Tea Processing Energy . Drying is an energy intensive process in the tea factory. Drying is an energy intensive process in the tea factory. This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities and. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8 kwh, and. Fossil fuels are primarily utilized in the tea factories to.

from www.mdpi.com

This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities and. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. Drying is an energy intensive process in the tea factory. Drying is an energy intensive process in the tea factory. Fossil fuels are primarily utilized in the tea factories to. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8 kwh, and.

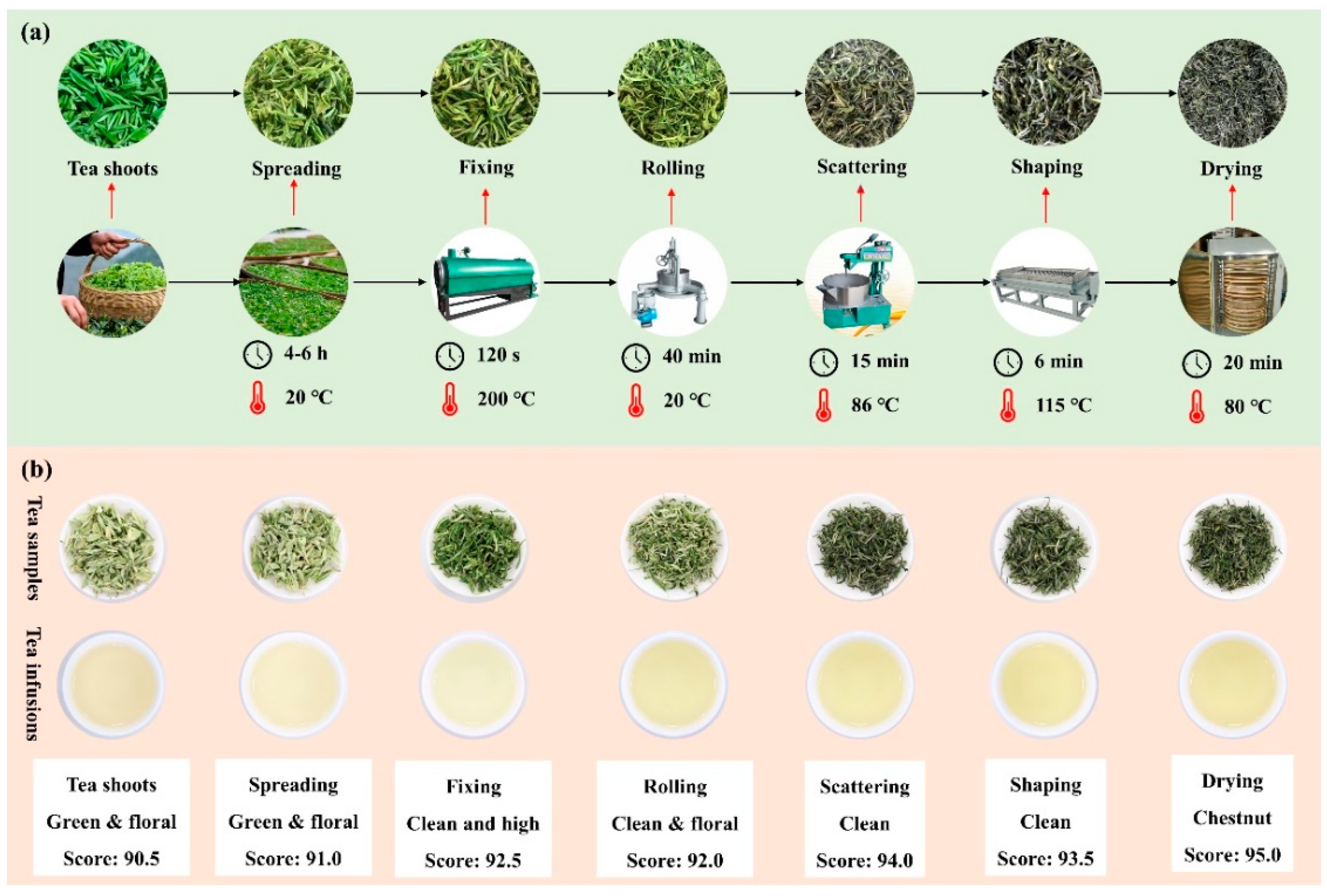

Dynamic Changes of Volatile Compounds during the Xinyang Maojian Green

Tea Processing Energy Drying is an energy intensive process in the tea factory. The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8 kwh, and. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. Drying is an energy intensive process in the tea factory. This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities and. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. Drying is an energy intensive process in the tea factory. Fossil fuels are primarily utilized in the tea factories to.

From www.mdpi.com

Dynamic Changes of Volatile Compounds during the Xinyang Maojian Green Tea Processing Energy Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. Drying is an energy intensive process in the tea factory. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. Fossil fuels are primarily utilized in the tea factories to. The findings indicate that the combined energy potential of. Tea Processing Energy.

From www.researchgate.net

(PDF) Enhancers of the energy efficiency in tea processing industry Tea Processing Energy Fossil fuels are primarily utilized in the tea factories to. Drying is an energy intensive process in the tea factory. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. The findings indicate that the combined energy potential of. Tea Processing Energy.

From studylib.net

Reducing Energy Consumption at Tea Processing Factories Tea Processing Energy The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8 kwh, and. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. Fossil fuels are primarily utilized in the tea factories to. Drying is an energy intensive process in the tea factory. Drying is an energy intensive process. Tea Processing Energy.

From lishantea.com

Tea Processing Steps Kumy Tea Plantation lishantea Tea Processing Energy Fossil fuels are primarily utilized in the tea factories to. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. Drying is an energy intensive process in the tea factory. Drying is an energy intensive process in the tea factory. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and. Tea Processing Energy.

From www.researchgate.net

Processing steps of Oolong tea Download Scientific Diagram Tea Processing Energy Drying is an energy intensive process in the tea factory. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities and. Fossil fuels are primarily utilized in the tea factories to. Drying is an energy intensive process in the. Tea Processing Energy.

From www.researchgate.net

1 Schematic diagram of different types of tea manufacturing Download Tea Processing Energy The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8 kwh, and. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. Drying is an energy intensive process in the tea factory. Fossil fuels are primarily utilized in the tea factories to. Energy sustainability in tea sector can. Tea Processing Energy.

From teaepicure.com

How Many Types of Teas Are There? · Tea Epicure Tea Processing Energy This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities and. Drying is an energy intensive process in the tea factory. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a. Tea Processing Energy.

From www.itoen-global.com

Japanese Green Tea Production Process ALL ABOUT GREEN TEA ITO EN Tea Processing Energy Fossil fuels are primarily utilized in the tea factories to. Drying is an energy intensive process in the tea factory. Drying is an energy intensive process in the tea factory. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. This paper briefly reviews the material and energy flows of the. Tea Processing Energy.

From lishantea.com

Tea Processing Steps Kumy Tea Plantation lishantea Tea Processing Energy Drying is an energy intensive process in the tea factory. The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8 kwh, and. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. Drying is an energy intensive process in the tea factory. Energy sustainability in tea sector can. Tea Processing Energy.

From www.slideshare.net

Processing of Tea Tea Processing Energy Drying is an energy intensive process in the tea factory. The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8 kwh, and. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. Typical manufacturing process of tea beverage includes extraction, clarification,. Tea Processing Energy.

From teatime.cc

Aligning Tea Processing with Environmental Sustainability Tea Processing Energy Drying is an energy intensive process in the tea factory. Fossil fuels are primarily utilized in the tea factories to. This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities and. The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8. Tea Processing Energy.

From siamteas.com

siamteas Lesson 8/3 Green Tea Processing siamteas Tea Processing Energy The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8 kwh, and. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. Fossil fuels are primarily utilized in the tea factories to. Drying is an energy intensive process in the tea. Tea Processing Energy.

From www.slideserve.com

PPT Processing technology of tea PowerPoint Presentation, free Tea Processing Energy Drying is an energy intensive process in the tea factory. This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities and. Drying is an energy intensive process in the tea factory. The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8. Tea Processing Energy.

From www.researchgate.net

General method of preparation of tea samples Download Scientific Diagram Tea Processing Energy Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. Drying is an energy intensive process in the tea factory. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities. Tea Processing Energy.

From www.uptontea.com

Tea Processing 101 Upton Tea Imports Tea Processing Energy This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities and. Drying is an energy intensive process in the tea factory. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and. Tea Processing Energy.

From www.cabi.org

Promoting sustainable tea production in India Tea Processing Energy The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8 kwh, and. Drying is an energy intensive process in the tea factory. This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities and. Energy sustainability in tea sector can be achieved. Tea Processing Energy.

From lishantea.com

Tea Processing Steps Kumy Tea Plantation lishantea Tea Processing Energy Fossil fuels are primarily utilized in the tea factories to. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. Drying is an energy intensive process in the tea factory. The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8 kwh, and. Drying is an energy intensive process. Tea Processing Energy.

From vietnam-tea.com

How is black tea made? The manufacturing process of the mostconsumed Tea Processing Energy Fossil fuels are primarily utilized in the tea factories to. This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities and. Drying is an energy intensive process in the tea factory. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. Energy sustainability in tea sector can be achieved. Tea Processing Energy.

From spiriteadrinks.com

What is Green Tea? Uses, Processing, Sipping, Brewing Tips Tea Processing Energy Drying is an energy intensive process in the tea factory. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. Drying is an energy intensive process in the tea factory. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. This paper briefly reviews the material and energy flows. Tea Processing Energy.

From www.researchgate.net

Processing steps of black tea. Download Scientific Diagram Tea Processing Energy Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. Fossil fuels are primarily utilized in the tea factories to. Drying is an energy intensive process in the tea factory. The findings indicate that the combined energy potential of. Tea Processing Energy.

From www.slideserve.com

PPT Global Tea Industry PowerPoint Presentation, free download ID Tea Processing Energy Drying is an energy intensive process in the tea factory. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. Fossil fuels are primarily utilized in the tea factories to. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. The findings indicate that the combined energy potential of. Tea Processing Energy.

From www.fluidpowersystems-expo.com

African tea processing industry seeks sustainability and efficiency Tea Processing Energy The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8 kwh, and. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. Drying is an energy intensive process in the tea factory. Fossil fuels are primarily utilized in the tea factories. Tea Processing Energy.

From www.teamachinerys.com

Black/Green/Oolong/Ivan Tea Processing Machine Wit Tea Machinery Tea Processing Energy Fossil fuels are primarily utilized in the tea factories to. The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8 kwh, and. Drying is an energy intensive process in the tea factory. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. Drying is an energy intensive process. Tea Processing Energy.

From khatabook.com

A Guide to Tea Manufacturing 5 Steps of Tea Processing Tea Processing Energy Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. Drying is an energy intensive process in the tea factory. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10. Tea Processing Energy.

From siamteas.com

siamteas 6 Tea Processing CategoriesSystem siamteas Tea Processing Energy Drying is an energy intensive process in the tea factory. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities and. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a. Tea Processing Energy.

From siamteas.com

siamteas Tea Processing Steps 6 Categories Chart siamteas Tea Processing Energy Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8 kwh, and. This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities and. Fossil fuels are primarily utilized in. Tea Processing Energy.

From lishantea.com

Tea Processing Steps Kumy Tea Plantation lishantea Tea Processing Energy Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. Drying is an energy intensive process in the tea factory. Fossil fuels are primarily utilized in the tea factories to. Drying is an energy intensive process in the tea factory. This paper briefly reviews the material and energy flows of the. Tea Processing Energy.

From www.mdpi.com

Identification of Key Components Responsible for the Aromatic Quality Tea Processing Energy Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. Drying is an energy intensive process in the tea factory. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities. Tea Processing Energy.

From www.howitworksdaily.com

Where does tea come from? How It Works Tea Processing Energy Drying is an energy intensive process in the tea factory. Fossil fuels are primarily utilized in the tea factories to. This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities and. Drying is an energy intensive process in the tea factory. Energy sustainability in tea sector can be achieved through ghg. Tea Processing Energy.

From pt.slideshare.net

Tea manufacturing process part 1 Tea Processing Energy Drying is an energy intensive process in the tea factory. This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities and. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. Drying is an energy intensive process in the tea factory. Typical. Tea Processing Energy.

From www.tftfluid.com

Membrane for Tea Extraction Tea Processing Energy The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8 kwh, and. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. This paper briefly reviews the material and. Tea Processing Energy.

From siamteas.com

siamteas My Little Tea School The ABC of TEA Yellow Tea Processing Tea Processing Energy This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities and. The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8 kwh, and. Drying is an energy intensive process in the tea factory. Typical manufacturing process of tea beverage includes extraction,. Tea Processing Energy.

From www.youtube.com

Tea Processing Explained in Full How Raw Tea Leaves are Transformed Tea Processing Energy This paper briefly reviews the material and energy flows of the malawian tea industry, in order to identify opportunities and. Drying is an energy intensive process in the tea factory. Drying is an energy intensive process in the tea factory. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. The findings indicate that the combined energy potential. Tea Processing Energy.

From khatabook.com

A Guide to Tea Manufacturing 5 Steps of Tea Processing Tea Processing Energy The findings indicate that the combined energy potential of factory and garden tea waste was found to be 2.78x10 8 kwh, and. Fossil fuels are primarily utilized in the tea factories to. Drying is an energy intensive process in the tea factory. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a. Tea Processing Energy.

From www.pinterest.com

How is Tea Made? The Processing and Production of True Teas Cup Tea Processing Energy Drying is an energy intensive process in the tea factory. Fossil fuels are primarily utilized in the tea factories to. Typical manufacturing process of tea beverage includes extraction, clarification, sterilization and drying. Energy sustainability in tea sector can be achieved through ghg reduction by switching to macadamia briquettes as a source. Drying is an energy intensive process in the tea. Tea Processing Energy.