Surface Finish Rating . Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. Surface finishes define the final appearance of parts after. The table below converts surface. The standard surface finish for a machined part is usually 3.2 μm ra. The method (technology) for measuring surface finish: Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. What is the standard surface finish in machining? Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes.

from mavink.com

Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. The table below converts surface. The method (technology) for measuring surface finish: The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. The standard surface finish for a machined part is usually 3.2 μm ra. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. What is the standard surface finish in machining? Surface finishes define the final appearance of parts after.

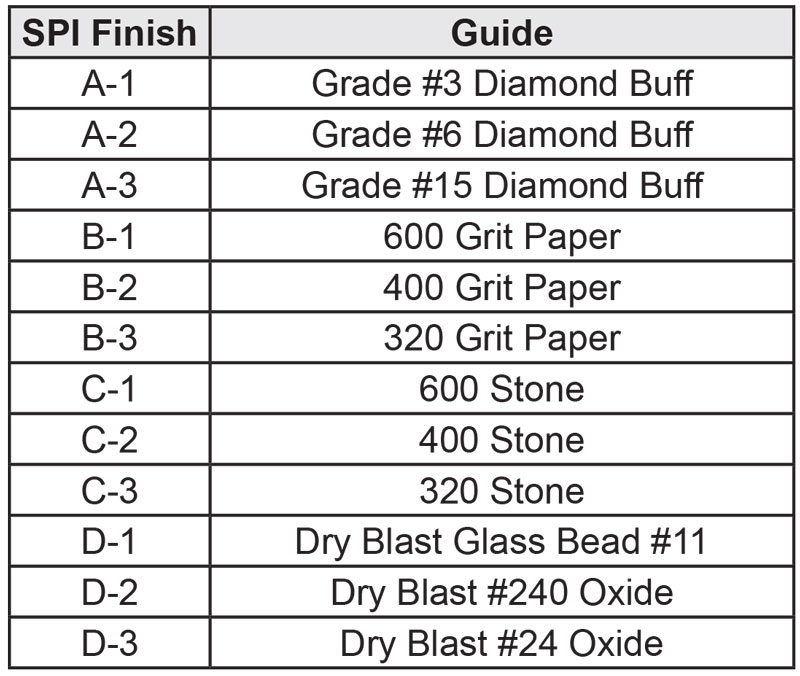

Spi Surface Finish Chart

Surface Finish Rating The method (technology) for measuring surface finish: What is the standard surface finish in machining? Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. The standard surface finish for a machined part is usually 3.2 μm ra. The method (technology) for measuring surface finish: Surface finishes define the final appearance of parts after. Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. The table below converts surface. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool.

From mechutopia.com

Surface Finishing in CNC Machining with Symbols, Charts, RZ,RA Surface Finish Rating What is the standard surface finish in machining? Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. The standard surface finish for a machined part is usually 3.2 μm ra. The surface roughness chart is a tool used by engineers and manufacturers to understand the various. Surface Finish Rating.

From mavink.com

Surface Roughness Grades Surface Finish Rating What is the standard surface finish in machining? The method (technology) for measuring surface finish: The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. Surface finish is. Surface Finish Rating.

From moseys.com

Machining Surface Finish Chart & Specifications Moseys Production Surface Finish Rating Surface finishes define the final appearance of parts after. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. The table below converts surface. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. What is the standard surface finish in machining? The method (technology) for measuring surface finish: Surface. Surface Finish Rating.

From gahess.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Finish Rating The method (technology) for measuring surface finish: The table below converts surface. The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. Additionally, manufacturers can use the surface finish conversion chart to. Surface Finish Rating.

From at-machining.com

Surface Finish Chart A Guide to Understanding Surface Finishing Chart Surface Finish Rating The table below converts surface. The standard surface finish for a machined part is usually 3.2 μm ra. Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. Surface finishes define the final appearance of parts after. The surface roughness chart is a tool used by engineers. Surface Finish Rating.

From mavink.com

Spi Surface Finish Chart Surface Finish Rating The standard surface finish for a machined part is usually 3.2 μm ra. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. Surface finishes define the final appearance of parts after. What is the standard surface finish in machining? The surface roughness chart is a tool used by engineers and manufacturers to. Surface Finish Rating.

From www.wevolver.com

The Comprehensive Guide to Surface Finish Techniques, Standards and Surface Finish Rating What is the standard surface finish in machining? The standard surface finish for a machined part is usually 3.2 μm ra. The method (technology) for measuring surface finish: Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. Additionally, manufacturers can use the surface finish conversion chart. Surface Finish Rating.

From hollandapt.blog

Sanitary Surface Finish Chart Holland Applied Technologies Surface Finish Rating The method (technology) for measuring surface finish: Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. The table below converts surface. Surface roughness measures the closely spaced. Surface Finish Rating.

From mavink.com

Iso Surface Finish Chart Surface Finish Rating Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. The standard surface finish for a machined part is usually 3.2 μm ra. The method (technology) for measuring surface finish:. Surface Finish Rating.

From at-machining.com

Surface Finish Chart A Guide to Understanding Surface Finishing Chart Surface Finish Rating Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. Surface finishes define the final appearance of parts after. Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and. Surface Finish Rating.

From mungfali.com

Surface Finish Roughness Chart Surface Finish Rating The standard surface finish for a machined part is usually 3.2 μm ra. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. Surface finishes define the final. Surface Finish Rating.

From www.engineeringchoice.com

What is Surface Finish? Units, Symbols & Chart Surface Finish Rating Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. The standard surface finish for a machined part is usually 3.2 μm ra. The table below converts surface. The method (technology) for measuring surface. Surface Finish Rating.

From www.gdandtbasics.com

SurfaceFinishSymbolsChart1 GD&T Basics Surface Finish Rating The method (technology) for measuring surface finish: Surface finishes define the final appearance of parts after. What is the standard surface finish in machining? Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface. Surface Finish Rating.

From www.slideserve.com

PPT Surface Finish PowerPoint Presentation, free download ID3866407 Surface Finish Rating The table below converts surface. The standard surface finish for a machined part is usually 3.2 μm ra. The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. Additionally, manufacturers can use. Surface Finish Rating.

From www.rapiddirect.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Surface Finish Rating The method (technology) for measuring surface finish: Surface finishes define the final appearance of parts after. What is the standard surface finish in machining? Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness. Surface Finish Rating.

From www.kemalmfg.com

A Comprehensive Guide to Surface Roughness, its Measurement, Standards Surface Finish Rating The standard surface finish for a machined part is usually 3.2 μm ra. The table below converts surface. The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. What is the standard. Surface Finish Rating.

From mungfali.com

Ra Surface Roughness Chart Surface Finish Rating The method (technology) for measuring surface finish: What is the standard surface finish in machining? Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. Surface roughness measures the closely. Surface Finish Rating.

From www.runyonsurfaceprep.com

Surface Profile Inspection Guide from SP1 to SP10 Runyon Surface Prep Surface Finish Rating Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. The table below converts surface. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. The surface. Surface Finish Rating.

From lynelloswald.blogspot.com

machining surface finish symbols triangle Lynell Oswald Surface Finish Rating Surface finishes define the final appearance of parts after. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in. Surface Finish Rating.

From www.scribd.com

Surface Finish to DIN ISO 1302 PDF Pipe (Fluid Conveyance Surface Finish Rating The table below converts surface. The method (technology) for measuring surface finish: Surface finishes define the final appearance of parts after. Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. The surface roughness chart is a tool used by engineers and manufacturers to understand the various. Surface Finish Rating.

From www.cnccookbook.com.s3-website-us-east-1.amazonaws.com

Surface Finish Symbols and Roughness Conversion Chart Tables Surface Finish Rating What is the standard surface finish in machining? The method (technology) for measuring surface finish: Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. The table below converts surface. The surface roughness chart. Surface Finish Rating.

From www.nextgentooling.com

Understanding Surface Finish RMS vs Ra NEXT GENERATION TOOLING Surface Finish Rating The standard surface finish for a machined part is usually 3.2 μm ra. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. What is the standard surface finish in machining? Surface finishes define the final appearance of parts after. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes.. Surface Finish Rating.

From www.graco.com

Concrete Surface Preparation Part 3 Grades of Concrete Roughness Surface Finish Rating Surface finishes define the final appearance of parts after. The table below converts surface. What is the standard surface finish in machining? The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool.. Surface Finish Rating.

From www.scribd.com

EDM Surface Finish Charts Metalworking Mechanical Engineering Surface Finish Rating Surface finishes define the final appearance of parts after. The table below converts surface. The standard surface finish for a machined part is usually 3.2 μm ra. The method (technology) for measuring surface finish: Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. Surface finish is a measure of the overall texture. Surface Finish Rating.

From bceweb.org

Surface Finish Chart Ra A Visual Reference of Charts Chart Master Surface Finish Rating What is the standard surface finish in machining? The method (technology) for measuring surface finish: Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. Surface finishes define the final appearance of parts after. The table below converts surface. Surface roughness measures the closely spaced irregularities or. Surface Finish Rating.

From www.scribd.com

Surface Finish Machinng Chart PDF PDF Surface Roughness Machining Surface Finish Rating The method (technology) for measuring surface finish: What is the standard surface finish in machining? Surface finishes define the final appearance of parts after. The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. Additionally, manufacturers can use the surface finish conversion chart to compare. Surface Finish Rating.

From www.scribd.com

Surface Finish Chart Surface Finish Rating The method (technology) for measuring surface finish: The standard surface finish for a machined part is usually 3.2 μm ra. The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. The table below converts surface. Additionally, manufacturers can use the surface finish conversion chart to. Surface Finish Rating.

From gle-precision.com

Surface Finish Requirements GLE Precision, Bridgeport, MI. Surface Finish Rating Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. What is the standard surface finish in machining? Surface finishes define the final appearance of parts after. The standard surface finish for a machined part is usually 3.2 μm ra. The method (technology) for measuring surface finish:. Surface Finish Rating.

From isofinishing.com

Surface Roughness Chart Comparison ISO Finishing Surface Finish Rating The table below converts surface. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. Surface finishes define the final appearance of parts after. The standard surface finish for a machined part. Surface Finish Rating.

From isofinishing.com

Surface Roughness Chart ISO Finishing Surface Finish Rating Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. The method (technology) for measuring surface finish: Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. The table below converts surface. What is the standard surface finish in machining? Surface finish is a measure of the overall texture of. Surface Finish Rating.

From www.scribd.com

Surface Roughness Conversion Chart Surface Finish Rating The table below converts surface. What is the standard surface finish in machining? Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. The method (technology) for measuring surface finish: Additionally, manufacturers can use. Surface Finish Rating.

From www.iron-foundry.com

Machining surface finish chart, conversion, comparator, method, degree Surface Finish Rating The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. The standard surface finish for a machined part is usually 3.2 μm ra. Surface roughness measures the closely spaced irregularities or variations, such as cutting tool. Surface finish is a measure of the overall texture. Surface Finish Rating.

From www.forturetools.com

Abrasives grit size Forture Tools Surface Finish Rating Surface finishes define the final appearance of parts after. The standard surface finish for a machined part is usually 3.2 μm ra. The method (technology) for measuring surface finish: Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. Surface roughness measures the closely spaced irregularities or. Surface Finish Rating.

From gbu-presnenskij.ru

Surface Finish Symbols And Roughness Conversion Chart, 49 OFF Surface Finish Rating The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. Surface finishes define the final appearance of parts after. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. Surface finish is a measure of the overall texture. Surface Finish Rating.

From oliverrandall.z13.web.core.windows.net

Rms Surface Roughness Chart Surface Finish Rating The method (technology) for measuring surface finish: Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of. The surface roughness chart is a tool used by engineers and manufacturers to understand the various levels of surface finish in machining and manufacturing processes. The table below converts surface.. Surface Finish Rating.