Automatic Assembly Method . Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. Automated assemblies can be categorized into two installation strategies. Industrial robots have been used in the various manufacturing processes such as part handling, palletizing, welding, assembly, processing and. In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. The first involves the use of robots to manipulate.

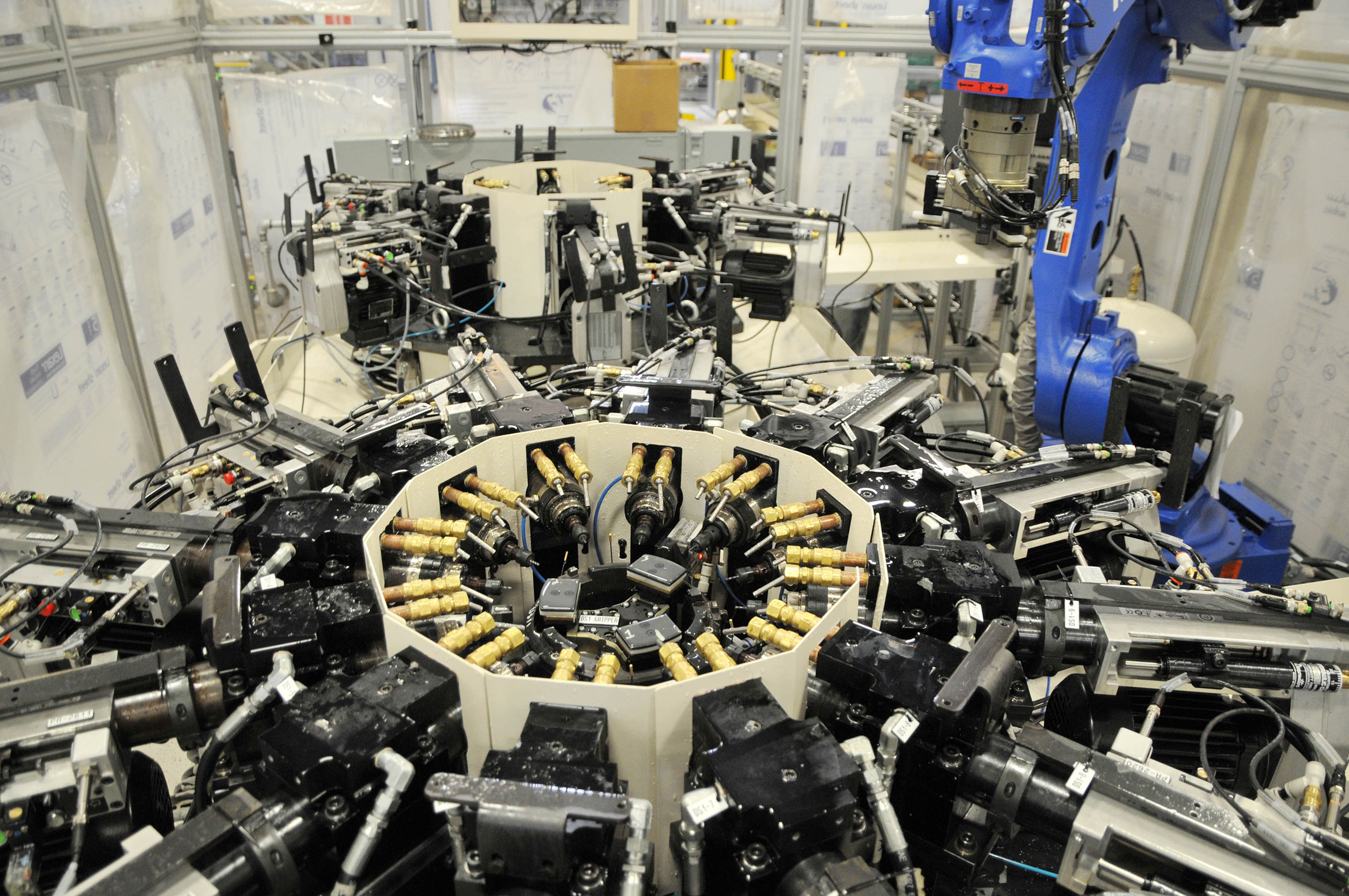

from www.promation.com

The first involves the use of robots to manipulate. In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. Industrial robots have been used in the various manufacturing processes such as part handling, palletizing, welding, assembly, processing and. Automated assemblies can be categorized into two installation strategies.

Automated Assembly Systems Promation Automotive

Automatic Assembly Method Automated assemblies can be categorized into two installation strategies. Automated assemblies can be categorized into two installation strategies. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. The first involves the use of robots to manipulate. A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. Industrial robots have been used in the various manufacturing processes such as part handling, palletizing, welding, assembly, processing and. This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad.

From www.researchgate.net

Automatic assembly system for a frame structure Download Scientific Automatic Assembly Method This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. Industrial robots have been used in the various manufacturing processes such as part handling, palletizing, welding, assembly, processing and. A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. In this work, we present. Automatic Assembly Method.

From www.kellertechnology.com

Common Part Transfer Methods for Factory Automation Automatic Assembly Method Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. Industrial robots have been used in the various manufacturing processes such as part handling, palletizing, welding, assembly, processing and. This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. The first involves the use. Automatic Assembly Method.

From eureka.patsnap.com

Automatic assembly production line and assembly method for household Automatic Assembly Method A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. The first involves the use of robots to manipulate. Automated assemblies can be categorized into two installation strategies. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. Industrial robots have been. Automatic Assembly Method.

From www2.tm-robot.com

On Designing an Automatic Assembly Line Techman Robot Automatic Assembly Method A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. The first involves the use of robots to manipulate. Automated assemblies can be categorized into two installation strategies. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. This paper conducts a. Automatic Assembly Method.

From www.promaticautomation.com

Automotive Assembly Lines Promatic Automation Automatic Assembly Method A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. Automated assemblies can be categorized into two installation strategies. The first involves the use of robots to manipulate. In this work, we present the. Automatic Assembly Method.

From www.researchgate.net

Layout diagram of automatic assembly machine Download Scientific Diagram Automatic Assembly Method In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. Automated assemblies can be categorized into two installation strategies. Autohic harnesses the knowledge derived from manual correction within assembly tools. Automatic Assembly Method.

From www.researchgate.net

(PDF) Modeling automatic assembly and disassembly operations for Automatic Assembly Method The first involves the use of robots to manipulate. This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. Automated assemblies can be categorized into two installation strategies. In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. Autohic harnesses the knowledge. Automatic Assembly Method.

From www.rnaautomation.com

Automated Assembly Machines, Special Purpose Machines RNA Automation Automatic Assembly Method Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. The first involves the use. Automatic Assembly Method.

From www.researchgate.net

(PDF) Digital TwinDriven Control Method for Robotic Automatic Assembly Automatic Assembly Method The first involves the use of robots to manipulate. A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. Industrial robots have been used in the various manufacturing processes such as part handling, palletizing, welding, assembly, processing and. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49). Automatic Assembly Method.

From www.u2robotics.com

Automatic assembly machine, automation system solutions Automatic Assembly Method Automated assemblies can be categorized into two installation strategies. Industrial robots have been used in the various manufacturing processes such as part handling, palletizing, welding, assembly, processing and. The first involves the use of robots to manipulate. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. A truly flexible assembly. Automatic Assembly Method.

From www.youtube.com

Lock Catch Automatic Assembly Machine Get The Best Machine for Your Automatic Assembly Method A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. The first involves the use. Automatic Assembly Method.

From www.researchgate.net

(PDF) An efficient method of automatic assembly sequence planning for Automatic Assembly Method In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. Industrial. Automatic Assembly Method.

From www.researchgate.net

(PDF) Automatic assembly of a commercial cavity block system Automatic Assembly Method This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. The first involves the use. Automatic Assembly Method.

From www.wevolver.com

How Assembly Line Automation is Revolutionizing Manufacturing? Types Automatic Assembly Method Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. Automated assemblies can be categorized into two installation strategies. In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. This paper conducts a systematic literature review to identify research publications. Automatic Assembly Method.

From www.rnaautomation.com

Assembly Automation Systems RNA Automation Automatic Assembly Method In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. Automated assemblies can be categorized into two installation strategies. The first involves the use of robots to manipulate. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. Industrial robots. Automatic Assembly Method.

From nuspark.com

Assembly Machines Nuspark Automatic Assembly Method Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. A truly flexible. Automatic Assembly Method.

From www.youtube.com

automatic assembly machine002 YouTube Automatic Assembly Method A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. The first involves the use of robots to manipulate. Industrial robots have been used in the various manufacturing processes such. Automatic Assembly Method.

From www.huaxu668.com

Automatic Assembly lineAutomatic Assembly line Automatic Assembly Method In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. The first involves the use of robots to manipulate. Automated assemblies can be categorized into two installation strategies. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. This paper. Automatic Assembly Method.

From www.promation.com

Automated Assembly Systems Promation Automotive Automatic Assembly Method Automated assemblies can be categorized into two installation strategies. The first involves the use of robots to manipulate. In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. Industrial robots. Automatic Assembly Method.

From www.tqc.co.uk

Automatic Assembly Line Machines & Automation System Solutions Automatic Assembly Method Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. Industrial. Automatic Assembly Method.

From www.tw-automation.com

What Does a Fully Automated Assembly Line Look Like? Automatic Assembly Method A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. In this work, we present. Automatic Assembly Method.

From www.youtube.com

Automatic Assembly Machines Tecnodinamica YouTube Automatic Assembly Method This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. Industrial robots have been used in the various manufacturing processes such as part handling, palletizing, welding, assembly, processing and. In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. The first involves. Automatic Assembly Method.

From www.rnaautomation.com

Assembly Automation Systems RNA Automation Automatic Assembly Method Automated assemblies can be categorized into two installation strategies. This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. The first involves the use of robots to manipulate. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. In this work, we present the. Automatic Assembly Method.

From nuspark.com

Fully Automatic Assembly Line Gizmo Cap Nuspark Automatic Assembly Method This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. Automated assemblies can be categorized into two installation strategies. In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based. Automatic Assembly Method.

From www.automatedproduction.co.uk

Assembly Automation Systems Automated Production Ltd Automatic Assembly Method The first involves the use of robots to manipulate. In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. Industrial robots have been used in the various manufacturing processes such as part handling, palletizing, welding, assembly, processing and. A truly flexible assembly system would enable precision assembly, include flexible. Automatic Assembly Method.

From www.tqc.co.uk

Assembly Automation Machines and Automated System Solutions Automatic Assembly Method Industrial robots have been used in the various manufacturing processes such as part handling, palletizing, welding, assembly, processing and. A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. The first involves the use of robots to manipulate. This paper conducts a systematic literature review to identify research publications that quantify. Automatic Assembly Method.

From pcbinsider.com

What is Mechanical Assembly? Mechanical Assembly Processes Automatic Assembly Method A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. Industrial robots have been used. Automatic Assembly Method.

From www.tm-robot.com.cn

On Designing an Automatic Assembly Line Techman Robot Automatic Assembly Method In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. Industrial robots have. Automatic Assembly Method.

From sp-automation.co.uk

Designing & Building Assembly Systems SP Automation & Robotics Automatic Assembly Method Industrial robots have been used in the various manufacturing processes such as part handling, palletizing, welding, assembly, processing and. A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. This. Automatic Assembly Method.

From www.dreamstime.com

Installer of SMD Parts on Boards and Soldering Parts. Machine for Automatic Assembly Method This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. The first involves the use of robots to manipulate. Industrial robots have been used in the various manufacturing processes such as part handling, palletizing,. Automatic Assembly Method.

From www.assemblymag.com

Automated Assembly System Moves Hitachi in Right Direction 20160104 Automatic Assembly Method Industrial robots have been used in the various manufacturing processes such as part handling, palletizing, welding, assembly, processing and. Automated assemblies can be categorized into two installation strategies. A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. In this work, we present the automatic assembly synthesis model (aasm), connecting a. Automatic Assembly Method.

From eureka.patsnap.com

Automatic assembly method and assembly system for strain gauge Eureka Automatic Assembly Method Automated assemblies can be categorized into two installation strategies. Industrial robots have been used in the various manufacturing processes such as part handling, palletizing, welding, assembly, processing and. The first involves the use of robots to manipulate. This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. A truly flexible assembly system would. Automatic Assembly Method.

From www.mcalpin-ind.com

The Assembly Process in Manufacturing Automatic Assembly Method A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. Autohic harnesses the. Automatic Assembly Method.

From www.lacconveyors.co.uk

Automatic Assembly Processes L.A.C. Conveyors & Automation Automatic Assembly Method In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. This paper conducts a systematic literature review to identify research publications that quantify the fitness for automated. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. The first involves. Automatic Assembly Method.

From www.tm-robot.com

The Benefits of Automatic Assembly Lines Techman Robot Automatic Assembly Method In this work, we present the automatic assembly synthesis model (aasm), connecting a knowledge based engineering (kbe) system and a cad. Autohic harnesses the knowledge derived from manual correction within assembly tools (48, 49) to provide a fully automated, deep. A truly flexible assembly system would enable precision assembly, include flexible part feeding, grasping, and fixturing, as well as. Industrial. Automatic Assembly Method.