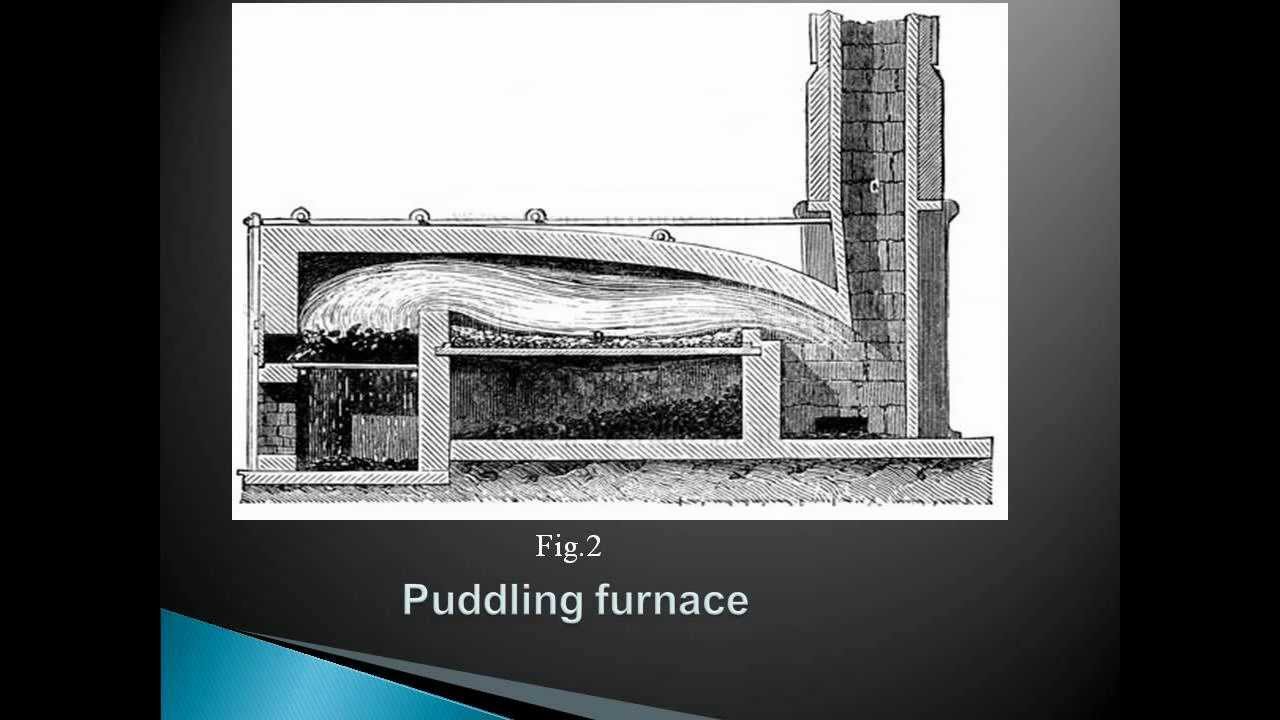

Puddling Industrial Revolution Definition . The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was a period of global. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. Unlike in the finery the iron was not. Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the molten. Puddling was the first successful process for making malleable iron from pig iron without using charcoal.

from www.youtube.com

Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. Puddling was the first successful process for making malleable iron from pig iron without using charcoal. Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was a period of global. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. Unlike in the finery the iron was not. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the molten. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed.

Production Of Wrought Iron In Puddling Furnace YouTube

Puddling Industrial Revolution Definition Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. Unlike in the finery the iron was not. Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. Puddling was the first successful process for making malleable iron from pig iron without using charcoal. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the molten. The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was a period of global.

From www.revolutionaryplayers.org.uk

The PuddlingFurnace Revolutionary Players Puddling Industrial Revolution Definition Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. The industrial revolution, sometimes divided into the first industrial revolution and second industrial. Puddling Industrial Revolution Definition.

From gamesmartz.com

Industrial Revolution Definition & Image GameSmartz Puddling Industrial Revolution Definition This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. Unlike in the finery the iron was not. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the molten. Puddled iron,. Puddling Industrial Revolution Definition.

From www.alamy.com

Puddling furnace hires stock photography and images Alamy Puddling Industrial Revolution Definition Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was a period of global. Unlike in the finery the iron was not. Puddled iron, a landmark innovation of the industrial. Puddling Industrial Revolution Definition.

From slideplayer.com

Industrial Revolution Urbanization Simulation ppt download Puddling Industrial Revolution Definition Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. Puddling was the first successful process for making malleable iron from pig iron without using charcoal. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation. Puddling Industrial Revolution Definition.

From smallworkshop.co.uk

Wrought Iron Puddling Industrial Revolution Definition Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. The puddling process is a method used to convert pig iron into wrought. Puddling Industrial Revolution Definition.

From www.culturenlmuseums.co.uk

Puddlers, Shinglers & Rollers the Story of Malleable Iron CultureNL Puddling Industrial Revolution Definition The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was a period of global. Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. Unlike in the finery the iron was not. The puddling process is a method used to convert pig iron into wrought iron by. Puddling Industrial Revolution Definition.

From www.slideserve.com

PPT The Industrial Revolution PowerPoint Presentation, free download Puddling Industrial Revolution Definition Puddling was the first successful process for making malleable iron from pig iron without using charcoal. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process. Puddling Industrial Revolution Definition.

From workingtheflame.com

Interesting Facts About Sheet Metal (History, Science, & Industry Puddling Industrial Revolution Definition Puddling was the first successful process for making malleable iron from pig iron without using charcoal. Unlike in the finery the iron was not. The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was a period of global. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent. Puddling Industrial Revolution Definition.

From www.culturenlmuseums.co.uk

Puddlers, Shinglers & Rollers the Story of Malleable Iron CultureNL Puddling Industrial Revolution Definition The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was a period of global. Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to. Puddling Industrial Revolution Definition.

From quizlet.com

Industrial RevolutionStandard 1 Review Diagram Quizlet Puddling Industrial Revolution Definition Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and. Puddling Industrial Revolution Definition.

From www.culturenlmuseums.co.uk

Puddlers, Shinglers & Rollers the Story of Malleable Iron CultureNL Puddling Industrial Revolution Definition Unlike in the finery the iron was not. Puddling was the first successful process for making malleable iron from pig iron without using charcoal. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the molten. Puddling was the process of choice for producing wrought iron and steel for. Puddling Industrial Revolution Definition.

From www.history.com

Industrial Revolution Definition and Inventions HISTORY Puddling Industrial Revolution Definition Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. Unlike in the finery the iron was not. This method involved decarburizing molten. Puddling Industrial Revolution Definition.

From www.culturenlmuseums.co.uk

Puddlers, Shinglers & Rollers the Story of Malleable Iron CultureNL Puddling Industrial Revolution Definition The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the molten. Puddling was the first successful process for making malleable iron from pig iron without using charcoal. The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was a period of global. Puddling process,. Puddling Industrial Revolution Definition.

From www.slideserve.com

PPT THE INDUSTRIAL REVOLUTION PowerPoint Presentation, free download Puddling Industrial Revolution Definition This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. Puddling was the process of choice for producing wrought iron and. Puddling Industrial Revolution Definition.

From www.slideserve.com

PPT Puddling Furnace PowerPoint Presentation ID1459870 Puddling Industrial Revolution Definition Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. Puddling was the first successful process for making malleable iron from pig iron without using charcoal. Unlike in the finery the iron was not. Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a. Puddling Industrial Revolution Definition.

From www.slideshare.net

Ind revolution nex classes Puddling Industrial Revolution Definition The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the molten. The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was a period of global. Puddling was the process of choice for producing wrought iron and steel for most of the 19th century.. Puddling Industrial Revolution Definition.

From www.alamy.com

puddling furnace, 1872 Stock Photo Alamy Puddling Industrial Revolution Definition Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat. Puddling Industrial Revolution Definition.

From www.youtube.com

Puddling Definition Need Advantages YouTube Puddling Industrial Revolution Definition The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was a period of global. Unlike in the finery the iron was not. Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. Puddling was the first successful process for making malleable iron from pig iron without using. Puddling Industrial Revolution Definition.

From www.alamy.com

Puddling furnace Man on the left is paddling pig iron to remove carbon Puddling Industrial Revolution Definition Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. Unlike in the finery the iron was not. The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was a period of global. This method involved decarburizing molten pig iron in a reverberatory furnace,. Puddling Industrial Revolution Definition.

From www.investopedia.com

Industrial Revolution Definition, History, Pros, and Cons Puddling Industrial Revolution Definition The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the molten. Puddling was the first successful process for making malleable iron from pig iron without using charcoal. Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as. Puddling Industrial Revolution Definition.

From firearmshistory.blogspot.com

Firearms History, Technology & Development Metals Used in Firearms XI Puddling Industrial Revolution Definition This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. Unlike in the finery the iron was not. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the molten. Puddling was. Puddling Industrial Revolution Definition.

From interestingengineering.com

Industrial Revolution Inventions Industrial Era Inventions Puddling Industrial Revolution Definition Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. Puddling was the first successful process for making malleable iron from pig iron without using charcoal. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon. Puddling Industrial Revolution Definition.

From www.alamy.com

Iron working puddling process hires stock photography and images Alamy Puddling Industrial Revolution Definition This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. The puddling process is a method used to convert pig iron into wrought iron by. Puddling Industrial Revolution Definition.

From www.alamy.com

Puddling iron hires stock photography and images Alamy Puddling Industrial Revolution Definition This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. The puddling process is a method used to. Puddling Industrial Revolution Definition.

From www.youtube.com

Industrial Revolution. Episode 6 Puddling Process (1784) Henry Cort Puddling Industrial Revolution Definition Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. Puddling was the process of choice for producing wrought iron and steel for most of the 19th century. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed. Puddling Industrial Revolution Definition.

From www.superstock.com

Henry Cort (17401800) is best known for pioneering the puddling Puddling Industrial Revolution Definition Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. Puddling was the first successful process for making malleable iron from pig iron without using charcoal. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon. Puddling Industrial Revolution Definition.

From www.greelane.com

El papel del hierro en la Revolución Industrial Puddling Industrial Revolution Definition Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the molten. The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was. Puddling Industrial Revolution Definition.

From flowvella.com

Vintidgegram industrial revolution Screen 10 on FlowVella Puddling Industrial Revolution Definition The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was a period of global. Puddling was the first successful process for making malleable iron from pig iron without using charcoal. Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. The puddling process. Puddling Industrial Revolution Definition.

From www.meisterdrucke.uk

Industrial Revolution Puddling furnace Puddler Ovens (Puddlage Puddling Industrial Revolution Definition Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. The puddling process is a method used to convert pig iron into wrought. Puddling Industrial Revolution Definition.

From www.slideshare.net

Industrial Revolution Puddling Industrial Revolution Definition The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the molten. Unlike in the finery the iron was not. Puddling was the first successful process for making malleable iron from pig iron without using charcoal. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by. Puddling Industrial Revolution Definition.

From what-is-this.net

puddling definition What is Puddling Industrial Revolution Definition The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was a period of global. Puddled iron, a landmark innovation of the industrial revolution, was a form of refined iron produced through a process known as puddling. Puddling was the first successful process for making malleable iron from pig iron without using charcoal. Puddling was the. Puddling Industrial Revolution Definition.

From www.culturenlmuseums.co.uk

Puddlers, Shinglers & Rollers the Story of Malleable Iron CultureNL Puddling Industrial Revolution Definition The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was a period of global. Puddling process, method of converting pig iron into wrought iron by subjecting it to heat and frequent stirring in a furnace in the presence of. Puddling was the first successful process for making malleable iron from pig iron without using charcoal.. Puddling Industrial Revolution Definition.

From www.youtube.com

Production Of Wrought Iron In Puddling Furnace YouTube Puddling Industrial Revolution Definition This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. Puddling was the first successful process for making malleable iron from pig iron without using charcoal. The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was a period. Puddling Industrial Revolution Definition.

From www.alamy.com

Puddling iron hires stock photography and images Alamy Puddling Industrial Revolution Definition This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. The industrial revolution, sometimes divided into the first industrial revolution and second industrial revolution, was a period of global. Puddling process, method of converting pig iron into wrought iron by subjecting it to. Puddling Industrial Revolution Definition.

From slideplayer.com

AP World History The Industrial Revolution ppt download Puddling Industrial Revolution Definition Unlike in the finery the iron was not. This method involved decarburizing molten pig iron in a reverberatory furnace, which, by stirring with rods, allowed impurities like carbon and silicon to be oxidized and removed. The puddling process is a method used to convert pig iron into wrought iron by removing impurities through oxidation and agitating the molten. Puddled iron,. Puddling Industrial Revolution Definition.