Pneumatic Diaphragm Valve Working Principle . Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for diesel engines. By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific process needs. Diaphragm valves, also called membrane valves, can handle various types of media,. This mechanism provides accurate and precise. In the open position, the diaphragm flexes, allowing the fluid to pass through the valve. Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. The valves that are used to control the pressure, direction, and flow rate of compressed air are called pneumatic valves.

from www.linquip.com

Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. Diaphragm valves, also called membrane valves, can handle various types of media,. In the open position, the diaphragm flexes, allowing the fluid to pass through the valve. The valves that are used to control the pressure, direction, and flow rate of compressed air are called pneumatic valves. This mechanism provides accurate and precise. By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific process needs. Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for diesel engines.

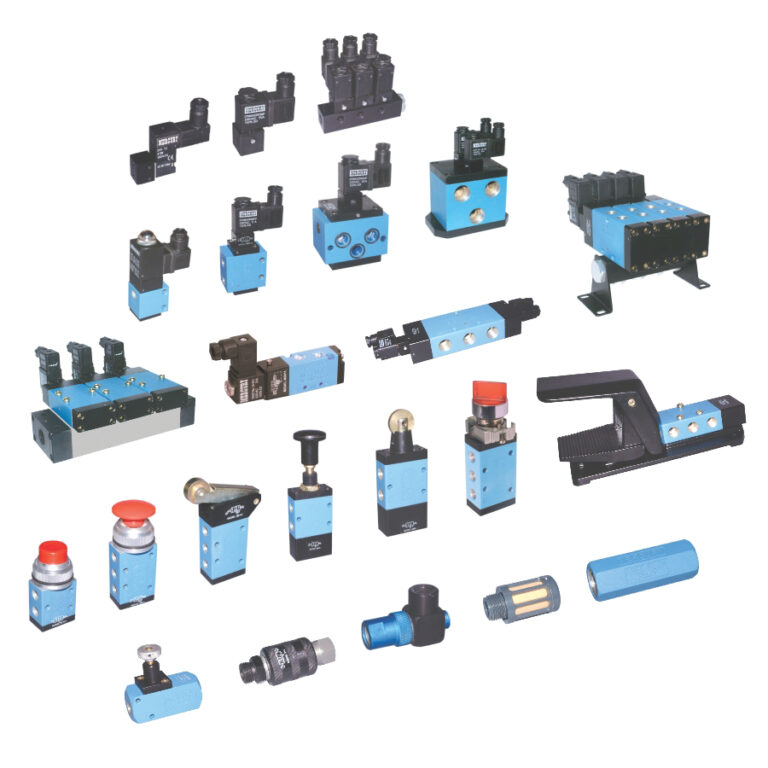

5 Types of Pneumatic Valves & Their Working Principles Linquip

Pneumatic Diaphragm Valve Working Principle Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for diesel engines. The valves that are used to control the pressure, direction, and flow rate of compressed air are called pneumatic valves. Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. In the open position, the diaphragm flexes, allowing the fluid to pass through the valve. This mechanism provides accurate and precise. Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for diesel engines. By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific process needs. Diaphragm valves, also called membrane valves, can handle various types of media,.

From www.dreamstime.com

Diaphragm or Membrane Pump Working Process Diagram Example Drawing Pneumatic Diaphragm Valve Working Principle By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific process needs. In the open position, the diaphragm flexes, allowing the fluid to pass through the valve. The valves that are used to control the pressure,. Pneumatic Diaphragm Valve Working Principle.

From www.spares-for-pumps.com

Discover How does a Diaphragm Pump work SPS Pneumatic Diaphragm Valve Working Principle The valves that are used to control the pressure, direction, and flow rate of compressed air are called pneumatic valves. This mechanism provides accurate and precise. Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for diesel engines. Diaphragm valves are linear motion valves, ideal for. Pneumatic Diaphragm Valve Working Principle.

From www.linquip.com

5 Types of Pneumatic Valves & Their Working Principles Linquip Pneumatic Diaphragm Valve Working Principle Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. This mechanism provides accurate and precise. Diaphragm valves, also called membrane valves, can handle various types of media,. Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for diesel engines. In the. Pneumatic Diaphragm Valve Working Principle.

From mungfali.com

Pneumatic Solenoid Valve Diagram Pneumatic Diaphragm Valve Working Principle By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific process needs. This mechanism provides accurate and precise. Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless. Pneumatic Diaphragm Valve Working Principle.

From www.youtube.com

Valve principle plastic diaphragm valve YouTube Pneumatic Diaphragm Valve Working Principle This mechanism provides accurate and precise. By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific process needs. Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless. Pneumatic Diaphragm Valve Working Principle.

From www.iqsdirectory.com

3Way Solenoid Valve What Is It? How Does It Work? Pneumatic Diaphragm Valve Working Principle Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. The valves that are used to control the pressure, direction, and flow rate of compressed air are called pneumatic valves. Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for diesel engines.. Pneumatic Diaphragm Valve Working Principle.

From www.youtube.com

Working Principle of Pneumatic Actuator and actuated butterfly valve Pneumatic Diaphragm Valve Working Principle Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for diesel engines. Diaphragm valves, also called membrane valves, can handle various types of media,. In the open position, the diaphragm flexes, allowing the fluid to pass through the valve. Diaphragm valves are linear motion valves, ideal. Pneumatic Diaphragm Valve Working Principle.

From www.iqsdirectory.com

Solenoid Valve What Is It? How It Works, Materials & Uses Pneumatic Diaphragm Valve Working Principle By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific process needs. Diaphragm valves, also called membrane valves, can handle various types of media,. This mechanism provides accurate and precise. In the open position, the diaphragm. Pneumatic Diaphragm Valve Working Principle.

From engineeringlearner.com

Pneumatic Valve Types & Working Principle Engineering Learner Pneumatic Diaphragm Valve Working Principle The valves that are used to control the pressure, direction, and flow rate of compressed air are called pneumatic valves. Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. This mechanism provides accurate and precise. Diaphragm valves, also called membrane valves, can handle various types of media,. In the open position, the diaphragm flexes, allowing. Pneumatic Diaphragm Valve Working Principle.

From engineeringlearner.com

Pneumatic Valve Types & Working Principle Engineering Learner Pneumatic Diaphragm Valve Working Principle Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for diesel engines. Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. In the open position, the diaphragm flexes, allowing the fluid to pass through the valve. The valves that are used. Pneumatic Diaphragm Valve Working Principle.

From www.biodod.gr

Air Operated Diaphragm PumpsBiodod Labrakis Bros Pneumatic Diaphragm Valve Working Principle This mechanism provides accurate and precise. The valves that are used to control the pressure, direction, and flow rate of compressed air are called pneumatic valves. Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. In the open position, the diaphragm flexes, allowing the fluid to pass through the valve. Diaphragm valves, also called membrane. Pneumatic Diaphragm Valve Working Principle.

From control.com

Pneumatic Actuator Response Basic Principles of Control Valves and Pneumatic Diaphragm Valve Working Principle By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific process needs. In the open position, the diaphragm flexes, allowing the fluid to pass through the valve. Diaphragm valves, also called membrane valves, can handle various. Pneumatic Diaphragm Valve Working Principle.

From www.youtube.com

3 2 Way Pneumatic Diaphragm Operated Control Valve YouTube Pneumatic Diaphragm Valve Working Principle Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. Diaphragm valves, also called membrane valves, can handle various types of media,. This mechanism provides accurate and precise. By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these. Pneumatic Diaphragm Valve Working Principle.

From www.linquip.com

What Is Linear Valve? Working Principles & Types Complete Explanation Pneumatic Diaphragm Valve Working Principle By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific process needs. Diaphragm valves, also called membrane valves, can handle various types of media,. This mechanism provides accurate and precise. Pneumatic systems rely on the force. Pneumatic Diaphragm Valve Working Principle.

From www.ecomena.org

Diaphragm Valve Types, Functions and Applications Pneumatic Diaphragm Valve Working Principle Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for diesel engines. Diaphragm valves, also called membrane valves, can handle various types of media,. This mechanism provides accurate and precise. In the. Pneumatic Diaphragm Valve Working Principle.

From www.youtube.com

Valve principle diaphragm valve with metal body YouTube Pneumatic Diaphragm Valve Working Principle Diaphragm valves, also called membrane valves, can handle various types of media,. This mechanism provides accurate and precise. Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. The valves that are used to control the pressure, direction, and flow rate of compressed air are called pneumatic valves. Pneumatic systems rely on the force of compressed. Pneumatic Diaphragm Valve Working Principle.

From www.vrogue.co

Diaphragm Pump Working Principle Popular Types Of Dia vrogue.co Pneumatic Diaphragm Valve Working Principle The valves that are used to control the pressure, direction, and flow rate of compressed air are called pneumatic valves. By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific process needs. Pneumatic systems rely on. Pneumatic Diaphragm Valve Working Principle.

From www.vrc-usa.com

Pneumatic Valve Positioner Working Principle • VRC Pneumatic Diaphragm Valve Working Principle This mechanism provides accurate and precise. By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific process needs. Diaphragm valves, also called membrane valves, can handle various types of media,. Diaphragm valves are linear motion valves,. Pneumatic Diaphragm Valve Working Principle.

From yts-pumps.eu

How does Air Double Diaphragm Pump work YTS Japan Pneumatic Diaphragm Valve Working Principle This mechanism provides accurate and precise. Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. In the open position, the diaphragm flexes, allowing the fluid to pass through the valve. The valves that are used to control the pressure, direction, and flow rate of compressed air are called pneumatic valves. Diaphragm valves, also called membrane. Pneumatic Diaphragm Valve Working Principle.

From www.vrogue.co

How Do Pneumatic Actuators Valves Work Pneumatic Actu vrogue.co Pneumatic Diaphragm Valve Working Principle Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for diesel engines. Diaphragm valves, also called membrane valves, can handle various types of media,. In the open position, the diaphragm flexes, allowing the fluid to pass through the valve. This mechanism provides accurate and precise. By. Pneumatic Diaphragm Valve Working Principle.

From www.linquip.com

5 Types of Pneumatic Valves & Their Working Principles Linquip Pneumatic Diaphragm Valve Working Principle Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. Diaphragm valves, also called membrane valves, can handle various types of media,. The valves that are used to control the pressure, direction, and flow rate of compressed air are called pneumatic valves. Pneumatic systems rely on the force of compressed air to transmit power and can. Pneumatic Diaphragm Valve Working Principle.

From www.yonjoupump.com

Air Driven Mini Pneumatic Diaphragm Pump Pneumatic Diaphragm Valve Working Principle The valves that are used to control the pressure, direction, and flow rate of compressed air are called pneumatic valves. This mechanism provides accurate and precise. By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific. Pneumatic Diaphragm Valve Working Principle.

From www.youtube.com

Diaphragm Valve Operation Demonstration YouTube Pneumatic Diaphragm Valve Working Principle Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for diesel engines. In the open position, the diaphragm flexes, allowing the fluid to pass through the valve. Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. Diaphragm valves, also called membrane. Pneumatic Diaphragm Valve Working Principle.

From depidiomas.unitru.edu.pe

Diaphragm Valves Types, Uses, Features And Benefits, 59 OFF Pneumatic Diaphragm Valve Working Principle Diaphragm valves, also called membrane valves, can handle various types of media,. In the open position, the diaphragm flexes, allowing the fluid to pass through the valve. Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. This mechanism provides accurate and precise. By understanding the basic principles of diaphragm valves, their construction and working, types. Pneumatic Diaphragm Valve Working Principle.

From instrumentationtools.com

Working Principle of Pneumatic Actuators Parts of Pneumatic Actuator Pneumatic Diaphragm Valve Working Principle The valves that are used to control the pressure, direction, and flow rate of compressed air are called pneumatic valves. Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. This mechanism provides accurate and precise. Diaphragm valves, also called membrane valves, can handle various types of media,. In the open position, the diaphragm flexes, allowing. Pneumatic Diaphragm Valve Working Principle.

From www.vrogue.co

How Diaphragm Valves Work Advantages Of Diaphragm Val vrogue.co Pneumatic Diaphragm Valve Working Principle Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. Diaphragm valves, also called membrane valves, can handle various types of media,. By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific. Pneumatic Diaphragm Valve Working Principle.

From www.vrogue.co

Diaphragm Valves Construction Types And Applications vrogue.co Pneumatic Diaphragm Valve Working Principle By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific process needs. Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. This mechanism provides accurate and precise. Pneumatic systems rely on. Pneumatic Diaphragm Valve Working Principle.

From control.com

Valve Positioners Basic Principles of Control Valves and Actuators Pneumatic Diaphragm Valve Working Principle The valves that are used to control the pressure, direction, and flow rate of compressed air are called pneumatic valves. By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific process needs. Pneumatic systems rely on. Pneumatic Diaphragm Valve Working Principle.

From www.pneumaticdiaphragmvalves.com

Working principle and characteristics of vacuum diaphragm valves Pneumatic Diaphragm Valve Working Principle This mechanism provides accurate and precise. Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. The valves that are used to control the pressure, direction, and flow rate of compressed air are called pneumatic valves. By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance. Pneumatic Diaphragm Valve Working Principle.

From www.iqsdirectory.com

Diaphragm Valves Types, Uses, Features and Benefits Pneumatic Diaphragm Valve Working Principle Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for diesel engines. Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. In the open position, the diaphragm flexes, allowing the fluid to pass through the valve. The valves that are used. Pneumatic Diaphragm Valve Working Principle.

From www.ntgdvalve.com

Pneumatic Diaphragm Valve Manufacturer Pneumatic Diaphragm Valve Working Principle By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific process needs. In the open position, the diaphragm flexes, allowing the fluid to pass through the valve. Pneumatic systems rely on the force of compressed air. Pneumatic Diaphragm Valve Working Principle.

From www.pneumaticdiaphragmvalves.com

The working principle of pneumatic diaphragm valves Diaphragm Valve Pneumatic Diaphragm Valve Working Principle In the open position, the diaphragm flexes, allowing the fluid to pass through the valve. Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for diesel engines. Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. The valves that are used. Pneumatic Diaphragm Valve Working Principle.

From www.electricalvolt.com

Spring and Diaphragm Pneumatic Actuator Its Parts, Types & Working Pneumatic Diaphragm Valve Working Principle Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for diesel engines. By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific. Pneumatic Diaphragm Valve Working Principle.

From www.iqsdirectory.com

Diaphragm Valves Types, Uses, Features and Benefits Pneumatic Diaphragm Valve Working Principle By understanding the basic principles of diaphragm valves, their construction and working, types and applications, advantages and disadvantages, and maintenance requirements, industrial professionals can select and operate these valves effectively to meet their specific process needs. Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for. Pneumatic Diaphragm Valve Working Principle.

From engineeringlearner.com

Diaphragm Valve Types, Parts, Uses, Working, Application, Material Pneumatic Diaphragm Valve Working Principle In the open position, the diaphragm flexes, allowing the fluid to pass through the valve. Diaphragm valves are linear motion valves, ideal for controlling fluid movement with high precision. Pneumatic systems rely on the force of compressed air to transmit power and can be found in countless applications, such as power tools for diesel engines. This mechanism provides accurate and. Pneumatic Diaphragm Valve Working Principle.