Wind Turbine Pitch Bearing . design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. pitch bearings are key components for the pitch system of wind turbines, and their reliability is closely. this design guideline describes the design criteria, calculation methods, and applicable standards recommended for use in. wind turbines need to be positioned correctly if they are to generate the maximum amount of energy. the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily. First, the nacelle must be. modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus.

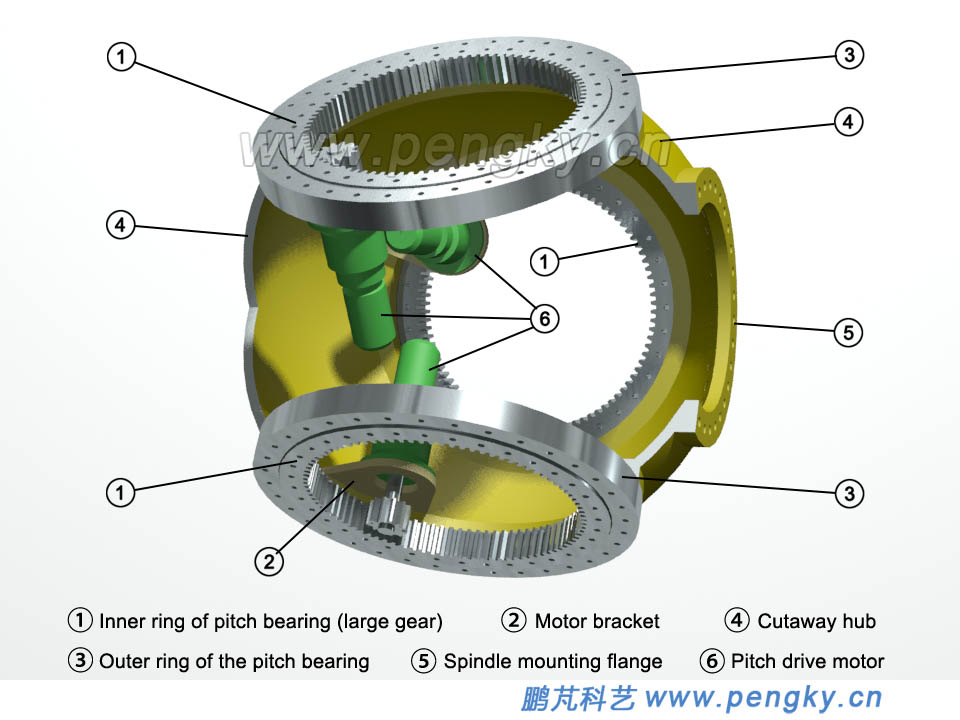

from www.pengky.cn

the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. wind turbines need to be positioned correctly if they are to generate the maximum amount of energy. First, the nacelle must be. modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus. this design guideline describes the design criteria, calculation methods, and applicable standards recommended for use in. the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily. pitch bearings are key components for the pitch system of wind turbines, and their reliability is closely.

Independent Pitch System Horizontal Axis Wind Turbine PengKy

Wind Turbine Pitch Bearing this design guideline describes the design criteria, calculation methods, and applicable standards recommended for use in. First, the nacelle must be. the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily. this design guideline describes the design criteria, calculation methods, and applicable standards recommended for use in. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. pitch bearings are key components for the pitch system of wind turbines, and their reliability is closely. wind turbines need to be positioned correctly if they are to generate the maximum amount of energy. modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus.

From www.pengky.cn

Independent Pitch System Horizontal Axis Wind Turbine PengKy Wind Turbine Pitch Bearing pitch bearings are key components for the pitch system of wind turbines, and their reliability is closely. First, the nacelle must be. the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life.. Wind Turbine Pitch Bearing.

From www.pengky.cn

Independent Pitch System Horizontal Axis Wind Turbine PengKy Wind Turbine Pitch Bearing design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. this design guideline describes the design criteria, calculation methods, and applicable standards recommended for use in. modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus. wind turbines need to be. Wind Turbine Pitch Bearing.

From www.liebherr.com

Main bearings for wind turbines Liebherr Wind Turbine Pitch Bearing First, the nacelle must be. the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus. the test parameters represent typical operating conditions of wind turbine pitch bearings. Wind Turbine Pitch Bearing.

From www.bearingtips.com

New pitch bearing at WindEnergy Hamburg Bearing Tips Wind Turbine Pitch Bearing the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily. First, the nacelle must be. . Wind Turbine Pitch Bearing.

From chinazys.en.made-in-china.com

Zys Wind Turbine Systems Yaw and Pitch Rolling Bearing 010.30.710 Wind Turbine Pitch Bearing design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. First, the nacelle must be. modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle. Wind Turbine Pitch Bearing.

From www.ui-pi.net

Pitch Slewing Bearing for 1.5MW Wind Turbine Manufacturers and Wind Turbine Pitch Bearing wind turbines need to be positioned correctly if they are to generate the maximum amount of energy. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily. modern wind turbines use large turntable bearings at. Wind Turbine Pitch Bearing.

From pengky.cn

Drive rod Unified Pitch Drive Mechanism Horizontal Axis Wind Turbine Wind Turbine Pitch Bearing pitch bearings are key components for the pitch system of wind turbines, and their reliability is closely. this design guideline describes the design criteria, calculation methods, and applicable standards recommended for use in. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. wind turbines need to be positioned correctly if. Wind Turbine Pitch Bearing.

From www.zys-bearing.com

Main shaft bearing for wind turbine Wind Turbine Pitch Bearing design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus. pitch bearings are key components for the pitch system of wind turbines, and their reliability is closely. the design guideline 03. Wind Turbine Pitch Bearing.

From www.windpowermonthly.com

Compact pitch bearing unit promises fully integrated solution for wind Wind Turbine Pitch Bearing the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily. wind turbines need to be positioned correctly if they are to generate the maximum amount of energy. First, the nacelle must be. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. pitch bearings are. Wind Turbine Pitch Bearing.

From www.hgbearing.net

Supply Pitch Bearing Of Wind Turbine Generator Wholesale Factory Wind Turbine Pitch Bearing the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. pitch bearings are key components for the pitch system of wind turbines, and their reliability is closely. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. modern wind turbines use. Wind Turbine Pitch Bearing.

From www.thyssenkrupp.com

Wind turbines our key components Wind Turbine Pitch Bearing the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. First, the nacelle must be. modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus. pitch bearings are key components for the pitch system of wind turbines,. Wind Turbine Pitch Bearing.

From www.pengky.cn

Wind Turbine Bearings Horizontal Axis Wind Turbine PengKy Wind Turbine Pitch Bearing modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus. pitch bearings are key components for the pitch system of wind turbines, and their reliability is closely. First, the nacelle must be. wind turbines need to be positioned correctly if they are to generate the maximum amount. Wind Turbine Pitch Bearing.

From www.motioncontroltips.com

How to prevent false brinelling in rollingelement bearings Wind Turbine Pitch Bearing wind turbines need to be positioned correctly if they are to generate the maximum amount of energy. the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. First, the nacelle must be.. Wind Turbine Pitch Bearing.

From www.mdpi.com

Energies Free FullText A DataDriven Approach for Condition Wind Turbine Pitch Bearing wind turbines need to be positioned correctly if they are to generate the maximum amount of energy. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. modern wind turbines use. Wind Turbine Pitch Bearing.

From www.pengky.cn

Wind Turbine Bearings Horizontal Axis Wind Turbine PengKy Wind Turbine Pitch Bearing the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily. this design guideline describes the design criteria, calculation methods, and applicable standards recommended for use in. pitch bearings are key components for the pitch system of wind turbines, and their reliability is closely. design aspects and methodologies to determine pitch. Wind Turbine Pitch Bearing.

From www.pengky.cn

Wind Turbine Bearings Horizontal Axis Wind Turbine PengKy Wind Turbine Pitch Bearing First, the nacelle must be. the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus. wind turbines need to be positioned correctly if they are to generate. Wind Turbine Pitch Bearing.

From www.keba.com

Pitch control and yawing systems for optimal wind turbine design KEBA Wind Turbine Pitch Bearing First, the nacelle must be. the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily. the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. pitch bearings are key components for the pitch system of wind turbines, and their reliability is. Wind Turbine Pitch Bearing.

From www.pengky.cn

Independent Pitch System Horizontal Axis Wind Turbine PengKy Wind Turbine Pitch Bearing this design guideline describes the design criteria, calculation methods, and applicable standards recommended for use in. modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. the design guideline 03 (dg03). Wind Turbine Pitch Bearing.

From www.youtube.com

Wind Turbine Blade Bearing Exchange YouTube Wind Turbine Pitch Bearing modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily. the design guideline 03 (dg03). Wind Turbine Pitch Bearing.

From www.windpowerengineering.com

Extending wind turbine life with pitch bearing upgrades Wind Turbine Pitch Bearing design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. pitch bearings are key components for the pitch system of wind turbines, and their reliability is closely. the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. this design guideline describes. Wind Turbine Pitch Bearing.

From www.pengky.cn

Wind Turbine Bearings Horizontal Axis Wind Turbine PengKy Wind Turbine Pitch Bearing the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily. this design guideline describes the design criteria, calculation methods, and applicable standards recommended for use in. the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. pitch bearings are key. Wind Turbine Pitch Bearing.

From www.powertransmissionworld.com

Wind turbines are up to three times more reliable Power Transmission Wind Turbine Pitch Bearing the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. this design guideline describes the design criteria, calculation methods, and applicable standards recommended for use in. wind turbines need to be. Wind Turbine Pitch Bearing.

From craneslewring.com

Buy Wind Turbine Slewing Ring Bearings Yaw Bearings Pitch Bearing CV Wind Turbine Pitch Bearing First, the nacelle must be. modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus. this design guideline describes the design criteria, calculation methods, and applicable standards recommended for use in. the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily.. Wind Turbine Pitch Bearing.

From www.pengky.cn

Independent Pitch System Horizontal Axis Wind Turbine PengKy Wind Turbine Pitch Bearing the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily. this design guideline describes the design criteria, calculation methods, and applicable standards recommended for use in. modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus. design aspects and methodologies. Wind Turbine Pitch Bearing.

From motion-drives.com

Global Wind Turbine Bearing Market 2016 Timken Company, Scheerer Wind Turbine Pitch Bearing design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. wind turbines need to be positioned correctly if they are to generate the maximum amount of energy. this design guideline describes the design criteria, calculation methods, and applicable standards recommended for use in. modern wind turbines use large turntable bearings at. Wind Turbine Pitch Bearing.

From www.pengky.cn

Wind Turbine Bearings Horizontal Axis Wind Turbine PengKy Wind Turbine Pitch Bearing this design guideline describes the design criteria, calculation methods, and applicable standards recommended for use in. First, the nacelle must be. pitch bearings are key components for the pitch system of wind turbines, and their reliability is closely. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. wind turbines need. Wind Turbine Pitch Bearing.

From www.pengky.cn

Independent Pitch System Horizontal Axis Wind Turbine PengKy Wind Turbine Pitch Bearing modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus. the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. First, the nacelle must be. . Wind Turbine Pitch Bearing.

From www.windsystemsmag.com

The World of Turbine Bearings Wind Systems Magazine Wind Turbine Pitch Bearing First, the nacelle must be. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle. Wind Turbine Pitch Bearing.

From www.liebherr.com

Main bearings for wind turbines Liebherr Wind Turbine Pitch Bearing First, the nacelle must be. the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. pitch bearings are key components for the pitch system of wind turbines, and their reliability is closely. this design guideline describes the design criteria, calculation methods, and applicable standards recommended for use. Wind Turbine Pitch Bearing.

From www.researchgate.net

Pitch control strategy used in wind turbine Download Scientific Diagram Wind Turbine Pitch Bearing wind turbines need to be positioned correctly if they are to generate the maximum amount of energy. this design guideline describes the design criteria, calculation methods, and applicable standards recommended for use in. First, the nacelle must be. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. the test parameters. Wind Turbine Pitch Bearing.

From www.pengky.cn

Wind Turbine Bearings Horizontal Axis Wind Turbine PengKy Wind Turbine Pitch Bearing the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus. the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily. . Wind Turbine Pitch Bearing.

From www.malloywind.com

Upgraded Blade Bearings for your WTG — Malloy Wind Wind Turbine Pitch Bearing the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily. wind turbines need to be positioned correctly if they are to generate the maximum amount of energy. First, the nacelle must be. the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the. Wind Turbine Pitch Bearing.

From laptrinhx.com

Extending wind turbine life with pitch bearing upgrades LaptrinhX / News Wind Turbine Pitch Bearing the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. pitch bearings are key components for the pitch system of wind turbines, and their reliability is closely. modern wind turbines use large turntable bearings at. Wind Turbine Pitch Bearing.

From www.slewing-bearing.com

slewing bearings for wind turbines Wind Turbine Pitch Bearing the design guideline 03 (dg03) published by the national renewable energy laboratory in 2009 is widely used in the wind. First, the nacelle must be. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. pitch bearings are key components for the pitch system of wind turbines, and their reliability is closely.. Wind Turbine Pitch Bearing.

From lyjwbearings.en.made-in-china.com

Wind Turbine Pitch Bearing China Slewing Bearing and Pitch Bearing Wind Turbine Pitch Bearing modern wind turbines use large turntable bearings at the root of each blade to enable pitch angle changes and thus. the test parameters represent typical operating conditions of wind turbine pitch bearings and can be easily. First, the nacelle must be. design aspects and methodologies to determine pitch and yaw bearing static capacity and fatigue life. . Wind Turbine Pitch Bearing.