Stacking Space Requirements . Stacks should be vertical (not leaning). Sufficient space must be allowed between stacks for safe movement. help prevent injuries when stacking materials, workers must do the following: Pallets should be used to keep materials off the ground. the occupational safety and health administration (osha) lists general requirements for material storage in “ 1926.250 (h). Ohs regulations of each jurisdiction include requirements for stacking, storing and piling of. each stack should be for one material only (not mixed). adequate clearance and working space for safe movement and storage of materials. Maintain a free space of about 1 m on all sides of the stacked. As with capacity labeling and anchoring, osha doesn’t specifically regulate stacking height. make sure a gap of about 1 m from the ceiling, roof or sprinkler heads. A maximum stack height must be set (depending on the material’s strength and stability). stacking and height. general ohs stacking rules vary by province. Plan and elevation drawings plan and elevation drawings should include:

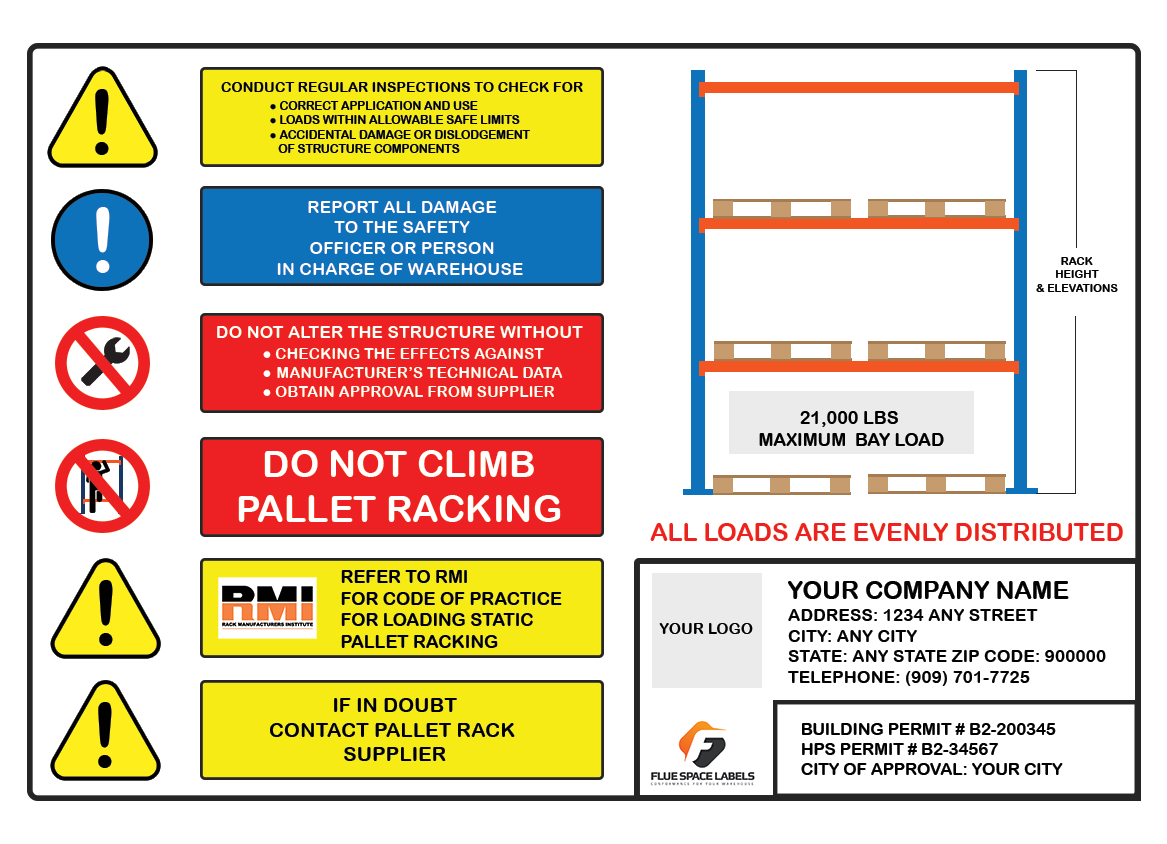

from fluespacelabels.com

Plan and elevation drawings plan and elevation drawings should include: Maintain a free space of about 1 m on all sides of the stacked. Stack lumber no more than 16 feet high if. A maximum stack height must be set (depending on the material’s strength and stability). help prevent injuries when stacking materials, workers must do the following: As with capacity labeling and anchoring, osha doesn’t specifically regulate stacking height. make sure a gap of about 1 m from the ceiling, roof or sprinkler heads. Pallets should be used to keep materials off the ground. stacking and height. Sufficient space must be allowed between stacks for safe movement.

Pallet Rack Load Capacity Signs Flue Space Labels

Stacking Space Requirements Maintain a free space of about 1 m on all sides of the stacked. Stacks should be vertical (not leaning). Stack lumber no more than 16 feet high if. Ohs regulations of each jurisdiction include requirements for stacking, storing and piling of. Sufficient space must be allowed between stacks for safe movement. general ohs stacking rules vary by province. adequate clearance and working space for safe movement and storage of materials. each stack should be for one material only (not mixed). the occupational safety and health administration (osha) lists general requirements for material storage in “ 1926.250 (h). As with capacity labeling and anchoring, osha doesn’t specifically regulate stacking height. A maximum stack height must be set (depending on the material’s strength and stability). stacking and height. Plan and elevation drawings plan and elevation drawings should include: Pallets should be used to keep materials off the ground. help prevent injuries when stacking materials, workers must do the following: Maintain a free space of about 1 m on all sides of the stacked.

From www.worksafe.govt.nz

Safe stacking of sawn timber and board materials WorkSafe Stacking Space Requirements general ohs stacking rules vary by province. make sure a gap of about 1 m from the ceiling, roof or sprinkler heads. Stack lumber no more than 16 feet high if. Maintain a free space of about 1 m on all sides of the stacked. help prevent injuries when stacking materials, workers must do the following: . Stacking Space Requirements.

From www.stackingplans.net

Stacking Plans 3D Stacking Plan 11 Stacking Space Requirements make sure a gap of about 1 m from the ceiling, roof or sprinkler heads. Plan and elevation drawings plan and elevation drawings should include: As with capacity labeling and anchoring, osha doesn’t specifically regulate stacking height. Pallets should be used to keep materials off the ground. Sufficient space must be allowed between stacks for safe movement. stacking. Stacking Space Requirements.

From blocksandlots.com

What is a Stacking Plan? Blocks & Lots Stacking Space Requirements general ohs stacking rules vary by province. Maintain a free space of about 1 m on all sides of the stacked. each stack should be for one material only (not mixed). Stack lumber no more than 16 feet high if. adequate clearance and working space for safe movement and storage of materials. help prevent injuries when. Stacking Space Requirements.

From www.researchgate.net

(PDF) Design of large gathering spaces space requirements, volumes Stacking Space Requirements Stack lumber no more than 16 feet high if. help prevent injuries when stacking materials, workers must do the following: Sufficient space must be allowed between stacks for safe movement. each stack should be for one material only (not mixed). stacking and height. make sure a gap of about 1 m from the ceiling, roof or. Stacking Space Requirements.

From pdfbag.com

Flare Stack Height Calculation & Design Exposure Limits Safety PDFBAG Stacking Space Requirements stacking and height. Stacks should be vertical (not leaning). Ohs regulations of each jurisdiction include requirements for stacking, storing and piling of. make sure a gap of about 1 m from the ceiling, roof or sprinkler heads. the occupational safety and health administration (osha) lists general requirements for material storage in “ 1926.250 (h). adequate clearance. Stacking Space Requirements.

From globalsecurity.org

FM 5560 Army Terminal Operations Chptr 6 Marshaling Yard Operations Stacking Space Requirements Ohs regulations of each jurisdiction include requirements for stacking, storing and piling of. each stack should be for one material only (not mixed). make sure a gap of about 1 m from the ceiling, roof or sprinkler heads. Stack lumber no more than 16 feet high if. stacking and height. Plan and elevation drawings plan and elevation. Stacking Space Requirements.

From library.municode.com

Municode Library Stacking Space Requirements Pallets should be used to keep materials off the ground. Ohs regulations of each jurisdiction include requirements for stacking, storing and piling of. stacking and height. A maximum stack height must be set (depending on the material’s strength and stability). Sufficient space must be allowed between stacks for safe movement. general ohs stacking rules vary by province. . Stacking Space Requirements.

From www.homenish.com

Standard Laundry Space Requirements (with 4 Drawings & Layouts) Homenish Stacking Space Requirements Plan and elevation drawings plan and elevation drawings should include: adequate clearance and working space for safe movement and storage of materials. each stack should be for one material only (not mixed). Stack lumber no more than 16 feet high if. Sufficient space must be allowed between stacks for safe movement. Stacks should be vertical (not leaning). . Stacking Space Requirements.

From interiorpras.blogspot.com

Prasetyo's Design Journal STACKING PLAN, a guideline to generate Stacking Space Requirements Plan and elevation drawings plan and elevation drawings should include: Sufficient space must be allowed between stacks for safe movement. make sure a gap of about 1 m from the ceiling, roof or sprinkler heads. Stack lumber no more than 16 feet high if. help prevent injuries when stacking materials, workers must do the following: Stacks should be. Stacking Space Requirements.

From www.abcalc.biz

Stacking Plans Stacking Space Requirements Sufficient space must be allowed between stacks for safe movement. stacking and height. Pallets should be used to keep materials off the ground. help prevent injuries when stacking materials, workers must do the following: Plan and elevation drawings plan and elevation drawings should include: A maximum stack height must be set (depending on the material’s strength and stability).. Stacking Space Requirements.

From www.ngrave.io

What Does Stacking Sats Mean? Best ways to HODL NGRAVE Stacking Space Requirements stacking and height. Stack lumber no more than 16 feet high if. make sure a gap of about 1 m from the ceiling, roof or sprinkler heads. help prevent injuries when stacking materials, workers must do the following: As with capacity labeling and anchoring, osha doesn’t specifically regulate stacking height. Stacks should be vertical (not leaning). A. Stacking Space Requirements.

From codelibrary.amlegal.com

§ 155.077 OFFSTREET PARKING. Stacking Space Requirements Ohs regulations of each jurisdiction include requirements for stacking, storing and piling of. Maintain a free space of about 1 m on all sides of the stacked. general ohs stacking rules vary by province. stacking and height. each stack should be for one material only (not mixed). Stack lumber no more than 16 feet high if. Sufficient. Stacking Space Requirements.

From library.municode.com

Municode Library Stacking Space Requirements each stack should be for one material only (not mixed). adequate clearance and working space for safe movement and storage of materials. Stacks should be vertical (not leaning). Stack lumber no more than 16 feet high if. the occupational safety and health administration (osha) lists general requirements for material storage in “ 1926.250 (h). A maximum stack. Stacking Space Requirements.

From library.municode.com

Municode Library Stacking Space Requirements Plan and elevation drawings plan and elevation drawings should include: Ohs regulations of each jurisdiction include requirements for stacking, storing and piling of. stacking and height. the occupational safety and health administration (osha) lists general requirements for material storage in “ 1926.250 (h). Stack lumber no more than 16 feet high if. make sure a gap of. Stacking Space Requirements.

From aurora.municipal.codes

4.6.7 DRIVETHROUGH STACKING AREAS Aurora Unified Development Ordinance Stacking Space Requirements adequate clearance and working space for safe movement and storage of materials. stacking and height. Ohs regulations of each jurisdiction include requirements for stacking, storing and piling of. help prevent injuries when stacking materials, workers must do the following: Stack lumber no more than 16 feet high if. make sure a gap of about 1 m. Stacking Space Requirements.

From www.researchgate.net

The required stacking area in m 2 Download Scientific Diagram Stacking Space Requirements stacking and height. Sufficient space must be allowed between stacks for safe movement. Maintain a free space of about 1 m on all sides of the stacked. Plan and elevation drawings plan and elevation drawings should include: general ohs stacking rules vary by province. A maximum stack height must be set (depending on the material’s strength and stability).. Stacking Space Requirements.

From measureupcorp.com

Space Management Software Measure Up Corp Contact Us Stacking Space Requirements Stacks should be vertical (not leaning). help prevent injuries when stacking materials, workers must do the following: general ohs stacking rules vary by province. A maximum stack height must be set (depending on the material’s strength and stability). Plan and elevation drawings plan and elevation drawings should include: Pallets should be used to keep materials off the ground.. Stacking Space Requirements.

From www.officespacesoftware.com

Optimizing Workspaces with Block and Stack Planning Stacking Space Requirements A maximum stack height must be set (depending on the material’s strength and stability). stacking and height. Stack lumber no more than 16 feet high if. adequate clearance and working space for safe movement and storage of materials. Pallets should be used to keep materials off the ground. make sure a gap of about 1 m from. Stacking Space Requirements.

From fluespacelabels.com

Pallet Rack Load Capacity Signs Flue Space Labels Stacking Space Requirements stacking and height. general ohs stacking rules vary by province. each stack should be for one material only (not mixed). Sufficient space must be allowed between stacks for safe movement. Pallets should be used to keep materials off the ground. adequate clearance and working space for safe movement and storage of materials. Stack lumber no more. Stacking Space Requirements.

From cartifact.com

stacking plans — Cartifact Stacking Space Requirements Stack lumber no more than 16 feet high if. help prevent injuries when stacking materials, workers must do the following: adequate clearance and working space for safe movement and storage of materials. Maintain a free space of about 1 m on all sides of the stacked. stacking and height. A maximum stack height must be set (depending. Stacking Space Requirements.

From warehouselift.com

Warehouse Layout Design Forklift Aisle Width Guide Warehouse Lift Stacking Space Requirements adequate clearance and working space for safe movement and storage of materials. Ohs regulations of each jurisdiction include requirements for stacking, storing and piling of. Stacks should be vertical (not leaning). Sufficient space must be allowed between stacks for safe movement. stacking and height. Plan and elevation drawings plan and elevation drawings should include: Stack lumber no more. Stacking Space Requirements.

From medium.com

What is a Stacking Plan in Real Estate by Clarence Cai Medium Stacking Space Requirements Maintain a free space of about 1 m on all sides of the stacked. general ohs stacking rules vary by province. adequate clearance and working space for safe movement and storage of materials. Plan and elevation drawings plan and elevation drawings should include: Pallets should be used to keep materials off the ground. stacking and height. A. Stacking Space Requirements.

From www.pinterest.co.kr

stacking diagram space planning How to plan, Space planning, Cafeteria Stacking Space Requirements Maintain a free space of about 1 m on all sides of the stacked. A maximum stack height must be set (depending on the material’s strength and stability). general ohs stacking rules vary by province. adequate clearance and working space for safe movement and storage of materials. Plan and elevation drawings plan and elevation drawings should include: Sufficient. Stacking Space Requirements.

From basicsafetyandtraining.solutions

STACKING AND STORAGE Basic Safety and Training Solutions Stacking Space Requirements Stacks should be vertical (not leaning). Pallets should be used to keep materials off the ground. help prevent injuries when stacking materials, workers must do the following: the occupational safety and health administration (osha) lists general requirements for material storage in “ 1926.250 (h). Maintain a free space of about 1 m on all sides of the stacked.. Stacking Space Requirements.

From t3bayside.com

Stacking Plan T3Bayside Stacking Space Requirements Maintain a free space of about 1 m on all sides of the stacked. As with capacity labeling and anchoring, osha doesn’t specifically regulate stacking height. stacking and height. A maximum stack height must be set (depending on the material’s strength and stability). Plan and elevation drawings plan and elevation drawings should include: Pallets should be used to keep. Stacking Space Requirements.

From www.certifyme.net

5 Tips for Stacking Pallets Properly Stacking Space Requirements general ohs stacking rules vary by province. Plan and elevation drawings plan and elevation drawings should include: Ohs regulations of each jurisdiction include requirements for stacking, storing and piling of. stacking and height. help prevent injuries when stacking materials, workers must do the following: Maintain a free space of about 1 m on all sides of the. Stacking Space Requirements.

From spaceaidmfg.com

Stacking Racks and industrial racks designed by Stacking Space Requirements Maintain a free space of about 1 m on all sides of the stacked. Ohs regulations of each jurisdiction include requirements for stacking, storing and piling of. general ohs stacking rules vary by province. adequate clearance and working space for safe movement and storage of materials. A maximum stack height must be set (depending on the material’s strength. Stacking Space Requirements.

From www.researchgate.net

(PDF) Design of large gathering spaces space requirements, volumes Stacking Space Requirements general ohs stacking rules vary by province. Pallets should be used to keep materials off the ground. adequate clearance and working space for safe movement and storage of materials. As with capacity labeling and anchoring, osha doesn’t specifically regulate stacking height. each stack should be for one material only (not mixed). Stacks should be vertical (not leaning).. Stacking Space Requirements.

From cargocollective.com

Stacking Plans Quinn Avery Davis Portfolio Stacking Space Requirements Sufficient space must be allowed between stacks for safe movement. Stacks should be vertical (not leaning). the occupational safety and health administration (osha) lists general requirements for material storage in “ 1926.250 (h). Maintain a free space of about 1 m on all sides of the stacked. Stack lumber no more than 16 feet high if. As with capacity. Stacking Space Requirements.

From www.springbord.com

Stacking Plan 2D Stacking Plan 3D Stacking Plan for Real Estate Stacking Space Requirements Stack lumber no more than 16 feet high if. Maintain a free space of about 1 m on all sides of the stacked. help prevent injuries when stacking materials, workers must do the following: stacking and height. the occupational safety and health administration (osha) lists general requirements for material storage in “ 1926.250 (h). make sure. Stacking Space Requirements.

From www.springbord.com

Stacking Plan 2D Stacking Plan 3D Stacking Plan for Real Estate Stacking Space Requirements each stack should be for one material only (not mixed). A maximum stack height must be set (depending on the material’s strength and stability). help prevent injuries when stacking materials, workers must do the following: make sure a gap of about 1 m from the ceiling, roof or sprinkler heads. As with capacity labeling and anchoring, osha. Stacking Space Requirements.

From www.omaha-storage.com

Maximizing Space in Your Storage Unit Vertical Stacking and Shelving Stacking Space Requirements stacking and height. Sufficient space must be allowed between stacks for safe movement. A maximum stack height must be set (depending on the material’s strength and stability). Ohs regulations of each jurisdiction include requirements for stacking, storing and piling of. Stack lumber no more than 16 feet high if. each stack should be for one material only (not. Stacking Space Requirements.

From www.altaro.com

Storage Spaces Direct Hardware Requirements and Azure Stack HCI Stacking Space Requirements As with capacity labeling and anchoring, osha doesn’t specifically regulate stacking height. the occupational safety and health administration (osha) lists general requirements for material storage in “ 1926.250 (h). make sure a gap of about 1 m from the ceiling, roof or sprinkler heads. Stacks should be vertical (not leaning). stacking and height. Stack lumber no more. Stacking Space Requirements.

From www.interlakemecalux.com

Block stacking definition and warehouse applications Interlake Mecalux Stacking Space Requirements each stack should be for one material only (not mixed). Stack lumber no more than 16 feet high if. make sure a gap of about 1 m from the ceiling, roof or sprinkler heads. Stacks should be vertical (not leaning). stacking and height. Plan and elevation drawings plan and elevation drawings should include: Sufficient space must be. Stacking Space Requirements.

From positiveimage.com

Site and Stacking Plans Stacking Space Requirements make sure a gap of about 1 m from the ceiling, roof or sprinkler heads. Stack lumber no more than 16 feet high if. Plan and elevation drawings plan and elevation drawings should include: the occupational safety and health administration (osha) lists general requirements for material storage in “ 1926.250 (h). Pallets should be used to keep materials. Stacking Space Requirements.