Surface Roughness Visual Measurement . The power of r and s parameters. Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed of several machined components;. Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured using a numerical scale. For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both surfaces at. A surface condition is often. In today’s advanced manufacturing world,. Geometric analysis allows a visual and subjective evaluation of roughness (a qualitative assessment), whereas computation. In this article, we will explore the concept of measuring surface roughness, its importance in various industries, and the methods used for measurement. We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these measurements. We report a study of the correlation between three optical methods for characterizing surface roughness:

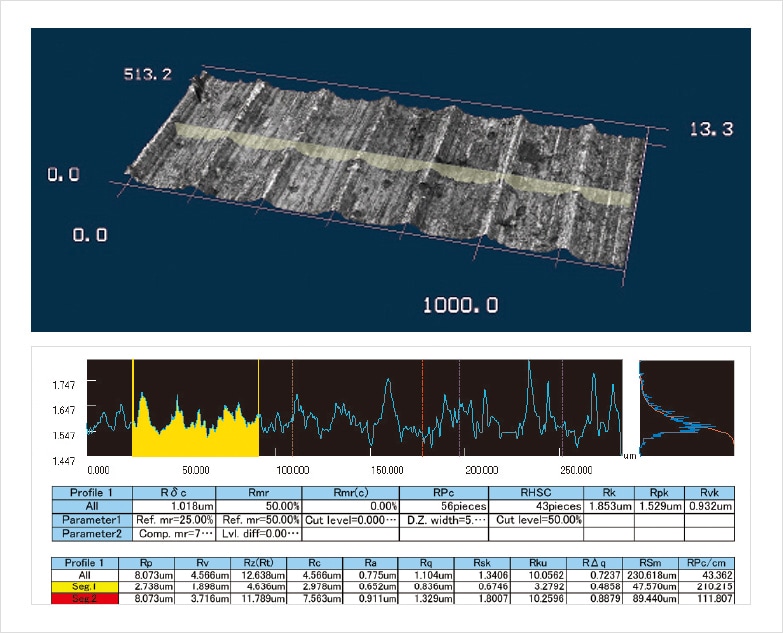

from www.keyence.com

In this article, we will explore the concept of measuring surface roughness, its importance in various industries, and the methods used for measurement. In today’s advanced manufacturing world,. For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both surfaces at. A surface condition is often. Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed of several machined components;. We report a study of the correlation between three optical methods for characterizing surface roughness: We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these measurements. Geometric analysis allows a visual and subjective evaluation of roughness (a qualitative assessment), whereas computation. Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured using a numerical scale. The power of r and s parameters.

Roughness Measurement Examples Introduction To Roughness KEYENCE

Surface Roughness Visual Measurement The power of r and s parameters. A surface condition is often. For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both surfaces at. We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these measurements. Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed of several machined components;. The power of r and s parameters. In today’s advanced manufacturing world,. Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured using a numerical scale. Geometric analysis allows a visual and subjective evaluation of roughness (a qualitative assessment), whereas computation. We report a study of the correlation between three optical methods for characterizing surface roughness: In this article, we will explore the concept of measuring surface roughness, its importance in various industries, and the methods used for measurement.

From www.confovis.com

Roughness measurement optical 3D surface metrology Surface Roughness Visual Measurement We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these measurements. In today’s advanced manufacturing world,. Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed of several machined components;. Surface roughness can be evaluated by visual appearances and tactile sensation and can. Surface Roughness Visual Measurement.

From www.keyence.com

Roughness Measurement Examples Introduction To Roughness KEYENCE Surface Roughness Visual Measurement The power of r and s parameters. We report a study of the correlation between three optical methods for characterizing surface roughness: A surface condition is often. Geometric analysis allows a visual and subjective evaluation of roughness (a qualitative assessment), whereas computation. We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of. Surface Roughness Visual Measurement.

From isofinishing.com

Surface Roughness Chart ISO Finishing Surface Roughness Visual Measurement For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both surfaces at. A surface condition is often. Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed of several machined components;. Surface roughness can be evaluated by visual appearances and tactile sensation and can. Surface Roughness Visual Measurement.

From oliverrandall.z13.web.core.windows.net

Rms Surface Roughness Chart Surface Roughness Visual Measurement We report a study of the correlation between three optical methods for characterizing surface roughness: In today’s advanced manufacturing world,. The power of r and s parameters. Geometric analysis allows a visual and subjective evaluation of roughness (a qualitative assessment), whereas computation. Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed. Surface Roughness Visual Measurement.

From www.youtube.com

Surface Roughness Tester Profilometer Phase II SRG4600Surface Surface Roughness Visual Measurement In this article, we will explore the concept of measuring surface roughness, its importance in various industries, and the methods used for measurement. For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both surfaces at. In today’s advanced manufacturing world,. A surface condition is often. Surface roughness is a key parameter in. Surface Roughness Visual Measurement.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Roughness Visual Measurement Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed of several machined components;. We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these measurements. We report a study of the correlation between three optical methods for characterizing surface roughness: Surface roughness can. Surface Roughness Visual Measurement.

From www.researchgate.net

Types of surface roughness measurement Download Scientific Diagram Surface Roughness Visual Measurement Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed of several machined components;. For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both surfaces at. The power of r and s parameters. We report a study of the correlation between three optical methods. Surface Roughness Visual Measurement.

From www.researchgate.net

(a) Surface roughness measurement setup; (b) typical surface profile Surface Roughness Visual Measurement We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these measurements. In this article, we will explore the concept of measuring surface roughness, its importance in various industries, and the methods used for measurement. In today’s advanced manufacturing world,. Surface roughness can be evaluated by visual appearances and tactile sensation and. Surface Roughness Visual Measurement.

From www.researchgate.net

Surface roughness measurement procedure a white light interferometer Surface Roughness Visual Measurement Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured using a numerical scale. We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these measurements. For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both surfaces at. Geometric. Surface Roughness Visual Measurement.

From www.researchgate.net

Surface roughness measurement. Download Scientific Diagram Surface Roughness Visual Measurement We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these measurements. In today’s advanced manufacturing world,. In this article, we will explore the concept of measuring surface roughness, its importance in various industries, and the methods used for measurement. We report a study of the correlation between three optical methods for. Surface Roughness Visual Measurement.

From www.filmetrics.com

Surface Roughness Measurements and Surface Finish Measurements Surface Roughness Visual Measurement Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured using a numerical scale. In this article, we will explore the concept of measuring surface roughness, its importance in various industries, and the methods used for measurement. We report a study of the correlation between three optical methods for characterizing surface roughness: For a more. Surface Roughness Visual Measurement.

From www.taylor-hobson.com

Surface Finish Tester Portable Surface Roughness Tester Surface Surface Roughness Visual Measurement In today’s advanced manufacturing world,. Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed of several machined components;. Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured using a numerical scale. For a more accurate assessment of surface roughness, a comparative microscope can be used,. Surface Roughness Visual Measurement.

From www.researchgate.net

Surface roughness measurements. The images, sample 3 (S3, above), and Surface Roughness Visual Measurement Geometric analysis allows a visual and subjective evaluation of roughness (a qualitative assessment), whereas computation. Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured using a numerical scale. We report a study of the correlation between three optical methods for characterizing surface roughness: The power of r and s parameters. We will also discuss. Surface Roughness Visual Measurement.

From mavink.com

Surface Roughness Units Surface Roughness Visual Measurement In today’s advanced manufacturing world,. In this article, we will explore the concept of measuring surface roughness, its importance in various industries, and the methods used for measurement. We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these measurements. Surface roughness can be evaluated by visual appearances and tactile sensation and. Surface Roughness Visual Measurement.

From www.researchgate.net

Surface roughness measurement procedures Download Scientific Diagram Surface Roughness Visual Measurement Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured using a numerical scale. We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these measurements. In today’s advanced manufacturing world,. We report a study of the correlation between three optical methods for characterizing surface roughness: The. Surface Roughness Visual Measurement.

From www.youtube.com

Surface Roughness Measurement 10 point Rz method YouTube Surface Roughness Visual Measurement We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these measurements. Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured using a numerical scale. In this article, we will explore the concept of measuring surface roughness, its importance in various industries, and the methods used. Surface Roughness Visual Measurement.

From www.researchgate.net

Schematic of methodology for surface roughness measurement (a) and Surface Roughness Visual Measurement Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed of several machined components;. For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both surfaces at. A surface condition is often. In this article, we will explore the concept of measuring surface roughness, its. Surface Roughness Visual Measurement.

From www.keyence.com

Roughness Measurement Examples Introduction To Roughness KEYENCE Surface Roughness Visual Measurement For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both surfaces at. We report a study of the correlation between three optical methods for characterizing surface roughness: The power of r and s parameters. In today’s advanced manufacturing world,. Geometric analysis allows a visual and subjective evaluation of roughness (a qualitative assessment),. Surface Roughness Visual Measurement.

From www.engineeringchoice.com

What Is Surface Roughness? Unit, Chart, Measurement Surface Roughness Visual Measurement We report a study of the correlation between three optical methods for characterizing surface roughness: Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured using a numerical scale. In today’s advanced manufacturing world,. In this article, we will explore the concept of measuring surface roughness, its importance in various industries, and the methods used. Surface Roughness Visual Measurement.

From imagesee.biz

Surface Roughness Explained IMAGESEE Surface Roughness Visual Measurement For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both surfaces at. We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these measurements. In today’s advanced manufacturing world,. Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured. Surface Roughness Visual Measurement.

From www.kemalmfg.com

A Comprehensive Guide to Surface Roughness, its Measurement, Standards Surface Roughness Visual Measurement We report a study of the correlation between three optical methods for characterizing surface roughness: Geometric analysis allows a visual and subjective evaluation of roughness (a qualitative assessment), whereas computation. We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these measurements. In this article, we will explore the concept of measuring. Surface Roughness Visual Measurement.

From bakergauges.com

Surface Roughness Tester Roughness Tester Baker Gauges Surface Roughness Visual Measurement For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both surfaces at. The power of r and s parameters. We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these measurements. Geometric analysis allows a visual and subjective evaluation of roughness (a qualitative assessment),. Surface Roughness Visual Measurement.

From www.tribonet.org

Surface Roughness Measurement About Tribology Surface Roughness Visual Measurement Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed of several machined components;. For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both surfaces at. The power of r and s parameters. In this article, we will explore the concept of measuring surface. Surface Roughness Visual Measurement.

From www.youtube.com

Surface Roughness Measurement An Overview of Technique and Analysis Surface Roughness Visual Measurement In this article, we will explore the concept of measuring surface roughness, its importance in various industries, and the methods used for measurement. Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured using a numerical scale. The power of r and s parameters. In today’s advanced manufacturing world,. Geometric analysis allows a visual and. Surface Roughness Visual Measurement.

From get-it-made.co.uk

Surface Roughness Explained Ra Roughness Chart Surface Roughness Visual Measurement The power of r and s parameters. We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these measurements. In this article, we will explore the concept of measuring surface roughness, its importance in various industries, and the methods used for measurement. In today’s advanced manufacturing world,. Surface roughness can be evaluated. Surface Roughness Visual Measurement.

From www.keyence.com

Roughness Measurement Examples Introduction To Roughness KEYENCE Surface Roughness Visual Measurement Geometric analysis allows a visual and subjective evaluation of roughness (a qualitative assessment), whereas computation. Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed of several machined components;. For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both surfaces at. A surface condition. Surface Roughness Visual Measurement.

From www.researchgate.net

Surface roughness (a) Surface measurement setup, (b) Surface roughness Surface Roughness Visual Measurement Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured using a numerical scale. In today’s advanced manufacturing world,. Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed of several machined components;. We will also discuss the challenges associated with measuring surface roughness and how to. Surface Roughness Visual Measurement.

From www.ansndt.com

Surface Roughness Measurement from NDT Solutions Surface Roughness Visual Measurement Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured using a numerical scale. Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed of several machined components;. We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these. Surface Roughness Visual Measurement.

From www.scribd.com

LC Surface Roughness Measurements Surface Roughness Visual Measurement A surface condition is often. Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed of several machined components;. Geometric analysis allows a visual and subjective evaluation of roughness (a qualitative assessment), whereas computation. We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of. Surface Roughness Visual Measurement.

From www.edmdept.com

3D Metrology & Surface Roughness Measurement EDMIS Surface Roughness Visual Measurement The power of r and s parameters. Geometric analysis allows a visual and subjective evaluation of roughness (a qualitative assessment), whereas computation. In today’s advanced manufacturing world,. For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both surfaces at. Surface roughness can be evaluated by visual appearances and tactile sensation and can. Surface Roughness Visual Measurement.

From www.researchgate.net

Variety of surface roughness indicators and typical calculations [16 Surface Roughness Visual Measurement Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured using a numerical scale. In this article, we will explore the concept of measuring surface roughness, its importance in various industries, and the methods used for measurement. For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both. Surface Roughness Visual Measurement.

From mavink.com

Rms Surface Roughness Chart Surface Roughness Visual Measurement Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed of several machined components;. The power of r and s parameters. Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured using a numerical scale. In this article, we will explore the concept of measuring surface roughness,. Surface Roughness Visual Measurement.

From www.youtube.com

Visual Inpection of Surface Roughness YouTube Surface Roughness Visual Measurement Surface roughness is a key parameter in many industrial devices and significantly affects the quality and equipment composed of several machined components;. For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both surfaces at. A surface condition is often. In today’s advanced manufacturing world,. The power of r and s parameters. In. Surface Roughness Visual Measurement.

From www.adcole.com

Surface Roughness Measurement & Analysis Actionable Data for High Surface Roughness Visual Measurement We report a study of the correlation between three optical methods for characterizing surface roughness: We will also discuss the challenges associated with measuring surface roughness and how to interpret the results of these measurements. Surface roughness can be evaluated by visual appearances and tactile sensation and can be measured using a numerical scale. Geometric analysis allows a visual and. Surface Roughness Visual Measurement.

From www.researchgate.net

The measurement of surface roughness Download Scientific Diagram Surface Roughness Visual Measurement For a more accurate assessment of surface roughness, a comparative microscope can be used, which allows viewing both surfaces at. In this article, we will explore the concept of measuring surface roughness, its importance in various industries, and the methods used for measurement. A surface condition is often. We will also discuss the challenges associated with measuring surface roughness and. Surface Roughness Visual Measurement.