Vacuum Casting Diagram . It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. This method suits prototypes or. This differs from a closely related process, injection molding (im), in which the liquid materials are pushed into the mold by force.

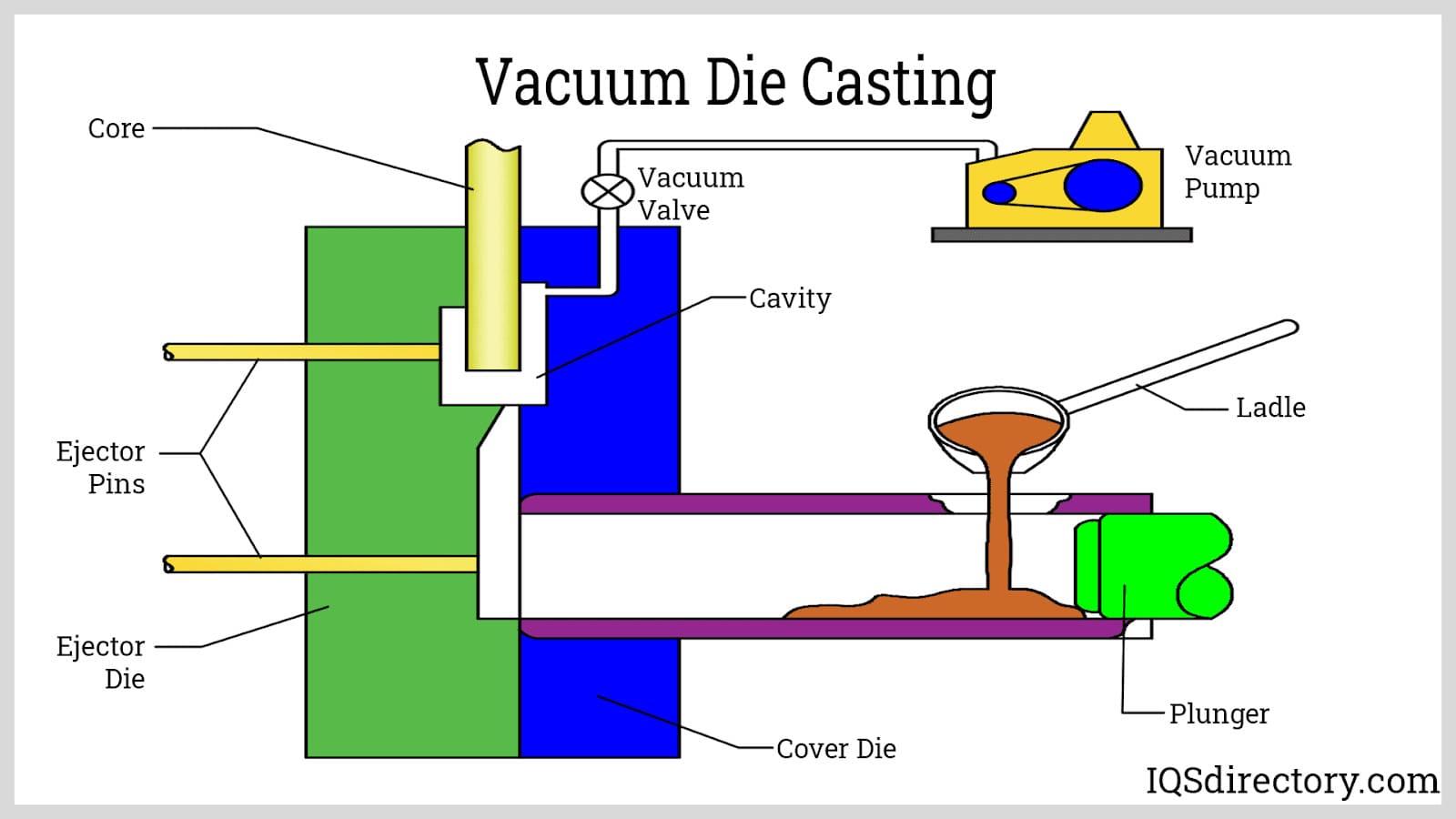

from www.iqsdirectory.com

By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. This differs from a closely related process, injection molding (im), in which the liquid materials are pushed into the mold by force. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. This method suits prototypes or. In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum.

Aluminum Casting What Is It? How Is it Made? Advantages

Vacuum Casting Diagram This differs from a closely related process, injection molding (im), in which the liquid materials are pushed into the mold by force. This method suits prototypes or. By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. This differs from a closely related process, injection molding (im), in which the liquid materials are pushed into the mold by force. In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum.

From www.slideserve.com

PPT Introducing Dow Epoxy Systems for PowerPoint Presentation ID608481 Vacuum Casting Diagram Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. This differs from a closely related. Vacuum Casting Diagram.

From www.thelibraryofmanufacturing.com

Vacuum Casting or Vprocess Vacuum Casting Diagram In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. It involves creating a mould of the desired part and then injecting liquid plastic or. Vacuum Casting Diagram.

From www.researchgate.net

The principle schematic diagram of the vacuum and lowpressure casting Vacuum Casting Diagram Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. This differs from a closely related process, injection molding (im), in which the liquid materials are pushed into the mold by force. In this paper we are investigating. Vacuum Casting Diagram.

From www.researchgate.net

Vacuum casting process. (Courtesy of M CP) Download Scientific Diagram Vacuum Casting Diagram It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. This method suits prototypes or. In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. Vacuum casting, otherwise called polyurethane casting or urethane casting, is. Vacuum Casting Diagram.

From www.researchgate.net

Vacuum casting equipment Download Scientific Diagram Vacuum Casting Diagram This method suits prototypes or. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. This. Vacuum Casting Diagram.

From www.youtube.com

Vacuum Forming Process Working Applications ENGINEERING STUDY Vacuum Casting Diagram It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting. Vacuum Casting Diagram.

From www.rocheindustry.com

Handbook The Ultimate Guide To Vacuum Casting Vacuum Casting Diagram By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. This method suits prototypes or. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. Vacuum casting, otherwise called polyurethane casting or urethane casting, is a. Vacuum Casting Diagram.

From www.summative.in

Vacuum Casting Services Summative Engineering Vacuum Casting Diagram In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. By leveraging the principles of. Vacuum Casting Diagram.

From www.rtprototype.com

Why Choose Vacuum Casting for Medical Products? Ruitai Mould Vacuum Casting Diagram This differs from a closely related process, injection molding (im), in which the liquid materials are pushed into the mold by force. By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the. Vacuum Casting Diagram.

From www.researchgate.net

—The schematic diagram of the vacuum and low pressure casting process Vacuum Casting Diagram This differs from a closely related process, injection molding (im), in which the liquid materials are pushed into the mold by force. In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. It involves creating a mould of the desired part and then injecting liquid plastic or. Vacuum Casting Diagram.

From www.metalprintindia.co

Vacuum Casting Metal Print Vacuum Casting Diagram Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. In this paper we are investigating. Vacuum Casting Diagram.

From www.iqsdirectory.com

Aluminum Casting What Is It? How Is it Made? Advantages Vacuum Casting Diagram It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the. Vacuum Casting Diagram.

From www.hordrt.com

From Prototype to Reality Vacuum Casting Vacuum Casting Diagram Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. This method suits prototypes or.. Vacuum Casting Diagram.

From www.open.edu

Resin shell casting OpenLearn Open University Vacuum Casting Diagram It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. This differs from a closely related process, injection molding (im), in which the liquid materials. Vacuum Casting Diagram.

From www.pcbway.com

Features of Three Types Vacuum Casting 3D Printing PCBway Vacuum Casting Diagram In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes. Vacuum Casting Diagram.

From www.ar-deko.su.premier-sols.com

Compact Vacuum Arc Melting System with Vacuum Casting Mold for 6mm Dia Vacuum Casting Diagram In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. This method suits prototypes or.. Vacuum Casting Diagram.

From www.lcrapid.com

The Working Principle of Vacuum Casting and Its Advantages of the Three Vacuum Casting Diagram Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. This method suits prototypes or. In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in.. Vacuum Casting Diagram.

From www.thelibraryofmanufacturing.com

Pressure Casting Vacuum Casting Diagram This method suits prototypes or. Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. It. Vacuum Casting Diagram.

From www.researchgate.net

8 Automated vacuum casting plant of an epoxy composition Vacuum Casting Diagram Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. This method suits prototypes or. It. Vacuum Casting Diagram.

From www.researchgate.net

Schematic procedure of vacuum arc remelting Download Scientific Diagram Vacuum Casting Diagram By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. This method suits prototypes or. In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. It involves creating a mould of the desired part and. Vacuum Casting Diagram.

From www.pinterest.com

Pin on Information to use Vacuum Casting Diagram Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. This method suits prototypes or. This. Vacuum Casting Diagram.

From www.researchgate.net

Vacuum casting process. (Courtesy of M CP) Download Scientific Diagram Vacuum Casting Diagram In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. This differs from a closely related process, injection molding (im), in which the liquid materials. Vacuum Casting Diagram.

From www.giessereilexikon.com

Vacuumassisted die casting Vacuum Casting Diagram This method suits prototypes or. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. This differs from a closely related process, injection molding (im), in. Vacuum Casting Diagram.

From www.youtube.com

Vacuum Molding Expandable Mold Casting Processes. YouTube Vacuum Casting Diagram Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. This method suits prototypes or. By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. It. Vacuum Casting Diagram.

From www.researchgate.net

Schematic diagram of high temperature vertical vacuum casting machine Vacuum Casting Diagram This method suits prototypes or. Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. This. Vacuum Casting Diagram.

From www.iqsdirectory.com

Die Casting What is it? Overview, Process, Design, Material Vacuum Casting Diagram Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. In this paper we are investigating. Vacuum Casting Diagram.

From en.jyzzsb.com

Introduction of vacuum casting equipment Vacuum casting equipment Vacuum Casting Diagram Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. In this paper we are investigating. Vacuum Casting Diagram.

From www.thelibraryofmanufacturing.com

Vacuum Casting or Vprocess Vacuum Casting Diagram By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. It involves creating a mould of. Vacuum Casting Diagram.

From www.open.edu

"V" Process (Vacuum sealed moulding process) OpenLearn Open University Vacuum Casting Diagram Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. This differs from a closely related process, injection molding (im), in which the liquid materials are pushed into the mold by force. This method suits prototypes or. It. Vacuum Casting Diagram.

From www.marmaxdesign.com

Guide to vacuum casting MarMax Vacuum Casting Diagram This method suits prototypes or. By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. Vacuum casting, otherwise called polyurethane casting or urethane casting, is a. Vacuum Casting Diagram.

From www.kaiao-rprt.com

what is vacuum casting? Kaiao Rapid Manufacturing Co., Limited. Vacuum Casting Diagram This differs from a closely related process, injection molding (im), in which the liquid materials are pushed into the mold by force. By leveraging the principles of a vacuum environment, mold preparation, and material selection, vacuum casting enables the creation of complex geometries with. It involves creating a mould of the desired part and then injecting liquid plastic or metal. Vacuum Casting Diagram.

From www.researchgate.net

General process flow for vacuum casting technique of polymer Vacuum Casting Diagram Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. This method suits prototypes or.. Vacuum Casting Diagram.

From ppcpinc.com

Pennsylvania Precision Cast Parts Investment Casting Process Vacuum Casting Diagram This method suits prototypes or. In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. This differs from a closely related process, injection molding (im), in which the liquid materials are pushed into the mold by force. Vacuum casting, otherwise called polyurethane casting or urethane casting, is. Vacuum Casting Diagram.

From www.researchgate.net

A photo and schematic illustration of internal structure of Vacuum Casting Diagram This method suits prototypes or. Vacuum casting, otherwise called polyurethane casting or urethane casting, is a manufacturing process that makes a cast of an object by drawing a liquid material into a silicone mold using a vacuum. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. This. Vacuum Casting Diagram.

From www.open.edu

Sand casting OpenLearn Open University Vacuum Casting Diagram This method suits prototypes or. In this paper we are investigating the microstructure, porosity, surface roughness and mechanical properties of the component developed using vacuum pressure casting in. It involves creating a mould of the desired part and then injecting liquid plastic or metal into the mould under a vacuum. By leveraging the principles of a vacuum environment, mold preparation,. Vacuum Casting Diagram.