Welding Current Too Low . Welding defects such as porosity, blowholes, undercut weld cracking, incomplete, fusion, slag inclusion, incomplete penetration, spatter. If the welding current is too low,. The current setting in welding is very important because it determines the amount of heat that is generated. Welding current can affect the heat input, the metal transfer mode, and the weld penetration. When voltage is set low you will start getting excessive reinforcement in the weld. While many variables can influence a weld's quality, including the type and thickness of the base material, the four primary factors affecting it are welding current, welding. It is directly correlated to wire feed speed (wfs): If the current is too high, it can cause problems such as burn. Reinforcement doesn’t add strength to the weld and may result in increased costs due to additional filler metal required as well as additional labor to make the weld. The current setting is too high. Using wrong polarity that did not match the used. Welding amperage refers to the amount and speed of electricity flowing in a circuit, which affects the heat available to melt the welding wire and the base material. Welding arc is loud and spatters excessively. The speed and volume of filler metal going into the weld.

from www.mig-welding.co.uk

If the current is too high, it can cause problems such as burn. When voltage is set low you will start getting excessive reinforcement in the weld. Reinforcement doesn’t add strength to the weld and may result in increased costs due to additional filler metal required as well as additional labor to make the weld. Welding current can affect the heat input, the metal transfer mode, and the weld penetration. Welding amperage refers to the amount and speed of electricity flowing in a circuit, which affects the heat available to melt the welding wire and the base material. The speed and volume of filler metal going into the weld. The current setting is too high. Welding arc is loud and spatters excessively. It is directly correlated to wire feed speed (wfs): Using wrong polarity that did not match the used.

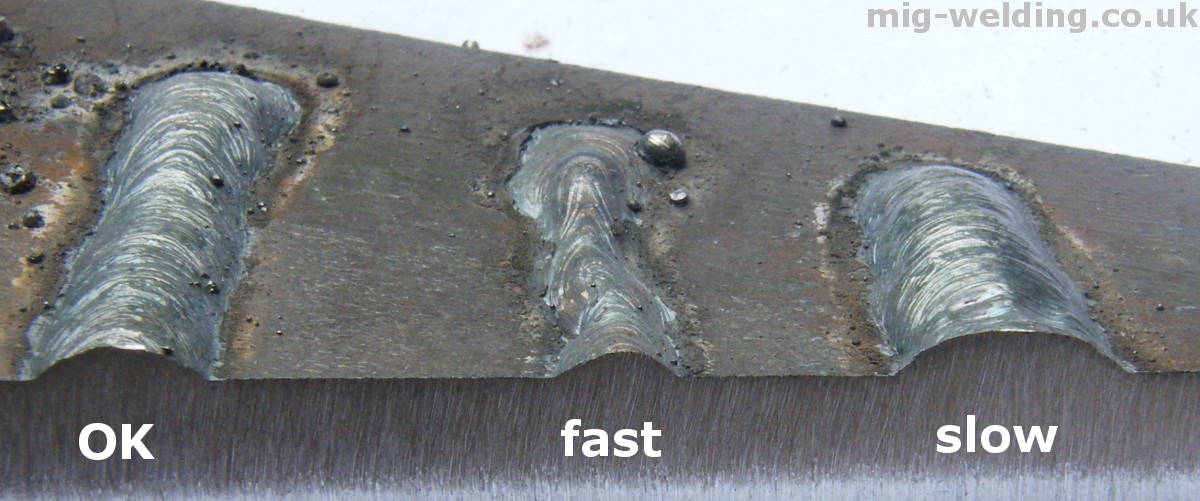

Arc Welding Faults Examples of Speed, Arc Length, and Current Problems

Welding Current Too Low The current setting is too high. It is directly correlated to wire feed speed (wfs): If the welding current is too low,. Welding current can affect the heat input, the metal transfer mode, and the weld penetration. While many variables can influence a weld's quality, including the type and thickness of the base material, the four primary factors affecting it are welding current, welding. The current setting in welding is very important because it determines the amount of heat that is generated. When voltage is set low you will start getting excessive reinforcement in the weld. If the current is too high, it can cause problems such as burn. Using wrong polarity that did not match the used. Welding amperage refers to the amount and speed of electricity flowing in a circuit, which affects the heat available to melt the welding wire and the base material. Reinforcement doesn’t add strength to the weld and may result in increased costs due to additional filler metal required as well as additional labor to make the weld. Welding defects such as porosity, blowholes, undercut weld cracking, incomplete, fusion, slag inclusion, incomplete penetration, spatter. Welding arc is loud and spatters excessively. The current setting is too high. The speed and volume of filler metal going into the weld.

From www.cushyfamily.com

How To Measure Welding Current? (Finally Explained!) Welding Current Too Low Reinforcement doesn’t add strength to the weld and may result in increased costs due to additional filler metal required as well as additional labor to make the weld. The current setting in welding is very important because it determines the amount of heat that is generated. Welding defects such as porosity, blowholes, undercut weld cracking, incomplete, fusion, slag inclusion, incomplete. Welding Current Too Low.

From www.slideshare.net

Welding Inspection Cswip Welding Current Too Low Reinforcement doesn’t add strength to the weld and may result in increased costs due to additional filler metal required as well as additional labor to make the weld. The speed and volume of filler metal going into the weld. The current setting is too high. If the welding current is too low,. Welding defects such as porosity, blowholes, undercut weld. Welding Current Too Low.

From technoweld.com.au

The Most Common Welding Defects Causes and Remedies Technoweld Welding Current Too Low If the welding current is too low,. The current setting is too high. Welding current can affect the heat input, the metal transfer mode, and the weld penetration. Welding arc is loud and spatters excessively. While many variables can influence a weld's quality, including the type and thickness of the base material, the four primary factors affecting it are welding. Welding Current Too Low.

From studylib.net

welding defects Welding Current Too Low The current setting in welding is very important because it determines the amount of heat that is generated. Welding current can affect the heat input, the metal transfer mode, and the weld penetration. Welding defects such as porosity, blowholes, undercut weld cracking, incomplete, fusion, slag inclusion, incomplete penetration, spatter. While many variables can influence a weld's quality, including the type. Welding Current Too Low.

From weldingtorchapes.com

Welding process parameters of CO2 gas shielded welding 2/3 APES Welding Current Too Low If the welding current is too low,. Reinforcement doesn’t add strength to the weld and may result in increased costs due to additional filler metal required as well as additional labor to make the weld. It is directly correlated to wire feed speed (wfs): Welding amperage refers to the amount and speed of electricity flowing in a circuit, which affects. Welding Current Too Low.

From www.slideshare.net

Welding Inspection Cswip Welding Current Too Low Welding defects such as porosity, blowholes, undercut weld cracking, incomplete, fusion, slag inclusion, incomplete penetration, spatter. The speed and volume of filler metal going into the weld. It is directly correlated to wire feed speed (wfs): Using wrong polarity that did not match the used. While many variables can influence a weld's quality, including the type and thickness of the. Welding Current Too Low.

From weldingofwelders.com

Undercut in Welding Welding of Welders Welding Current Too Low While many variables can influence a weld's quality, including the type and thickness of the base material, the four primary factors affecting it are welding current, welding. Welding arc is loud and spatters excessively. Welding current can affect the heat input, the metal transfer mode, and the weld penetration. If the welding current is too low,. If the current is. Welding Current Too Low.

From weldersmanual.com

Welding Undercut What Is It? And How to Avoid It! Welders Manual Welding Current Too Low Welding amperage refers to the amount and speed of electricity flowing in a circuit, which affects the heat available to melt the welding wire and the base material. The current setting in welding is very important because it determines the amount of heat that is generated. When voltage is set low you will start getting excessive reinforcement in the weld.. Welding Current Too Low.

From www.mig-welding.co.uk

Arc Welding Faults Examples of Speed, Arc Length, and Current Problems Welding Current Too Low Reinforcement doesn’t add strength to the weld and may result in increased costs due to additional filler metal required as well as additional labor to make the weld. Welding arc is loud and spatters excessively. Welding amperage refers to the amount and speed of electricity flowing in a circuit, which affects the heat available to melt the welding wire and. Welding Current Too Low.

From technoweld.com.au

The Most Common Welding Defects Causes and Remedies Technoweld Welding Current Too Low Welding arc is loud and spatters excessively. Welding defects such as porosity, blowholes, undercut weld cracking, incomplete, fusion, slag inclusion, incomplete penetration, spatter. Reinforcement doesn’t add strength to the weld and may result in increased costs due to additional filler metal required as well as additional labor to make the weld. Welding amperage refers to the amount and speed of. Welding Current Too Low.

From www.mig-welding.co.uk

Arc Welding Faults Examples of Speed, Arc Length, and Current Problems Welding Current Too Low Welding arc is loud and spatters excessively. If the current is too high, it can cause problems such as burn. Using wrong polarity that did not match the used. The current setting in welding is very important because it determines the amount of heat that is generated. The speed and volume of filler metal going into the weld. If the. Welding Current Too Low.

From technoweld.com.au

The Most Common Welding Defects Causes and Remedies Welding Current Too Low It is directly correlated to wire feed speed (wfs): The current setting in welding is very important because it determines the amount of heat that is generated. Welding amperage refers to the amount and speed of electricity flowing in a circuit, which affects the heat available to melt the welding wire and the base material. Welding arc is loud and. Welding Current Too Low.

From welderchoice.com

What are Types of Welding Defects? Causes, and Remedies Welding Current Too Low Reinforcement doesn’t add strength to the weld and may result in increased costs due to additional filler metal required as well as additional labor to make the weld. The current setting is too high. It is directly correlated to wire feed speed (wfs): Welding arc is loud and spatters excessively. If the current is too high, it can cause problems. Welding Current Too Low.

From www.howtoresistanceweld.info

Design HowTo Resistance Weld Welding Current Too Low The current setting is too high. While many variables can influence a weld's quality, including the type and thickness of the base material, the four primary factors affecting it are welding current, welding. Welding defects such as porosity, blowholes, undercut weld cracking, incomplete, fusion, slag inclusion, incomplete penetration, spatter. Reinforcement doesn’t add strength to the weld and may result in. Welding Current Too Low.

From toolvee.com

4 Common Welding Defects Causes And Solutions Too! 2024 Welding Current Too Low If the welding current is too low,. Welding amperage refers to the amount and speed of electricity flowing in a circuit, which affects the heat available to melt the welding wire and the base material. The current setting in welding is very important because it determines the amount of heat that is generated. Using wrong polarity that did not match. Welding Current Too Low.

From leniran.blogspot.com

Welding Defect Welding Current Too Low Welding amperage refers to the amount and speed of electricity flowing in a circuit, which affects the heat available to melt the welding wire and the base material. Welding current can affect the heat input, the metal transfer mode, and the weld penetration. The current setting is too high. While many variables can influence a weld's quality, including the type. Welding Current Too Low.

From www.theweldingmaster.com

What is Welding Defects Types, Causes and Remedies? The Welding Master Welding Current Too Low The current setting in welding is very important because it determines the amount of heat that is generated. It is directly correlated to wire feed speed (wfs): Welding amperage refers to the amount and speed of electricity flowing in a circuit, which affects the heat available to melt the welding wire and the base material. Welding current can affect the. Welding Current Too Low.

From www.slideserve.com

PPT Mig Welding PowerPoint Presentation, free download ID5756487 Welding Current Too Low Welding defects such as porosity, blowholes, undercut weld cracking, incomplete, fusion, slag inclusion, incomplete penetration, spatter. Using wrong polarity that did not match the used. Reinforcement doesn’t add strength to the weld and may result in increased costs due to additional filler metal required as well as additional labor to make the weld. While many variables can influence a weld's. Welding Current Too Low.

From www.polysoude.com

Weldingwithpulsedcurrent Polysoude Welding Current Too Low Welding arc is loud and spatters excessively. Using wrong polarity that did not match the used. The current setting is too high. The current setting in welding is very important because it determines the amount of heat that is generated. While many variables can influence a weld's quality, including the type and thickness of the base material, the four primary. Welding Current Too Low.

From www.jhotpotinfo.com

Different Types of Welding Defects Causes and Remedies JhotpotInfo Welding Current Too Low When voltage is set low you will start getting excessive reinforcement in the weld. While many variables can influence a weld's quality, including the type and thickness of the base material, the four primary factors affecting it are welding current, welding. Welding amperage refers to the amount and speed of electricity flowing in a circuit, which affects the heat available. Welding Current Too Low.

From www.mig-welding.co.uk

Arc Welding Faults Examples of Speed, Arc Length, and Current Problems Welding Current Too Low The current setting in welding is very important because it determines the amount of heat that is generated. Welding defects such as porosity, blowholes, undercut weld cracking, incomplete, fusion, slag inclusion, incomplete penetration, spatter. The speed and volume of filler metal going into the weld. Reinforcement doesn’t add strength to the weld and may result in increased costs due to. Welding Current Too Low.

From www.youtube.com

EFFECTS OF WELDING CURRENT & VELOCITY IN GAS METAL ARC WELDING FOR NI Welding Current Too Low The current setting in welding is very important because it determines the amount of heat that is generated. The current setting is too high. Welding current can affect the heat input, the metal transfer mode, and the weld penetration. If the welding current is too low,. The speed and volume of filler metal going into the weld. When voltage is. Welding Current Too Low.

From www.tws.edu

Understanding Welding Current and Polarity Tulsa Welding School Welding Current Too Low Welding amperage refers to the amount and speed of electricity flowing in a circuit, which affects the heat available to melt the welding wire and the base material. The speed and volume of filler metal going into the weld. The current setting in welding is very important because it determines the amount of heat that is generated. Welding defects such. Welding Current Too Low.

From www.researchgate.net

b) Simulation for welding current increment (Welding current and Welding Current Too Low Using wrong polarity that did not match the used. The speed and volume of filler metal going into the weld. It is directly correlated to wire feed speed (wfs): If the current is too high, it can cause problems such as burn. While many variables can influence a weld's quality, including the type and thickness of the base material, the. Welding Current Too Low.

From blog.thepipingmart.com

What Does Resistance Welding Mean? ThePipingMart Blog Welding Current Too Low The current setting in welding is very important because it determines the amount of heat that is generated. Welding arc is loud and spatters excessively. Using wrong polarity that did not match the used. Welding current can affect the heat input, the metal transfer mode, and the weld penetration. The current setting is too high. If the welding current is. Welding Current Too Low.

From www.mig-welding.co.uk

Arc Welding Faults Examples of Speed, Arc Length, and Current Problems Welding Current Too Low The current setting in welding is very important because it determines the amount of heat that is generated. It is directly correlated to wire feed speed (wfs): Using wrong polarity that did not match the used. If the welding current is too low,. Welding arc is loud and spatters excessively. When voltage is set low you will start getting excessive. Welding Current Too Low.

From electricalindustry.ca

Stray Welding Current Damage Electrical Industry News Week Welding Current Too Low If the welding current is too low,. When voltage is set low you will start getting excessive reinforcement in the weld. Welding arc is loud and spatters excessively. Reinforcement doesn’t add strength to the weld and may result in increased costs due to additional filler metal required as well as additional labor to make the weld. Welding amperage refers to. Welding Current Too Low.

From www.machinemfg.com

Selecting Welding Voltage and Current Tips MachineMFG Welding Current Too Low When voltage is set low you will start getting excessive reinforcement in the weld. Reinforcement doesn’t add strength to the weld and may result in increased costs due to additional filler metal required as well as additional labor to make the weld. The current setting in welding is very important because it determines the amount of heat that is generated.. Welding Current Too Low.

From www.slideserve.com

PPT Module 3 Domestic Heating/MMA Welding Unit 5 Manual Arc Welding Welding Current Too Low Welding defects such as porosity, blowholes, undercut weld cracking, incomplete, fusion, slag inclusion, incomplete penetration, spatter. Welding amperage refers to the amount and speed of electricity flowing in a circuit, which affects the heat available to melt the welding wire and the base material. If the welding current is too low,. It is directly correlated to wire feed speed (wfs):. Welding Current Too Low.

From mewelding.com

Arc Welding With Constant Voltage Welding Current Too Low Welding defects such as porosity, blowholes, undercut weld cracking, incomplete, fusion, slag inclusion, incomplete penetration, spatter. The speed and volume of filler metal going into the weld. Reinforcement doesn’t add strength to the weld and may result in increased costs due to additional filler metal required as well as additional labor to make the weld. Welding amperage refers to the. Welding Current Too Low.

From www.youtube.com

Flux Core Welding The Basics You Need to know YouTube Welding Current Too Low Welding amperage refers to the amount and speed of electricity flowing in a circuit, which affects the heat available to melt the welding wire and the base material. The current setting in welding is very important because it determines the amount of heat that is generated. It is directly correlated to wire feed speed (wfs): While many variables can influence. Welding Current Too Low.

From weldguru.com

MIG Welder Settings Explained (with Chart) Weld Guru Welding Current Too Low When voltage is set low you will start getting excessive reinforcement in the weld. Welding current can affect the heat input, the metal transfer mode, and the weld penetration. If the current is too high, it can cause problems such as burn. Welding defects such as porosity, blowholes, undercut weld cracking, incomplete, fusion, slag inclusion, incomplete penetration, spatter. If the. Welding Current Too Low.

From technoweld.com.au

The Most Common Welding Defects Causes and Remedies Welding Current Too Low Welding current can affect the heat input, the metal transfer mode, and the weld penetration. Welding arc is loud and spatters excessively. While many variables can influence a weld's quality, including the type and thickness of the base material, the four primary factors affecting it are welding current, welding. Welding defects such as porosity, blowholes, undercut weld cracking, incomplete, fusion,. Welding Current Too Low.

From rickyswelding.com

What Are Some Common Welding Mistakes And How To Avoid Them? Ricky's Welding Current Too Low The current setting in welding is very important because it determines the amount of heat that is generated. If the current is too high, it can cause problems such as burn. It is directly correlated to wire feed speed (wfs): While many variables can influence a weld's quality, including the type and thickness of the base material, the four primary. Welding Current Too Low.

From weldguru.com

Spot Welding Explained What is It? And How Does it Work? Welding Current Too Low Welding current can affect the heat input, the metal transfer mode, and the weld penetration. Using wrong polarity that did not match the used. Reinforcement doesn’t add strength to the weld and may result in increased costs due to additional filler metal required as well as additional labor to make the weld. The speed and volume of filler metal going. Welding Current Too Low.