wire Brush efficiently prepare surfaces for welding with the best tools. for precision work and finishing, flap discs are often the preferred choice, while wire wheels excel in aggressive material removal tasks. Due to changes in the welding. Choose the right brush for the job and get the most out of it. make sure the workspace is tidy and. Flap Disc Or Wire Brush.

From www.princessauto.com

4 pc Assorted Wire Brush and Flap Wheel Set Flap Disc Or Wire Brush confused about wire wheel brushes? flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Learn about the different types of wire wheel brushes, including their uses, safety precautions, and maintenance tips. Due to changes in the welding processes. If achieving a smooth surface finish is crucial, flap discs are more suitable due. Flap Disc Or Wire Brush.

From www.scnindustrial.com

3M ScotchBrite Flap Brushes SCN Industrial Flap Disc Or Wire Brush flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Explore the advantages of using grinding wheels, wire brushes, and flap discs. Due to changes in the welding processes. make sure the workspace is tidy and has adequate ventilation, and remove any combustible materials. efficiently prepare surfaces for welding with the best. Flap Disc Or Wire Brush.

From www.ebay.co.uk

5pc FLAP DISC TWIST KNOT SEMI FLAT WIRE WHEEL CUP BRUSH for 115MM ANGLE Flap Disc Or Wire Brush confused about wire wheel brushes? efficiently prepare surfaces for welding with the best tools. Choose the right brush for the job and get the most out of it. Explore the advantages of using grinding wheels, wire brushes, and flap discs. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. make. Flap Disc Or Wire Brush.

From www.buzzweld.co.uk

Dronco 100mm HeavyDuty Tapered Wire Brush Wheel Crimped Buzzweld Coatings Flap Disc Or Wire Brush flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Due to changes in the welding processes. Explore the advantages of using grinding wheels, wire brushes, and flap discs. Due to changes in the welding. Choose the right brush for the job and get the most out of it. confused about wire wheel. Flap Disc Or Wire Brush.

From www.tooltime.co.uk

5 PACK FLAP DISC TWIST KNOT SEMI FLAT WIRE WHEEL CUP BRUSH 115MM ANGLE Flap Disc Or Wire Brush If achieving a smooth surface finish is crucial, flap discs are more suitable due to their finer abrasive grits and controlled stock removal. Due to changes in the welding. Explore the advantages of using grinding wheels, wire brushes, and flap discs. make sure the workspace is tidy and has adequate ventilation, and remove any combustible materials. confused about. Flap Disc Or Wire Brush.

From www.carousell.ph

Kenmax Wire Brush, Flap Disc, Mounted Stone, Commercial & Industrial Flap Disc Or Wire Brush Choose the right brush for the job and get the most out of it. confused about wire wheel brushes? Learn about the different types of wire wheel brushes, including their uses, safety precautions, and maintenance tips. Due to changes in the welding processes. If achieving a smooth surface finish is crucial, flap discs are more suitable due to their. Flap Disc Or Wire Brush.

From www.empireabrasives.com

4" Nylon Wire Strip Flap Brush 1/4" Hex Shank Flap Disc Or Wire Brush make sure the workspace is tidy and has adequate ventilation, and remove any combustible materials. Due to changes in the welding. Learn about the different types of wire wheel brushes, including their uses, safety precautions, and maintenance tips. Due to changes in the welding processes. for precision work and finishing, flap discs are often the preferred choice, while. Flap Disc Or Wire Brush.

From www.delunabrasives.com

China Cutting Disc, Grinding Disc, Flap Disc, Wire Brush Suppliers Flap Disc Or Wire Brush flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Explore the advantages of using grinding wheels, wire brushes, and flap discs. efficiently prepare surfaces for welding with the best tools. If achieving a smooth surface finish is crucial, flap discs are more suitable due to their finer abrasive grits and controlled stock. Flap Disc Or Wire Brush.

From www.alamy.com

Set of different tools for grinding metal wire bristle brush Flap Disc Or Wire Brush Choose the right brush for the job and get the most out of it. efficiently prepare surfaces for welding with the best tools. Learn about the different types of wire wheel brushes, including their uses, safety precautions, and maintenance tips. make sure the workspace is tidy and has adequate ventilation, and remove any combustible materials. confused about. Flap Disc Or Wire Brush.

From www.thefabricator.com

Wire brushes, grinding wheels, and flap discs, oh my! Flap Disc Or Wire Brush Due to changes in the welding processes. Learn about the different types of wire wheel brushes, including their uses, safety precautions, and maintenance tips. If achieving a smooth surface finish is crucial, flap discs are more suitable due to their finer abrasive grits and controlled stock removal. Choose the right brush for the job and get the most out of. Flap Disc Or Wire Brush.

From www.thefabricator.com

Wire brushes, grinding wheels, and flap discs, oh my! Flap Disc Or Wire Brush Learn about the different types of wire wheel brushes, including their uses, safety precautions, and maintenance tips. Due to changes in the welding. flap discs were developed as an alternative to resin bonded grinding wheels and fiber discs. Choose the right brush for the job and get the most out of it. Due to changes in the welding processes.. Flap Disc Or Wire Brush.

From www.empireabrasives.com

4" Nylon Wire Strip Flap Brush 1/4" Hex Shank Flap Disc Or Wire Brush for precision work and finishing, flap discs are often the preferred choice, while wire wheels excel in aggressive material removal tasks. Due to changes in the welding. Due to changes in the welding processes. Explore the advantages of using grinding wheels, wire brushes, and flap discs. flap discs were developed as an alternative to resin bonded grinding wheels. Flap Disc Or Wire Brush.