What Speed To Turn Steel On A Lathe . These factors determine the cutting. Velocity is measured in units of length per unit time, for. Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface of the material as it moves across the cutting tool. The lathe speed directly influences cutting speed, feed rate, and surface feet per minute. Find the turning formulas needed for lathe turning. Ft should not exceed 90% of maximum load stated for the bar used. To achieve optimal results, it is essential to. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. The feed rate and spindle speed determine how fast the lathe cutting tool moves and how quickly the material is removed. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes.

from www.slideserve.com

Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. The feed rate and spindle speed determine how fast the lathe cutting tool moves and how quickly the material is removed. The lathe speed directly influences cutting speed, feed rate, and surface feet per minute. Velocity is measured in units of length per unit time, for. Find the turning formulas needed for lathe turning. Ft should not exceed 90% of maximum load stated for the bar used. Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface of the material as it moves across the cutting tool. These factors determine the cutting. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. To achieve optimal results, it is essential to.

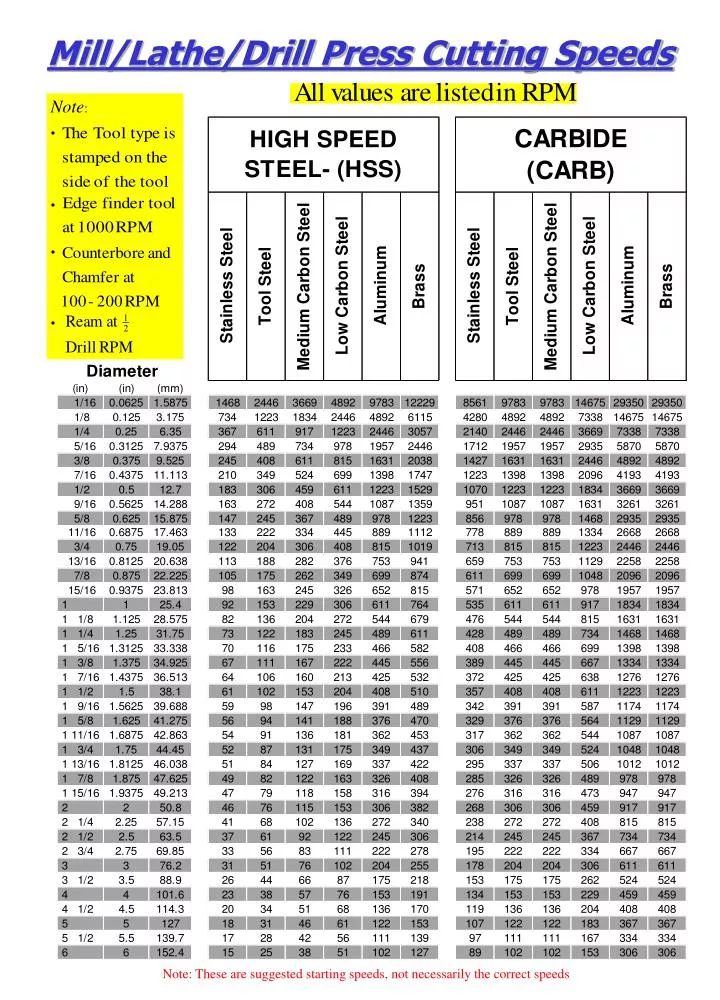

PPT Mill/Lathe/Drill Press Cutting Speeds PowerPoint Presentation

What Speed To Turn Steel On A Lathe Find the turning formulas needed for lathe turning. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. Ft should not exceed 90% of maximum load stated for the bar used. To achieve optimal results, it is essential to. These factors determine the cutting. The lathe speed directly influences cutting speed, feed rate, and surface feet per minute. Velocity is measured in units of length per unit time, for. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. The feed rate and spindle speed determine how fast the lathe cutting tool moves and how quickly the material is removed. Find the turning formulas needed for lathe turning. Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface of the material as it moves across the cutting tool.

From www.yashmachine.com

Importance of Lathe Machines for Metal Shaping Industries Yash Machine What Speed To Turn Steel On A Lathe These factors determine the cutting. Find the turning formulas needed for lathe turning. Ft should not exceed 90% of maximum load stated for the bar used. To achieve optimal results, it is essential to. The feed rate and spindle speed determine how fast the lathe cutting tool moves and how quickly the material is removed. Turning speeds are adjusted to. What Speed To Turn Steel On A Lathe.

From woodworkadvice.com

Drill Press Speed Chart Your 2021 Guide Woodwork Advice What Speed To Turn Steel On A Lathe These factors determine the cutting. Ft should not exceed 90% of maximum load stated for the bar used. The feed rate and spindle speed determine how fast the lathe cutting tool moves and how quickly the material is removed. Find the turning formulas needed for lathe turning. Velocity is measured in units of length per unit time, for. To achieve. What Speed To Turn Steel On A Lathe.

From caltech-mce-lab.wikidot.com

Lathe Information Caltech MCE Lab What Speed To Turn Steel On A Lathe Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. These factors determine the cutting. The feed rate and spindle speed determine how fast the lathe cutting tool moves and how quickly the material is removed. Velocity is measured in units of length per unit. What Speed To Turn Steel On A Lathe.

From mavink.com

Tabel Cutting Speed What Speed To Turn Steel On A Lathe Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. Find the turning formulas needed for lathe turning. Velocity. What Speed To Turn Steel On A Lathe.

From tubingchina.com

Speeds and Feeds for Turning Stainless Steel What Speed To Turn Steel On A Lathe Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. To achieve optimal results, it is essential to. Velocity is measured in units of length per unit time, for. The lathe speed directly influences cutting speed, feed rate, and surface feet per minute. Cutting speed. What Speed To Turn Steel On A Lathe.

From mungfali.com

Lathe Speeds And Feeds Chart What Speed To Turn Steel On A Lathe Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. Cutting speed (often abbreviated vc) on a lathe is. What Speed To Turn Steel On A Lathe.

From www.youtube.com

Turning Steel on a lathe "slow motion" YouTube What Speed To Turn Steel On A Lathe These factors determine the cutting. To achieve optimal results, it is essential to. Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface of the material as it moves across the cutting tool. The lathe speed directly influences cutting speed, feed rate, and surface feet per minute. Ft should not exceed 90% of maximum load stated. What Speed To Turn Steel On A Lathe.

From thehabitofwoodworking.com

How Fast Do Lathes Spin? The Habit of Woodworking What Speed To Turn Steel On A Lathe To achieve optimal results, it is essential to. Velocity is measured in units of length per unit time, for. Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface of the material as it moves across the cutting tool. Find the turning formulas needed for lathe turning. Cutting speed is the spindle speed, while it can. What Speed To Turn Steel On A Lathe.

From mavink.com

Metal Lathe Speed Chart What Speed To Turn Steel On A Lathe Velocity is measured in units of length per unit time, for. To achieve optimal results, it is essential to. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. The lathe speed directly influences cutting speed, feed rate, and surface feet per minute. The. What Speed To Turn Steel On A Lathe.

From www.pinterest.com

Milling cutter speeds Tool company, Lathe tools, Machine shop What Speed To Turn Steel On A Lathe Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. Find the turning formulas needed for lathe turning. These factors determine the cutting. The lathe speed directly influences cutting speed, feed rate, and surface feet per minute. Velocity is measured in units of length. What Speed To Turn Steel On A Lathe.

From mellowpine.com

Speeds and Feeds Beginner Guide with Table MellowPine What Speed To Turn Steel On A Lathe The feed rate and spindle speed determine how fast the lathe cutting tool moves and how quickly the material is removed. The lathe speed directly influences cutting speed, feed rate, and surface feet per minute. Ft should not exceed 90% of maximum load stated for the bar used. Cutting speed (often abbreviated vc) on a lathe is the velocity of. What Speed To Turn Steel On A Lathe.

From www.harveyperformance.com

The 3 Critical Factors of Turning Speeds and Feeds In The Loupe What Speed To Turn Steel On A Lathe Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface of the material as it moves across the cutting tool. Find the turning formulas needed for lathe turning. Velocity is measured in units of length per unit time, for. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut. What Speed To Turn Steel On A Lathe.

From www.youtube.com

Metal Lathe Tutorial 21 Speeds & Feeds YouTube What Speed To Turn Steel On A Lathe Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface of the material as it moves across the cutting tool. Find the turning formulas needed for lathe turning. Ft should not exceed 90% of maximum load stated for the bar used. Cutting speed is the spindle speed, while it can be regarded as the speed of. What Speed To Turn Steel On A Lathe.

From mungfali.com

Lathe Speeds And Feeds Chart What Speed To Turn Steel On A Lathe Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. The feed rate and spindle speed determine how fast the lathe cutting tool moves and how quickly the material is removed. Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface. What Speed To Turn Steel On A Lathe.

From www.youtube.com

02_04_P2 Cutting Speed, Feed, and Machining Time for Turning a Part on What Speed To Turn Steel On A Lathe These factors determine the cutting. To achieve optimal results, it is essential to. Velocity is measured in units of length per unit time, for. Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface of the material as it moves across the cutting tool. Turning speeds are adjusted to the feed rate of the mini lathe. What Speed To Turn Steel On A Lathe.

From dat.perueduca.edu.pe

Lathe Cutting Speed Chart Pdf Printable Templates Free What Speed To Turn Steel On A Lathe Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface of the material as it moves across the cutting tool. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. Velocity is measured in units of length per unit time,. What Speed To Turn Steel On A Lathe.

From www.pinterest.com

How to turn steel alloy on a lathe termsll • Handcrafted metal works What Speed To Turn Steel On A Lathe These factors determine the cutting. Velocity is measured in units of length per unit time, for. To achieve optimal results, it is essential to. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. Turning speeds are adjusted to the feed rate of the mini. What Speed To Turn Steel On A Lathe.

From www.youtube.com

3 How to Calculate the correct Lathe turning speed YouTube What Speed To Turn Steel On A Lathe Ft should not exceed 90% of maximum load stated for the bar used. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at. What Speed To Turn Steel On A Lathe.

From mavink.com

Tabel Cutting Speed What Speed To Turn Steel On A Lathe The lathe speed directly influences cutting speed, feed rate, and surface feet per minute. These factors determine the cutting. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. Velocity is measured in units of length per unit time, for. Turning speeds are adjusted to. What Speed To Turn Steel On A Lathe.

From tubingchina.com

Speeds and Feeds for Turning Stainless Steel What Speed To Turn Steel On A Lathe Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface of the material as it moves across the cutting tool. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. The feed rate and spindle speed determine how fast the lathe. What Speed To Turn Steel On A Lathe.

From bssa.org.uk

Speeds and feeds for turning stainless steels British Stainless Steel What Speed To Turn Steel On A Lathe The lathe speed directly influences cutting speed, feed rate, and surface feet per minute. To achieve optimal results, it is essential to. Ft should not exceed 90% of maximum load stated for the bar used. Velocity is measured in units of length per unit time, for. The feed rate and spindle speed determine how fast the lathe cutting tool moves. What Speed To Turn Steel On A Lathe.

From www.youtube.com

Turning stainless steel on the lathe Modify and improve an old tool What Speed To Turn Steel On A Lathe To achieve optimal results, it is essential to. Velocity is measured in units of length per unit time, for. Ft should not exceed 90% of maximum load stated for the bar used. These factors determine the cutting. The lathe speed directly influences cutting speed, feed rate, and surface feet per minute. Cutting speed (often abbreviated vc) on a lathe is. What Speed To Turn Steel On A Lathe.

From thehabitofwoodworking.com

What Rpm Should Steel Be Turned At On A Lathe? The Habit of Woodworking What Speed To Turn Steel On A Lathe The feed rate and spindle speed determine how fast the lathe cutting tool moves and how quickly the material is removed. Velocity is measured in units of length per unit time, for. Find the turning formulas needed for lathe turning. Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface of the material as it moves. What Speed To Turn Steel On A Lathe.

From lamer.poolhome.es

Lathe Spindle Speed Chart Lamer What Speed To Turn Steel On A Lathe To achieve optimal results, it is essential to. Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface of the material as it moves across the cutting tool. Find the turning formulas needed for lathe turning. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves. What Speed To Turn Steel On A Lathe.

From www.slideserve.com

PPT Mill/Lathe/Drill Press Cutting Speeds PowerPoint Presentation What Speed To Turn Steel On A Lathe The feed rate and spindle speed determine how fast the lathe cutting tool moves and how quickly the material is removed. Ft should not exceed 90% of maximum load stated for the bar used. Velocity is measured in units of length per unit time, for. The lathe speed directly influences cutting speed, feed rate, and surface feet per minute. Turning. What Speed To Turn Steel On A Lathe.

From bceweb.org

Lathe Cutting Speeds And Feeds Chart Metric A Visual Reference of What Speed To Turn Steel On A Lathe Find the turning formulas needed for lathe turning. Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface of the material as it moves across the cutting tool. To achieve optimal results, it is essential to. The lathe speed directly influences cutting speed, feed rate, and surface feet per minute. These factors determine the cutting. The. What Speed To Turn Steel On A Lathe.

From tubingchina.com

Speeds and Feeds for Turning Stainless Steel What Speed To Turn Steel On A Lathe To achieve optimal results, it is essential to. Ft should not exceed 90% of maximum load stated for the bar used. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. The feed rate and spindle speed determine how fast the lathe cutting tool moves. What Speed To Turn Steel On A Lathe.

From technologystudent.com

Using the Automatic Traverse to Turn a Length of Steel What Speed To Turn Steel On A Lathe Velocity is measured in units of length per unit time, for. The feed rate and spindle speed determine how fast the lathe cutting tool moves and how quickly the material is removed. To achieve optimal results, it is essential to. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and. What Speed To Turn Steel On A Lathe.

From www.scribd.com

Stellram Turning Cutting Speeds Inch PDF Stainless Steel Steel What Speed To Turn Steel On A Lathe Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. The lathe speed directly influences cutting speed, feed rate, and surface feet per minute. Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface of the material as it moves. What Speed To Turn Steel On A Lathe.

From mavink.com

Lathe Tooling Chart What Speed To Turn Steel On A Lathe To achieve optimal results, it is essential to. The feed rate and spindle speed determine how fast the lathe cutting tool moves and how quickly the material is removed. Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface of the material as it moves across the cutting tool. Turning speeds are adjusted to the feed. What Speed To Turn Steel On A Lathe.

From tubingchina.com

Speeds and Feeds for Turning Stainless Steel What Speed To Turn Steel On A Lathe Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. The lathe speed directly influences cutting speed, feed rate, and surface feet per minute. Ft should not exceed 90% of maximum load stated for the bar used. The feed rate and spindle speed determine. What Speed To Turn Steel On A Lathe.

From engineeringskill.blogspot.com

Engineering Skill II LAB 1 LATHE / TURNING WORK What Speed To Turn Steel On A Lathe Ft should not exceed 90% of maximum load stated for the bar used. Find the turning formulas needed for lathe turning. The feed rate and spindle speed determine how fast the lathe cutting tool moves and how quickly the material is removed. Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the. What Speed To Turn Steel On A Lathe.

From imagetou.com

How To Run A Metal Lathe Image to u What Speed To Turn Steel On A Lathe These factors determine the cutting. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. The feed rate and spindle speed determine how fast the lathe cutting tool moves and how quickly the material is removed. Cutting speed is the spindle speed, while it. What Speed To Turn Steel On A Lathe.

From fixfixkeith.z6.web.core.windows.net

How To Set Up A Metal Lathe What Speed To Turn Steel On A Lathe Cutting speed (often abbreviated vc) on a lathe is the velocity of the surface of the material as it moves across the cutting tool. Velocity is measured in units of length per unit time, for. The feed rate and spindle speed determine how fast the lathe cutting tool moves and how quickly the material is removed. To achieve optimal results,. What Speed To Turn Steel On A Lathe.

From bceweb.org

Metal Lathe Cutting Speed Chart Rpm A Visual Reference of Charts What Speed To Turn Steel On A Lathe Cutting speed is the spindle speed, while it can be regarded as the speed of tool or the work moves at the point of cut. Turning speeds are adjusted to the feed rate of the mini lathe (0.004/rev.), a depth of cut of 0.040, and a tool life of 180 minutes. Ft should not exceed 90% of maximum load stated. What Speed To Turn Steel On A Lathe.