Forklift Tire Wear Indicator . Signs that forklift tires need replacement: As the forklift tires wear down, a highly visible orange band appears on the tire surface indicating that replacement tires should be ordered and service fitting scheduled. How and when to replace forklift tires safely. Common signs of forklift tire wear and tear are an easy indicator to watch out for. When to replace forklift tires. Running an underinflated forklift tire will cause sidewall separation, blow outs, rapid tread wear and bead failures. There’s a magical line called the “wear line”. Once the tread wears down to the wear indicator bars (typically 3/16 inch or 4.8 mm), the tires should be replaced. Wear & tear signs will show up right away, if you know what to look for. In 2014 we gave you the top of the numbers method in: Both cushion forklift tires and. Monitor the tread depth regularly. Here are a few telltale signs that it’s time to replace your trusty forklift tires: Inspect tires for chunks missing from the tread or sidewalls, as well as cracks. You should not operate on tires.

from gotire.com

You should not operate on tires. Signs that forklift tires need replacement: Forklift tires typically have a wear line indicating their. As the forklift tires wear down, a highly visible orange band appears on the tire surface indicating that replacement tires should be ordered and service fitting scheduled. There’s a magical line called the “wear line”. Wear & tear signs will show up right away, if you know what to look for. Running an underinflated forklift tire will cause sidewall separation, blow outs, rapid tread wear and bead failures. Once the tread wears down to the wear indicator bars (typically 3/16 inch or 4.8 mm), the tires should be replaced. Monitor the tread depth regularly. In 2014 we gave you the top of the numbers method in:

GoTire Guide on the Minimum Tire Tread Depth

Forklift Tire Wear Indicator You should not operate on tires. Monitor the tread depth regularly. When to replace forklift tires. In 2014 we gave you the top of the numbers method in: Both cushion forklift tires and. Inspect tires for chunks missing from the tread or sidewalls, as well as cracks. Common signs of forklift tire wear and tear are an easy indicator to watch out for. There’s a magical line called the “wear line”. Here are a few telltale signs that it’s time to replace your trusty forklift tires: Signs that forklift tires need replacement: Running an underinflated forklift tire will cause sidewall separation, blow outs, rapid tread wear and bead failures. You should not operate on tires. How and when to replace forklift tires safely. Once the tread wears down to the wear indicator bars (typically 3/16 inch or 4.8 mm), the tires should be replaced. Wear & tear signs will show up right away, if you know what to look for. Forklift tires typically have a wear line indicating their.

From www.masonlift.com

LevelLite Fork Tilt Indicator Forklift Tire Wear Indicator When to replace forklift tires. You should not operate on tires. Signs that forklift tires need replacement: Here are a few telltale signs that it’s time to replace your trusty forklift tires: Inspect tires for chunks missing from the tread or sidewalls, as well as cracks. Monitor the tread depth regularly. As the forklift tires wear down, a highly visible. Forklift Tire Wear Indicator.

From evagibson.z13.web.core.windows.net

Tire Wear Ratings Chart Forklift Tire Wear Indicator Both cushion forklift tires and. How and when to replace forklift tires safely. There’s a magical line called the “wear line”. As the forklift tires wear down, a highly visible orange band appears on the tire surface indicating that replacement tires should be ordered and service fitting scheduled. Wear & tear signs will show up right away, if you know. Forklift Tire Wear Indicator.

From www.hankooktire.com

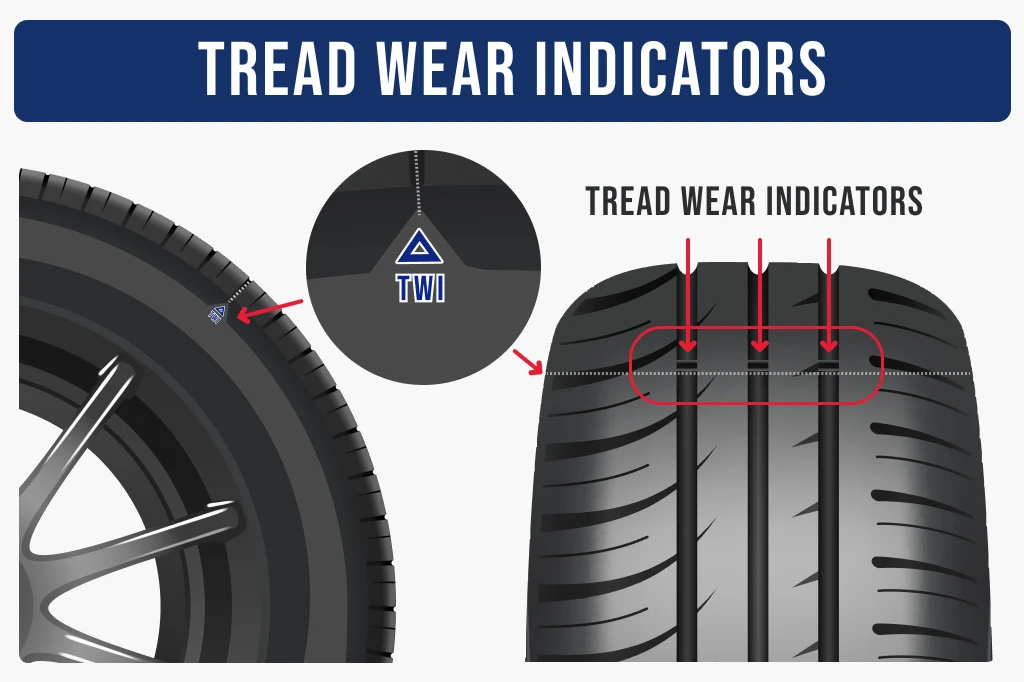

Tread Wear Tire Care Guide Hankook Tire US site Forklift Tire Wear Indicator Common signs of forklift tire wear and tear are an easy indicator to watch out for. Wear & tear signs will show up right away, if you know what to look for. In 2014 we gave you the top of the numbers method in: Once the tread wears down to the wear indicator bars (typically 3/16 inch or 4.8 mm),. Forklift Tire Wear Indicator.

From www.edentyres.com

How to Understand and Read your tyres Eden Tyres & Servicing Forklift Tire Wear Indicator Wear & tear signs will show up right away, if you know what to look for. In 2014 we gave you the top of the numbers method in: Once the tread wears down to the wear indicator bars (typically 3/16 inch or 4.8 mm), the tires should be replaced. There’s a magical line called the “wear line”. Signs that forklift. Forklift Tire Wear Indicator.

From www.carlist.my

Understanding Tyre Tread Wear Indicators Auto News Carlist.my Forklift Tire Wear Indicator There’s a magical line called the “wear line”. As the forklift tires wear down, a highly visible orange band appears on the tire surface indicating that replacement tires should be ordered and service fitting scheduled. Inspect tires for chunks missing from the tread or sidewalls, as well as cracks. When to replace forklift tires. Signs that forklift tires need replacement:. Forklift Tire Wear Indicator.

From www.gtradial-us.com

Tire Maintenance GT Radial Tires Forklift Tire Wear Indicator How and when to replace forklift tires safely. Both cushion forklift tires and. As the forklift tires wear down, a highly visible orange band appears on the tire surface indicating that replacement tires should be ordered and service fitting scheduled. Here are a few telltale signs that it’s time to replace your trusty forklift tires: You should not operate on. Forklift Tire Wear Indicator.

From www.shutterstock.com

Worn Out Tyre Tread Wear Indicators Stock Photo 1545369779 Shutterstock Forklift Tire Wear Indicator You should not operate on tires. Both cushion forklift tires and. Monitor the tread depth regularly. How and when to replace forklift tires safely. Here are a few telltale signs that it’s time to replace your trusty forklift tires: There’s a magical line called the “wear line”. Common signs of forklift tire wear and tear are an easy indicator to. Forklift Tire Wear Indicator.

From exoxpzkmg.blob.core.windows.net

How To Check Tire Wear Indicators at Kim Manning blog Forklift Tire Wear Indicator Common signs of forklift tire wear and tear are an easy indicator to watch out for. There’s a magical line called the “wear line”. How and when to replace forklift tires safely. As the forklift tires wear down, a highly visible orange band appears on the tire surface indicating that replacement tires should be ordered and service fitting scheduled. Both. Forklift Tire Wear Indicator.

From www.goodyear.com

How To Measure Tire Tread Depth Goodyear Tires Forklift Tire Wear Indicator There’s a magical line called the “wear line”. You should not operate on tires. Forklift tires typically have a wear line indicating their. Inspect tires for chunks missing from the tread or sidewalls, as well as cracks. Common signs of forklift tire wear and tear are an easy indicator to watch out for. Here are a few telltale signs that. Forklift Tire Wear Indicator.

From gotire.com

GoTire Guide on the Minimum Tire Tread Depth Forklift Tire Wear Indicator There’s a magical line called the “wear line”. Once the tread wears down to the wear indicator bars (typically 3/16 inch or 4.8 mm), the tires should be replaced. As the forklift tires wear down, a highly visible orange band appears on the tire surface indicating that replacement tires should be ordered and service fitting scheduled. Wear & tear signs. Forklift Tire Wear Indicator.

From www.sacramentolift.com

Forklift Tires and Replacement Forklift Tire Wear Indicator You should not operate on tires. There’s a magical line called the “wear line”. Inspect tires for chunks missing from the tread or sidewalls, as well as cracks. As the forklift tires wear down, a highly visible orange band appears on the tire surface indicating that replacement tires should be ordered and service fitting scheduled. Signs that forklift tires need. Forklift Tire Wear Indicator.

From tyregeek.com.au

Tyre/Tread Wear Indicator What Is It? How To Read It? Forklift Tire Wear Indicator There’s a magical line called the “wear line”. You should not operate on tires. How and when to replace forklift tires safely. Once the tread wears down to the wear indicator bars (typically 3/16 inch or 4.8 mm), the tires should be replaced. In 2014 we gave you the top of the numbers method in: Wear & tear signs will. Forklift Tire Wear Indicator.

From www.youtube.com

Tread wear Indicator on TyresWhen to change car tyres YouTube Forklift Tire Wear Indicator Both cushion forklift tires and. Running an underinflated forklift tire will cause sidewall separation, blow outs, rapid tread wear and bead failures. Inspect tires for chunks missing from the tread or sidewalls, as well as cracks. Monitor the tread depth regularly. In 2014 we gave you the top of the numbers method in: Signs that forklift tires need replacement: Here. Forklift Tire Wear Indicator.

From tiregrades.com

Tread Wear Indicator (How To Read) TireGrades Forklift Tire Wear Indicator In 2014 we gave you the top of the numbers method in: When to replace forklift tires. Both cushion forklift tires and. Wear & tear signs will show up right away, if you know what to look for. Monitor the tread depth regularly. How and when to replace forklift tires safely. As the forklift tires wear down, a highly visible. Forklift Tire Wear Indicator.

From ehfcv.com

Continental New ContiPT18 Solid Tire for Material Handling EHFCV Forklift Tire Wear Indicator How and when to replace forklift tires safely. There’s a magical line called the “wear line”. As the forklift tires wear down, a highly visible orange band appears on the tire surface indicating that replacement tires should be ordered and service fitting scheduled. You should not operate on tires. Wear & tear signs will show up right away, if you. Forklift Tire Wear Indicator.

From www.conger.com

Forklift Tires The Ultimate Guide [Read Sizes & Compare Types] Forklift Tire Wear Indicator In 2014 we gave you the top of the numbers method in: When to replace forklift tires. There’s a magical line called the “wear line”. Here are a few telltale signs that it’s time to replace your trusty forklift tires: Both cushion forklift tires and. How and when to replace forklift tires safely. Signs that forklift tires need replacement: Forklift. Forklift Tire Wear Indicator.

From www.samsmechanical.com

Pneumatic vs. Cushion Tire Forklifts Which is Best for You? Forklift Tire Wear Indicator Both cushion forklift tires and. Forklift tires typically have a wear line indicating their. You should not operate on tires. Here are a few telltale signs that it’s time to replace your trusty forklift tires: Signs that forklift tires need replacement: There’s a magical line called the “wear line”. As the forklift tires wear down, a highly visible orange band. Forklift Tire Wear Indicator.

From tyrepowernewcastle.com.au

Tyre Wear Indicators Newcastle Tyrepower Forklift Tire Wear Indicator When to replace forklift tires. Monitor the tread depth regularly. Forklift tires typically have a wear line indicating their. Here are a few telltale signs that it’s time to replace your trusty forklift tires: As the forklift tires wear down, a highly visible orange band appears on the tire surface indicating that replacement tires should be ordered and service fitting. Forklift Tire Wear Indicator.

From www.wheelhero.com

WheelHero’s Guide for When to Replace Tires! Forklift Tire Wear Indicator Inspect tires for chunks missing from the tread or sidewalls, as well as cracks. Running an underinflated forklift tire will cause sidewall separation, blow outs, rapid tread wear and bead failures. As the forklift tires wear down, a highly visible orange band appears on the tire surface indicating that replacement tires should be ordered and service fitting scheduled. In 2014. Forklift Tire Wear Indicator.

From www.atlastoyota.com

Forklift Tires Equipment Tires Atlas Toyota Forklift Tire Wear Indicator When to replace forklift tires. How and when to replace forklift tires safely. Forklift tires typically have a wear line indicating their. Running an underinflated forklift tire will cause sidewall separation, blow outs, rapid tread wear and bead failures. Wear & tear signs will show up right away, if you know what to look for. Signs that forklift tires need. Forklift Tire Wear Indicator.

From lystugg6ggaragerepair.z14.web.core.windows.net

Tire Wear Indicator Bars Forklift Tire Wear Indicator When to replace forklift tires. In 2014 we gave you the top of the numbers method in: There’s a magical line called the “wear line”. Signs that forklift tires need replacement: Once the tread wears down to the wear indicator bars (typically 3/16 inch or 4.8 mm), the tires should be replaced. Here are a few telltale signs that it’s. Forklift Tire Wear Indicator.

From www.adaptalift.com.au

How to Measure and Read Forklift Tyre Sizes Forklift Tire Wear Indicator Signs that forklift tires need replacement: As the forklift tires wear down, a highly visible orange band appears on the tire surface indicating that replacement tires should be ordered and service fitting scheduled. Monitor the tread depth regularly. In 2014 we gave you the top of the numbers method in: When to replace forklift tires. Wear & tear signs will. Forklift Tire Wear Indicator.

From exoxpzkmg.blob.core.windows.net

How To Check Tire Wear Indicators at Kim Manning blog Forklift Tire Wear Indicator Signs that forklift tires need replacement: Once the tread wears down to the wear indicator bars (typically 3/16 inch or 4.8 mm), the tires should be replaced. Running an underinflated forklift tire will cause sidewall separation, blow outs, rapid tread wear and bead failures. Common signs of forklift tire wear and tear are an easy indicator to watch out for.. Forklift Tire Wear Indicator.

From www.conger.com

Forklift Cushion Tire Wear Scale, Buy Now Conger Industries Inc. Forklift Tire Wear Indicator Signs that forklift tires need replacement: Both cushion forklift tires and. When to replace forklift tires. Wear & tear signs will show up right away, if you know what to look for. Common signs of forklift tire wear and tear are an easy indicator to watch out for. Monitor the tread depth regularly. How and when to replace forklift tires. Forklift Tire Wear Indicator.

From www.roadsafety.co.za

Monitor your tyres with the tread wear indicator Road Safety Blog Forklift Tire Wear Indicator Inspect tires for chunks missing from the tread or sidewalls, as well as cracks. Common signs of forklift tire wear and tear are an easy indicator to watch out for. Here are a few telltale signs that it’s time to replace your trusty forklift tires: There’s a magical line called the “wear line”. As the forklift tires wear down, a. Forklift Tire Wear Indicator.

From www.pinterest.com

Be sure to regularly inspect your forklift tires for wear and damage Forklift Tire Wear Indicator Signs that forklift tires need replacement: Inspect tires for chunks missing from the tread or sidewalls, as well as cracks. In 2014 we gave you the top of the numbers method in: Wear & tear signs will show up right away, if you know what to look for. Once the tread wears down to the wear indicator bars (typically 3/16. Forklift Tire Wear Indicator.

From www.conger.com

Forklift Cushion Tire Wear Scale, Buy Now Conger Industries Inc. Forklift Tire Wear Indicator Wear & tear signs will show up right away, if you know what to look for. Forklift tires typically have a wear line indicating their. Here are a few telltale signs that it’s time to replace your trusty forklift tires: Common signs of forklift tire wear and tear are an easy indicator to watch out for. Inspect tires for chunks. Forklift Tire Wear Indicator.

From vehicleinspection.nzta.govt.nz

Guidance for vehicle inspectors when checking tyre tread depth NZTA Forklift Tire Wear Indicator How and when to replace forklift tires safely. Here are a few telltale signs that it’s time to replace your trusty forklift tires: Wear & tear signs will show up right away, if you know what to look for. Running an underinflated forklift tire will cause sidewall separation, blow outs, rapid tread wear and bead failures. Once the tread wears. Forklift Tire Wear Indicator.

From www.summitforklifttires.com

Do I Need New Forklift Tires? Summit Industrial Tire Service Forklift Tire Wear Indicator Inspect tires for chunks missing from the tread or sidewalls, as well as cracks. Once the tread wears down to the wear indicator bars (typically 3/16 inch or 4.8 mm), the tires should be replaced. When to replace forklift tires. As the forklift tires wear down, a highly visible orange band appears on the tire surface indicating that replacement tires. Forklift Tire Wear Indicator.

From www.reddit.com

Tire tread wear guide r/coolguides Forklift Tire Wear Indicator In 2014 we gave you the top of the numbers method in: When to replace forklift tires. Monitor the tread depth regularly. Here are a few telltale signs that it’s time to replace your trusty forklift tires: Inspect tires for chunks missing from the tread or sidewalls, as well as cracks. Common signs of forklift tire wear and tear are. Forklift Tire Wear Indicator.

From simpletire.com

Tire Wear Bar Is it Time to Change Your Tires? SimpleTire Forklift Tire Wear Indicator Running an underinflated forklift tire will cause sidewall separation, blow outs, rapid tread wear and bead failures. Wear & tear signs will show up right away, if you know what to look for. As the forklift tires wear down, a highly visible orange band appears on the tire surface indicating that replacement tires should be ordered and service fitting scheduled.. Forklift Tire Wear Indicator.

From www.ebay.com

Understanding Tire Tread Depth eBay Motors Blog Forklift Tire Wear Indicator As the forklift tires wear down, a highly visible orange band appears on the tire surface indicating that replacement tires should be ordered and service fitting scheduled. There’s a magical line called the “wear line”. When to replace forklift tires. Wear & tear signs will show up right away, if you know what to look for. You should not operate. Forklift Tire Wear Indicator.

From www.corwheels.com

Tire Wear Bar Indicators What Tread Depth To Replace Tires? Forklift Tire Wear Indicator Forklift tires typically have a wear line indicating their. How and when to replace forklift tires safely. Both cushion forklift tires and. You should not operate on tires. Here are a few telltale signs that it’s time to replace your trusty forklift tires: Signs that forklift tires need replacement: Monitor the tread depth regularly. Common signs of forklift tire wear. Forklift Tire Wear Indicator.

From lystugg6ggaragerepair.z14.web.core.windows.net

Tire Wear Indicator Bars Forklift Tire Wear Indicator Wear & tear signs will show up right away, if you know what to look for. There’s a magical line called the “wear line”. Running an underinflated forklift tire will cause sidewall separation, blow outs, rapid tread wear and bead failures. Signs that forklift tires need replacement: Once the tread wears down to the wear indicator bars (typically 3/16 inch. Forklift Tire Wear Indicator.

From mavink.com

Tire Tread Wear Indicator Forklift Tire Wear Indicator There’s a magical line called the “wear line”. Inspect tires for chunks missing from the tread or sidewalls, as well as cracks. Signs that forklift tires need replacement: Monitor the tread depth regularly. Once the tread wears down to the wear indicator bars (typically 3/16 inch or 4.8 mm), the tires should be replaced. Forklift tires typically have a wear. Forklift Tire Wear Indicator.