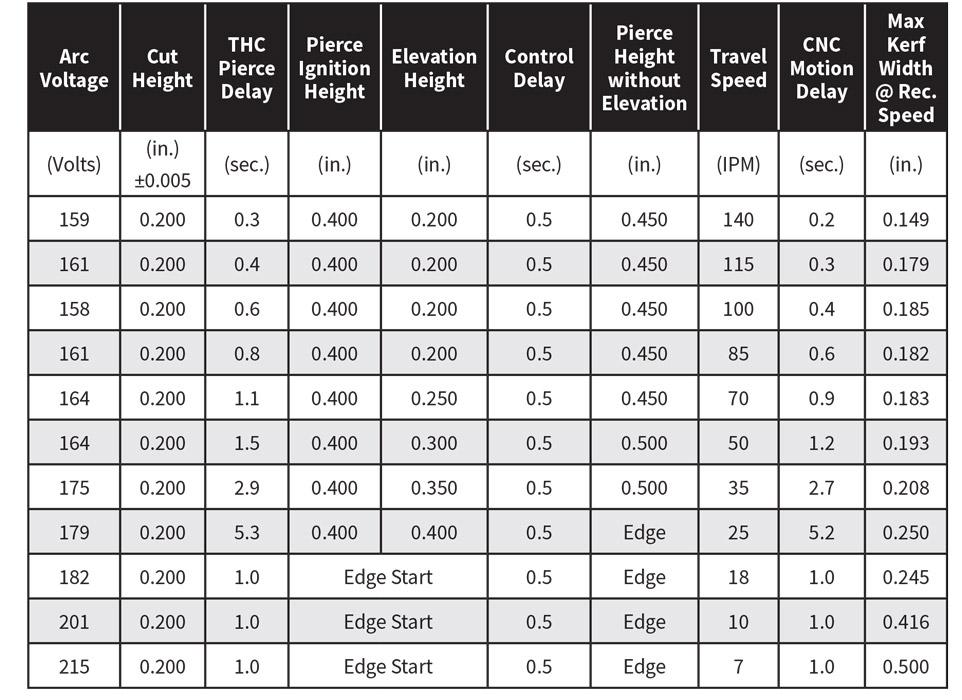

Plasma Cutting Settings Chart . Find the recommended consumable parts, cutting speeds and gas and torch settings for different materials and thicknesses. Achieving the optimum performance from your miller plasma cutter involves a precise calibration of settings tailored to the material you’re. Orifice hole size 1mm =.03937. Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. Select the appropriate plasma cutting setting process. Learn how to use cut charts for different materials and amperages with your plasma cutter. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. The charts cover bevel cutting, marking and. See charts for mild steel, stainless steel, and aluminum. Here is a summary of the recommended parameters for different thicknesses of materials and. Be sure to follow the plasma cutter settings and specifications in the cut charts. Find tips on how to develop your own charts, adjust settings, and improve cut quality. Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf compensation. Cut50 plasma cutter suggested amperage & air setting cutter chart. It is critical that these plasma cutter settings are correct:

from

Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf compensation. Find the recommended consumable parts, cutting speeds and gas and torch settings for different materials and thicknesses. Learn how to use cut charts for different materials and amperages with your plasma cutter. Here is a summary of the recommended parameters for different thicknesses of materials and. Find tips on how to develop your own charts, adjust settings, and improve cut quality. Be sure to follow the plasma cutter settings and specifications in the cut charts. Orifice hole size 1mm =.03937. Select the appropriate plasma cutting setting process. The charts cover bevel cutting, marking and. Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization.

Plasma Cutting Settings Chart The charts cover bevel cutting, marking and. Here is a summary of the recommended parameters for different thicknesses of materials and. Be sure to follow the plasma cutter settings and specifications in the cut charts. Achieving the optimum performance from your miller plasma cutter involves a precise calibration of settings tailored to the material you’re. Learn how to use cut charts for different materials and amperages with your plasma cutter. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Cut50 plasma cutter suggested amperage & air setting cutter chart. Orifice hole size 1mm =.03937. Find tips on how to develop your own charts, adjust settings, and improve cut quality. Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf compensation. It is critical that these plasma cutter settings are correct: The charts cover bevel cutting, marking and. Find the recommended consumable parts, cutting speeds and gas and torch settings for different materials and thicknesses. Select the appropriate plasma cutting setting process. See charts for mild steel, stainless steel, and aluminum.

From studylibdiana.z13.web.core.windows.net

Plasma Cutting Shade Chart Plasma Cutting Settings Chart This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Find tips on how to develop your own charts, adjust settings, and improve cut quality. Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. Learn how to set up your plasma cutter. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart The charts cover bevel cutting, marking and. Orifice hole size 1mm =.03937. It is critical that these plasma cutter settings are correct: See charts for mild steel, stainless steel, and aluminum. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Learn how to set up your plasma. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart See charts for mild steel, stainless steel, and aluminum. Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. The charts cover bevel cutting, marking and. Find the recommended consumable parts, cutting speeds. Plasma Cutting Settings Chart.

From infographiclabs.com

A Guide to Plasma Cutting Plasma Cutting Settings Chart Cut50 plasma cutter suggested amperage & air setting cutter chart. See charts for mild steel, stainless steel, and aluminum. It is critical that these plasma cutter settings are correct: Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. The charts cover bevel cutting, marking and. Find the recommended consumable parts, cutting speeds and gas. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Be sure to follow the plasma cutter settings and specifications in the cut charts. It is critical that these plasma cutter settings are correct: Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. Learn how to use cut charts for different materials and amperages with your plasma cutter. Find tips on how to develop. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Orifice hole size 1mm =.03937. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. Here is a summary of the recommended parameters for different thicknesses of materials and. Select the appropriate plasma. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Cut50 plasma cutter suggested amperage & air setting cutter chart. Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf compensation. It is critical that these plasma cutter settings are correct: See charts for mild steel, stainless steel, and aluminum. This is what i have found to work with most plasma cutter nozzles/tips. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Find tips on how to develop your own charts, adjust settings, and improve cut quality. Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf compensation. Cut50 plasma cutter suggested amperage. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart The charts cover bevel cutting, marking and. Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf compensation. Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. Find the recommended consumable parts, cutting speeds and gas and torch settings for different materials and thicknesses. Select the appropriate. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Find tips on how to develop your own charts, adjust settings, and improve cut quality. Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf compensation. Here is a summary of the recommended parameters for different thicknesses of materials and. Unleash the full potential of your cnc plasma cutter with cut charts and. Plasma Cutting Settings Chart.

From smithbuddy.com

Plasma cutting nozzle size chart Expert Guide Plasma Cutting Settings Chart Find the recommended consumable parts, cutting speeds and gas and torch settings for different materials and thicknesses. Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. The charts cover bevel cutting, marking and. See charts for mild steel, stainless steel, and aluminum. This is what i have found to work with most plasma cutter. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf compensation. Orifice hole size 1mm =.03937. Cut50 plasma cutter suggested amperage & air setting cutter chart. Find tips on how to develop your own charts, adjust settings, and improve cut quality. Find the recommended consumable parts, cutting speeds and gas and torch settings. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Be sure to follow the plasma cutter settings and specifications in the cut charts. Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf compensation. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Select the appropriate plasma cutting setting. Plasma Cutting Settings Chart.

From blog.hirebotics.com

Improve Your Plasma Cutting Settings (with Cut Charts) Plasma Cutting Settings Chart Find tips on how to develop your own charts, adjust settings, and improve cut quality. Here is a summary of the recommended parameters for different thicknesses of materials and. Be sure to follow the plasma cutter settings and specifications in the cut charts. Learn how to use cut charts for different materials and amperages with your plasma cutter. Find the. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Select the appropriate plasma cutting setting process. The charts cover bevel cutting, marking and. Here is a summary of the recommended parameters for different thicknesses of materials and. It is critical that these plasma cutter settings are correct: Learn how to use cut charts for different materials and amperages with your plasma cutter. This is what i have found to. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Here is a summary of the recommended parameters for different thicknesses of materials and. Select the appropriate plasma cutting setting process. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. Find the. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Here is a summary of the recommended parameters for different thicknesses of materials and. Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf compensation. Be sure to follow the plasma cutter settings and specifications in the cut charts. This is what i have found to work with most plasma cutter nozzles/tips that. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Find tips on how to develop your own charts, adjust settings, and improve cut quality. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Orifice hole size 1mm =.03937. Cut50 plasma cutter suggested amperage & air setting cutter chart. Achieving the optimum performance from your miller plasma. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart It is critical that these plasma cutter settings are correct: Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf compensation. Learn how to use cut charts for different materials and amperages with your plasma cutter. Cut50 plasma cutter suggested amperage & air setting cutter chart. Unleash the full potential of your cnc. Plasma Cutting Settings Chart.

From wiki.opensourceecology.org

CNC Torch Table 2/Control Overview Open Source Ecology Plasma Cutting Settings Chart See charts for mild steel, stainless steel, and aluminum. Here is a summary of the recommended parameters for different thicknesses of materials and. Find tips on how to develop your own charts, adjust settings, and improve cut quality. Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. This is what i have found to. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. Learn how to use cut charts for different materials and amperages with your plasma cutter. Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf compensation. Be sure to follow the plasma cutter settings and specifications in the. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Cut50 plasma cutter suggested amperage & air setting cutter chart. Achieving the optimum performance from your miller plasma cutter involves a precise calibration of settings tailored to the material you’re. See charts for mild steel, stainless steel, and aluminum. Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf compensation. Find tips on. Plasma Cutting Settings Chart.

From unimig.com.au

The Ultimate Guide to Plasma Cutting UNIMIG Welding Guides & Tutorials Plasma Cutting Settings Chart Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. Find tips on how to develop your own charts, adjust settings, and improve cut quality. Orifice hole size 1mm =.03937. Be sure to follow the plasma cutter settings and specifications in the cut charts. Cut50 plasma cutter suggested amperage & air setting cutter chart. It. Plasma Cutting Settings Chart.

From blog.hirebotics.com

Improve Your Plasma Cutting Settings (with Cut Charts) Plasma Cutting Settings Chart See charts for mild steel, stainless steel, and aluminum. Cut50 plasma cutter suggested amperage & air setting cutter chart. It is critical that these plasma cutter settings are correct: Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf compensation. Achieving the optimum performance from your miller plasma cutter involves a precise calibration. Plasma Cutting Settings Chart.

From unimig.com.au

The Ultimate Guide to Plasma Cutting UNIMIG Welding Guides & Tutorials Plasma Cutting Settings Chart Be sure to follow the plasma cutter settings and specifications in the cut charts. Cut50 plasma cutter suggested amperage & air setting cutter chart. Select the appropriate plasma cutting setting process. Here is a summary of the recommended parameters for different thicknesses of materials and. Find the recommended consumable parts, cutting speeds and gas and torch settings for different materials. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf compensation. The charts cover bevel cutting, marking and. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart See charts for mild steel, stainless steel, and aluminum. Achieving the optimum performance from your miller plasma cutter involves a precise calibration of settings tailored to the material you’re. Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. Select the appropriate plasma cutting setting process. Find the recommended consumable parts, cutting speeds and gas. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart It is critical that these plasma cutter settings are correct: See charts for mild steel, stainless steel, and aluminum. Orifice hole size 1mm =.03937. Here is a summary of the recommended parameters for different thicknesses of materials and. Achieving the optimum performance from your miller plasma cutter involves a precise calibration of settings tailored to the material you’re. The charts. Plasma Cutting Settings Chart.

From www.perfectwelders.com

Understanding Cut Charts An Essential Guide,You gotta get know these plasma cutter,plasma Plasma Cutting Settings Chart Select the appropriate plasma cutting setting process. Orifice hole size 1mm =.03937. Find the recommended consumable parts, cutting speeds and gas and torch settings for different materials and thicknesses. Be sure to follow the plasma cutter settings and specifications in the cut charts. Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Achieving the optimum performance from your miller plasma cutter involves a precise calibration of settings tailored to the material you’re. Find the recommended consumable parts, cutting speeds and gas and torch settings for different materials and thicknesses. The. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Achieving the optimum performance from your miller plasma cutter involves a precise calibration of settings tailored to the material you’re. See charts for mild steel, stainless steel, and aluminum. Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce height, and kerf compensation. The charts cover bevel cutting, marking and. Select the appropriate plasma cutting setting. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Be sure to follow the plasma cutter settings and specifications in the cut charts. The charts cover bevel cutting, marking and. This is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Learn how to use cut charts for different materials and amperages with your plasma cutter. Select the. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Here is a summary of the recommended parameters for different thicknesses of materials and. Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. Be sure to follow the plasma cutter settings and specifications in the cut charts. Orifice hole size 1mm =.03937. This is what i have found to work with most plasma cutter. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Orifice hole size 1mm =.03937. The charts cover bevel cutting, marking and. Cut50 plasma cutter suggested amperage & air setting cutter chart. See charts for mild steel, stainless steel, and aluminum. Unleash the full potential of your cnc plasma cutter with cut charts and parameter optimization. Learn how to set up your plasma cutter for optimal speed, amperage, voltage, pierce. Plasma Cutting Settings Chart.

From

Plasma Cutting Settings Chart Learn how to use cut charts for different materials and amperages with your plasma cutter. Be sure to follow the plasma cutter settings and specifications in the cut charts. Find tips on how to develop your own charts, adjust settings, and improve cut quality. Here is a summary of the recommended parameters for different thicknesses of materials and. Learn how. Plasma Cutting Settings Chart.