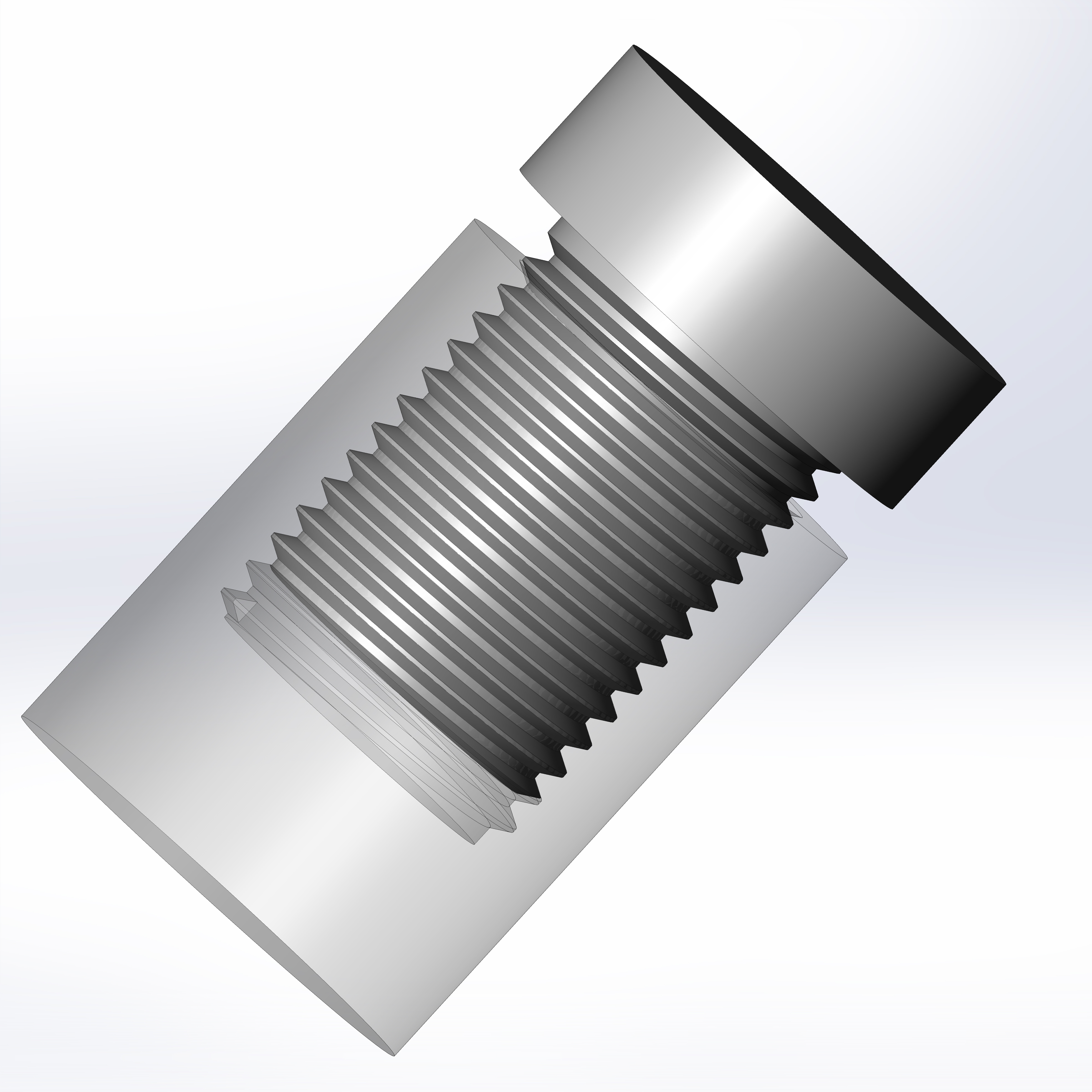

Solidworks Tap Vs Die . Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? You can create helical threads on cylindrical edges or faces using profile sketches and store custom thread profiles as library features. Should i extrude cut a 0.2010'' hole then use the tap thread feature? Try solidworks® freeused in over 80 countries What are they, and what's the difference between the two? There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. When threads get damaged on bolts or in bolt holes, there are two options: Solidworks thread wizard | how to make metric die and metric tap thread in solidworks. Taps & dies, or thread chasers. For solidworks external threads the options such as metric or inch die can be used, whereas options like metric or inch tap are best suited to threaded holes. Using the “thread” feature, users can define the beginning of a thread, specify an offset, set end conditions, specify the size, diameter, pitch and rotation angle and choose various options. Why do i have sets of each?

from thebloughs.net

Solidworks thread wizard | how to make metric die and metric tap thread in solidworks. For solidworks external threads the options such as metric or inch die can be used, whereas options like metric or inch tap are best suited to threaded holes. Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? What are they, and what's the difference between the two? You can create helical threads on cylindrical edges or faces using profile sketches and store custom thread profiles as library features. Try solidworks® freeused in over 80 countries Using the “thread” feature, users can define the beginning of a thread, specify an offset, set end conditions, specify the size, diameter, pitch and rotation angle and choose various options. Taps & dies, or thread chasers. There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. Should i extrude cut a 0.2010'' hole then use the tap thread feature?

Accurate Threads in SolidWorks Tom's Maker Site

Solidworks Tap Vs Die Solidworks thread wizard | how to make metric die and metric tap thread in solidworks. Taps & dies, or thread chasers. Should i extrude cut a 0.2010'' hole then use the tap thread feature? What are they, and what's the difference between the two? Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? When threads get damaged on bolts or in bolt holes, there are two options: Try solidworks® freeused in over 80 countries Solidworks thread wizard | how to make metric die and metric tap thread in solidworks. You can create helical threads on cylindrical edges or faces using profile sketches and store custom thread profiles as library features. There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. For solidworks external threads the options such as metric or inch die can be used, whereas options like metric or inch tap are best suited to threaded holes. Using the “thread” feature, users can define the beginning of a thread, specify an offset, set end conditions, specify the size, diameter, pitch and rotation angle and choose various options. Why do i have sets of each?

From michaellord.me

SOLIDWORKS 2016 At First Glance SOLIDWORKS Michael Lord Solidworks Tap Vs Die Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? Using the “thread” feature, users can define the beginning of a thread, specify an offset, set end conditions, specify the size, diameter, pitch and rotation angle and choose various options. Taps & dies, or thread chasers. You can create helical threads on cylindrical edges. Solidworks Tap Vs Die.

From www.youtube.com

SolidWorks Advanced Surface tutorial Water Tap Fitting YouTube Solidworks Tap Vs Die There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? For solidworks external threads the options such as metric or inch die can be used, whereas options like metric or inch tap. Solidworks Tap Vs Die.

From www.engineeringclicks.com

SOLIDWORKS external thread The SOLIDWORKS thread tool EngineeringClicks Solidworks Tap Vs Die Try solidworks® freeused in over 80 countries There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. When threads get damaged on bolts or in bolt holes, there are two options: Taps & dies, or thread chasers. Using the “thread” feature, users can define the beginning of a. Solidworks Tap Vs Die.

From www.javelin-tech.com

SOLIDWORKS Cosmetic Thread Display in Part, Assembly & Drawings Solidworks Tap Vs Die Try solidworks® freeused in over 80 countries Why do i have sets of each? When threads get damaged on bolts or in bolt holes, there are two options: Using the “thread” feature, users can define the beginning of a thread, specify an offset, set end conditions, specify the size, diameter, pitch and rotation angle and choose various options. For solidworks. Solidworks Tap Vs Die.

From klambzstq.blob.core.windows.net

What Are Taps And Dies Made From at Tony Haines blog Solidworks Tap Vs Die Solidworks thread wizard | how to make metric die and metric tap thread in solidworks. Using the “thread” feature, users can define the beginning of a thread, specify an offset, set end conditions, specify the size, diameter, pitch and rotation angle and choose various options. Should i extrude cut a 0.2010'' hole then use the tap thread feature? You can. Solidworks Tap Vs Die.

From trimech.com

How to Use Cosmetic Threads in SOLIDWORKS TriMech Solidworks Tap Vs Die You can create helical threads on cylindrical edges or faces using profile sketches and store custom thread profiles as library features. Should i extrude cut a 0.2010'' hole then use the tap thread feature? Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? Taps & dies, or thread chasers. Why do i have. Solidworks Tap Vs Die.

From www.youtube.com

Design of Spiral Tap Bit in solidworks Size M8X1.25 Solidworks Solidworks Tap Vs Die There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. Should i extrude cut a 0.2010'' hole then use the tap thread feature? What are they, and what's the difference between the two? Using the “thread” feature, users can define the beginning of a thread, specify an offset,. Solidworks Tap Vs Die.

From www.youtube.com

Solidworks tutorial I Design of Tap Bit M14 in Solidworks YouTube Solidworks Tap Vs Die Should i extrude cut a 0.2010'' hole then use the tap thread feature? You can create helical threads on cylindrical edges or faces using profile sketches and store custom thread profiles as library features. Solidworks thread wizard | how to make metric die and metric tap thread in solidworks. Should i extrude boss/base a ''rod'' of 0.642'' then use the. Solidworks Tap Vs Die.

From www.solidsolutions.ie

SOLIDWORKS Tips How to Create Threads in SOLIDWORKS Solidworks Tap Vs Die Solidworks thread wizard | how to make metric die and metric tap thread in solidworks. For solidworks external threads the options such as metric or inch die can be used, whereas options like metric or inch tap are best suited to threaded holes. Taps & dies, or thread chasers. Using the “thread” feature, users can define the beginning of a. Solidworks Tap Vs Die.

From www.cati.com

SOLIDWORKS Thread Profiles Computer Aided Technology Solidworks Tap Vs Die When threads get damaged on bolts or in bolt holes, there are two options: There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. Solidworks thread wizard | how to make metric die and metric tap thread in solidworks. Taps & dies, or thread chasers. Why do i. Solidworks Tap Vs Die.

From www.youtube.com

SolidWorks Tutorial For Beginners Exercise 189 (Hand Taps) YouTube Solidworks Tap Vs Die Solidworks thread wizard | how to make metric die and metric tap thread in solidworks. Using the “thread” feature, users can define the beginning of a thread, specify an offset, set end conditions, specify the size, diameter, pitch and rotation angle and choose various options. You can create helical threads on cylindrical edges or faces using profile sketches and store. Solidworks Tap Vs Die.

From www.youtube.com

Solidworks Tips 60 Making threads (Die & Tap) using Hole Wizard YouTube Solidworks Tap Vs Die Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? Try solidworks® freeused in over 80 countries Taps & dies, or thread chasers. What are they, and what's the difference between the two? There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually. Solidworks Tap Vs Die.

From www.youtube.com

Solidworks thread wizard How to make metric die and metric tap thread Solidworks Tap Vs Die For solidworks external threads the options such as metric or inch die can be used, whereas options like metric or inch tap are best suited to threaded holes. Using the “thread” feature, users can define the beginning of a thread, specify an offset, set end conditions, specify the size, diameter, pitch and rotation angle and choose various options. You can. Solidworks Tap Vs Die.

From www.youtube.com

SolidWorks How To Tap Holes! YouTube Solidworks Tap Vs Die Should i extrude cut a 0.2010'' hole then use the tap thread feature? Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? Taps & dies, or thread chasers. Solidworks thread wizard | how to make metric die and metric tap thread in solidworks. When threads get damaged on bolts or in bolt holes,. Solidworks Tap Vs Die.

From www.solidsolutions.ie

How to Thread a Hole in SOLIDWORKS Solidworks Tap Vs Die There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. When threads get damaged on bolts or in bolt holes, there are two options: What are they, and what's the difference between the two? You can create helical threads on cylindrical edges or faces using profile sketches and. Solidworks Tap Vs Die.

From www.perceptioneng.com

SolidWorks Threading — Perception Engineering Solidworks Tap Vs Die For solidworks external threads the options such as metric or inch die can be used, whereas options like metric or inch tap are best suited to threaded holes. When threads get damaged on bolts or in bolt holes, there are two options: Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? Why do. Solidworks Tap Vs Die.

From www.youtube.com

Solidworks tips 54 Calculating drill bit size for M10 tap and Solidworks Tap Vs Die Why do i have sets of each? When threads get damaged on bolts or in bolt holes, there are two options: Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? Should i extrude cut a 0.2010'' hole then use the tap thread feature? Taps & dies, or thread chasers. You can create helical. Solidworks Tap Vs Die.

From www.youtube.com

SolidWorks Drawings Practice for Taper Thread Pipe YouTube Solidworks Tap Vs Die Solidworks thread wizard | how to make metric die and metric tap thread in solidworks. Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. What are they, and what's the difference. Solidworks Tap Vs Die.

From www.youtube.com

Solidworks tutorial Represéntation de filetage mise en plan die Solidworks Tap Vs Die There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? For solidworks external threads the options such as metric or inch die can be used, whereas options like metric or inch tap. Solidworks Tap Vs Die.

From www.youtube.com

Solidworks advanced tutorials Making CSK, Cbore & Tap Holes with Hole Solidworks Tap Vs Die Should i extrude cut a 0.2010'' hole then use the tap thread feature? Why do i have sets of each? What are they, and what's the difference between the two? Try solidworks® freeused in over 80 countries Taps & dies, or thread chasers. For solidworks external threads the options such as metric or inch die can be used, whereas options. Solidworks Tap Vs Die.

From www.youtube.com

SolidWorks 2017 Revolve and Tap (Upper Die Center Pin) YouTube Solidworks Tap Vs Die Taps & dies, or thread chasers. Why do i have sets of each? There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. Using the “thread” feature, users can define the beginning of a thread, specify an offset, set end conditions, specify the size, diameter, pitch and rotation. Solidworks Tap Vs Die.

From www.engineeringclicks.com

SOLIDWORKS external thread The SOLIDWORKS thread tool EngineeringClicks Solidworks Tap Vs Die When threads get damaged on bolts or in bolt holes, there are two options: What are they, and what's the difference between the two? Taps & dies, or thread chasers. There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. Should i extrude boss/base a ''rod'' of 0.642''. Solidworks Tap Vs Die.

From joihxxiyv.blob.core.windows.net

Bottoming Tap Vs Straight Tap Solidworks at Jessica Busick blog Solidworks Tap Vs Die Taps & dies, or thread chasers. Why do i have sets of each? Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? You can create helical threads on cylindrical edges or faces using profile sketches and store custom thread profiles as library features. There is a huge range of standard thread sizes to. Solidworks Tap Vs Die.

From joihxxiyv.blob.core.windows.net

Bottoming Tap Vs Straight Tap Solidworks at Jessica Busick blog Solidworks Tap Vs Die Solidworks thread wizard | how to make metric die and metric tap thread in solidworks. Should i extrude cut a 0.2010'' hole then use the tap thread feature? Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? Using the “thread” feature, users can define the beginning of a thread, specify an offset, set. Solidworks Tap Vs Die.

From www.youtube.com

SOLIDWORKS Assembly Tutorial 1 Water Tap Part 4 YouTube Solidworks Tap Vs Die Why do i have sets of each? For solidworks external threads the options such as metric or inch die can be used, whereas options like metric or inch tap are best suited to threaded holes. Should i extrude cut a 0.2010'' hole then use the tap thread feature? There is a huge range of standard thread sizes to choose from. Solidworks Tap Vs Die.

From www.youtube.com

Solidworks tutorial sketch Tap Bit in Solidworks Solidworks YouTube Solidworks Tap Vs Die Try solidworks® freeused in over 80 countries What are they, and what's the difference between the two? Should i extrude cut a 0.2010'' hole then use the tap thread feature? For solidworks external threads the options such as metric or inch die can be used, whereas options like metric or inch tap are best suited to threaded holes. Taps &. Solidworks Tap Vs Die.

From grabcad.com

Solidworks water tap (2) GrabCAD Tutorials Solidworks Tap Vs Die Should i extrude cut a 0.2010'' hole then use the tap thread feature? Why do i have sets of each? There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? Solidworks thread. Solidworks Tap Vs Die.

From www.youtube.com

SOLIDWORKS THREAD METRIC TAP FEATURE SOLIDWORKS TUTORIALS BY Solidworks Tap Vs Die Taps & dies, or thread chasers. Why do i have sets of each? Try solidworks® freeused in over 80 countries Solidworks thread wizard | how to make metric die and metric tap thread in solidworks. You can create helical threads on cylindrical edges or faces using profile sketches and store custom thread profiles as library features. Should i extrude boss/base. Solidworks Tap Vs Die.

From www.youtube.com

How to design M20 Tap bit in Solidworks Solidworks Tutorial YouTube Solidworks Tap Vs Die Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? For solidworks external threads the options such as metric or inch die can be used, whereas options like metric or inch tap are best suited to threaded holes. When threads get damaged on bolts or in bolt holes, there are two options: Try solidworks®. Solidworks Tap Vs Die.

From thebloughs.net

Accurate Threads in SolidWorks Tom's Maker Site Solidworks Tap Vs Die There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. Solidworks thread wizard | how to make metric die and metric tap thread in solidworks. Taps & dies, or thread chasers. Should i extrude boss/base a ''rod'' of 0.642'' then use the die thread feature like this? You. Solidworks Tap Vs Die.

From telegra.ph

Solidworks Рекомендуемые Видеокарты Telegraph Solidworks Tap Vs Die Solidworks thread wizard | how to make metric die and metric tap thread in solidworks. What are they, and what's the difference between the two? There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. You can create helical threads on cylindrical edges or faces using profile sketches. Solidworks Tap Vs Die.

From www.youtube.com

Tap modeling in Solidworks YouTube Solidworks Tap Vs Die There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. Taps & dies, or thread chasers. Try solidworks® freeused in over 80 countries Using the “thread” feature, users can define the beginning of a thread, specify an offset, set end conditions, specify the size, diameter, pitch and rotation. Solidworks Tap Vs Die.

From www.youtube.com

SolidWorks Tutorial 2021! Exercise 107! Thread Metric Tap/Die step by Solidworks Tap Vs Die When threads get damaged on bolts or in bolt holes, there are two options: Try solidworks® freeused in over 80 countries Should i extrude cut a 0.2010'' hole then use the tap thread feature? There is a huge range of standard thread sizes to choose from and the diameter and pitch can also be manually overridden. What are they, and. Solidworks Tap Vs Die.

From www.youtube.com

Creating Threads Using SOLIDWORKS 2020 YouTube Solidworks Tap Vs Die For solidworks external threads the options such as metric or inch die can be used, whereas options like metric or inch tap are best suited to threaded holes. Should i extrude cut a 0.2010'' hole then use the tap thread feature? Try solidworks® freeused in over 80 countries When threads get damaged on bolts or in bolt holes, there are. Solidworks Tap Vs Die.

From www.youtube.com

Solidworks tutorial die design YouTube Solidworks Tap Vs Die Try solidworks® freeused in over 80 countries Taps & dies, or thread chasers. Solidworks thread wizard | how to make metric die and metric tap thread in solidworks. Using the “thread” feature, users can define the beginning of a thread, specify an offset, set end conditions, specify the size, diameter, pitch and rotation angle and choose various options. Should i. Solidworks Tap Vs Die.