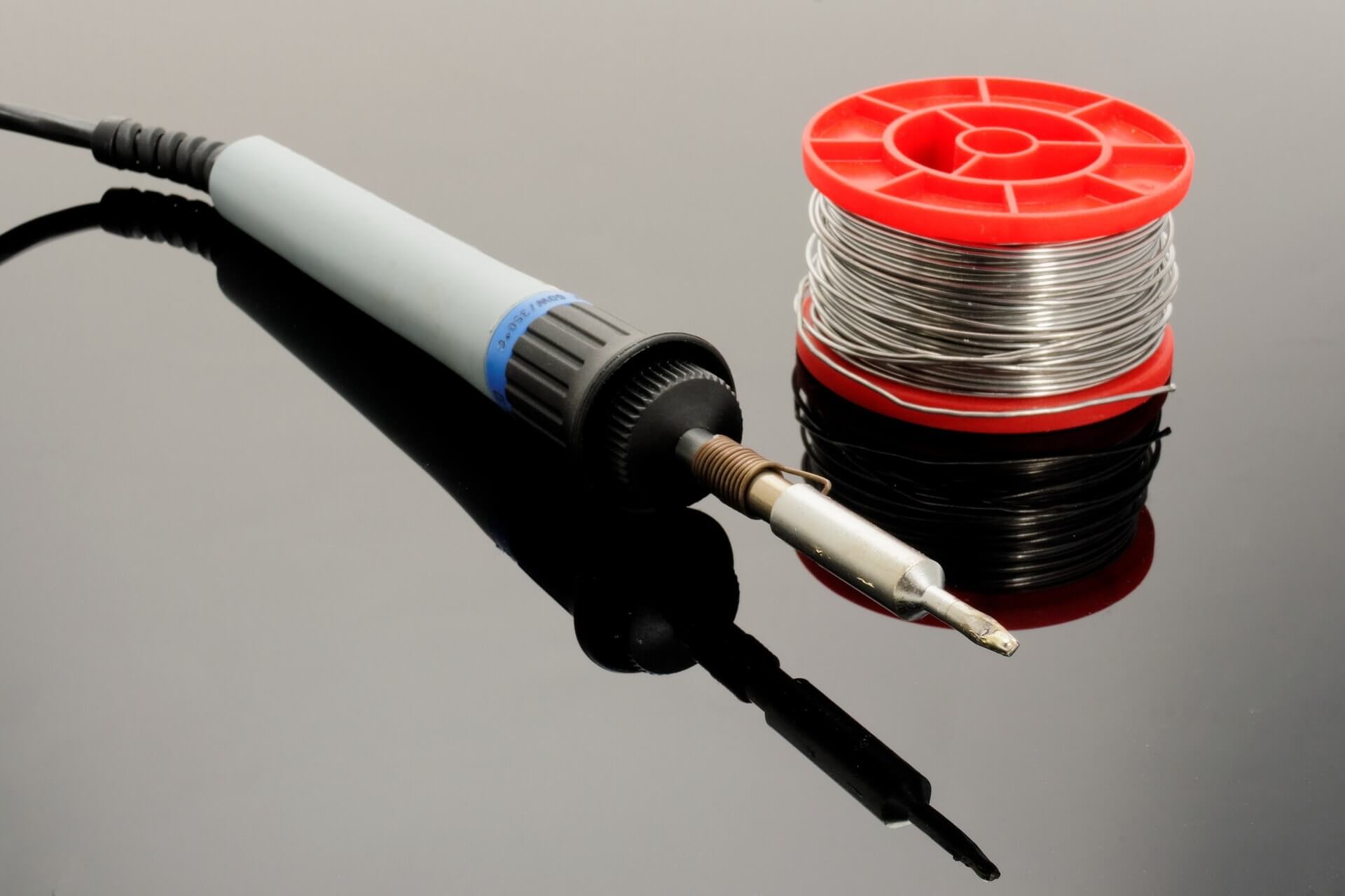

Soldering Not Working . In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper wire, as well as solutions for troubleshooting these issues. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. This prevents oxidation and corrosion. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. There are five main reasons why solder might not stick to metal. When using the iron, keep a little solder on the tip when the iron is in the stand. If there is too much solder, a solder sucker or solder wick. When the iron is not being used, keep some solder on the tip.

from analyseameter.com

There are five main reasons why solder might not stick to metal. If there is too much solder, a solder sucker or solder wick. When using the iron, keep a little solder on the tip when the iron is in the stand. In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper wire, as well as solutions for troubleshooting these issues. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. This prevents oxidation and corrosion. When the iron is not being used, keep some solder on the tip.

What is Soldering Iron and how to choose them Analyse A Meter

Soldering Not Working When using the iron, keep a little solder on the tip when the iron is in the stand. In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper wire, as well as solutions for troubleshooting these issues. There are five main reasons why solder might not stick to metal. This prevents oxidation and corrosion. When the iron is not being used, keep some solder on the tip. When using the iron, keep a little solder on the tip when the iron is in the stand. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. If there is too much solder, a solder sucker or solder wick.

From iphonewired.com

Fix Face ID (WITHOUT SOLDERING) Not Working with REFOX RP30 The Soldering Not Working When the iron is not being used, keep some solder on the tip. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. If there is too much solder, a solder sucker or solder wick. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the. Soldering Not Working.

From www.solonews.net

A Manual Guide to Use Soldering Iron Soldering Not Working In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper wire, as well as solutions for troubleshooting these issues. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. When the iron is not being used, keep some solder on the tip.. Soldering Not Working.

From schematiclibwhinged101.z21.web.core.windows.net

How To Properly Solder Wires For Electronics Soldering Not Working There are five main reasons why solder might not stick to metal. When the iron is not being used, keep some solder on the tip. This prevents oxidation and corrosion. If there is too much solder, a solder sucker or solder wick. When using the iron, keep a little solder on the tip when the iron is in the stand.. Soldering Not Working.

From www.youtube.com

Common Soldering Mistakes Soldering YouTube Soldering Not Working In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper wire, as well as solutions for troubleshooting these issues. This prevents oxidation and corrosion. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. If there is too much solder, a solder. Soldering Not Working.

From www.reddit.com

How do I fix this? Soldering not working at all it just falls back off Soldering Not Working When using the iron, keep a little solder on the tip when the iron is in the stand. If there is too much solder, a solder sucker or solder wick. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. When the iron is not being used, keep some. Soldering Not Working.

From www.build-electronic-circuits.com

The Soldering Tools That Make Your Life Easier Soldering Not Working When using the iron, keep a little solder on the tip when the iron is in the stand. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper wire, as well as. Soldering Not Working.

From rushpcb.com

What is a Solder Joint? RushPcb Soldering Not Working There are five main reasons why solder might not stick to metal. This prevents oxidation and corrosion. When using the iron, keep a little solder on the tip when the iron is in the stand. When the iron is not being used, keep some solder on the tip. If there is too much solder, a solder sucker or solder wick.. Soldering Not Working.

From tomverbeure.github.io

In The Lab Soldering Prototypes with Enamel Wire Electronics Soldering Not Working There are five main reasons why solder might not stick to metal. If there is too much solder, a solder sucker or solder wick. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces. Soldering Not Working.

From www.youtube.com

Iron Soldering Not Working YouTube Soldering Not Working Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. There are five main reasons why solder might not stick to metal. When the iron is not being used, keep some solder on the tip. When using the iron, keep a little solder on the tip when the iron. Soldering Not Working.

From vinatronic.com

Cold Solder How To Identify and Prevent Vinatronic inc. Soldering Not Working This prevents oxidation and corrosion. When using the iron, keep a little solder on the tip when the iron is in the stand. When the iron is not being used, keep some solder on the tip. In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper wire, as well. Soldering Not Working.

From www.youtube.com

Top 10 Things NOT to do when Soldering Intro to Soldering Safety Soldering Not Working When the iron is not being used, keep some solder on the tip. In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper wire, as well as solutions for troubleshooting these issues. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between. Soldering Not Working.

From analyseameter.com

What is Soldering Iron and how to choose them Analyse A Meter Soldering Not Working There are five main reasons why solder might not stick to metal. In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper wire, as well as solutions for troubleshooting these issues. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. Sometimes. Soldering Not Working.

From bodnarus.liveauctiongroup.com

Soldering Irons (not tested) Work Light (working) Craftsman Soldering Not Working If there is too much solder, a solder sucker or solder wick. When using the iron, keep a little solder on the tip when the iron is in the stand. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. This prevents oxidation and corrosion. When the iron is not being used, keep. Soldering Not Working.

From weldingmastermind.com

Five Reasons Your Solder Won’t Stick Welding Mastermind Soldering Not Working Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. When the iron is not being used, keep some solder on the tip. There are five main reasons why solder might not stick to metal. If there is too much solder, a solder sucker or solder wick. Sometimes the excess solder can be. Soldering Not Working.

From uvmfablab.net

Soldering UVM FabLab Soldering Not Working Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. This prevents oxidation and corrosion. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. When using the iron, keep a little solder on the tip when the iron is in the. Soldering Not Working.

From www.nj2x.com

NJ2X Soldering 101 Soldering Not Working This prevents oxidation and corrosion. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. When using the iron, keep a little solder on the tip when the iron is in the. Soldering Not Working.

From www.youtube.com

How to make Soldering Station workbench soldering solderingiron Soldering Not Working When the iron is not being used, keep some solder on the tip. There are five main reasons why solder might not stick to metal. This prevents oxidation and corrosion. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. If there is too much solder, a solder sucker or solder wick. When. Soldering Not Working.

From www.circuitbasics.com

Tips for Good Soldering Technique Circuit Basics Soldering Not Working Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. When using the iron, keep a little solder on the tip when the iron is in the stand. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. This prevents oxidation and. Soldering Not Working.

From www.alamy.com

woman soldering a circuit board in her tech office Stock Photo Alamy Soldering Not Working When the iron is not being used, keep some solder on the tip. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. This prevents oxidation and corrosion. In this blog post,. Soldering Not Working.

From www.youtube.com

Soldering not working, soldering iron current mar raha hai full repair Soldering Not Working Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. When the iron is not being used, keep some solder on the tip. In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper wire, as well as solutions. Soldering Not Working.

From karpova-lab.github.io

Additional Resources — Cerebro Wireless System 2.0.4 Soldering Not Working Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. When using the iron, keep a little solder on the tip when the iron is in the stand. In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper. Soldering Not Working.

From solderingironguide.com

Top 5 Best Cordless Soldering Irons [2021 Review] Solderingironguide Soldering Not Working Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. If there is too much solder, a solder sucker or solder wick. When the iron is not being used, keep some solder on the tip. This prevents oxidation and corrosion. In this blog post, we’ll explore some of the common reasons why solder. Soldering Not Working.

From www.reddit.com

Solder not melting r/soldering Soldering Not Working When using the iron, keep a little solder on the tip when the iron is in the stand. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper wire, as well as. Soldering Not Working.

From www.reddit.com

How To Connect These? Soldering NOT Working! r/arduino Soldering Not Working In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper wire, as well as solutions for troubleshooting these issues. This prevents oxidation and corrosion. There are five main reasons why solder might not stick to metal. When using the iron, keep a little solder on the tip when the. Soldering Not Working.

From solderingmind.com

Soldering Iron Not Heating Up 3 Most Common Reason and its Solutions Soldering Not Working When the iron is not being used, keep some solder on the tip. There are five main reasons why solder might not stick to metal. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. In this blog post, we’ll explore some of the common reasons why solder might. Soldering Not Working.

From www.dreamstime.com

Iron Soldering, Man Working on Iron Soldering, Welding Sparks Stock Soldering Not Working Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. When using the iron, keep a little solder on the tip when the iron is in the stand. In this blog post,. Soldering Not Working.

From thepopularhome.com

7 of the Best Soldering Stations in the Market Today Soldering Not Working If there is too much solder, a solder sucker or solder wick. When the iron is not being used, keep some solder on the tip. There are five main reasons why solder might not stick to metal. This prevents oxidation and corrosion. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the. Soldering Not Working.

From www.iowalum.com

What is Soldering? Three types of soldering methods Soldering Not Working This prevents oxidation and corrosion. In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper wire, as well as solutions for troubleshooting these issues. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. There are five main reasons why solder might. Soldering Not Working.

From www.youtube.com

Soldering station not working YouTube Soldering Not Working When using the iron, keep a little solder on the tip when the iron is in the stand. In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper wire, as well as solutions for troubleshooting these issues. This prevents oxidation and corrosion. There are five main reasons why solder. Soldering Not Working.

From www.instructables.com

Soldering Tutorial Inline Splicing 7 Steps (with Pictures Soldering Not Working When using the iron, keep a little solder on the tip when the iron is in the stand. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. This prevents oxidation and corrosion. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately. Soldering Not Working.

From adrkurs.pl

Soldering one of the methods of welding Soldering Not Working There are five main reasons why solder might not stick to metal. If there is too much solder, a solder sucker or solder wick. When the iron is not being used, keep some solder on the tip. When using the iron, keep a little solder on the tip when the iron is in the stand. Sometimes the excess solder can. Soldering Not Working.

From linksofstrathaven.com

How To Treat A Burn From A Soldering Iron? Update Soldering Not Working When using the iron, keep a little solder on the tip when the iron is in the stand. Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. This prevents oxidation and. Soldering Not Working.

From www.dreamstime.com

Iron Soldering, Man Working on Iron Soldering, Welding Sparks Stock Soldering Not Working Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper wire, as well as solutions for troubleshooting these issues. This prevents oxidation and corrosion. When using the iron, keep a little solder. Soldering Not Working.

From www.youtube.com

DIY Ultimate Wire Soldering Guide YouTube Soldering Not Working Sometimes the excess solder can be drawn off by dragging the tip of a hot iron between the two solder joints. This prevents oxidation and corrosion. Typically, the issues lie with lack of heat, dirty equipment, or product material, which could ultimately come. When the iron is not being used, keep some solder on the tip. In this blog post,. Soldering Not Working.

From moneyexpertsteam.blogspot.com

How To Fix a Broken Soldering Iron Thats Not Heating Up How To Fix Soldering Not Working If there is too much solder, a solder sucker or solder wick. In this blog post, we’ll explore some of the common reasons why solder might not adhere properly to surfaces like copper wire, as well as solutions for troubleshooting these issues. This prevents oxidation and corrosion. There are five main reasons why solder might not stick to metal. Sometimes. Soldering Not Working.