Internal Gear Tooth Thickness . As such, the measurement for an internal gear is. If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness at top is thinner. Involute gears can be manufactured easily, and the gearing has a. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. In order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine what the nominal tooth thickness should be. For power transmission gears, the tooth form most commonly used today is the involute profile. This calculator ensures the tooth thickness on your spur gear or helical gear is the right size using pins commonly found in your machine shop or easily ordered online. For internal gears, the tooth profile is opposite to that of the external spur gear.

from sensefas.weebly.com

If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness at top is thinner. Involute gears can be manufactured easily, and the gearing has a. For internal gears, the tooth profile is opposite to that of the external spur gear. As such, the measurement for an internal gear is. For power transmission gears, the tooth form most commonly used today is the involute profile. In order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine what the nominal tooth thickness should be. This calculator ensures the tooth thickness on your spur gear or helical gear is the right size using pins commonly found in your machine shop or easily ordered online. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and.

Gear tooth geometry calculator sensefas

Internal Gear Tooth Thickness In order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine what the nominal tooth thickness should be. For power transmission gears, the tooth form most commonly used today is the involute profile. In order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine what the nominal tooth thickness should be. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness at top is thinner. For internal gears, the tooth profile is opposite to that of the external spur gear. As such, the measurement for an internal gear is. This calculator ensures the tooth thickness on your spur gear or helical gear is the right size using pins commonly found in your machine shop or easily ordered online. Involute gears can be manufactured easily, and the gearing has a.

From www.martinsengineering.com

Gear Formula Information » Martins Corrugator Engineering Internal Gear Tooth Thickness In order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine what the nominal tooth thickness should be. For internal gears, the tooth profile is opposite to that of the external spur gear. If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness. Internal Gear Tooth Thickness.

From www.engineersedge.com

Gear Tooth Contact Stress Number Equation and Calculator Internal Gear Tooth Thickness This calculator ensures the tooth thickness on your spur gear or helical gear is the right size using pins commonly found in your machine shop or easily ordered online. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Involute gears can be manufactured easily, and the gearing has. Internal Gear Tooth Thickness.

From khkgears.net

Tooth Thickness KHK Gears Internal Gear Tooth Thickness If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness at top is thinner. This calculator ensures the tooth thickness on your spur gear or helical gear is the right size using pins commonly found in your machine shop or easily ordered online. In order to determine the tooth size of a gear. Internal Gear Tooth Thickness.

From www.groschopp.com

Gear Terminology, Knowing your teeth Groschopp Blog Internal Gear Tooth Thickness If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness at top is thinner. This calculator ensures the tooth thickness on your spur gear or helical gear is the right size using pins commonly found in your machine shop or easily ordered online. In the previous pages, we introduced the basics of gears,. Internal Gear Tooth Thickness.

From www.scribd.com

Inspection and Measurement of Tooth Thickness Gear Scientific Internal Gear Tooth Thickness For power transmission gears, the tooth form most commonly used today is the involute profile. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. For internal gears, the tooth profile is opposite to that of the external spur gear. In order to determine the tooth size of a. Internal Gear Tooth Thickness.

From slidetodoc.com

Gear tooth thickness Measurement by Constant Chord Method Internal Gear Tooth Thickness If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness at top is thinner. For power transmission gears, the tooth form most commonly used today is the involute profile. This calculator ensures the tooth thickness on your spur gear or helical gear is the right size using pins commonly found in your machine. Internal Gear Tooth Thickness.

From khkgears.net

Tooth Thickness KHK Gears Internal Gear Tooth Thickness This calculator ensures the tooth thickness on your spur gear or helical gear is the right size using pins commonly found in your machine shop or easily ordered online. For power transmission gears, the tooth form most commonly used today is the involute profile. For internal gears, the tooth profile is opposite to that of the external spur gear. In. Internal Gear Tooth Thickness.

From khkgears.net

Tooth Thickness KHK Gears Internal Gear Tooth Thickness As such, the measurement for an internal gear is. Involute gears can be manufactured easily, and the gearing has a. If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness at top is thinner. For power transmission gears, the tooth form most commonly used today is the involute profile. In order to determine. Internal Gear Tooth Thickness.

From slidetodoc.com

Gear tooth thickness Measurement by Constant Chord Method Internal Gear Tooth Thickness Involute gears can be manufactured easily, and the gearing has a. If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness at top is thinner. For internal gears, the tooth profile is opposite to that of the external spur gear. As such, the measurement for an internal gear is. For power transmission gears,. Internal Gear Tooth Thickness.

From slidetodoc.com

Gear tooth thickness Measurement by Constant Chord Method Internal Gear Tooth Thickness In order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine what the nominal tooth thickness should be. For internal gears, the tooth profile is opposite to that of the external spur gear. Involute gears can be manufactured easily, and the gearing has a. This calculator ensures the tooth thickness. Internal Gear Tooth Thickness.

From www.geartechnology.com

The Basics of Gear Theory Gear Technology Magazine Internal Gear Tooth Thickness This calculator ensures the tooth thickness on your spur gear or helical gear is the right size using pins commonly found in your machine shop or easily ordered online. As such, the measurement for an internal gear is. In order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine what. Internal Gear Tooth Thickness.

From www.pinterest.com

Gear tooth geometry. metal working Pinterest Teeth, CNC and Internal Gear Tooth Thickness If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness at top is thinner. As such, the measurement for an internal gear is. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. This calculator ensures the tooth thickness on your spur. Internal Gear Tooth Thickness.

From www.slideshare.net

Gear thread Internal Gear Tooth Thickness As such, the measurement for an internal gear is. Involute gears can be manufactured easily, and the gearing has a. For internal gears, the tooth profile is opposite to that of the external spur gear. In order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine what the nominal tooth. Internal Gear Tooth Thickness.

From khkgears.net

Tooth Thickness KHK Gears Internal Gear Tooth Thickness This calculator ensures the tooth thickness on your spur gear or helical gear is the right size using pins commonly found in your machine shop or easily ordered online. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. As such, the measurement for an internal gear is. For. Internal Gear Tooth Thickness.

From khkgears.net

Tooth Thickness KHK Gears Internal Gear Tooth Thickness For power transmission gears, the tooth form most commonly used today is the involute profile. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness at top is thinner. This calculator ensures. Internal Gear Tooth Thickness.

From slidetodoc.com

Gear tooth thickness Measurement by Constant Chord Method Internal Gear Tooth Thickness As such, the measurement for an internal gear is. If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness at top is thinner. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. In order to determine the tooth size of a. Internal Gear Tooth Thickness.

From www.scribd.com

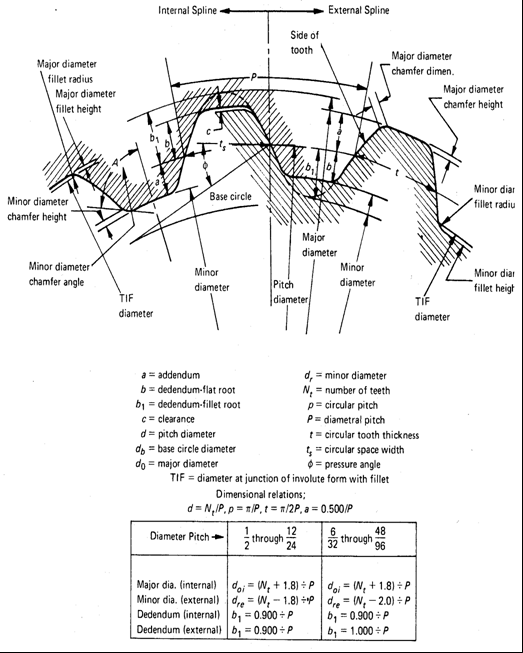

Internal and External Spline Teeth _ Gears _ Internal and External Internal Gear Tooth Thickness In order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine what the nominal tooth thickness should be. This calculator ensures the tooth thickness on your spur gear or helical gear is the right size using pins commonly found in your machine shop or easily ordered online. For power transmission. Internal Gear Tooth Thickness.

From www.slideserve.com

PPT Nomenclature of Spur Gear Teeth PowerPoint Presentation, free Internal Gear Tooth Thickness For power transmission gears, the tooth form most commonly used today is the involute profile. In order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine what the nominal tooth thickness should be. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth'. Internal Gear Tooth Thickness.

From www.scribd.com

Tooth Thickness Gear Mechanical Engineering Internal Gear Tooth Thickness For power transmission gears, the tooth form most commonly used today is the involute profile. For internal gears, the tooth profile is opposite to that of the external spur gear. Involute gears can be manufactured easily, and the gearing has a. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth. Internal Gear Tooth Thickness.

From mechanicstips.blogspot.com

Terminology of Gear Tooth MechanicsTips Internal Gear Tooth Thickness If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness at top is thinner. This calculator ensures the tooth thickness on your spur gear or helical gear is the right size using pins commonly found in your machine shop or easily ordered online. For power transmission gears, the tooth form most commonly used. Internal Gear Tooth Thickness.

From www.slideserve.com

PPT Nomenclature of Spur Gear Teeth PowerPoint Presentation, free Internal Gear Tooth Thickness In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness at top is thinner. In order to determine the tooth size of a gear after taking into account the backlash allowance, you. Internal Gear Tooth Thickness.

From www.zhygear.com

Calculation principle of chord tooth thickness and chord tooth height Internal Gear Tooth Thickness This calculator ensures the tooth thickness on your spur gear or helical gear is the right size using pins commonly found in your machine shop or easily ordered online. For internal gears, the tooth profile is opposite to that of the external spur gear. Involute gears can be manufactured easily, and the gearing has a. In the previous pages, we. Internal Gear Tooth Thickness.

From sensefas.weebly.com

Gear tooth geometry calculator sensefas Internal Gear Tooth Thickness As such, the measurement for an internal gear is. For power transmission gears, the tooth form most commonly used today is the involute profile. This calculator ensures the tooth thickness on your spur gear or helical gear is the right size using pins commonly found in your machine shop or easily ordered online. In order to determine the tooth size. Internal Gear Tooth Thickness.

From electricalworkbook.com

What is Gear Tooth Vernier Caliper? Working Principle, Construction Internal Gear Tooth Thickness For power transmission gears, the tooth form most commonly used today is the involute profile. For internal gears, the tooth profile is opposite to that of the external spur gear. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. If a positive correction is applied, such as to. Internal Gear Tooth Thickness.

From www.slideserve.com

PPT CGT 110 S 2013 PowerPoint Presentation, free download ID2122865 Internal Gear Tooth Thickness As such, the measurement for an internal gear is. In order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine what the nominal tooth thickness should be. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. This calculator. Internal Gear Tooth Thickness.

From www.youtube.com

L19 Gear Terminology Gear Tooth Thickness Measurement YouTube Internal Gear Tooth Thickness For power transmission gears, the tooth form most commonly used today is the involute profile. For internal gears, the tooth profile is opposite to that of the external spur gear. As such, the measurement for an internal gear is. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and.. Internal Gear Tooth Thickness.

From www.youtube.com

Gear Tooth Vernier Caliper Working Gear Tooth Thickness Measurement Internal Gear Tooth Thickness As such, the measurement for an internal gear is. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. In order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine what the nominal tooth thickness should be. For internal. Internal Gear Tooth Thickness.

From fractory.com

Types of Gears Gear Parameters & Tooth Profiles Fractory Internal Gear Tooth Thickness For power transmission gears, the tooth form most commonly used today is the involute profile. In order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine what the nominal tooth thickness should be. If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness. Internal Gear Tooth Thickness.

From khkgears.net

Tooth Thickness KHK Internal Gear Tooth Thickness Involute gears can be manufactured easily, and the gearing has a. In order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine what the nominal tooth thickness should be. As such, the measurement for an internal gear is. For power transmission gears, the tooth form most commonly used today is. Internal Gear Tooth Thickness.

From slidetodoc.com

Gear tooth thickness Measurement by Constant Chord Method Internal Gear Tooth Thickness Involute gears can be manufactured easily, and the gearing has a. As such, the measurement for an internal gear is. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. For internal gears, the tooth profile is opposite to that of the external spur gear. For power transmission gears,. Internal Gear Tooth Thickness.

From www.tec-science.com

Profile shift of involute gears tecscience Internal Gear Tooth Thickness For internal gears, the tooth profile is opposite to that of the external spur gear. Involute gears can be manufactured easily, and the gearing has a. In order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine what the nominal tooth thickness should be. This calculator ensures the tooth thickness. Internal Gear Tooth Thickness.

From khkgears.net

Tooth Thickness KHK Gears Internal Gear Tooth Thickness In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. If a positive correction is applied, such as to prevent undercut in a pinion, the tooth thickness at top is thinner. As such, the measurement for an internal gear is. For internal gears, the tooth profile is opposite to. Internal Gear Tooth Thickness.

From khkgears.net

Tooth Thickness KHK Gears Internal Gear Tooth Thickness As such, the measurement for an internal gear is. For power transmission gears, the tooth form most commonly used today is the involute profile. For internal gears, the tooth profile is opposite to that of the external spur gear. In order to determine the tooth size of a gear after taking into account the backlash allowance, you first must determine. Internal Gear Tooth Thickness.

From www.slideshare.net

Gear thread Internal Gear Tooth Thickness As such, the measurement for an internal gear is. For internal gears, the tooth profile is opposite to that of the external spur gear. This calculator ensures the tooth thickness on your spur gear or helical gear is the right size using pins commonly found in your machine shop or easily ordered online. For power transmission gears, the tooth form. Internal Gear Tooth Thickness.

From www.chegg.com

Solved Figure below shows the details of a spurgear teeth Internal Gear Tooth Thickness This calculator ensures the tooth thickness on your spur gear or helical gear is the right size using pins commonly found in your machine shop or easily ordered online. For power transmission gears, the tooth form most commonly used today is the involute profile. If a positive correction is applied, such as to prevent undercut in a pinion, the tooth. Internal Gear Tooth Thickness.