Welding Safe Operating Procedure . Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work. Regularly inspect the welding tip and shield for damage. This safety policy and procedure provides guidelines for safely performing welding operations. Ensure machine is correctly set up for current, voltage, wire feed and gas flow. Ensure work return cables make firm. When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure the handpiece safely. Always use arc screens to protect people and objects nearby from arc rays and sparks. Ensure the welder is switched off (and fume extraction if used) 2. Check for any damage to welder and cables at the end of job. It presents provisions for training, discussion on types of welding, safe work practices,.

from manualzz.com

This safety policy and procedure provides guidelines for safely performing welding operations. Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work. Always use arc screens to protect people and objects nearby from arc rays and sparks. Ensure the welder is switched off (and fume extraction if used) 2. Check for any damage to welder and cables at the end of job. Ensure work return cables make firm. Regularly inspect the welding tip and shield for damage. Ensure machine is correctly set up for current, voltage, wire feed and gas flow. When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure the handpiece safely. It presents provisions for training, discussion on types of welding, safe work practices,.

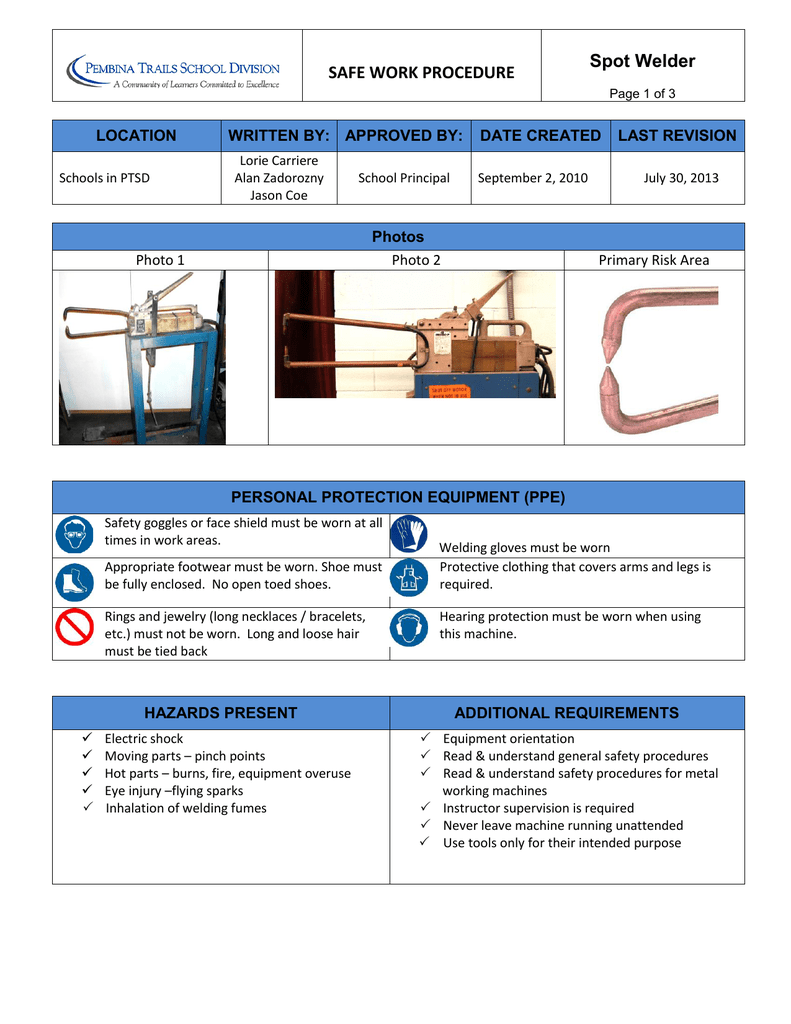

Spot Welder SAFE WORK PROCEDURE Manualzz

Welding Safe Operating Procedure This safety policy and procedure provides guidelines for safely performing welding operations. Ensure the welder is switched off (and fume extraction if used) 2. Check for any damage to welder and cables at the end of job. Ensure work return cables make firm. When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure the handpiece safely. Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work. It presents provisions for training, discussion on types of welding, safe work practices,. Ensure machine is correctly set up for current, voltage, wire feed and gas flow. Regularly inspect the welding tip and shield for damage. Always use arc screens to protect people and objects nearby from arc rays and sparks. This safety policy and procedure provides guidelines for safely performing welding operations.

From safetydocs.safetyculture.com

Welding MIG SOP SafetyDocs PDF & Word Templates Welding Safe Operating Procedure When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure the handpiece safely. Check for any damage to welder and cables at the end of job. Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work. Regularly inspect the welding tip and. Welding Safe Operating Procedure.

From weldingblos.netlify.app

Welding Machine Operating Procedure Welding Safe Operating Procedure Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work. Ensure machine is correctly set up for current, voltage, wire feed and gas flow. It presents provisions for training, discussion on types of welding, safe work practices,. This safety policy and procedure provides guidelines for safely performing welding operations. Always use arc. Welding Safe Operating Procedure.

From weldingmachinesbestbuy.blogspot.com

Welding Machine Operating Procedure Welding Safe Operating Procedure This safety policy and procedure provides guidelines for safely performing welding operations. Ensure machine is correctly set up for current, voltage, wire feed and gas flow. Ensure the welder is switched off (and fume extraction if used) 2. Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work. Ensure work return cables. Welding Safe Operating Procedure.

From www.scribd.com

Welding Machine Safety Operating Procedure PDF Welding Construction Welding Safe Operating Procedure Ensure work return cables make firm. Ensure the welder is switched off (and fume extraction if used) 2. Always use arc screens to protect people and objects nearby from arc rays and sparks. This safety policy and procedure provides guidelines for safely performing welding operations. It presents provisions for training, discussion on types of welding, safe work practices,. When welding. Welding Safe Operating Procedure.

From safetygwg.blogspot.com

Gas Welding And Cutting Safety Procedures GWG Welding Safe Operating Procedure It presents provisions for training, discussion on types of welding, safe work practices,. Always use arc screens to protect people and objects nearby from arc rays and sparks. Ensure the welder is switched off (and fume extraction if used) 2. When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure. Welding Safe Operating Procedure.

From www.scribd.com

Safe Operating Procedures SOP 19 Electric Arc Welder Small Welding Welding Safe Operating Procedure Ensure machine is correctly set up for current, voltage, wire feed and gas flow. When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure the handpiece safely. Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work. Check for any damage to. Welding Safe Operating Procedure.

From studylib.net

Safe Operating Procedures for Welding Purpose To define the safe Welding Safe Operating Procedure Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work. When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure the handpiece safely. Regularly inspect the welding tip and shield for damage. Ensure machine is correctly set up for current, voltage, wire. Welding Safe Operating Procedure.

From weldingperfection.com

Welding Safety Tips and Guide for Beginners Welding Judge Welding Safe Operating Procedure Ensure machine is correctly set up for current, voltage, wire feed and gas flow. When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure the handpiece safely. It presents provisions for training, discussion on types of welding, safe work practices,. Always use arc screens to protect people and objects nearby. Welding Safe Operating Procedure.

From doshtihome.blogspot.sg

DOSHTI WELDING AND CUTTING SAFETY PROCEDURE Welding Safe Operating Procedure It presents provisions for training, discussion on types of welding, safe work practices,. Check for any damage to welder and cables at the end of job. Ensure machine is correctly set up for current, voltage, wire feed and gas flow. When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure. Welding Safe Operating Procedure.

From www.scribd.com

Welding SOP 29 Feb 12 1 Welding Electric Heating Welding Safe Operating Procedure Ensure the welder is switched off (and fume extraction if used) 2. It presents provisions for training, discussion on types of welding, safe work practices,. Check for any damage to welder and cables at the end of job. Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work. Ensure work return cables. Welding Safe Operating Procedure.

From safetydocs.safetyculture.com

Welding SOP Instant Download Templates SafetyDocs Welding Safe Operating Procedure Ensure the welder is switched off (and fume extraction if used) 2. Check for any damage to welder and cables at the end of job. This safety policy and procedure provides guidelines for safely performing welding operations. Always use arc screens to protect people and objects nearby from arc rays and sparks. Ensure work return cables make firm. Ensure machine. Welding Safe Operating Procedure.

From studylib.net

Safe Work Procedure Template Welding Safe Operating Procedure When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure the handpiece safely. Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work. Ensure machine is correctly set up for current, voltage, wire feed and gas flow. Ensure the welder is switched. Welding Safe Operating Procedure.

From www.dexform.com

Safe work procedure oxyfuel gas welding in Word and Pdf formats Welding Safe Operating Procedure Regularly inspect the welding tip and shield for damage. When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure the handpiece safely. This safety policy and procedure provides guidelines for safely performing welding operations. It presents provisions for training, discussion on types of welding, safe work practices,. Ensure work return. Welding Safe Operating Procedure.

From www.youtube.com

Personal safety and welding safety safety first in welding PPE Welding Safe Operating Procedure It presents provisions for training, discussion on types of welding, safe work practices,. Regularly inspect the welding tip and shield for damage. This safety policy and procedure provides guidelines for safely performing welding operations. Ensure machine is correctly set up for current, voltage, wire feed and gas flow. Ensure both gas bottles are off and the welder secured with bottles. Welding Safe Operating Procedure.

From www.vrogue.co

Welding Mig Sop Safetydocs Pdf Word Templates vrogue.co Welding Safe Operating Procedure When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure the handpiece safely. Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work. Check for any damage to welder and cables at the end of job. Ensure machine is correctly set up. Welding Safe Operating Procedure.

From ehsdailyadvisor.blr.com

Infographic Welding and Cutting Safety EHS Daily Advisor Welding Safe Operating Procedure Check for any damage to welder and cables at the end of job. Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work. It presents provisions for training, discussion on types of welding, safe work practices,. Always use arc screens to protect people and objects nearby from arc rays and sparks. Ensure. Welding Safe Operating Procedure.

From safetydocs.safetyculture.com

Welding TIG SOP SafetyDocs PDF & Word Templates Welding Safe Operating Procedure Check for any damage to welder and cables at the end of job. Ensure the welder is switched off (and fume extraction if used) 2. When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure the handpiece safely. Always use arc screens to protect people and objects nearby from arc. Welding Safe Operating Procedure.

From doshtihome.blogspot.com

DOSHTI WELDING AND CUTTING SAFETY PROCEDURE Welding Safe Operating Procedure It presents provisions for training, discussion on types of welding, safe work practices,. Always use arc screens to protect people and objects nearby from arc rays and sparks. Check for any damage to welder and cables at the end of job. Ensure the welder is switched off (and fume extraction if used) 2. Regularly inspect the welding tip and shield. Welding Safe Operating Procedure.

From www.hollyfab.com

Common Welding Methods Welding Safe Operating Procedure Ensure the welder is switched off (and fume extraction if used) 2. Ensure machine is correctly set up for current, voltage, wire feed and gas flow. Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work. Always use arc screens to protect people and objects nearby from arc rays and sparks. It. Welding Safe Operating Procedure.

From studylib.net

SAFETY OPERATING PROCEDURE Welding Safe Operating Procedure Ensure the welder is switched off (and fume extraction if used) 2. It presents provisions for training, discussion on types of welding, safe work practices,. This safety policy and procedure provides guidelines for safely performing welding operations. Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work. Regularly inspect the welding tip. Welding Safe Operating Procedure.

From safewaysystems.co.uk

Welding & flamecutting Training & Safety Posters & Booklets Safeway Welding Safe Operating Procedure This safety policy and procedure provides guidelines for safely performing welding operations. Ensure the welder is switched off (and fume extraction if used) 2. It presents provisions for training, discussion on types of welding, safe work practices,. Ensure machine is correctly set up for current, voltage, wire feed and gas flow. Ensure both gas bottles are off and the welder. Welding Safe Operating Procedure.

From weldguru.com

4 Main Types of Welding Processes (with diagrams) Welding Safe Operating Procedure It presents provisions for training, discussion on types of welding, safe work practices,. Regularly inspect the welding tip and shield for damage. Ensure the welder is switched off (and fume extraction if used) 2. Check for any damage to welder and cables at the end of job. This safety policy and procedure provides guidelines for safely performing welding operations. Always. Welding Safe Operating Procedure.

From www.twi-global.com

Welding Procedure TWI Welding Safe Operating Procedure It presents provisions for training, discussion on types of welding, safe work practices,. Always use arc screens to protect people and objects nearby from arc rays and sparks. Ensure machine is correctly set up for current, voltage, wire feed and gas flow. When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine. Welding Safe Operating Procedure.

From safetydocs.safetyculture.com

Rotary Welding Machine SOP SafetyDocs PDF & Word Templates Welding Safe Operating Procedure Ensure machine is correctly set up for current, voltage, wire feed and gas flow. Regularly inspect the welding tip and shield for damage. It presents provisions for training, discussion on types of welding, safe work practices,. Always use arc screens to protect people and objects nearby from arc rays and sparks. Check for any damage to welder and cables at. Welding Safe Operating Procedure.

From studylib.net

Welding Safety Procedures Welding Safe Operating Procedure Ensure the welder is switched off (and fume extraction if used) 2. This safety policy and procedure provides guidelines for safely performing welding operations. It presents provisions for training, discussion on types of welding, safe work practices,. Check for any damage to welder and cables at the end of job. When welding is finished or interrupted, turn off the shielding. Welding Safe Operating Procedure.

From www.highspeedtraining.co.uk

Welding Hazards and Safety Precautions List of Examples Welding Safe Operating Procedure Ensure machine is correctly set up for current, voltage, wire feed and gas flow. Always use arc screens to protect people and objects nearby from arc rays and sparks. This safety policy and procedure provides guidelines for safely performing welding operations. When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and. Welding Safe Operating Procedure.

From tigweldingshadezomesan.blogspot.com

Tig Welding Shade Welding Safety Posters Welding Safe Operating Procedure Always use arc screens to protect people and objects nearby from arc rays and sparks. Ensure machine is correctly set up for current, voltage, wire feed and gas flow. It presents provisions for training, discussion on types of welding, safe work practices,. Ensure the welder is switched off (and fume extraction if used) 2. Ensure work return cables make firm.. Welding Safe Operating Procedure.

From studylib.net

Safe Work Procedure Arc Welder Welding Safe Operating Procedure This safety policy and procedure provides guidelines for safely performing welding operations. When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure the handpiece safely. Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work. Regularly inspect the welding tip and shield. Welding Safe Operating Procedure.

From fitwelding.com

Safe Operating Procedures A StepbyStep Guide for Workplace Safety Welding Safe Operating Procedure When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure the handpiece safely. Ensure work return cables make firm. It presents provisions for training, discussion on types of welding, safe work practices,. Ensure the welder is switched off (and fume extraction if used) 2. Ensure machine is correctly set up. Welding Safe Operating Procedure.

From www.lincolntech.edu

Popular Types of Welding Processes Explained Welding Safe Operating Procedure Ensure work return cables make firm. Regularly inspect the welding tip and shield for damage. Always use arc screens to protect people and objects nearby from arc rays and sparks. Ensure the welder is switched off (and fume extraction if used) 2. Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work.. Welding Safe Operating Procedure.

From sitemate.com

Welding Safe Work Method Statement Welding SWMS Welding Safe Operating Procedure It presents provisions for training, discussion on types of welding, safe work practices,. Ensure machine is correctly set up for current, voltage, wire feed and gas flow. Always use arc screens to protect people and objects nearby from arc rays and sparks. Ensure both gas bottles are off and the welder secured with bottles stored upright at completion of work.. Welding Safe Operating Procedure.

From manualzz.com

Spot Welder SAFE WORK PROCEDURE Manualzz Welding Safe Operating Procedure This safety policy and procedure provides guidelines for safely performing welding operations. Regularly inspect the welding tip and shield for damage. It presents provisions for training, discussion on types of welding, safe work practices,. Check for any damage to welder and cables at the end of job. Ensure the welder is switched off (and fume extraction if used) 2. Ensure. Welding Safe Operating Procedure.

From stock.adobe.com

Welder wearing welding mask, respirator, gloves, protective clothing Welding Safe Operating Procedure Ensure machine is correctly set up for current, voltage, wire feed and gas flow. Always use arc screens to protect people and objects nearby from arc rays and sparks. When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure the handpiece safely. Ensure both gas bottles are off and the. Welding Safe Operating Procedure.

From www.reddit.com

Welding Safety Tips. Infographics Welding Safe Operating Procedure Regularly inspect the welding tip and shield for damage. It presents provisions for training, discussion on types of welding, safe work practices,. When welding is finished or interrupted, turn off the shielding gas at the regulator, turn off the machine and secure the handpiece safely. Check for any damage to welder and cables at the end of job. This safety. Welding Safe Operating Procedure.

From studylib.net

MIG Welder Welding Safe Operating Procedure Always use arc screens to protect people and objects nearby from arc rays and sparks. Ensure machine is correctly set up for current, voltage, wire feed and gas flow. Ensure work return cables make firm. Regularly inspect the welding tip and shield for damage. Ensure the welder is switched off (and fume extraction if used) 2. When welding is finished. Welding Safe Operating Procedure.