How To Make Kiln Cement . It involves high temperatures, controlled environments,. Clinkerization through the kiln is a complex and essential step in cement production. The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound. The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. Blending in higher ratios of limestone or scms can reduce a plant’s carbon footprint by up to 10%. Do you want to learn how to make cement. You can easily make brick kilns once you’ve determined the needed dimensions. Well keep on reading and you can learn the easy steps to making your own concrete. The basic dry process system consists of the kiln and a suspension preheater.

from www.slideserve.com

The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound. Blending in higher ratios of limestone or scms can reduce a plant’s carbon footprint by up to 10%. The basic dry process system consists of the kiln and a suspension preheater. It involves high temperatures, controlled environments,. You can easily make brick kilns once you’ve determined the needed dimensions. Clinkerization through the kiln is a complex and essential step in cement production. Do you want to learn how to make cement. Well keep on reading and you can learn the easy steps to making your own concrete.

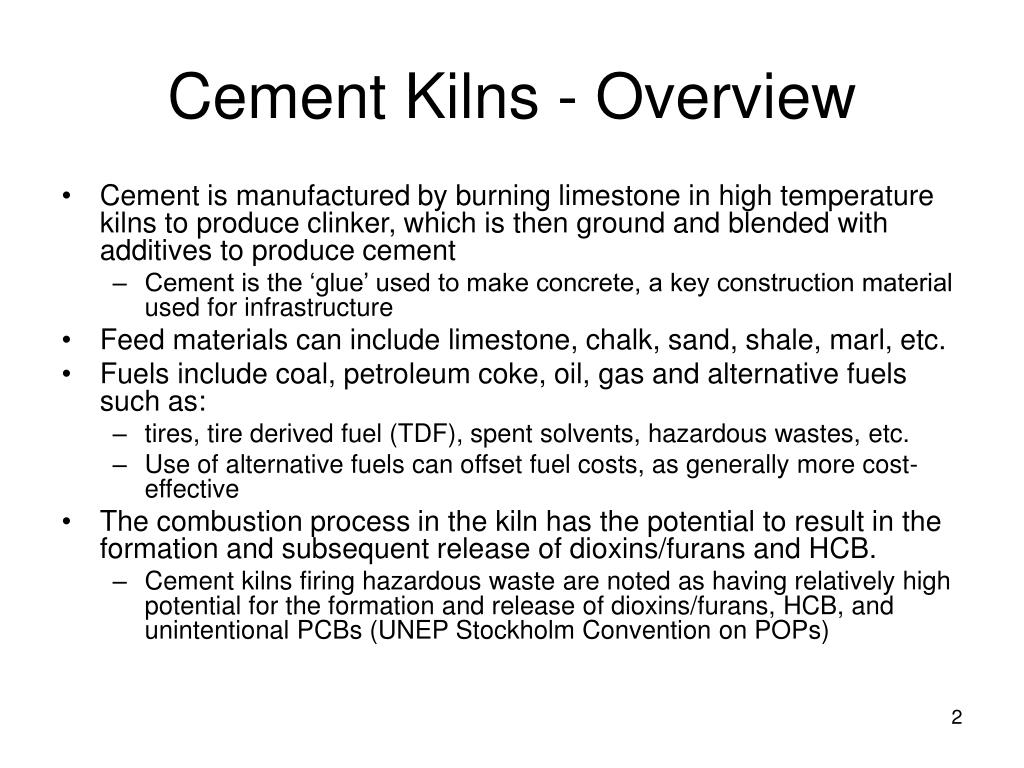

PPT Cement Kilns Overview PowerPoint Presentation, free download

How To Make Kiln Cement Clinkerization through the kiln is a complex and essential step in cement production. The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. The basic dry process system consists of the kiln and a suspension preheater. Clinkerization through the kiln is a complex and essential step in cement production. Do you want to learn how to make cement. The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound. It involves high temperatures, controlled environments,. Well keep on reading and you can learn the easy steps to making your own concrete. Blending in higher ratios of limestone or scms can reduce a plant’s carbon footprint by up to 10%. You can easily make brick kilns once you’ve determined the needed dimensions.

From ar.inspiredpencil.com

Lime Kiln Process Temperature How To Make Kiln Cement The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. Blending in higher ratios of limestone or scms can reduce a plant’s carbon footprint by up to 10%. It involves high temperatures, controlled environments,. Well keep on reading and you can learn the easy steps to making your own concrete. Clinkerization through the. How To Make Kiln Cement.

From sephakucement.co.za

The beating heart of the cement manufacturing process the kiln How To Make Kiln Cement The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound. Do you want to learn how to make cement. Clinkerization through the kiln is a complex and essential step in cement production. Blending in higher ratios of limestone or scms can reduce a plant’s carbon footprint by. How To Make Kiln Cement.

From www.cementkilns.co.uk

Cement Kilns Wet and semiwet process kilns How To Make Kiln Cement You can easily make brick kilns once you’ve determined the needed dimensions. Well keep on reading and you can learn the easy steps to making your own concrete. The basic dry process system consists of the kiln and a suspension preheater. Clinkerization through the kiln is a complex and essential step in cement production. The clinker keeps cooling and a. How To Make Kiln Cement.

From sockthanks29.pythonanywhere.com

How To Build A Kiln For Ceramics Sockthanks29 How To Make Kiln Cement The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound. Blending in higher ratios of limestone or scms can reduce a plant’s carbon footprint by up to 10%. Do you want to learn how to make cement. It involves high temperatures, controlled environments,. You can easily make. How To Make Kiln Cement.

From www.cementequipment.org

Rings Formation in the Cement kiln by Thamer HA M'tr INFINITY FOR How To Make Kiln Cement Blending in higher ratios of limestone or scms can reduce a plant’s carbon footprint by up to 10%. It involves high temperatures, controlled environments,. Well keep on reading and you can learn the easy steps to making your own concrete. You can easily make brick kilns once you’ve determined the needed dimensions. The raw materials, limestone and shale for example,. How To Make Kiln Cement.

From www.cementkilns.co.uk

Cement Kilns Southam How To Make Kiln Cement The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. You can easily make brick kilns once you’ve determined the needed dimensions. The basic dry process system consists of the kiln and a suspension preheater. Do you want to learn how to make cement. It involves high temperatures, controlled environments,. Clinkerization through the. How To Make Kiln Cement.

From ancientpottery.how

Make a Primitive Kiln at Home Easy to Follow Instructions with Photos How To Make Kiln Cement Blending in higher ratios of limestone or scms can reduce a plant’s carbon footprint by up to 10%. The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. Well keep on reading and you can learn the easy steps to making your own concrete. Do you want to learn how to make cement.. How To Make Kiln Cement.

From www.youtube.com

Cement manufacturing Process How to make OPC & PPC Cement by Kiln Dry How To Make Kiln Cement Clinkerization through the kiln is a complex and essential step in cement production. Well keep on reading and you can learn the easy steps to making your own concrete. The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. The clinker keeps cooling and a ball mill grinds it with gypsum or other. How To Make Kiln Cement.

From www.rotarykilnfactory.com

Cement Kiln Is Our Hot Sales And The Rotary Cement Kiln's Price Is Very How To Make Kiln Cement The basic dry process system consists of the kiln and a suspension preheater. Do you want to learn how to make cement. Well keep on reading and you can learn the easy steps to making your own concrete. You can easily make brick kilns once you’ve determined the needed dimensions. The clinker keeps cooling and a ball mill grinds it. How To Make Kiln Cement.

From www.cementplantequipment.com

Shaft Kiln Vertical Shaft Kiln Vertical Kiln AGICO Kiln In Cement How To Make Kiln Cement The basic dry process system consists of the kiln and a suspension preheater. You can easily make brick kilns once you’ve determined the needed dimensions. The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound. It involves high temperatures, controlled environments,. Blending in higher ratios of limestone. How To Make Kiln Cement.

From www.cementkilns.co.uk

Cement Kilns Early rotary kilns How To Make Kiln Cement Do you want to learn how to make cement. You can easily make brick kilns once you’ve determined the needed dimensions. Well keep on reading and you can learn the easy steps to making your own concrete. The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound.. How To Make Kiln Cement.

From www.researchgate.net

Components of a cement kiln form the type precalciner and its special How To Make Kiln Cement Well keep on reading and you can learn the easy steps to making your own concrete. The basic dry process system consists of the kiln and a suspension preheater. The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. The clinker keeps cooling and a ball mill grinds it with gypsum or other. How To Make Kiln Cement.

From www.cementkilns.co.uk

Cement Kilns Early kilns How To Make Kiln Cement Blending in higher ratios of limestone or scms can reduce a plant’s carbon footprint by up to 10%. The basic dry process system consists of the kiln and a suspension preheater. The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. Do you want to learn how to make cement. You can easily. How To Make Kiln Cement.

From www.researchgate.net

Schematic of the cement kiln with integrated CaL process. Download How To Make Kiln Cement The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. Do you want to learn how to make cement. It involves high temperatures, controlled environments,. Blending in higher ratios of limestone or scms can reduce a plant’s carbon footprint by up to 10%. You can easily make brick kilns once you’ve determined the. How To Make Kiln Cement.

From www.slideserve.com

PPT Cement Kilns Overview PowerPoint Presentation, free download How To Make Kiln Cement Well keep on reading and you can learn the easy steps to making your own concrete. The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound. You can easily make brick kilns once you’ve determined the needed dimensions. Blending in higher ratios of limestone or scms can. How To Make Kiln Cement.

From wikiwaste.org.uk

Cement Kilns WikiWaste How To Make Kiln Cement Clinkerization through the kiln is a complex and essential step in cement production. The basic dry process system consists of the kiln and a suspension preheater. It involves high temperatures, controlled environments,. The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. Do you want to learn how to make cement. The clinker. How To Make Kiln Cement.

From www.youtube.com

Rotary Kiln Working Principles And Function In Cement Production. YouTube How To Make Kiln Cement Blending in higher ratios of limestone or scms can reduce a plant’s carbon footprint by up to 10%. The basic dry process system consists of the kiln and a suspension preheater. It involves high temperatures, controlled environments,. The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound.. How To Make Kiln Cement.

From www.slideserve.com

PPT Tips to help you make your rotary kiln cement plant cost How To Make Kiln Cement The basic dry process system consists of the kiln and a suspension preheater. The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound. Well keep on reading and you can. How To Make Kiln Cement.

From www.youtube.com

Rotary cement Kiln refractories installation refractory bricks How To Make Kiln Cement You can easily make brick kilns once you’ve determined the needed dimensions. Well keep on reading and you can learn the easy steps to making your own concrete. The basic dry process system consists of the kiln and a suspension preheater. The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. It involves. How To Make Kiln Cement.

From www.jcadg.com

Cement Just Got A Makeover Arch Blog JCA Design Group How To Make Kiln Cement Well keep on reading and you can learn the easy steps to making your own concrete. The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound. The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. The basic dry process. How To Make Kiln Cement.

From www.youtube.com

Kiln Light Up Complete Process 👍 Cement Industry 👍Technical Information How To Make Kiln Cement The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound. Clinkerization through the kiln is a complex and essential step in cement production. Do you want to learn how to make cement. The basic dry process system consists of the kiln and a suspension preheater. The raw. How To Make Kiln Cement.

From www.alibaba.com

Portland Cement Manufacturing Plant/rotary Kiln For Production Project How To Make Kiln Cement The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound. It involves high temperatures, controlled environments,. Well keep on reading and you can learn the easy steps to making your own concrete. Do you want to learn how to make cement. You can easily make brick kilns. How To Make Kiln Cement.

From www.youtube.com

Kiln Main Burner Types Used In Cement Plants (Kiln System)_ English How To Make Kiln Cement Do you want to learn how to make cement. The basic dry process system consists of the kiln and a suspension preheater. It involves high temperatures, controlled environments,. The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound. The raw materials, limestone and shale for example, are. How To Make Kiln Cement.

From www.cementplantequipment.com

Cement Rotary Kiln Rotary Kiln Rotary Kiln Manufacturers AGICO How To Make Kiln Cement The basic dry process system consists of the kiln and a suspension preheater. Blending in higher ratios of limestone or scms can reduce a plant’s carbon footprint by up to 10%. The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound. Clinkerization through the kiln is a. How To Make Kiln Cement.

From www.cementequipment.org

Cement Kiln Process Chemistry Combustion INFINITY FOR CEMENT EQUIPMENT How To Make Kiln Cement You can easily make brick kilns once you’ve determined the needed dimensions. Blending in higher ratios of limestone or scms can reduce a plant’s carbon footprint by up to 10%. It involves high temperatures, controlled environments,. Clinkerization through the kiln is a complex and essential step in cement production. The clinker keeps cooling and a ball mill grinds it with. How To Make Kiln Cement.

From www.rotarykilnfactory.com

Provide 0.5mm Tolerance Cement Rotary Kiln For Cement Factories How To Make Kiln Cement It involves high temperatures, controlled environments,. The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound. The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. Do you want to learn how to make cement. You can easily make brick. How To Make Kiln Cement.

From www.youtube.com

How To Operate Main Burner For Kiln Cement From The Begining_ English How To Make Kiln Cement Clinkerization through the kiln is a complex and essential step in cement production. It involves high temperatures, controlled environments,. The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. The basic dry process system consists of the kiln and a suspension preheater. The clinker keeps cooling and a ball mill grinds it with. How To Make Kiln Cement.

From www.aluminabricks.com

How to prolong rotary cement kiln coating life ? RS Kiln Refractory How To Make Kiln Cement It involves high temperatures, controlled environments,. Do you want to learn how to make cement. The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. Blending in higher ratios of limestone or scms can reduce a plant’s carbon footprint by up to 10%. You can easily make brick kilns once you’ve determined the. How To Make Kiln Cement.

From civilengineersforum.com

How To Make Cement Step by Step Guide How To Make Kiln Cement Clinkerization through the kiln is a complex and essential step in cement production. The basic dry process system consists of the kiln and a suspension preheater. Blending in higher ratios of limestone or scms can reduce a plant’s carbon footprint by up to 10%. Do you want to learn how to make cement. Well keep on reading and you can. How To Make Kiln Cement.

From rotarykilnsupplier.com

Cement Rotary Kiln Rotary Kiln Supplier Capacity 10010000tpd How To Make Kiln Cement The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. Do you want to learn how to make cement. You can easily make brick kilns once you’ve determined the needed dimensions. Clinkerization through the kiln is a complex and essential step in cement production. Well keep on reading and you can learn the. How To Make Kiln Cement.

From www.hxjqcrushers.com

Cement Rotary KilnCircumgyrate Cement KilnCement Making Machinery How To Make Kiln Cement Well keep on reading and you can learn the easy steps to making your own concrete. Do you want to learn how to make cement. The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about 150 billion grains per pound. The basic dry process system consists of the kiln and a suspension. How To Make Kiln Cement.

From www.cementequipment.org

Cement Production Process from A to Z INFINITY FOR CEMENT EQUIPMENT How To Make Kiln Cement The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. Well keep on reading and you can learn the easy steps to making your own concrete. It involves high temperatures, controlled environments,. The basic dry process system consists of the kiln and a suspension preheater. Clinkerization through the kiln is a complex and. How To Make Kiln Cement.

From www.machine-crusher.com

Rotary Kiln How To Make Kiln Cement Do you want to learn how to make cement. Well keep on reading and you can learn the easy steps to making your own concrete. The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. Clinkerization through the kiln is a complex and essential step in cement production. The clinker keeps cooling and. How To Make Kiln Cement.

From www.rotarykilnfactory.com

Cement Kiln Is Our Hot Sales And The Rotary Cement Kiln's Price Is Very How To Make Kiln Cement Clinkerization through the kiln is a complex and essential step in cement production. The basic dry process system consists of the kiln and a suspension preheater. Well keep on reading and you can learn the easy steps to making your own concrete. The clinker keeps cooling and a ball mill grinds it with gypsum or other ingredients into fine cement—about. How To Make Kiln Cement.

From www.youtube.com

How to make a kiln part 2 YouTube How To Make Kiln Cement The raw materials, limestone and shale for example, are ground finely and blended to produce the raw. Well keep on reading and you can learn the easy steps to making your own concrete. Blending in higher ratios of limestone or scms can reduce a plant’s carbon footprint by up to 10%. Clinkerization through the kiln is a complex and essential. How To Make Kiln Cement.