Sheet Metal Hole Punch Shapes . Readers will learn about the. To form indents and holes, in pieces of modern metal, sheet metal punching is. Some of the most common geometric shapes for punched holes include rectangles, squares, and circles. Sheet metal hole punching is a common method to create a hole in a metal sheet. In real practice, the process of hole punching. There are various types of punches used in sheet metal punching, including round punches, oblong punches, square punches,. Hole shaving is yet another way to minimize sheet distortion. Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. Metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom steel punch. Sheet metal punching is the process of creating holes and shapes in sheet metal using a punch and die. When hole shaving, the machine uses the same die size but two. This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet.

from www.alibaba.com

When hole shaving, the machine uses the same die size but two. Metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom steel punch. Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. To form indents and holes, in pieces of modern metal, sheet metal punching is. Sheet metal punching is the process of creating holes and shapes in sheet metal using a punch and die. Hole shaving is yet another way to minimize sheet distortion. In real practice, the process of hole punching. Some of the most common geometric shapes for punched holes include rectangles, squares, and circles. Sheet metal hole punching is a common method to create a hole in a metal sheet. This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet.

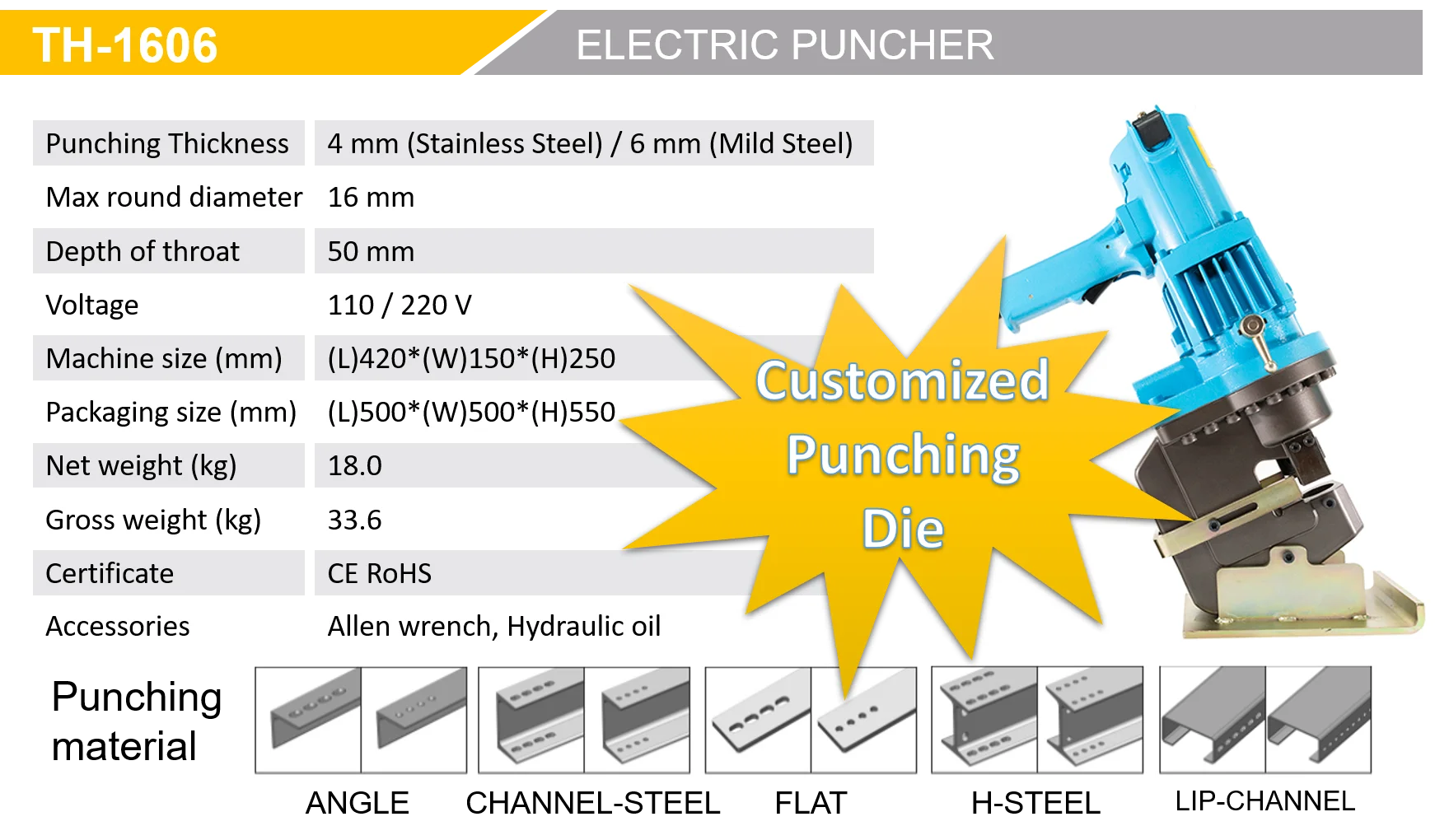

Professional Manufacturer Sheet Metal Hole Punch Buy Hole Punch,Sheet

Sheet Metal Hole Punch Shapes There are various types of punches used in sheet metal punching, including round punches, oblong punches, square punches,. Metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom steel punch. Sheet metal punching is the process of creating holes and shapes in sheet metal using a punch and die. There are various types of punches used in sheet metal punching, including round punches, oblong punches, square punches,. In real practice, the process of hole punching. Hole shaving is yet another way to minimize sheet distortion. This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. When hole shaving, the machine uses the same die size but two. To form indents and holes, in pieces of modern metal, sheet metal punching is. Some of the most common geometric shapes for punched holes include rectangles, squares, and circles. Sheet metal hole punching is a common method to create a hole in a metal sheet. Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. Readers will learn about the.

From www.swingline.com

Swingline Punches Heavy Duty & Specialty Punches Swingline® 1 Sheet Metal Hole Punch Shapes Metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom steel punch. Sheet metal hole punching is a common method to create a hole in a metal sheet. When hole shaving, the machine uses the same die size but two. To form indents and holes, in pieces of. Sheet Metal Hole Punch Shapes.

From www.youtube.com

15Pc Hand Punch Set Sheet Metal Hole Punching Tools YouTube Sheet Metal Hole Punch Shapes When hole shaving, the machine uses the same die size but two. Readers will learn about the. This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. Sheet metal punching is the process of creating holes and shapes in sheet metal using a punch and die. Sheet metal punching is. Sheet Metal Hole Punch Shapes.

From www.tooled-up.com

Q Max Sheet Metal Square Hole Punch Metric Hole Punches Sheet Metal Hole Punch Shapes Readers will learn about the. This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. In real practice, the process of hole punching. Hole shaving is yet another way to minimize sheet distortion. Sheet metal punching is the process of creating holes and shapes in sheet metal using a punch. Sheet Metal Hole Punch Shapes.

From forums.autodesk.com

Inventor Sheet Metal Punch Table / Hole Table identical punch shapes Sheet Metal Hole Punch Shapes Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. Sheet metal hole punching is a common method to create a hole in a metal sheet. Hole shaving is. Sheet Metal Hole Punch Shapes.

From mathildalevesque.blogspot.com

custom hole punch shapes Mathilda Levesque Sheet Metal Hole Punch Shapes This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. Readers will learn about the. Sheet metal hole punching is a common method to create a hole in a metal sheet. There are various types of punches used in sheet metal punching, including round punches, oblong punches, square punches,. Sheet. Sheet Metal Hole Punch Shapes.

From store.brewpi.com

Q.max Sheet Metal Hole Punch 32.5 mm Mashing Sheet Metal Hole Punch Shapes Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. Some of the most common geometric shapes for punched holes include rectangles, squares, and circles. This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. Metal punching is the. Sheet Metal Hole Punch Shapes.

From store.brewpi.com

Q.max Sheet Metal Hole Punch 47mm Sheet Metal Hole Punch Shapes In real practice, the process of hole punching. Metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom steel punch. This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. There are various types of punches used in. Sheet Metal Hole Punch Shapes.

From bahamas.desertcart.com

Buy BEAMNOVA Hydraulic Sheet Metal Hole Punch Tools 15 Ton Hole Sheet Metal Hole Punch Shapes Readers will learn about the. To form indents and holes, in pieces of modern metal, sheet metal punching is. Sheet metal hole punching is a common method to create a hole in a metal sheet. When hole shaving, the machine uses the same die size but two. Sheet metal punching is a metalworking technique that involves using a punch and. Sheet Metal Hole Punch Shapes.

From www.pro-lift-montagetechnik.com

Rectangular sheet metal punch and die, 35mm x 65mm, 00564 ProLift Sheet Metal Hole Punch Shapes This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. In real practice, the process of hole punching. Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. Some of the most common geometric shapes for punched holes include. Sheet Metal Hole Punch Shapes.

From www.carbuilder.com

51mm (2") Sheet Metal Hole Punch from Car Builder Sheet Metal Hole Punch Shapes Hole shaving is yet another way to minimize sheet distortion. In real practice, the process of hole punching. Metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom steel punch. Readers will learn about the. This process is also known as sheet metal hole punching because it makes. Sheet Metal Hole Punch Shapes.

From www.ebay.com.au

For Q.Max Sheet Metal Punch Hole Punch Many Size 16mm to 50 mm eBay Sheet Metal Hole Punch Shapes Sheet metal hole punching is a common method to create a hole in a metal sheet. There are various types of punches used in sheet metal punching, including round punches, oblong punches, square punches,. Some of the most common geometric shapes for punched holes include rectangles, squares, and circles. To form indents and holes, in pieces of modern metal, sheet. Sheet Metal Hole Punch Shapes.

From www.walmart.com

1 Ton Aviation Power Punch Kit Sheet Metal Hole Punching 7 Sizes Die Sheet Metal Hole Punch Shapes To form indents and holes, in pieces of modern metal, sheet metal punching is. When hole shaving, the machine uses the same die size but two. In real practice, the process of hole punching. This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. Sheet metal punching is a metalworking. Sheet Metal Hole Punch Shapes.

From www.carbuilder.com

25.4mm (1") Square Sheet Metal Hole Punch Sheet Metal Hole Punch Shapes Hole shaving is yet another way to minimize sheet distortion. Readers will learn about the. When hole shaving, the machine uses the same die size but two. To form indents and holes, in pieces of modern metal, sheet metal punching is. This process is also known as sheet metal hole punching because it makes different shapes of holes on the. Sheet Metal Hole Punch Shapes.

From www.rapidonline.com

QMax QMA20M Sheet Metal Hole Punch 20mm Rapid Online Sheet Metal Hole Punch Shapes Sheet metal punching is the process of creating holes and shapes in sheet metal using a punch and die. Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. When hole shaving, the machine uses the same die size but two. Sheet metal hole punching is a common method. Sheet Metal Hole Punch Shapes.

From www.carbuilder.com

75mm Sheet Metal Hole Punch Sheet Metal Hole Punch Shapes In real practice, the process of hole punching. Readers will learn about the. When hole shaving, the machine uses the same die size but two. Sheet metal hole punching is a common method to create a hole in a metal sheet. There are various types of punches used in sheet metal punching, including round punches, oblong punches, square punches,. Sheet. Sheet Metal Hole Punch Shapes.

From forums.autodesk.com

Inventor Sheet Metal Punch Table / Hole Table identical punch shapes Sheet Metal Hole Punch Shapes Readers will learn about the. To form indents and holes, in pieces of modern metal, sheet metal punching is. This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. Some of the most common geometric shapes for punched holes include rectangles, squares, and circles. When hole shaving, the machine uses. Sheet Metal Hole Punch Shapes.

From www.tooled-up.com

Q Max Sheet Metal Hole Punch Metric Hole Punches Sheet Metal Hole Punch Shapes When hole shaving, the machine uses the same die size but two. This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. Some of the most common geometric shapes for punched holes include rectangles, squares, and circles. In real practice, the process of hole punching. To form indents and holes,. Sheet Metal Hole Punch Shapes.

From www.walmart.com

21050 Metal Hole Punch Set with Puncher, 16 Piece, This hole punch kit Sheet Metal Hole Punch Shapes When hole shaving, the machine uses the same die size but two. Sheet metal punching is the process of creating holes and shapes in sheet metal using a punch and die. To form indents and holes, in pieces of modern metal, sheet metal punching is. Sheet metal hole punching is a common method to create a hole in a metal. Sheet Metal Hole Punch Shapes.

From www.walmart.com

Hand Held Power Punch, Sheet Metal Hole Punch Kit Sheet Metal Hole Punch Shapes Readers will learn about the. There are various types of punches used in sheet metal punching, including round punches, oblong punches, square punches,. To form indents and holes, in pieces of modern metal, sheet metal punching is. Some of the most common geometric shapes for punched holes include rectangles, squares, and circles. Metal punching is the process of cutting a. Sheet Metal Hole Punch Shapes.

From www.walmart.com

HERCHR Metal Air Hole Punch, Sheet Metal Air Punch, Pneumatic Sheet Sheet Metal Hole Punch Shapes Sheet metal hole punching is a common method to create a hole in a metal sheet. This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. Sheet metal punching is the process of creating holes and shapes in sheet metal using a punch and die. In real practice, the process. Sheet Metal Hole Punch Shapes.

From www.alibaba.com

Professional Manufacturer Sheet Metal Hole Punch Buy Hole Punch,Sheet Sheet Metal Hole Punch Shapes This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. There are various types of punches used in sheet metal punching, including round punches, oblong punches, square punches,. Sheet. Sheet Metal Hole Punch Shapes.

From www.alibaba.com

Sheet Metal Hole Punch Tool Map60 Heavy Duty Puncher Set Round Hole Sheet Metal Hole Punch Shapes Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. There are various types of punches used in sheet metal punching, including round punches, oblong punches, square punches,. Readers. Sheet Metal Hole Punch Shapes.

From www.youtube.com

Sheet metal hole punching "SPEED PUNCH™" from Greenlee up to 3x Sheet Metal Hole Punch Shapes Metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom steel punch. Sheet metal hole punching is a common method to create a hole in a metal sheet. In real practice, the process of hole punching. Readers will learn about the. To form indents and holes, in pieces. Sheet Metal Hole Punch Shapes.

From www.pro-lift-montagetechnik.com

Square sheet metal punch and die, 92mm x 92mm, 00566 ProLift Sheet Metal Hole Punch Shapes Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. In real practice, the process of hole punching. Readers will learn about the. Metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom steel punch. Hole shaving. Sheet Metal Hole Punch Shapes.

From unipunch.com

Metal Extruded Hole Punch Tooling UniPunch Sheet Metal Hole Punch Shapes This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. Sheet metal punching is the process of creating holes and shapes in sheet metal using a punch and die. Some of the most common geometric shapes for punched holes include rectangles, squares, and circles. Sheet metal hole punching is a. Sheet Metal Hole Punch Shapes.

From www.carbuilder.com

19mm (3/4") Sheet Metal Hole Punch Sheet Metal Hole Punch Shapes Readers will learn about the. Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. Sheet metal punching is the process of creating holes and shapes in sheet metal. Sheet Metal Hole Punch Shapes.

From www.tooled-up.com

Whitney No.7 Sheet Metal Hand Punch and Die Set Hole Punches Sheet Metal Hole Punch Shapes Readers will learn about the. In real practice, the process of hole punching. Sheet metal hole punching is a common method to create a hole in a metal sheet. Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. Some of the most common geometric shapes for punched holes. Sheet Metal Hole Punch Shapes.

From www.youtube.com

Harbor Freight Deep Sheet Metal Hole Punch Review YouTube Sheet Metal Hole Punch Shapes Some of the most common geometric shapes for punched holes include rectangles, squares, and circles. Metal punching is the process of cutting a hole or impressing a form on the surface of sheet metal using a custom steel punch. Readers will learn about the. Sheet metal hole punching is a common method to create a hole in a metal sheet.. Sheet Metal Hole Punch Shapes.

From www.jewelrysupply.com

Metal Hole Punch Sheet Metal Hole Punch For Beaders and Jewelers Sheet Metal Hole Punch Shapes To form indents and holes, in pieces of modern metal, sheet metal punching is. Hole shaving is yet another way to minimize sheet distortion. Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. Sheet metal hole punching is a common method to create a hole in a metal. Sheet Metal Hole Punch Shapes.

From www.pro-lift-montagetechnik.com

Round sheet metal hole punch and die, 102.7mm diameter, with draw stud Sheet Metal Hole Punch Shapes There are various types of punches used in sheet metal punching, including round punches, oblong punches, square punches,. In real practice, the process of hole punching. Hole shaving is yet another way to minimize sheet distortion. Readers will learn about the. Sheet metal punching is the process of creating holes and shapes in sheet metal using a punch and die.. Sheet Metal Hole Punch Shapes.

From www.pro-lift-montagetechnik.com

Rectangular sheet metal punch and die, 46mm x 92mm, draw stud + nut Sheet Metal Hole Punch Shapes There are various types of punches used in sheet metal punching, including round punches, oblong punches, square punches,. Sheet metal punching is the process of creating holes and shapes in sheet metal using a punch and die. Some of the most common geometric shapes for punched holes include rectangles, squares, and circles. To form indents and holes, in pieces of. Sheet Metal Hole Punch Shapes.

From www.wnealservices.com

Metal Hole Punch WNS W. Neal Services Sheet Metal Hole Punch Shapes To form indents and holes, in pieces of modern metal, sheet metal punching is. There are various types of punches used in sheet metal punching, including round punches, oblong punches, square punches,. Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. Readers will learn about the. When hole. Sheet Metal Hole Punch Shapes.

From www.wnealservices.com

Metal Hole Punch WNS W. Neal Services Sheet Metal Hole Punch Shapes This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. Sheet metal hole punching is a common method to create a hole in a metal sheet. Sheet metal punching is the process of creating holes and shapes in sheet metal using a punch and die. Hole shaving is yet another. Sheet Metal Hole Punch Shapes.

From www.giangrandi.org

How to drill large holes in sheet metal Sheet Metal Hole Punch Shapes In real practice, the process of hole punching. Readers will learn about the. Sheet metal punching is a metalworking technique that involves using a punch and die set to create holes or shapes in. Hole shaving is yet another way to minimize sheet distortion. Sheet metal hole punching is a common method to create a hole in a metal sheet.. Sheet Metal Hole Punch Shapes.

From www.thefabricator.com

Forming on the modern punch press sheet metal fabrication’s Swiss army Sheet Metal Hole Punch Shapes Some of the most common geometric shapes for punched holes include rectangles, squares, and circles. Hole shaving is yet another way to minimize sheet distortion. This process is also known as sheet metal hole punching because it makes different shapes of holes on the sheet. Sheet metal punching is a metalworking technique that involves using a punch and die set. Sheet Metal Hole Punch Shapes.