Epoxy Resin Acoustic Guitar . In this instructable i will show you how i made the body for my carbon fiber acoustic guitar, part of a workshop at techshop. We’ve not, however, come across a home build quite like. Ian davlin from lark street music shows us how to patch a hole in an acoustic guitar body. A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. The crack in the headstock is. It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening the fibers with marine grade epoxy. Think of a material, and we’ve probably seen some intrepid engineer create a fully functioning electric guitar out of it. You do, but you can handle the guitar and do the. It shines in its great gap filling ability, control. Not because you don't need to let it harden overnight;

from www.youtube.com

In this instructable i will show you how i made the body for my carbon fiber acoustic guitar, part of a workshop at techshop. Ian davlin from lark street music shows us how to patch a hole in an acoustic guitar body. It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening the fibers with marine grade epoxy. A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. It shines in its great gap filling ability, control. The crack in the headstock is. We’ve not, however, come across a home build quite like. You do, but you can handle the guitar and do the. Not because you don't need to let it harden overnight; Think of a material, and we’ve probably seen some intrepid engineer create a fully functioning electric guitar out of it.

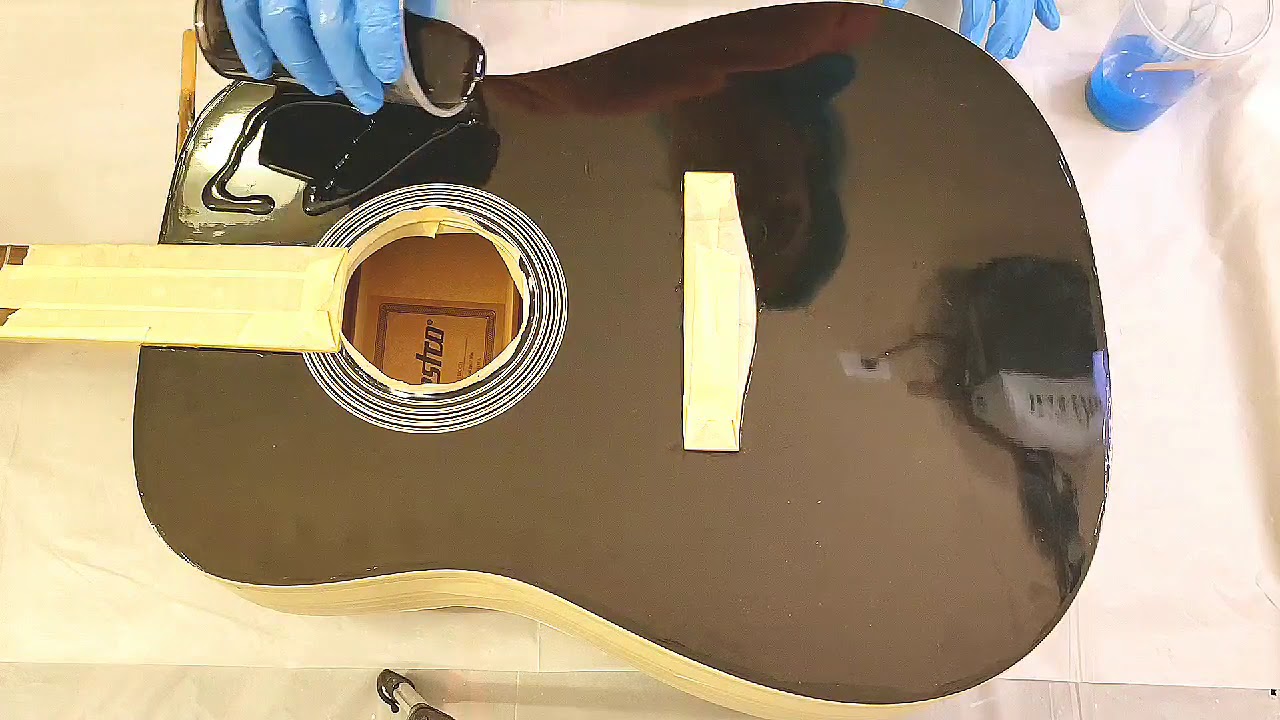

Gibson Guitar Epoxy Resin Pour YouTube

Epoxy Resin Acoustic Guitar In this instructable i will show you how i made the body for my carbon fiber acoustic guitar, part of a workshop at techshop. Think of a material, and we’ve probably seen some intrepid engineer create a fully functioning electric guitar out of it. Ian davlin from lark street music shows us how to patch a hole in an acoustic guitar body. It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening the fibers with marine grade epoxy. A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. Not because you don't need to let it harden overnight; You do, but you can handle the guitar and do the. We’ve not, however, come across a home build quite like. It shines in its great gap filling ability, control. The crack in the headstock is. In this instructable i will show you how i made the body for my carbon fiber acoustic guitar, part of a workshop at techshop.

From www.glasscastresin.com

Poisonwood Epoxy Resin River Guitar GlassCast Epoxy Resin Acoustic Guitar Ian davlin from lark street music shows us how to patch a hole in an acoustic guitar body. We’ve not, however, come across a home build quite like. It shines in its great gap filling ability, control. Think of a material, and we’ve probably seen some intrepid engineer create a fully functioning electric guitar out of it. A combination of. Epoxy Resin Acoustic Guitar.

From www.youtube.com

I Built magma guitar with epoxy resin and glass.【chapter2】 YouTube Epoxy Resin Acoustic Guitar Ian davlin from lark street music shows us how to patch a hole in an acoustic guitar body. You do, but you can handle the guitar and do the. Think of a material, and we’ve probably seen some intrepid engineer create a fully functioning electric guitar out of it. It shines in its great gap filling ability, control. In this. Epoxy Resin Acoustic Guitar.

From www.pinterest.com

121 best INLAY images on Pinterest Epoxy, Synthetic resin and Resin Epoxy Resin Acoustic Guitar Think of a material, and we’ve probably seen some intrepid engineer create a fully functioning electric guitar out of it. You do, but you can handle the guitar and do the. It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening the fibers with marine grade epoxy. We’ve not, however, come across a home. Epoxy Resin Acoustic Guitar.

From www.youtube.com

I Built magma guitar with epoxy resin and glass.【chapter1】 YouTube Epoxy Resin Acoustic Guitar The crack in the headstock is. A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. Ian davlin from lark street music shows us how to patch a hole in an acoustic guitar body. Not because you don't need to let it harden overnight; In this instructable i will show you how i. Epoxy Resin Acoustic Guitar.

From theawesomer.com

This Stunning Electric Guitar is Made of Wood and Epoxy Resin Epoxy Resin Acoustic Guitar In this instructable i will show you how i made the body for my carbon fiber acoustic guitar, part of a workshop at techshop. The crack in the headstock is. You do, but you can handle the guitar and do the. It shines in its great gap filling ability, control. Not because you don't need to let it harden overnight;. Epoxy Resin Acoustic Guitar.

From www.youtube.com

Epoxy resin on mahogany Guitar Building Finish YouTube Epoxy Resin Acoustic Guitar Think of a material, and we’ve probably seen some intrepid engineer create a fully functioning electric guitar out of it. It shines in its great gap filling ability, control. We’ve not, however, come across a home build quite like. It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening the fibers with marine grade. Epoxy Resin Acoustic Guitar.

From www.youtube.com

I Built an “EXPLODED” GUITAR out of EPOXY RESIN and COPPER PIPE YouTube Epoxy Resin Acoustic Guitar A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. Think of a material, and we’ve probably seen some intrepid engineer create a fully functioning electric guitar out of it. Not because you don't need to let it harden overnight; It shines in its great gap filling ability, control. In this instructable i. Epoxy Resin Acoustic Guitar.

From www.pinterest.com

Golden Geode. Recycled acoustic guitar with epoxy resin art. Epoxy Epoxy Resin Acoustic Guitar You do, but you can handle the guitar and do the. It shines in its great gap filling ability, control. In this instructable i will show you how i made the body for my carbon fiber acoustic guitar, part of a workshop at techshop. Ian davlin from lark street music shows us how to patch a hole in an acoustic. Epoxy Resin Acoustic Guitar.

From www.youtube.com

Epoxy resin guitar finish YouTube Epoxy Resin Acoustic Guitar It shines in its great gap filling ability, control. The crack in the headstock is. We’ve not, however, come across a home build quite like. It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening the fibers with marine grade epoxy. Think of a material, and we’ve probably seen some intrepid engineer create a. Epoxy Resin Acoustic Guitar.

From www.guitarristas.info

Esta guitarra tiene un río de resina epoxi atravesando el cuerpo de Epoxy Resin Acoustic Guitar The crack in the headstock is. It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening the fibers with marine grade epoxy. Ian davlin from lark street music shows us how to patch a hole in an acoustic guitar body. A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres. Epoxy Resin Acoustic Guitar.

From www.pinterest.com

Guitar made from Poisonwood and epoxy resin Electric guitar design Epoxy Resin Acoustic Guitar Think of a material, and we’ve probably seen some intrepid engineer create a fully functioning electric guitar out of it. In this instructable i will show you how i made the body for my carbon fiber acoustic guitar, part of a workshop at techshop. Ian davlin from lark street music shows us how to patch a hole in an acoustic. Epoxy Resin Acoustic Guitar.

From www.pinterest.com

Clear Casting Resin in a beautiful guitar. Done my Epoxy Resin Acoustic Guitar It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening the fibers with marine grade epoxy. Think of a material, and we’ve probably seen some intrepid engineer create a fully functioning electric guitar out of it. A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. You. Epoxy Resin Acoustic Guitar.

From www.youtube.com

Woodworker Makes Custom River Guitars With Epoxy YouTube Epoxy Resin Acoustic Guitar It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening the fibers with marine grade epoxy. It shines in its great gap filling ability, control. A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. Think of a material, and we’ve probably seen some intrepid engineer create. Epoxy Resin Acoustic Guitar.

From co.pinterest.com

Golden Geode. Recycled Acoustic Guitar With Epoxy Resin Art. Etsy Epoxy Resin Acoustic Guitar You do, but you can handle the guitar and do the. The crack in the headstock is. Ian davlin from lark street music shows us how to patch a hole in an acoustic guitar body. We’ve not, however, come across a home build quite like. It shines in its great gap filling ability, control. In this instructable i will show. Epoxy Resin Acoustic Guitar.

From www.pinterest.com

MANFRIEDY custom epoxy guitar Guitar, Etsy, Cool guitar Epoxy Resin Acoustic Guitar In this instructable i will show you how i made the body for my carbon fiber acoustic guitar, part of a workshop at techshop. Not because you don't need to let it harden overnight; We’ve not, however, come across a home build quite like. It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening. Epoxy Resin Acoustic Guitar.

From www.youtube.com

I Built a Guitar Out of Epoxy Resin YouTube Epoxy Resin Acoustic Guitar It shines in its great gap filling ability, control. Ian davlin from lark street music shows us how to patch a hole in an acoustic guitar body. Think of a material, and we’ve probably seen some intrepid engineer create a fully functioning electric guitar out of it. The crack in the headstock is. You do, but you can handle the. Epoxy Resin Acoustic Guitar.

From www.pinterest.de

Guitar made of wood and epoxy resin Guitar kits, Custom guitars, Guitar Epoxy Resin Acoustic Guitar It shines in its great gap filling ability, control. Ian davlin from lark street music shows us how to patch a hole in an acoustic guitar body. Not because you don't need to let it harden overnight; Think of a material, and we’ve probably seen some intrepid engineer create a fully functioning electric guitar out of it. You do, but. Epoxy Resin Acoustic Guitar.

From www.youtube.com

I Built an Epoxy Resin River Guitar YouTube Epoxy Resin Acoustic Guitar We’ve not, however, come across a home build quite like. You do, but you can handle the guitar and do the. A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. Not because you don't need to let it harden overnight; Think of a material, and we’ve probably seen some intrepid engineer create. Epoxy Resin Acoustic Guitar.

From www.pinterest.com

Epoxy guitar body Epoxy telecaster body Epoxy Fender body Custom made Epoxy Resin Acoustic Guitar A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. We’ve not, however, come across a home build quite like. The crack in the headstock is. It shines in its great gap filling ability, control. In this instructable i will show you how i made the body for my carbon fiber acoustic guitar,. Epoxy Resin Acoustic Guitar.

From www.youtube.com

I Built a Clear Guitar Out of Epoxy YouTube Epoxy Resin Acoustic Guitar A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening the fibers with marine grade epoxy. In this instructable i will show you how i made the body for my carbon fiber acoustic guitar, part of a. Epoxy Resin Acoustic Guitar.

From br.pinterest.com

Epoxy Resin l piso madeira resina artesanato Electric guitar Epoxy Resin Acoustic Guitar In this instructable i will show you how i made the body for my carbon fiber acoustic guitar, part of a workshop at techshop. The crack in the headstock is. Not because you don't need to let it harden overnight; Ian davlin from lark street music shows us how to patch a hole in an acoustic guitar body. We’ve not,. Epoxy Resin Acoustic Guitar.

From www.pinterest.com

MANFRIEDY custom epoxy guitar Esp Guitars, Unique Guitars, Custom Epoxy Resin Acoustic Guitar A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. You do, but you can handle the guitar and do the. We’ve not, however, come across a home build quite like. Ian davlin from lark street music shows us how to patch a hole in an acoustic guitar body. Not because you don't. Epoxy Resin Acoustic Guitar.

From www.youtube.com

Epoxy resin acoustic guitar created with our art kits YouTube Epoxy Resin Acoustic Guitar It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening the fibers with marine grade epoxy. Not because you don't need to let it harden overnight; Think of a material, and we’ve probably seen some intrepid engineer create a fully functioning electric guitar out of it. You do, but you can handle the guitar. Epoxy Resin Acoustic Guitar.

From www.youtube.com

I POURED RESIN ON MY FRIEND'S GUITAR YouTube Epoxy Resin Acoustic Guitar We’ve not, however, come across a home build quite like. It shines in its great gap filling ability, control. You do, but you can handle the guitar and do the. It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening the fibers with marine grade epoxy. A combination of west system 105 epoxy resin,. Epoxy Resin Acoustic Guitar.

From www.youtube.com

Gibson Guitar Epoxy Resin Pour YouTube Epoxy Resin Acoustic Guitar In this instructable i will show you how i made the body for my carbon fiber acoustic guitar, part of a workshop at techshop. You do, but you can handle the guitar and do the. Not because you don't need to let it harden overnight; Ian davlin from lark street music shows us how to patch a hole in an. Epoxy Resin Acoustic Guitar.

From www.pinterest.com

Epoxy Resin Projects l resina banheiro Guitar design, Electric Epoxy Resin Acoustic Guitar Not because you don't need to let it harden overnight; It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening the fibers with marine grade epoxy. The crack in the headstock is. You do, but you can handle the guitar and do the. Think of a material, and we’ve probably seen some intrepid engineer. Epoxy Resin Acoustic Guitar.

From www.youtube.com

SD Workstation Epoxy resin on Acoustic Guitar missing inlays. YouTube Epoxy Resin Acoustic Guitar Not because you don't need to let it harden overnight; Think of a material, and we’ve probably seen some intrepid engineer create a fully functioning electric guitar out of it. A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. We’ve not, however, come across a home build quite like. You do, but. Epoxy Resin Acoustic Guitar.

From www.pinterest.de

Pin on Epoxy Resin Epoxy Resin Acoustic Guitar Think of a material, and we’ve probably seen some intrepid engineer create a fully functioning electric guitar out of it. A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. We’ve not, however, come across a home build quite like. It was made laying layers of carbon fiber and fiberglass over a cardboard. Epoxy Resin Acoustic Guitar.

From www.pinterest.de

Built my first ever guitar out of wood and epoxy. Check it out! Epoxy Resin Acoustic Guitar It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening the fibers with marine grade epoxy. A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. Ian davlin from lark street music shows us how to patch a hole in an acoustic guitar body. We’ve not, however,. Epoxy Resin Acoustic Guitar.

From www.pinterest.com

Epoxy guitar body Epoxy telecaster body Epoxy Fender body image 8 Epoxy Resin Acoustic Guitar A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. In this instructable i will show you how i made the body for my carbon fiber acoustic guitar, part of a workshop at techshop. Not because you don't need to let it harden overnight; It shines in its great gap filling ability, control.. Epoxy Resin Acoustic Guitar.

From www.pinterest.com

Epoxy Resin Art 🎨 on Instagram “Which guitar you like the most? 🎸 My Epoxy Resin Acoustic Guitar It shines in its great gap filling ability, control. Think of a material, and we’ve probably seen some intrepid engineer create a fully functioning electric guitar out of it. The crack in the headstock is. Ian davlin from lark street music shows us how to patch a hole in an acoustic guitar body. You do, but you can handle the. Epoxy Resin Acoustic Guitar.

From diyhuntress.com

diyepoxyresinoceanpourguitar10 DIY Huntress Epoxy Resin Acoustic Guitar It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening the fibers with marine grade epoxy. It shines in its great gap filling ability, control. We’ve not, however, come across a home build quite like. Not because you don't need to let it harden overnight; Think of a material, and we’ve probably seen some. Epoxy Resin Acoustic Guitar.

From www.reddit.com

I finally got brave enough and made my own telecaster using epoxy resin Epoxy Resin Acoustic Guitar A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. It was made laying layers of carbon fiber and fiberglass over a cardboard mold, then hardening the fibers with marine grade epoxy. We’ve not, however, come across a home build quite like. You do, but you can handle the guitar and do the.. Epoxy Resin Acoustic Guitar.

From www.pinterest.com

WiseBond Epoxy Guitar with Real Fish Epoxy, Guitar, Guitar artwork Epoxy Resin Acoustic Guitar Not because you don't need to let it harden overnight; The crack in the headstock is. In this instructable i will show you how i made the body for my carbon fiber acoustic guitar, part of a workshop at techshop. We’ve not, however, come across a home build quite like. Think of a material, and we’ve probably seen some intrepid. Epoxy Resin Acoustic Guitar.

From www.youtube.com

Renew Guitar with epoxy resin แปลงกีต้าเก่าให้เก่าแบบมีสไตล์ YouTube Epoxy Resin Acoustic Guitar A combination of west system 105 epoxy resin, 205 fast hardener and 303 microfibres are carefully mixed. It shines in its great gap filling ability, control. Not because you don't need to let it harden overnight; The crack in the headstock is. Ian davlin from lark street music shows us how to patch a hole in an acoustic guitar body.. Epoxy Resin Acoustic Guitar.