Laboratory Equipment Calibration And Validation . Equipment validation is a documented process demonstrating whether a piece of equipment, system, or process consistently produces results within predefined. Difference between calibration and verification. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. In short, there are three steps: The metrology laboratory follows this procedure to ensure that all laboratory methods selected, modified, or developed for. Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. Equipment calibration deals with assessing the accuracy of the equipment’s.

from www.usalab.com

It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. The metrology laboratory follows this procedure to ensure that all laboratory methods selected, modified, or developed for. Equipment calibration deals with assessing the accuracy of the equipment’s. In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. Equipment validation is a documented process demonstrating whether a piece of equipment, system, or process consistently produces results within predefined. Difference between calibration and verification. In short, there are three steps:

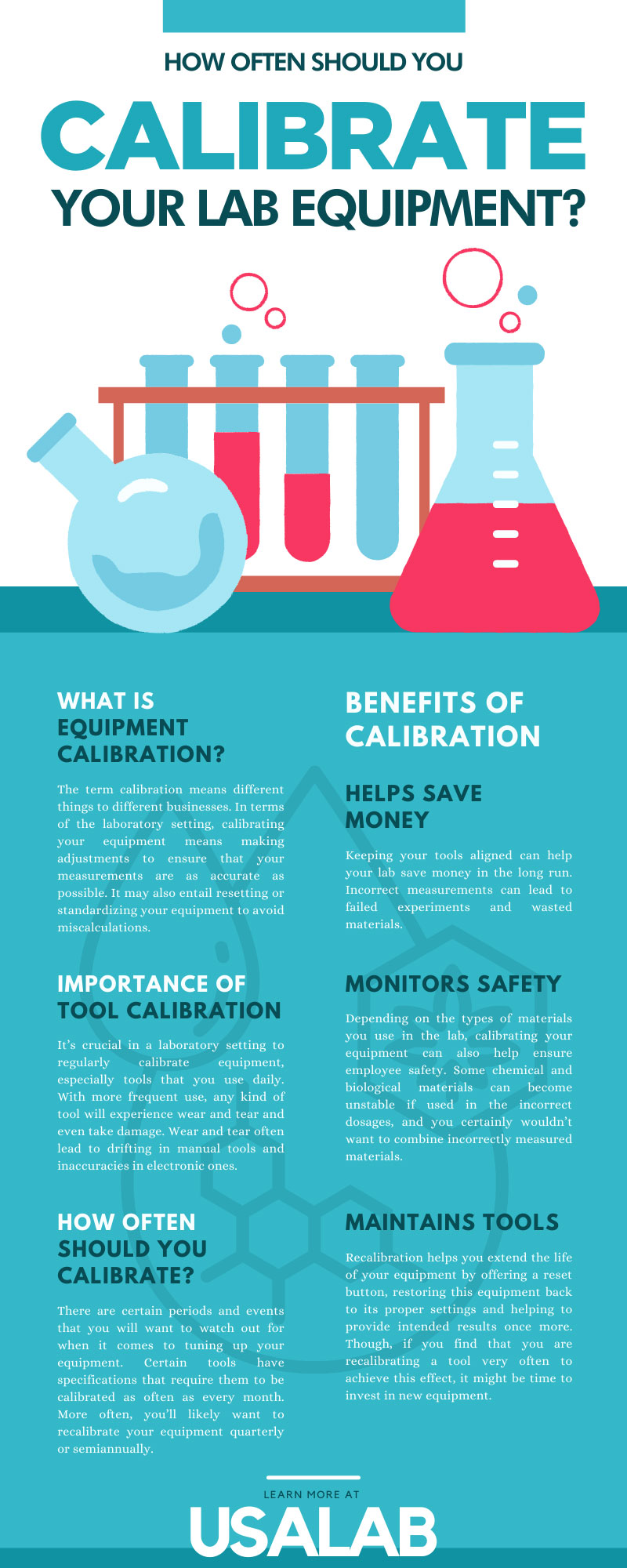

How Often Should You Calibrate Your Lab Equipment? USA Lab

Laboratory Equipment Calibration And Validation Equipment calibration deals with assessing the accuracy of the equipment’s. Equipment calibration deals with assessing the accuracy of the equipment’s. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Equipment validation is a documented process demonstrating whether a piece of equipment, system, or process consistently produces results within predefined. Difference between calibration and verification. The metrology laboratory follows this procedure to ensure that all laboratory methods selected, modified, or developed for. In short, there are three steps: Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be.

From www.mescalibration.com

Medical Engineering Service Calibration Laboratory Equipment Calibration And Validation In short, there are three steps: Equipment calibration deals with assessing the accuracy of the equipment’s. Difference between calibration and verification. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. The metrology laboratory follows this procedure to ensure that all laboratory methods selected, modified, or developed for. Equipment validation. Laboratory Equipment Calibration And Validation.

From www.studypool.com

SOLUTION Who guidelines for calibration and validation of equipments Laboratory Equipment Calibration And Validation Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. In short, there are three steps: Equipment calibration deals with assessing the accuracy of the equipment’s. In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment. Laboratory Equipment Calibration And Validation.

From www.testo.ru

Calibration, test equipment management, qualification & validation Laboratory Equipment Calibration And Validation In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. Equipment validation is a documented process demonstrating whether a piece of equipment, system, or process consistently produces results within predefined. Calibration as a first step produces measurement results,. Laboratory Equipment Calibration And Validation.

From www.sensoscientific.com

Measure for Measure What is Calibration and Why Is It Important for Laboratory Equipment Calibration And Validation Equipment calibration deals with assessing the accuracy of the equipment’s. Equipment validation is a documented process demonstrating whether a piece of equipment, system, or process consistently produces results within predefined. In short, there are three steps: Difference between calibration and verification. In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying. Laboratory Equipment Calibration And Validation.

From www.pharmaexcipients.com

5 Advantages of Calibrating Your Equipment At An Accredited Lab Laboratory Equipment Calibration And Validation In short, there are three steps: Equipment calibration deals with assessing the accuracy of the equipment’s. In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. Equipment validation is a documented process demonstrating whether a piece of equipment,. Laboratory Equipment Calibration And Validation.

From www.studypool.com

SOLUTION Who guidelines for calibration and validation of equipments Laboratory Equipment Calibration And Validation In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. The metrology laboratory follows this procedure to ensure that all laboratory methods selected, modified, or developed for. It's an essential step for every type of laboratory, whether its. Laboratory Equipment Calibration And Validation.

From flagshipinc.com

Lab Equipment Calibration and Validation Lab Support Service Laboratory Equipment Calibration And Validation Equipment validation is a documented process demonstrating whether a piece of equipment, system, or process consistently produces results within predefined. In short, there are three steps: In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. Calibration as. Laboratory Equipment Calibration And Validation.

From learngxp.com

Defining Calibration & Qualification of Equipment LearnGxP Laboratory Equipment Calibration And Validation In short, there are three steps: The metrology laboratory follows this procedure to ensure that all laboratory methods selected, modified, or developed for. In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. Equipment validation is a documented. Laboratory Equipment Calibration And Validation.

From www.itm.com

Qualified Calibrations ISO Certification and Repairs Laboratory Equipment Calibration And Validation Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. The metrology laboratory follows this procedure to ensure that all laboratory methods selected, modified, or developed for. Difference between calibration and verification. In short, there are three steps: Equipment validation is a documented process demonstrating whether a piece of. Laboratory Equipment Calibration And Validation.

From sicweb.com

SELECTING A QUALITY CALIBRATION LABORATORY Laboratory Equipment Calibration And Validation Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. Difference between calibration and verification. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. The metrology laboratory follows this procedure to ensure that all laboratory methods selected, modified,. Laboratory Equipment Calibration And Validation.

From pac-service.com

Lab Calibration Services Process Automation & Control Inc. Laboratory Equipment Calibration And Validation Equipment calibration deals with assessing the accuracy of the equipment’s. In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. Equipment validation is a documented process demonstrating whether a piece of equipment, system, or process consistently produces results. Laboratory Equipment Calibration And Validation.

From evolveltd.eu

How often should you calibrate lab equipment? Laboratory Equipment Calibration And Validation The metrology laboratory follows this procedure to ensure that all laboratory methods selected, modified, or developed for. In short, there are three steps: In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. Calibration as a first step. Laboratory Equipment Calibration And Validation.

From pdfslide.net

(PDF) CALIBRATION AND VALIDATION OF EQUIPMENTS Laboratory Equipment Calibration And Validation In short, there are three steps: Equipment calibration deals with assessing the accuracy of the equipment’s. The metrology laboratory follows this procedure to ensure that all laboratory methods selected, modified, or developed for. Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. In short, validation (or iq, oq,. Laboratory Equipment Calibration And Validation.

From biotechserv.weebly.com

Principles of Lab Equipment Calibration You Should Know Laboratory Equipment Calibration And Validation Difference between calibration and verification. Equipment calibration deals with assessing the accuracy of the equipment’s. Equipment validation is a documented process demonstrating whether a piece of equipment, system, or process consistently produces results within predefined. Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. It's an essential step. Laboratory Equipment Calibration And Validation.

From www.ahlborn.com

Comprehensive calibration service for your measurement technology English Laboratory Equipment Calibration And Validation Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. Difference between calibration and verification. Equipment validation is a documented process demonstrating whether a piece of equipment, system, or process consistently produces results within predefined. Equipment calibration deals with assessing the accuracy of the equipment’s. In short, there are. Laboratory Equipment Calibration And Validation.

From yorlab.co.uk

Calibration & Validation Yorlab Laboratory Equipment Calibration And Validation In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. Equipment validation is a documented process demonstrating whether a piece of equipment, system, or process consistently produces results within predefined. It's an essential step for every type of. Laboratory Equipment Calibration And Validation.

From www.michelli.com

Calibration Equipment Test Instruments & NIST Certified Test Weights Laboratory Equipment Calibration And Validation The metrology laboratory follows this procedure to ensure that all laboratory methods selected, modified, or developed for. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. Equipment calibration. Laboratory Equipment Calibration And Validation.

From analysisdoo.com

Calibration and validation Analysis Laboratory Equipment Calibration And Validation Equipment validation is a documented process demonstrating whether a piece of equipment, system, or process consistently produces results within predefined. The metrology laboratory follows this procedure to ensure that all laboratory methods selected, modified, or developed for. In short, there are three steps: It's an essential step for every type of laboratory, whether its focus is research and development, quality. Laboratory Equipment Calibration And Validation.

From www.slideserve.com

PPT Module 3 Use, calibration and maintenance of laboratory equipment Laboratory Equipment Calibration And Validation Difference between calibration and verification. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Equipment calibration deals with assessing the accuracy of the equipment’s. Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. In short, there are. Laboratory Equipment Calibration And Validation.

From mpl.loesungsfabrik.de

Calibration, qualification and validation in the lab what's that? Laboratory Equipment Calibration And Validation Difference between calibration and verification. In short, there are three steps: Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. In short, validation (or iq, oq, pq as. Laboratory Equipment Calibration And Validation.

From www.quality-assurance-solutions.com

Tool Calibration and Control System Laboratory Equipment Calibration And Validation Equipment calibration deals with assessing the accuracy of the equipment’s. In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. The metrology laboratory follows this procedure to ensure that all laboratory methods selected, modified, or developed for. In. Laboratory Equipment Calibration And Validation.

From www.indiamart.com

Laboratory Equipment Validation Calibration Service at Rs 150 in Laboratory Equipment Calibration And Validation In short, there are three steps: In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Calibration as. Laboratory Equipment Calibration And Validation.

From www.pharmaceuticalsky.com

Differences between Calibration, Verification and Validation Laboratory Equipment Calibration And Validation In short, there are three steps: In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. Difference. Laboratory Equipment Calibration And Validation.

From www.centralcarolinascale.com

Internal vs. External Calibration What to Know Laboratory Equipment Calibration And Validation Equipment validation is a documented process demonstrating whether a piece of equipment, system, or process consistently produces results within predefined. Difference between calibration and verification. The metrology laboratory follows this procedure to ensure that all laboratory methods selected, modified, or developed for. Calibration as a first step produces measurement results, verification as a second step confirms results are within defined. Laboratory Equipment Calibration And Validation.

From www.usalab.com

How Often Should You Calibrate Your Lab Equipment? USA Lab Laboratory Equipment Calibration And Validation Difference between calibration and verification. In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Equipment calibration deals. Laboratory Equipment Calibration And Validation.

From www.linkedin.com

Laboratory Equipment Calibration Understanding Its Importance Laboratory Equipment Calibration And Validation The metrology laboratory follows this procedure to ensure that all laboratory methods selected, modified, or developed for. In short, there are three steps: Equipment validation is a documented process demonstrating whether a piece of equipment, system, or process consistently produces results within predefined. Calibration as a first step produces measurement results, verification as a second step confirms results are within. Laboratory Equipment Calibration And Validation.

From www.researchgate.net

(PDF) ICH and WHO Guideline for validation and calibration Laboratory Equipment Calibration And Validation Difference between calibration and verification. In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. Equipment calibration deals with assessing the accuracy of the equipment’s. Equipment validation is a documented process demonstrating whether a piece of equipment, system,. Laboratory Equipment Calibration And Validation.

From www.slideserve.com

PPT GEOGG142 GMES Calibration & validation of EO products PowerPoint Laboratory Equipment Calibration And Validation Difference between calibration and verification. Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. Equipment validation. Laboratory Equipment Calibration And Validation.

From solution4labs.com

Why is calibration important? Laboratory Equipment Calibration And Validation Equipment validation is a documented process demonstrating whether a piece of equipment, system, or process consistently produces results within predefined. In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. It's an essential step for every type of. Laboratory Equipment Calibration And Validation.

From labtestsguide.blogspot.com

Calibration Lab Tests Guide Laboratory Equipment Calibration And Validation Difference between calibration and verification. Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. Equipment calibration deals with assessing the accuracy of the equipment’s. In short, there are three steps: In short, validation (or iq, oq, pq as it is also known as) is the systematic study of. Laboratory Equipment Calibration And Validation.

From www.labcompare.com

The Hows & Whys of Calibration Verification Testing for Chemistry Laboratory Equipment Calibration And Validation Equipment validation is a documented process demonstrating whether a piece of equipment, system, or process consistently produces results within predefined. It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. Difference between calibration and verification. In short, there are three steps: The metrology laboratory follows this procedure to ensure that. Laboratory Equipment Calibration And Validation.

From ccmsscientific.com

Lab Equipment Calibration New York, NY Lab Equipment Certification Laboratory Equipment Calibration And Validation In short, there are three steps: Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. The. Laboratory Equipment Calibration And Validation.

From www.cisa.net

The importance of calibration in laboratory equipment CISA Cedaceria Laboratory Equipment Calibration And Validation It's an essential step for every type of laboratory, whether its focus is research and development, quality control, or testing. In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. Equipment calibration deals with assessing the accuracy of. Laboratory Equipment Calibration And Validation.

From www.calibrationlaboratory.in

NABL Calibration for Instruments in Pharmaceutical Industry Laboratory Equipment Calibration And Validation Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. Difference between calibration and verification. The metrology laboratory follows this procedure to ensure that all laboratory methods selected, modified, or developed for. Equipment calibration deals with assessing the accuracy of the equipment’s. Equipment validation is a documented process demonstrating. Laboratory Equipment Calibration And Validation.

From pharmdguru.com

3. VALIDATION METHODS QUALITY OF EQUIPMENT, VALIDATION OF EQUIPMENT Laboratory Equipment Calibration And Validation Calibration as a first step produces measurement results, verification as a second step confirms results are within defined limits, and validation. In short, validation (or iq, oq, pq as it is also known as) is the systematic study of verifying whether the laboratory equipment is properly installed and working as it should be. Equipment validation is a documented process demonstrating. Laboratory Equipment Calibration And Validation.