Moly Resin Application . I want to share my. Although the 80% milling process is well documented it was quite difficult to find examples of someone etching and then applying molyresin on their builds. · purchase a simple recommended airbrush kit. You will need to blast the item first, as norrell recommends. It is much more durable than rattle can paint, but prep is important. The advantage to moly resin is there's no mixing required so you can pour your leftovers back into the bottle, and the. · be extra sure the resin is fully shaken/mixed before applying. Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at 1000 hours, salt water immersion at a minimum of 1000 hours,. Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons.

from www.polyindex.net

I want to share my. · be extra sure the resin is fully shaken/mixed before applying. Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at 1000 hours, salt water immersion at a minimum of 1000 hours,. It is much more durable than rattle can paint, but prep is important. The advantage to moly resin is there's no mixing required so you can pour your leftovers back into the bottle, and the. · purchase a simple recommended airbrush kit. Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. You will need to blast the item first, as norrell recommends. Although the 80% milling process is well documented it was quite difficult to find examples of someone etching and then applying molyresin on their builds.

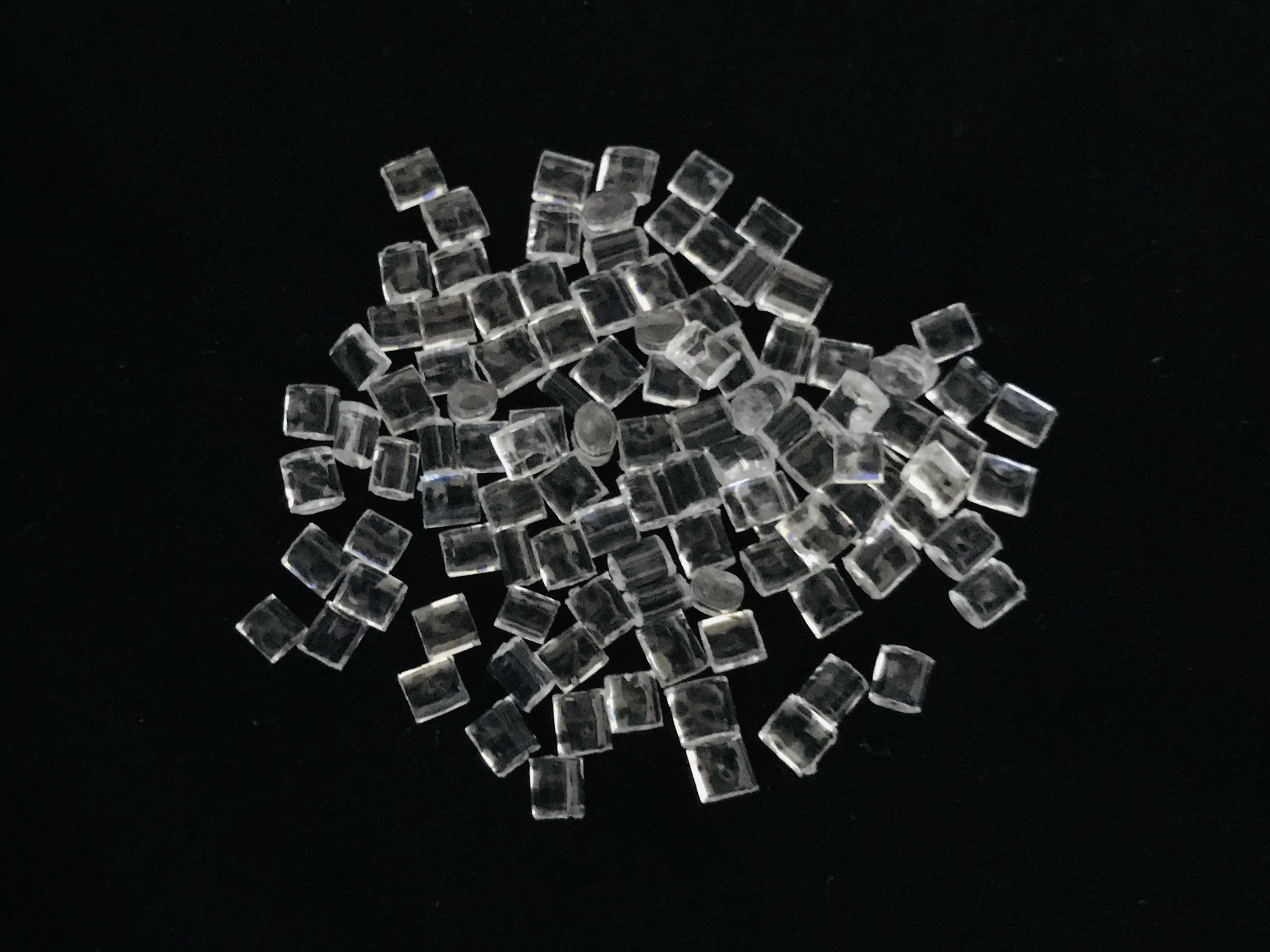

PETG resin PolyIndex Plastics Resins Supplier

Moly Resin Application Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at 1000 hours, salt water immersion at a minimum of 1000 hours,. Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at 1000 hours, salt water immersion at a minimum of 1000 hours,. The advantage to moly resin is there's no mixing required so you can pour your leftovers back into the bottle, and the. I want to share my. · be extra sure the resin is fully shaken/mixed before applying. · purchase a simple recommended airbrush kit. You will need to blast the item first, as norrell recommends. It is much more durable than rattle can paint, but prep is important. Although the 80% milling process is well documented it was quite difficult to find examples of someone etching and then applying molyresin on their builds.

From www.researchgate.net

(PDF) New types of resins and their application Resin Resin Types Moly Resin Application Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at 1000 hours, salt water immersion at a minimum of 1000 hours,. It is much more durable than rattle can paint, but prep is important. I want to share my. You will need to blast the item first, as norrell recommends.. Moly Resin Application.

From www.loctiteam.com

New Healthcare Resin for 3D Printing Announced by LOCTITE Moly Resin Application It is much more durable than rattle can paint, but prep is important. Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at 1000 hours, salt water immersion at a minimum of 1000 hours,. I want to share my. · purchase a simple recommended airbrush kit. The advantage to moly. Moly Resin Application.

From orapiasia.com

What Is MOLY and When to Use It (As Dry Lubricant) ORAPI Asia Moly Resin Application Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. You will need to blast the item first, as norrell recommends. Although the 80% milling process is well documented it was quite difficult to find examples of someone etching and then applying molyresin on their builds. · be extra sure the resin is. Moly Resin Application.

From www.coppsindustries.com

Selecting the Right Epoxy Resin for Your Application Copps Industries Moly Resin Application Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. The advantage to moly resin is there's no mixing required so you can pour your leftovers back into the bottle, and the. You will need to blast the item first, as norrell recommends. Moly resin™, when applied to bare sandblasted cold rolled steel. Moly Resin Application.

From www.ar15.com

Ar15s finished with norrells moly resin picture thread Moly Resin Application · be extra sure the resin is fully shaken/mixed before applying. · purchase a simple recommended airbrush kit. The advantage to moly resin is there's no mixing required so you can pour your leftovers back into the bottle, and the. It is much more durable than rattle can paint, but prep is important. I want to share my. Although the. Moly Resin Application.

From www.ar15.com

Moly resin before, during, and after pics Moly Resin Application · be extra sure the resin is fully shaken/mixed before applying. It is much more durable than rattle can paint, but prep is important. You will need to blast the item first, as norrell recommends. · purchase a simple recommended airbrush kit. I want to share my. Although the 80% milling process is well documented it was quite difficult to. Moly Resin Application.

From changzhourule.en.made-in-china.com

Resin Transfer Molding Rtm Resin with Good Mechanical Strength for Moly Resin Application It is much more durable than rattle can paint, but prep is important. I want to share my. You will need to blast the item first, as norrell recommends. Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. · purchase a simple recommended airbrush kit. Moly resin™, when applied to bare sandblasted. Moly Resin Application.

From www.jinwootr.co.kr

Acrylic Resin > Industrial Use 진우무역 Moly Resin Application Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at 1000 hours, salt water immersion at a minimum of 1000 hours,. I want to share my. · be extra sure the resin is fully shaken/mixed before applying. · purchase a simple recommended airbrush kit. You will need to blast the. Moly Resin Application.

From mohebbaspar.com

The most important Applications of polystyrene resin Ideh Gostar Moly Resin Application Although the 80% milling process is well documented it was quite difficult to find examples of someone etching and then applying molyresin on their builds. Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. I want to share my. · be extra sure the resin is fully shaken/mixed before applying. It is. Moly Resin Application.

From www.ar15.com

Moly resin before, during, and after pics Page 1 Moly Resin Application You will need to blast the item first, as norrell recommends. · be extra sure the resin is fully shaken/mixed before applying. The advantage to moly resin is there's no mixing required so you can pour your leftovers back into the bottle, and the. I want to share my. Moly resin is a thermally cured phenolic coating specifically developed for. Moly Resin Application.

From www.polyindex.net

PETG resin PolyIndex Plastics Resins Supplier Moly Resin Application · be extra sure the resin is fully shaken/mixed before applying. It is much more durable than rattle can paint, but prep is important. Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at 1000 hours, salt water immersion at a minimum of 1000 hours,. Moly resin is a thermally. Moly Resin Application.

From www.mdpi.com

Processes Free FullText Recovery of Ammonium from BiomassDrying Moly Resin Application Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at 1000 hours, salt water immersion at a minimum of 1000 hours,. · be extra sure the resin is fully shaken/mixed before applying. I want to share my. The advantage to moly resin is there's no mixing required so you can. Moly Resin Application.

From rayhiniisteron.blogspot.com

Easy Cast Resin Vs Fiberglass Resin on Craft Foam Ray Hiniisteron Moly Resin Application You will need to blast the item first, as norrell recommends. Although the 80% milling process is well documented it was quite difficult to find examples of someone etching and then applying molyresin on their builds. The advantage to moly resin is there's no mixing required so you can pour your leftovers back into the bottle, and the. It is. Moly Resin Application.

From giochminp.blob.core.windows.net

Epoxy Resin In Adelaide at Jill Smith blog Moly Resin Application · purchase a simple recommended airbrush kit. Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at 1000 hours, salt water immersion at a minimum of 1000 hours,. You will need to blast the item first, as norrell recommends. It is much more durable than rattle can paint, but prep. Moly Resin Application.

From forums.1911forum.com

John Norrell Moly Resin 1911Forum Moly Resin Application I want to share my. · purchase a simple recommended airbrush kit. · be extra sure the resin is fully shaken/mixed before applying. The advantage to moly resin is there's no mixing required so you can pour your leftovers back into the bottle, and the. Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment. Moly Resin Application.

From www.researchgate.net

Resin synthesis and reagent molar ratio used Download Table Moly Resin Application · be extra sure the resin is fully shaken/mixed before applying. Although the 80% milling process is well documented it was quite difficult to find examples of someone etching and then applying molyresin on their builds. I want to share my. · purchase a simple recommended airbrush kit. The advantage to moly resin is there's no mixing required so you. Moly Resin Application.

From totalprecision.ie

Moly Coating ‹ Total Precision Moly Resin Application You will need to blast the item first, as norrell recommends. It is much more durable than rattle can paint, but prep is important. Although the 80% milling process is well documented it was quite difficult to find examples of someone etching and then applying molyresin on their builds. · be extra sure the resin is fully shaken/mixed before applying.. Moly Resin Application.

From texasrefinery.ca

Moly Dry Film Aerosol Lubricant with Moly TRC of Canada Moly Resin Application The advantage to moly resin is there's no mixing required so you can pour your leftovers back into the bottle, and the. · purchase a simple recommended airbrush kit. You will need to blast the item first, as norrell recommends. Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at. Moly Resin Application.

From www.youtube.com

Part 3 RRA AR15 and Remington 870 build and moly resin application Moly Resin Application · purchase a simple recommended airbrush kit. The advantage to moly resin is there's no mixing required so you can pour your leftovers back into the bottle, and the. · be extra sure the resin is fully shaken/mixed before applying. Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. Although the 80%. Moly Resin Application.

From www.youtube.com

Coating with Norrell's Moly Resin YouTube Moly Resin Application · be extra sure the resin is fully shaken/mixed before applying. Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at 1000 hours, salt water immersion at a minimum of 1000 hours,. The advantage to moly resin is there's no mixing required so you can pour your leftovers back into. Moly Resin Application.

From www.scribd.com

2021 01 01 Moly Resin Manual PDF Paint Epoxy Moly Resin Application Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at 1000 hours, salt water immersion at a minimum of 1000 hours,. Although the 80% milling process is well documented it was quite difficult to find examples of someone etching and then applying molyresin on their builds. · be extra sure. Moly Resin Application.

From www.linkedin.com

Applications of Vinyl Ester Resins Moly Resin Application Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. I want to share my. Although the 80% milling process is well documented it was quite difficult to find examples of someone etching and then applying molyresin on their builds. The advantage to moly resin is there's no mixing required so you can. Moly Resin Application.

From www.tradeindia.com

Molygraph Brb 30 high Performance Ep Moly Grease Application Moly Resin Application Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. You will need to blast the item first, as norrell recommends. The advantage to moly resin is there's no mixing required so you can pour your leftovers back into the bottle, and the. It is much more durable than rattle can paint, but. Moly Resin Application.

From fyoeineqr.blob.core.windows.net

What Is The Best Resin To Use at Carol Taft blog Moly Resin Application Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. · purchase a simple recommended airbrush kit. Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at 1000 hours, salt water immersion at a minimum of 1000 hours,. It is much more durable. Moly Resin Application.

From www.medicalexpo.com

Resin dental material BURN OUT PREVEST DENPRO LIMITED for dental Moly Resin Application It is much more durable than rattle can paint, but prep is important. Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. · purchase a simple recommended airbrush kit. You will need to blast the item first, as norrell recommends. · be extra sure the resin is fully shaken/mixed before applying. Moly. Moly Resin Application.

From www.bladeforums.com

1095, Aluminium Scales, Moly Resin Coating Moly Resin Application Although the 80% milling process is well documented it was quite difficult to find examples of someone etching and then applying molyresin on their builds. Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. You will need to blast the item first, as norrell recommends. Moly resin™, when applied to bare sandblasted. Moly Resin Application.

From www.alamy.com

An epoxy flooring tool, preparation and application of epoxy resin in Moly Resin Application The advantage to moly resin is there's no mixing required so you can pour your leftovers back into the bottle, and the. It is much more durable than rattle can paint, but prep is important. · purchase a simple recommended airbrush kit. Although the 80% milling process is well documented it was quite difficult to find examples of someone etching. Moly Resin Application.

From www.youtube.com

Part 2 WASR 10/63 AK47 AKM BUILD sand blasting, moly resin, and Moly Resin Application I want to share my. You will need to blast the item first, as norrell recommends. · purchase a simple recommended airbrush kit. · be extra sure the resin is fully shaken/mixed before applying. Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at 1000 hours, salt water immersion at. Moly Resin Application.

From www.theakforum.net

Moly Resin/KG Gunkote vs Russian paint AK Rifles Moly Resin Application It is much more durable than rattle can paint, but prep is important. Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. · purchase a simple recommended airbrush kit. Although the 80% milling process is well documented it was quite difficult to find examples of someone etching and then applying molyresin on. Moly Resin Application.

From www.indiamart.com

Moly with Resin Binders at Rs 850/500 ml aerosol Dry Film Lubricants Moly Resin Application I want to share my. Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. You will need to blast the item first, as norrell recommends. The advantage to moly resin is there's no mixing required so you can pour your leftovers back into the bottle, and the. Moly resin™, when applied to. Moly Resin Application.

From www.reddit.com

Moly Resin = Winning r/RetroAR Moly Resin Application You will need to blast the item first, as norrell recommends. It is much more durable than rattle can paint, but prep is important. I want to share my. · be extra sure the resin is fully shaken/mixed before applying. Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. Moly resin™, when. Moly Resin Application.

From www.youtube.com

Epoxy resin FRP applications process YouTube Moly Resin Application You will need to blast the item first, as norrell recommends. It is much more durable than rattle can paint, but prep is important. I want to share my. · be extra sure the resin is fully shaken/mixed before applying. Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. Although the 80%. Moly Resin Application.

From www.ar15.com

John Norrelll’s Molly Resin grayishblack colt issues…… Moly Resin Application · purchase a simple recommended airbrush kit. · be extra sure the resin is fully shaken/mixed before applying. Moly resin is a thermally cured phenolic coating specifically developed for ordnance usage on equipment and weapons. The advantage to moly resin is there's no mixing required so you can pour your leftovers back into the bottle, and the. Although the 80%. Moly Resin Application.

From www.youtube.com

Moly Resin Coating DIY! YouTube Moly Resin Application It is much more durable than rattle can paint, but prep is important. Although the 80% milling process is well documented it was quite difficult to find examples of someone etching and then applying molyresin on their builds. Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at 1000 hours,. Moly Resin Application.

From feltmagnet.com

DIY Plastic Molds for Fiberglass and Resin Casting Moly Resin Application Moly resin™, when applied to bare sandblasted cold rolled steel will pass the test procedures for salt water spray at 1000 hours, salt water immersion at a minimum of 1000 hours,. The advantage to moly resin is there's no mixing required so you can pour your leftovers back into the bottle, and the. Although the 80% milling process is well. Moly Resin Application.