Hardness Scales Explained . Machined metal is usually between 10 and 65 h r c. knowing what rockwell scale strength you require ensures you’re getting exactly what blade hardness you need. Brinell is also a common unit used for. in machining, the most common is the “c” scale called h r c. The goal of the rockwell hardness test is to evaluate a material's suitability for the intended. when you perform a hardness test using the rockewell scale, you can determine the hardness of metals and alloys of all kinds. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The rockwell test measures the. the basics of the rockwell scale. the mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer. whether you need to convert a hardness measurement for a customer, understand what the hardness is of a.

from gallaghercorp.com

21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. the mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer. Brinell is also a common unit used for. Machined metal is usually between 10 and 65 h r c. knowing what rockwell scale strength you require ensures you’re getting exactly what blade hardness you need. the basics of the rockwell scale. The rockwell test measures the. when you perform a hardness test using the rockewell scale, you can determine the hardness of metals and alloys of all kinds. in machining, the most common is the “c” scale called h r c. The goal of the rockwell hardness test is to evaluate a material's suitability for the intended.

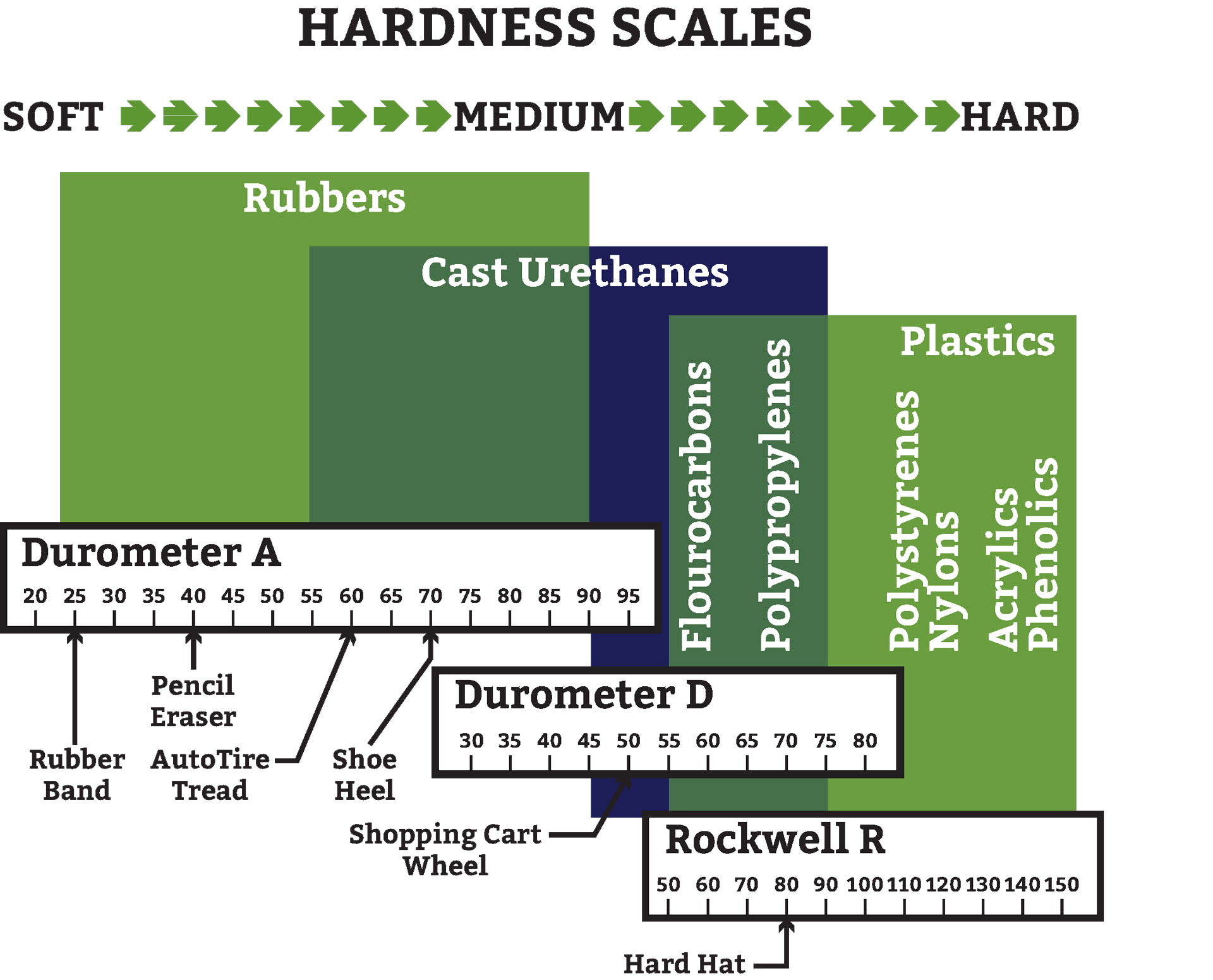

How to Use Urethane Durometer Hardness In Your Urethane Design

Hardness Scales Explained 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. knowing what rockwell scale strength you require ensures you’re getting exactly what blade hardness you need. The rockwell test measures the. whether you need to convert a hardness measurement for a customer, understand what the hardness is of a. the basics of the rockwell scale. in machining, the most common is the “c” scale called h r c. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The goal of the rockwell hardness test is to evaluate a material's suitability for the intended. when you perform a hardness test using the rockewell scale, you can determine the hardness of metals and alloys of all kinds. the mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer. Brinell is also a common unit used for. Machined metal is usually between 10 and 65 h r c.

From www.thenaturalsapphirecompany.com

The Mohs Scale Education Hardness Scales Explained The goal of the rockwell hardness test is to evaluate a material's suitability for the intended. the mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer. Machined metal is usually between 10 and 65 h r c. when you perform a hardness test using the rockewell. Hardness Scales Explained.

From mungfali.com

Metal Hardness Scale Chart Hardness Scales Explained the basics of the rockwell scale. in machining, the most common is the “c” scale called h r c. The goal of the rockwell hardness test is to evaluate a material's suitability for the intended. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. the mohs hardness scale is. Hardness Scales Explained.

From www.youtube.com

The Mohs Scale of Hardness Explained YouTube Hardness Scales Explained The goal of the rockwell hardness test is to evaluate a material's suitability for the intended. the basics of the rockwell scale. The rockwell test measures the. when you perform a hardness test using the rockewell scale, you can determine the hardness of metals and alloys of all kinds. whether you need to convert a hardness measurement. Hardness Scales Explained.

From www.gemselect.com

Gemstone Hardness Mohs Scale with Images and Charts Hardness Scales Explained Brinell is also a common unit used for. the basics of the rockwell scale. the mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer. when you perform a hardness test using the rockewell scale, you can determine the hardness of metals and alloys of all. Hardness Scales Explained.

From mungfali.com

Metal Hardness Scale Chart Hardness Scales Explained knowing what rockwell scale strength you require ensures you’re getting exactly what blade hardness you need. The goal of the rockwell hardness test is to evaluate a material's suitability for the intended. whether you need to convert a hardness measurement for a customer, understand what the hardness is of a. the mohs hardness scale is a qualitative. Hardness Scales Explained.

From jakagems.blogspot.com

Jaka Gems Lapidary Terms Explained Mohs Scale of Mineral Hardness Hardness Scales Explained 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. when you perform a hardness test using the rockewell scale, you can determine the hardness of metals and alloys of all kinds. The rockwell test measures the. Machined metal is usually between 10 and 65 h r c. the basics of. Hardness Scales Explained.

From exodipxtl.blob.core.windows.net

Hardness Test Standard at Ann Broman blog Hardness Scales Explained in machining, the most common is the “c” scale called h r c. whether you need to convert a hardness measurement for a customer, understand what the hardness is of a. The rockwell test measures the. Brinell is also a common unit used for. when you perform a hardness test using the rockewell scale, you can determine. Hardness Scales Explained.

From www.gordonengland.co.uk

Hardness Scale Relationship and Conversion Equivalence Chart Hardness Scales Explained when you perform a hardness test using the rockewell scale, you can determine the hardness of metals and alloys of all kinds. whether you need to convert a hardness measurement for a customer, understand what the hardness is of a. knowing what rockwell scale strength you require ensures you’re getting exactly what blade hardness you need. The. Hardness Scales Explained.

From polysynthesis.au

Shore Hardness Scales Measuring Material Hardness Hardness Scales Explained the basics of the rockwell scale. the mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer. in machining, the most common is the “c” scale called h r c. The goal of the rockwell hardness test is to evaluate a material's suitability for the intended.. Hardness Scales Explained.

From www.iqsdirectory.com

Polyurethane Molding What Is It? How Does It Work? Uses, Types Of Hardness Scales Explained the mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer. Machined metal is usually between 10 and 65 h r c. whether you need to convert a hardness measurement for a customer, understand what the hardness is of a. when you perform a hardness test. Hardness Scales Explained.

From flooringstype.com

Understanding Hardwood Floor Hardness Scale Flooring Designs Hardness Scales Explained whether you need to convert a hardness measurement for a customer, understand what the hardness is of a. Machined metal is usually between 10 and 65 h r c. knowing what rockwell scale strength you require ensures you’re getting exactly what blade hardness you need. The rockwell test measures the. in machining, the most common is the. Hardness Scales Explained.

From www.arptech.com.au

Durometer Shore Hardness Scale Explained ArpTechBlog Hardness Scales Explained the basics of the rockwell scale. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. Machined metal is usually between 10 and 65 h r c. knowing what rockwell scale strength you require ensures you’re getting exactly what blade hardness you need. the mohs hardness scale is a qualitative. Hardness Scales Explained.

From www.aeromarineproducts.com

Durometer Shore Hardness Scale Explained AeroMarine Hardness Scales Explained 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The goal of the rockwell hardness test is to evaluate a material's suitability for the intended. when you perform a hardness test using the rockewell scale, you can determine the hardness of metals and alloys of all kinds. the basics of. Hardness Scales Explained.

From www.paengineeringsupplies.com.au

Hardness Scale P&A Engineering Supplies Hardness Scales Explained in machining, the most common is the “c” scale called h r c. the mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer. Brinell is also a common unit used for. 21 rows the rockwell scale is a hardness scale based on indentation hardness of. Hardness Scales Explained.

From www.swiftsupplies.com.au

Durometer and Shore Hardness Explained Swift Supplies Hardness Scales Explained knowing what rockwell scale strength you require ensures you’re getting exactly what blade hardness you need. Machined metal is usually between 10 and 65 h r c. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. The rockwell test measures the. the mohs hardness scale is a qualitative test that. Hardness Scales Explained.

From thermalprocessing.com

Hardness scale conversion Thermal Processing Magazine Hardness Scales Explained in machining, the most common is the “c” scale called h r c. The goal of the rockwell hardness test is to evaluate a material's suitability for the intended. whether you need to convert a hardness measurement for a customer, understand what the hardness is of a. the basics of the rockwell scale. when you perform. Hardness Scales Explained.

From ar.inspiredpencil.com

Mohs Hardness Scale Hardness Scales Explained knowing what rockwell scale strength you require ensures you’re getting exactly what blade hardness you need. Brinell is also a common unit used for. The rockwell test measures the. when you perform a hardness test using the rockewell scale, you can determine the hardness of metals and alloys of all kinds. in machining, the most common is. Hardness Scales Explained.

From gallaghercorp.com

How to Use Urethane Durometer Hardness In Your Urethane Design Hardness Scales Explained Brinell is also a common unit used for. in machining, the most common is the “c” scale called h r c. when you perform a hardness test using the rockewell scale, you can determine the hardness of metals and alloys of all kinds. the basics of the rockwell scale. The rockwell test measures the. the mohs. Hardness Scales Explained.

From www.reddit.com

Updated Mohs' Hardness Scale stevenuniverse Hardness Scales Explained The goal of the rockwell hardness test is to evaluate a material's suitability for the intended. knowing what rockwell scale strength you require ensures you’re getting exactly what blade hardness you need. when you perform a hardness test using the rockewell scale, you can determine the hardness of metals and alloys of all kinds. the mohs hardness. Hardness Scales Explained.

From stunningblue.com

Mohs Scale Of Hardness What Does It Mean? Stunning Blue Hardness Scales Explained Brinell is also a common unit used for. The goal of the rockwell hardness test is to evaluate a material's suitability for the intended. in machining, the most common is the “c” scale called h r c. when you perform a hardness test using the rockewell scale, you can determine the hardness of metals and alloys of all. Hardness Scales Explained.

From learningzonemurarewa.z13.web.core.windows.net

Printable Mohs Hardness Scale Hardness Scales Explained Machined metal is usually between 10 and 65 h r c. whether you need to convert a hardness measurement for a customer, understand what the hardness is of a. Brinell is also a common unit used for. the basics of the rockwell scale. 21 rows the rockwell scale is a hardness scale based on indentation hardness of. Hardness Scales Explained.

From lookfordiagnosis.com

Hardness Hardness Scales Explained in machining, the most common is the “c” scale called h r c. the basics of the rockwell scale. Machined metal is usually between 10 and 65 h r c. the mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer. whether you need to. Hardness Scales Explained.

From mungfali.com

Metal Hardness Scale Chart Hardness Scales Explained Brinell is also a common unit used for. in machining, the most common is the “c” scale called h r c. the basics of the rockwell scale. The goal of the rockwell hardness test is to evaluate a material's suitability for the intended. The rockwell test measures the. 21 rows the rockwell scale is a hardness scale. Hardness Scales Explained.

From exoeessid.blob.core.windows.net

Why Are There Different Scales Of Hardness at John Akers blog Hardness Scales Explained in machining, the most common is the “c” scale called h r c. when you perform a hardness test using the rockewell scale, you can determine the hardness of metals and alloys of all kinds. Machined metal is usually between 10 and 65 h r c. the basics of the rockwell scale. The rockwell test measures the.. Hardness Scales Explained.

From ar.inspiredpencil.com

Mohs Hardness Scale Hardness Scales Explained Machined metal is usually between 10 and 65 h r c. the mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer. The rockwell test measures the. The goal of the rockwell hardness test is to evaluate a material's suitability for the intended. 21 rows the rockwell. Hardness Scales Explained.

From amesportablehardnesstesters.com

The Rockwell Metal Hardness Scales Explained Hardness Scales Explained the mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer. The goal of the rockwell hardness test is to evaluate a material's suitability for the intended. Machined metal is usually between 10 and 65 h r c. The rockwell test measures the. the basics of the. Hardness Scales Explained.

From www.machinemfg.com

The Ultimate Mohs Hardness Scale Guide & Chart MachineMFG Hardness Scales Explained The rockwell test measures the. Machined metal is usually between 10 and 65 h r c. knowing what rockwell scale strength you require ensures you’re getting exactly what blade hardness you need. The goal of the rockwell hardness test is to evaluate a material's suitability for the intended. the mohs hardness scale is a qualitative test that measures. Hardness Scales Explained.

From rangechange.ca

Contratto Papà famigerato obsidian mohs hardness scale Zoo anima tecnico Hardness Scales Explained in machining, the most common is the “c” scale called h r c. the basics of the rockwell scale. knowing what rockwell scale strength you require ensures you’re getting exactly what blade hardness you need. The goal of the rockwell hardness test is to evaluate a material's suitability for the intended. whether you need to convert. Hardness Scales Explained.

From knifeknowitall.com

Knife Steel Hardness Ratings Explained & Compared Knife KnowItAll Hardness Scales Explained whether you need to convert a hardness measurement for a customer, understand what the hardness is of a. Machined metal is usually between 10 and 65 h r c. when you perform a hardness test using the rockewell scale, you can determine the hardness of metals and alloys of all kinds. The goal of the rockwell hardness test. Hardness Scales Explained.

From www.pinterest.com

Updated Mohs Hardness Scale. Diamond is now listed as the 3rd Hardest Hardness Scales Explained the mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer. Brinell is also a common unit used for. knowing what rockwell scale strength you require ensures you’re getting exactly what blade hardness you need. when you perform a hardness test using the rockewell scale, you. Hardness Scales Explained.

From www.compoundchem.com

Compound Interest The Mohs Hardness Scale Comparing the hardness of Hardness Scales Explained Machined metal is usually between 10 and 65 h r c. whether you need to convert a hardness measurement for a customer, understand what the hardness is of a. the mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer. Brinell is also a common unit used. Hardness Scales Explained.

From www.hardnessgauge.com

What is the Rockwell Scale? Hardness Tester Hardness Scales Explained knowing what rockwell scale strength you require ensures you’re getting exactly what blade hardness you need. whether you need to convert a hardness measurement for a customer, understand what the hardness is of a. 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. the basics of the rockwell scale.. Hardness Scales Explained.

From sciencenotes.org

Mohs Hardness Scale Hardness Scales Explained when you perform a hardness test using the rockewell scale, you can determine the hardness of metals and alloys of all kinds. the basics of the rockwell scale. The rockwell test measures the. knowing what rockwell scale strength you require ensures you’re getting exactly what blade hardness you need. whether you need to convert a hardness. Hardness Scales Explained.

From gallaghercorp.com

Polyurethane Load Bearing Capacity Gallagher Polyurethane Parts Hardness Scales Explained knowing what rockwell scale strength you require ensures you’re getting exactly what blade hardness you need. The rockwell test measures the. whether you need to convert a hardness measurement for a customer, understand what the hardness is of a. Brinell is also a common unit used for. the mohs hardness scale is a qualitative test that measures. Hardness Scales Explained.

From www.acrotechinc.com

Urethane Durometers Acrotech Inc. Hardness Scales Explained 21 rows the rockwell scale is a hardness scale based on indentation hardness of a material. Machined metal is usually between 10 and 65 h r c. in machining, the most common is the “c” scale called h r c. when you perform a hardness test using the rockewell scale, you can determine the hardness of metals. Hardness Scales Explained.