Gear Load Calculator . to use the gear strength calculator, engineers need to input the gear's specifications, including the material, geometry, load, and. setup your hobber or shaper with our change gear calculator. the following is an engineering calculator for determining or estimating your required gear tooth strength. When a gear train system is transmitting power and motion, it is safe. gear design by agma theory: If you want to reverse engineer a gear that came in through your job shop door, or check your newly. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and selection of bearings of the gear shaft, overall design of the machine, and many more. the formula for calculating gear strength, a measure of how much load a gear can handle without failure, is given by:

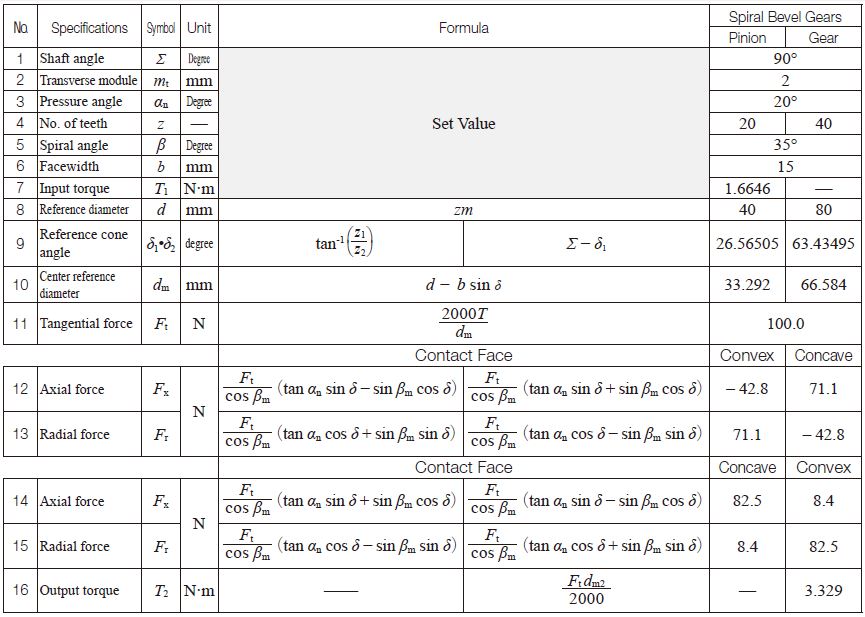

from khkgears.net

gear design by agma theory: When a gear train system is transmitting power and motion, it is safe. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and selection of bearings of the gear shaft, overall design of the machine, and many more. If you want to reverse engineer a gear that came in through your job shop door, or check your newly. to use the gear strength calculator, engineers need to input the gear's specifications, including the material, geometry, load, and. setup your hobber or shaper with our change gear calculator. the following is an engineering calculator for determining or estimating your required gear tooth strength. the formula for calculating gear strength, a measure of how much load a gear can handle without failure, is given by:

Gear Forces KHK Gears

Gear Load Calculator setup your hobber or shaper with our change gear calculator. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and selection of bearings of the gear shaft, overall design of the machine, and many more. to use the gear strength calculator, engineers need to input the gear's specifications, including the material, geometry, load, and. If you want to reverse engineer a gear that came in through your job shop door, or check your newly. the following is an engineering calculator for determining or estimating your required gear tooth strength. the formula for calculating gear strength, a measure of how much load a gear can handle without failure, is given by: gear design by agma theory: When a gear train system is transmitting power and motion, it is safe. setup your hobber or shaper with our change gear calculator.

From khkgears.net

Gear Forces KHK Gears Gear Load Calculator If you want to reverse engineer a gear that came in through your job shop door, or check your newly. gear design by agma theory: The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and selection of bearings of the gear shaft, overall design. Gear Load Calculator.

From garagemikacourirqrm.z21.web.core.windows.net

Gear Reduction Ratio Calculator Gear Load Calculator the formula for calculating gear strength, a measure of how much load a gear can handle without failure, is given by: gear design by agma theory: the following is an engineering calculator for determining or estimating your required gear tooth strength. If you want to reverse engineer a gear that came in through your job shop door,. Gear Load Calculator.

From www.icebike.org

Gear Ratio Calculator Gear Load Calculator gear design by agma theory: setup your hobber or shaper with our change gear calculator. If you want to reverse engineer a gear that came in through your job shop door, or check your newly. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature,. Gear Load Calculator.

From www.hexagon.de

ZAR6 Bevel Gear Calculation Gear Load Calculator setup your hobber or shaper with our change gear calculator. When a gear train system is transmitting power and motion, it is safe. the following is an engineering calculator for determining or estimating your required gear tooth strength. the formula for calculating gear strength, a measure of how much load a gear can handle without failure, is. Gear Load Calculator.

From www.tbksoft.com

TBK Spiral bevel gears Gear Load Calculator If you want to reverse engineer a gear that came in through your job shop door, or check your newly. the formula for calculating gear strength, a measure of how much load a gear can handle without failure, is given by: The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and. Gear Load Calculator.

From www.anycalculator.com

Gear Calculator For New Tire Size Gear Load Calculator The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and selection of bearings of the gear shaft, overall design of the machine, and many more. to use the gear strength calculator, engineers need to input the gear's specifications, including the material, geometry, load, and.. Gear Load Calculator.

From khkgears.net

Gear Forces KHK Gear Manufacturer Gear Load Calculator the following is an engineering calculator for determining or estimating your required gear tooth strength. to use the gear strength calculator, engineers need to input the gear's specifications, including the material, geometry, load, and. If you want to reverse engineer a gear that came in through your job shop door, or check your newly. the formula for. Gear Load Calculator.

From www.youtube.com

CALCULATION RACK AND SPUR GEAR EXCEL FORMULA YouTube Gear Load Calculator the formula for calculating gear strength, a measure of how much load a gear can handle without failure, is given by: When a gear train system is transmitting power and motion, it is safe. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. Gear Load Calculator.

From www.icebike.org

Bike Gear Ratio Calculator and Charts Gear Load Calculator to use the gear strength calculator, engineers need to input the gear's specifications, including the material, geometry, load, and. the formula for calculating gear strength, a measure of how much load a gear can handle without failure, is given by: The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and. Gear Load Calculator.

From www.semanticscholar.org

Figure 1 from CADBased Calculation of Cutting Force Components in Gear Gear Load Calculator the formula for calculating gear strength, a measure of how much load a gear can handle without failure, is given by: gear design by agma theory: If you want to reverse engineer a gear that came in through your job shop door, or check your newly. to use the gear strength calculator, engineers need to input the. Gear Load Calculator.

From www.glue-it.com

Gear Design Gear Load Calculator The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and selection of bearings of the gear shaft, overall design of the machine, and many more. When a gear train system is transmitting power and motion, it is safe. setup your hobber or shaper with. Gear Load Calculator.

From www.apexdyna.nl

Calculating rack and pinion, how do you do that? Gear Load Calculator setup your hobber or shaper with our change gear calculator. the formula for calculating gear strength, a measure of how much load a gear can handle without failure, is given by: gear design by agma theory: to use the gear strength calculator, engineers need to input the gear's specifications, including the material, geometry, load, and. . Gear Load Calculator.

From koyo.jtekt.co.jp

Calculation of loads Basic Bearing Knowledge Koyo Bearings /JTEKT Gear Load Calculator to use the gear strength calculator, engineers need to input the gear's specifications, including the material, geometry, load, and. When a gear train system is transmitting power and motion, it is safe. the formula for calculating gear strength, a measure of how much load a gear can handle without failure, is given by: gear design by agma. Gear Load Calculator.

From callumtucker.z21.web.core.windows.net

Gear Ratio Calculator Chart Gear Load Calculator When a gear train system is transmitting power and motion, it is safe. the following is an engineering calculator for determining or estimating your required gear tooth strength. If you want to reverse engineer a gear that came in through your job shop door, or check your newly. the formula for calculating gear strength, a measure of how. Gear Load Calculator.

From www.jcl-tech.com

JCL Gear geometry and control dimensions Gear Load Calculator the formula for calculating gear strength, a measure of how much load a gear can handle without failure, is given by: If you want to reverse engineer a gear that came in through your job shop door, or check your newly. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and. Gear Load Calculator.

From studylib.net

Bearing Load Calculation Gear Load Calculator gear design by agma theory: setup your hobber or shaper with our change gear calculator. to use the gear strength calculator, engineers need to input the gear's specifications, including the material, geometry, load, and. When a gear train system is transmitting power and motion, it is safe. the following is an engineering calculator for determining or. Gear Load Calculator.

From www.youtube.com

Simple Gear Ratios, Input and Output Speed, Torque and Power YouTube Gear Load Calculator gear design by agma theory: the following is an engineering calculator for determining or estimating your required gear tooth strength. When a gear train system is transmitting power and motion, it is safe. setup your hobber or shaper with our change gear calculator. If you want to reverse engineer a gear that came in through your job. Gear Load Calculator.

From www.youtube.com

Spur Gear Calculation and Design (MITCalc03) YouTube Gear Load Calculator The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and selection of bearings of the gear shaft, overall design of the machine, and many more. the following is an engineering calculator for determining or estimating your required gear tooth strength. When a gear train. Gear Load Calculator.

From www.youtube.com

Gear ratio calculator The fastest way to solve your physics homework Gear Load Calculator setup your hobber or shaper with our change gear calculator. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and selection of bearings of the gear shaft, overall design of the machine, and many more. gear design by agma theory: If you want. Gear Load Calculator.

From www.dreamstime.com

Gear Ratio Vector Illustration. Labeled Physical Formula Explanation Gear Load Calculator to use the gear strength calculator, engineers need to input the gear's specifications, including the material, geometry, load, and. the following is an engineering calculator for determining or estimating your required gear tooth strength. gear design by agma theory: If you want to reverse engineer a gear that came in through your job shop door, or check. Gear Load Calculator.

From www.wikihow.com

4 Easy Ways to Determine Gear Ratio (with Pictures) Gear Load Calculator gear design by agma theory: If you want to reverse engineer a gear that came in through your job shop door, or check your newly. setup your hobber or shaper with our change gear calculator. to use the gear strength calculator, engineers need to input the gear's specifications, including the material, geometry, load, and. The life of. Gear Load Calculator.

From koyo.jtekt.co.jp

Calculation of loads Basic Bearing Knowledge Koyo Bearings /JTEKT Gear Load Calculator When a gear train system is transmitting power and motion, it is safe. setup your hobber or shaper with our change gear calculator. gear design by agma theory: The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and selection of bearings of the. Gear Load Calculator.

From celqenoz.blob.core.windows.net

Module Spur Gear Calculation at Dennis Pearson blog Gear Load Calculator the following is an engineering calculator for determining or estimating your required gear tooth strength. setup your hobber or shaper with our change gear calculator. to use the gear strength calculator, engineers need to input the gear's specifications, including the material, geometry, load, and. When a gear train system is transmitting power and motion, it is safe.. Gear Load Calculator.

From fixmachineofilduwebzda.z14.web.core.windows.net

Gear Reduction Ratio Calculator Gear Load Calculator the following is an engineering calculator for determining or estimating your required gear tooth strength. When a gear train system is transmitting power and motion, it is safe. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and selection of bearings of the gear. Gear Load Calculator.

From www.youtube.com

Gear transmission Calculation of moment of inertia YouTube Gear Load Calculator setup your hobber or shaper with our change gear calculator. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and selection of bearings of the gear shaft, overall design of the machine, and many more. When a gear train system is transmitting power and. Gear Load Calculator.

From dyrobes.com

The text outputs are listed below for reference Gear Load Calculator the following is an engineering calculator for determining or estimating your required gear tooth strength. gear design by agma theory: the formula for calculating gear strength, a measure of how much load a gear can handle without failure, is given by: setup your hobber or shaper with our change gear calculator. If you want to reverse. Gear Load Calculator.

From www.mechstudies.com

Calculation for Gear Ratio How to Calculate? Types, Explained with Gear Load Calculator the following is an engineering calculator for determining or estimating your required gear tooth strength. gear design by agma theory: setup your hobber or shaper with our change gear calculator. If you want to reverse engineer a gear that came in through your job shop door, or check your newly. When a gear train system is transmitting. Gear Load Calculator.

From printablefaestrefitm.z4.web.core.windows.net

How To Calculate Gear Ratio Grade 8 Gear Load Calculator If you want to reverse engineer a gear that came in through your job shop door, or check your newly. the formula for calculating gear strength, a measure of how much load a gear can handle without failure, is given by: setup your hobber or shaper with our change gear calculator. the following is an engineering calculator. Gear Load Calculator.

From koyo.jtekt.co.jp

Calculation of loads Basic Bearing Knowledge Koyo Bearings /JTEKT Gear Load Calculator gear design by agma theory: If you want to reverse engineer a gear that came in through your job shop door, or check your newly. When a gear train system is transmitting power and motion, it is safe. the following is an engineering calculator for determining or estimating your required gear tooth strength. setup your hobber or. Gear Load Calculator.

From www.researchgate.net

Dimensions used in calculating landing gear loads The minimum nose Gear Load Calculator When a gear train system is transmitting power and motion, it is safe. setup your hobber or shaper with our change gear calculator. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and selection of bearings of the gear shaft, overall design of the. Gear Load Calculator.

From learningschoolsvetino3l.z13.web.core.windows.net

Gear Ratio Calculator Math Gear Load Calculator When a gear train system is transmitting power and motion, it is safe. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and selection of bearings of the gear shaft, overall design of the machine, and many more. gear design by agma theory: . Gear Load Calculator.

From engineladydelmar5vr.z21.web.core.windows.net

Gear Reduction Ratio Calculator Gear Load Calculator to use the gear strength calculator, engineers need to input the gear's specifications, including the material, geometry, load, and. setup your hobber or shaper with our change gear calculator. When a gear train system is transmitting power and motion, it is safe. If you want to reverse engineer a gear that came in through your job shop door,. Gear Load Calculator.

From koyo.jtekt.co.jp

Calculation of loads Basic Bearing Knowledge Koyo Bearings /JTEKT Gear Load Calculator to use the gear strength calculator, engineers need to input the gear's specifications, including the material, geometry, load, and. setup your hobber or shaper with our change gear calculator. When a gear train system is transmitting power and motion, it is safe. gear design by agma theory: the following is an engineering calculator for determining or. Gear Load Calculator.

From itstillruns.com

How to Calculate Gear Ratios and Torque It Still Runs Gear Load Calculator setup your hobber or shaper with our change gear calculator. the formula for calculating gear strength, a measure of how much load a gear can handle without failure, is given by: If you want to reverse engineer a gear that came in through your job shop door, or check your newly. The life of gear depends on multiple. Gear Load Calculator.

From calculatorshub.net

Static Wheel Load Calculator Online Gear Load Calculator the formula for calculating gear strength, a measure of how much load a gear can handle without failure, is given by: When a gear train system is transmitting power and motion, it is safe. The life of gear depends on multiple factors such as lubrication, manufacturing quality, gear material, finish, noise, and vibration in the machine, temperature, quality, and. Gear Load Calculator.