Tool Insert Shape . Can i sharpen cnc inserts? Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Turning is a common metalworking process in which a workpiece rotates while a. Plus, all the related charts and theory! Don't worry, we've got you covered with these helpful tips and insights. Unsure about which turning insert shape to use for your cnc turning operations? Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. What are the most common cnc insert shapes? Cnc turning insert shapes and their cutting properties. How often should i replace my cnc inserts? If you decide the tooling (e.g., if you are a programmer, process planner or industrial engineer), you have to know the naming convention thoroughly, as well as the logic. When we select an insert for an operation, we select it based on these.

from mavink.com

Unsure about which turning insert shape to use for your cnc turning operations? When we select an insert for an operation, we select it based on these. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Don't worry, we've got you covered with these helpful tips and insights. If you decide the tooling (e.g., if you are a programmer, process planner or industrial engineer), you have to know the naming convention thoroughly, as well as the logic. How often should i replace my cnc inserts? Can i sharpen cnc inserts? What are the most common cnc insert shapes? Turning is a common metalworking process in which a workpiece rotates while a. Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations.

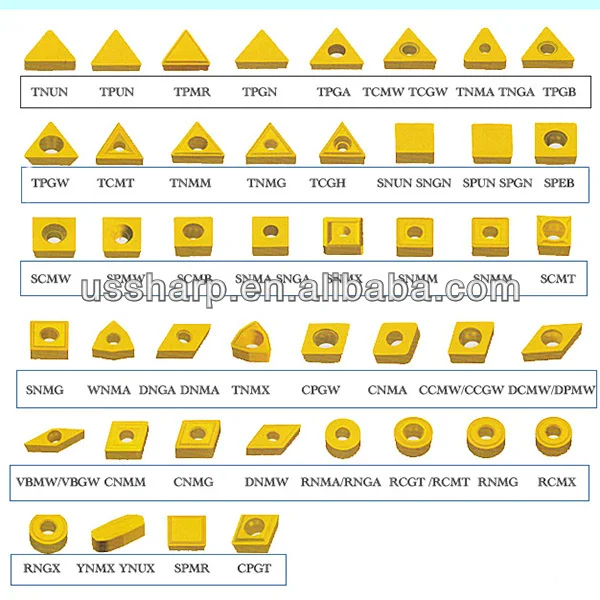

Lathe Tool Insert Chart

Tool Insert Shape How often should i replace my cnc inserts? When we select an insert for an operation, we select it based on these. If you decide the tooling (e.g., if you are a programmer, process planner or industrial engineer), you have to know the naming convention thoroughly, as well as the logic. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Don't worry, we've got you covered with these helpful tips and insights. Can i sharpen cnc inserts? Unsure about which turning insert shape to use for your cnc turning operations? Turning is a common metalworking process in which a workpiece rotates while a. Plus, all the related charts and theory! Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. How often should i replace my cnc inserts? Cnc turning insert shapes and their cutting properties. What are the most common cnc insert shapes? Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut.

From mxagumsbrs.blogspot.com

Shape Tool Install Shapes Into It S Tool Insert Shape Plus, all the related charts and theory! Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Cnc turning insert shapes and their cutting properties. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge. Tool Insert Shape.

From solutions.travers.com

Choosing The Right Insert For Aluminum Machining Tool Insert Shape Plus, all the related charts and theory! Cnc turning insert shapes and their cutting properties. If you decide the tooling (e.g., if you are a programmer, process planner or industrial engineer), you have to know the naming convention thoroughly, as well as the logic. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life.. Tool Insert Shape.

From www.shapes4free.com

Install Shapes into It’s Easy! Shapes4FREE Tool Insert Shape Cnc turning insert shapes and their cutting properties. Turning is a common metalworking process in which a workpiece rotates while a. Can i sharpen cnc inserts? Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. When we select an insert for an operation, we select it based. Tool Insert Shape.

From www.aliexpress.com

10pcs V shape VNMG160404 Carbide Inserts Processing Steel Lathe Turning Tool Insert Shape Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. What are the most common cnc insert shapes?. Tool Insert Shape.

From www.aliexpress.com

10pcs 55 Degree Diamond Shape Carbide Insert DCMT0702 YBC205 Inserts Tool Insert Shape Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. If you decide the tooling (e.g., if you are a programmer, process planner or industrial engineer), you have to know the naming convention thoroughly, as well as the logic. Cnc turning insert shapes and their cutting properties. Turning. Tool Insert Shape.

From cnc-turning-news.blogspot.com

Cnc Turning Insert Details Pdf CNC Turning News Tool Insert Shape How often should i replace my cnc inserts? If you decide the tooling (e.g., if you are a programmer, process planner or industrial engineer), you have to know the naming convention thoroughly, as well as the logic. Cnc turning insert shapes and their cutting properties. Can i sharpen cnc inserts? Understanding the material properties and machining conditions is crucial for. Tool Insert Shape.

From huanatools.com

How to choose the right carbide turning insert Huana Tools Tool Insert Shape Don't worry, we've got you covered with these helpful tips and insights. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Plus, all the related charts and theory! Can i sharpen cnc inserts? How often should i replace my cnc inserts? Unsure about which turning insert shape. Tool Insert Shape.

From www.template.net

How to Create Shapes in Adobe InDesign Tool Insert Shape Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Don't worry, we've got you covered with these helpful tips and insights. Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Turning is a common metalworking process in which a workpiece rotates while. Tool Insert Shape.

From mxagumsbrs.blogspot.com

Shape Tool Install Shapes Into It S Tool Insert Shape How often should i replace my cnc inserts? When we select an insert for an operation, we select it based on these. Unsure about which turning insert shape to use for your cnc turning operations? Plus, all the related charts and theory! Don't worry, we've got you covered with these helpful tips and insights. Can i sharpen cnc inserts? What. Tool Insert Shape.

From adrienj.tinosmarble.com

How to Insert Shapes in MS Word? Tool Insert Shape Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Plus, all the related charts and theory! Turning is a common metalworking process in which a workpiece rotates while a. How often should i. Tool Insert Shape.

From illustratorhow.com

4 Ways to Create Shapes in Adobe Illustrator (Tutorials) Tool Insert Shape Plus, all the related charts and theory! Don't worry, we've got you covered with these helpful tips and insights. Unsure about which turning insert shape to use for your cnc turning operations? Turning is a common metalworking process in which a workpiece rotates while a. Can i sharpen cnc inserts? Selecting the right turning inserts involves considering multiple factors, including. Tool Insert Shape.

From www.ukocarbide.com

How to choose a suitable corner radius for CNC turning inserts? Tool Insert Shape Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. What are the most common cnc insert shapes? Plus, all the related charts and theory! Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge. Tool Insert Shape.

From www.aliexpress.com

VNMG160404 Carbide Inserts V shape Gold Insert for Processing Steel CNC Tool Insert Shape Unsure about which turning insert shape to use for your cnc turning operations? Plus, all the related charts and theory! What are the most common cnc insert shapes? Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. When we select an insert for an operation, we select it based on these. Turning is a common. Tool Insert Shape.

From www.toollink.co.th

Toollink Co., Ltd. Shape&Size Toollink Co., Ltd. Tool Insert Shape Don't worry, we've got you covered with these helpful tips and insights. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Plus, all the related charts and theory! Turning is a common metalworking process in which a workpiece rotates while a. How often should i replace my cnc inserts? Cnc turning insert shapes. Tool Insert Shape.

From mavink.com

Lathe Tool Insert Chart Tool Insert Shape When we select an insert for an operation, we select it based on these. If you decide the tooling (e.g., if you are a programmer, process planner or industrial engineer), you have to know the naming convention thoroughly, as well as the logic. Can i sharpen cnc inserts? Plus, all the related charts and theory! Turning is a common metalworking. Tool Insert Shape.

From www.indezine.com

Insert Shapes in PowerPoint 2016 for Mac Tool Insert Shape Unsure about which turning insert shape to use for your cnc turning operations? What are the most common cnc insert shapes? Cnc turning insert shapes and their cutting properties. Can i sharpen cnc inserts? Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Don't worry, we've got. Tool Insert Shape.

From freegoogleslidestemplates.com

insertshapesgoogleslides Free Google Slides Templates Tool Insert Shape Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Cnc turning insert shapes and their cutting properties. How often should i replace my cnc inserts? Unsure about which turning insert shape to use for your cnc turning operations? Can i sharpen cnc inserts? If you decide the tooling (e.g., if you are a programmer, process. Tool Insert Shape.

From mxagumsbrs.blogspot.com

Shape Tool Install Shapes Into It S Tool Insert Shape Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. When we select an insert for an operation, we select it based on these. Unsure about which turning insert shape to use for your cnc turning operations? Turning is a common metalworking process in which a workpiece rotates while a. Don't worry, we've got. Tool Insert Shape.

From www.template.net

How to Create Shapes in Adobe InDesign Tool Insert Shape Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Turning is a common metalworking process in which a workpiece rotates while a. Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. How often should i replace my cnc inserts? Can i sharpen cnc inserts? Don't worry, we've got. Tool Insert Shape.

From www.youtube.com

Creating basic shapes in InDesign YouTube Tool Insert Shape Unsure about which turning insert shape to use for your cnc turning operations? Cnc turning insert shapes and their cutting properties. Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Don't worry, we've got you covered with these helpful tips and insights. When we select an insert for an operation, we select it based on. Tool Insert Shape.

From kuhltechnology.blogspot.com

Kuhl Educational Technology Shape Tool Adding Shapes in ActivInspire Tool Insert Shape Don't worry, we've got you covered with these helpful tips and insights. Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Unsure about which turning insert shape to use for your cnc turning. Tool Insert Shape.

From carbide.ultra-met.com

General Miscellaneous Shape Cutting Tool Inserts On UltraMet Tool Insert Shape If you decide the tooling (e.g., if you are a programmer, process planner or industrial engineer), you have to know the naming convention thoroughly, as well as the logic. Turning is a common metalworking process in which a workpiece rotates while a. Cnc turning insert shapes and their cutting properties. What are the most common cnc insert shapes? When we. Tool Insert Shape.

From www.wikihow.com

How to Insert a Shape in 9 Steps (with Pictures) Tool Insert Shape Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Unsure about which turning insert shape to use for your cnc turning operations? Turning is a common metalworking process in which a workpiece rotates while a. Cnc turning insert shapes and their cutting properties. What are the most common cnc insert shapes? Selecting the right turning. Tool Insert Shape.

From www.canadianmetalworking.com

The anatomy of a turning insert Tool Insert Shape Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Can i sharpen cnc inserts? Turning is a common metalworking process in which a workpiece rotates while a. What are the most common cnc insert shapes? Unsure about which turning insert shape to use for your cnc turning operations? If you decide the tooling (e.g., if. Tool Insert Shape.

From brmeccanicaitaly.com

Cutting tools and carbide Inserts Milling Inserts,Grooving Inserts Tool Insert Shape Cnc turning insert shapes and their cutting properties. If you decide the tooling (e.g., if you are a programmer, process planner or industrial engineer), you have to know the naming convention thoroughly, as well as the logic. Unsure about which turning insert shape to use for your cnc turning operations? Can i sharpen cnc inserts? Turning inserts are specialized cutting. Tool Insert Shape.

From www.youtube.com

Create Basic Shapes for Beginners With Coreldraw YouTube Tool Insert Shape What are the most common cnc insert shapes? If you decide the tooling (e.g., if you are a programmer, process planner or industrial engineer), you have to know the naming convention thoroughly, as well as the logic. Cnc turning insert shapes and their cutting properties. Turning is a common metalworking process in which a workpiece rotates while a. Unsure about. Tool Insert Shape.

From www.simplesheets.co

How To Insert Shapes In Excel in 6 Simple Steps Tool Insert Shape Cnc turning insert shapes and their cutting properties. Turning is a common metalworking process in which a workpiece rotates while a. If you decide the tooling (e.g., if you are a programmer, process planner or industrial engineer), you have to know the naming convention thoroughly, as well as the logic. What are the most common cnc insert shapes? Understanding the. Tool Insert Shape.

From www.carbidedepot.com

Insert Shape Selection Tool Insert Shape Turning inserts are specialized cutting tools used in machining processes, specifically in turning operations. Turning is a common metalworking process in which a workpiece rotates while a. When we select an insert for an operation, we select it based on these. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Don't worry, we've. Tool Insert Shape.

From www.lctcarbide.com

How to choose right turning insert in CNC machining? Tool Insert Shape Unsure about which turning insert shape to use for your cnc turning operations? Turning is a common metalworking process in which a workpiece rotates while a. Plus, all the related charts and theory! What are the most common cnc insert shapes? Cnc turning insert shapes and their cutting properties. Understanding the material properties and machining conditions is crucial for optimizing. Tool Insert Shape.

From huanatools.com

Positive Angle Inserts VS Negative Angle Inserts Huana Tools Tool Insert Shape Turning is a common metalworking process in which a workpiece rotates while a. Can i sharpen cnc inserts? Unsure about which turning insert shape to use for your cnc turning operations? If you decide the tooling (e.g., if you are a programmer, process planner or industrial engineer), you have to know the naming convention thoroughly, as well as the logic.. Tool Insert Shape.

From www.youtube.com

Word 2016 Tutorial Inserting Shapes Microsoft Training YouTube Tool Insert Shape Plus, all the related charts and theory! Cnc turning insert shapes and their cutting properties. Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Turning is a common metalworking process in which a workpiece rotates while a. What are the most common cnc insert shapes? Can i sharpen cnc inserts? Turning inserts are. Tool Insert Shape.

From www.zyjcarbide.com

Solid Carbide Inserts Shapes for Steel and Stainless Steel Tool Insert Shape How often should i replace my cnc inserts? Turning is a common metalworking process in which a workpiece rotates while a. If you decide the tooling (e.g., if you are a programmer, process planner or industrial engineer), you have to know the naming convention thoroughly, as well as the logic. Cnc turning insert shapes and their cutting properties. Selecting the. Tool Insert Shape.

From www.researchgate.net

Shapes of cutting inserts used in turning Download Scientific Diagram Tool Insert Shape Cnc turning insert shapes and their cutting properties. When we select an insert for an operation, we select it based on these. Turning is a common metalworking process in which a workpiece rotates while a. Unsure about which turning insert shape to use for your cnc turning operations? Can i sharpen cnc inserts? Selecting the right turning inserts involves considering. Tool Insert Shape.

From www.wodenco.com

How to Select the Right Carbide Inserts The Ultimate Guide Wodenco Tool Insert Shape Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Plus, all the related charts and theory! Understanding the material properties and machining conditions is crucial for optimizing performance and extending tool life. Unsure about which turning insert shape to use for your cnc turning operations? How often. Tool Insert Shape.

From excel-pratique.com

Excel Course Inserting Objects (shapes) Tool Insert Shape Selecting the right turning inserts involves considering multiple factors, including insert shape, grade, cutting edge length, nose radius, and depth of cut. Plus, all the related charts and theory! Turning is a common metalworking process in which a workpiece rotates while a. How often should i replace my cnc inserts? When we select an insert for an operation, we select. Tool Insert Shape.