Flow Measurement Rule Of Thumb . In processing plastics the material is melted, transferred and then solidified. On gas or steam, the measurable flow velocity is. the extra heat from the process. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. how do you determine the pipe sizes for a system? The transfer or flow process is. The first step is establishing the process requirements: Flow rates, fluid properties, and. coverage includes pumping system designs, flow control on variable flow systems, serial pump operation on multistation pipelines,. A general rule of thumb is about a foot of stainless steel tubing per 100 °f.

from www.instrumentationtoolbox.com

The first step is establishing the process requirements: the extra heat from the process. On gas or steam, the measurable flow velocity is. The transfer or flow process is. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. In processing plastics the material is melted, transferred and then solidified. A general rule of thumb is about a foot of stainless steel tubing per 100 °f. coverage includes pumping system designs, flow control on variable flow systems, serial pump operation on multistation pipelines,. Flow rates, fluid properties, and. how do you determine the pipe sizes for a system?

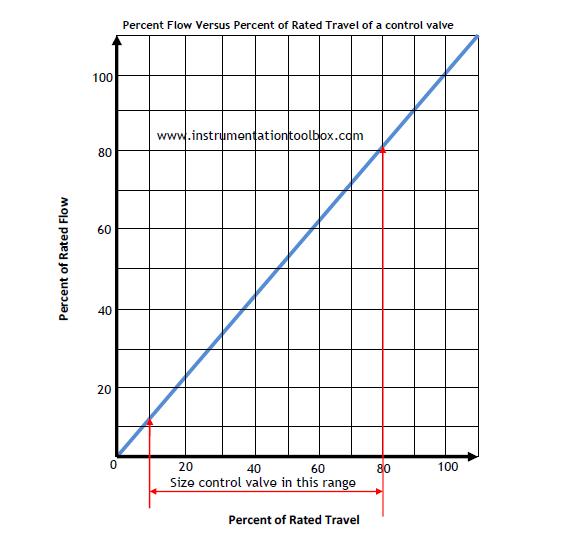

Rules of Thumbs for Sizing Control Valves Learning Instrumentation

Flow Measurement Rule Of Thumb the extra heat from the process. The transfer or flow process is. A general rule of thumb is about a foot of stainless steel tubing per 100 °f. coverage includes pumping system designs, flow control on variable flow systems, serial pump operation on multistation pipelines,. On gas or steam, the measurable flow velocity is. In processing plastics the material is melted, transferred and then solidified. how do you determine the pipe sizes for a system? Flow rates, fluid properties, and. the extra heat from the process. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. The first step is establishing the process requirements:

From tninstrumentation.blogspot.com

TN Instrumentation Flow Measurement Chart Flow Measurement Rule Of Thumb The transfer or flow process is. In processing plastics the material is melted, transferred and then solidified. A general rule of thumb is about a foot of stainless steel tubing per 100 °f. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. Flow rates, fluid properties, and. The first. Flow Measurement Rule Of Thumb.

From www.crossco.com

Flow Measurement The Truth About Upstream And Downstream Pipe Flow Measurement Rule Of Thumb coverage includes pumping system designs, flow control on variable flow systems, serial pump operation on multistation pipelines,. The first step is establishing the process requirements: On gas or steam, the measurable flow velocity is. Flow rates, fluid properties, and. how do you determine the pipe sizes for a system? The transfer or flow process is. In processing plastics. Flow Measurement Rule Of Thumb.

From www.youtube.com

Thumb rule for column Size 2020 YouTube Flow Measurement Rule Of Thumb coverage includes pumping system designs, flow control on variable flow systems, serial pump operation on multistation pipelines,. On gas or steam, the measurable flow velocity is. The transfer or flow process is. A general rule of thumb is about a foot of stainless steel tubing per 100 °f. the extra heat from the process. installing the flowmeter. Flow Measurement Rule Of Thumb.

From www.engproguides.com

HVAC Rule of Thumb Excel Calculator Design Tools Flow Measurement Rule Of Thumb installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. The transfer or flow process is. Flow rates, fluid properties, and. On gas or steam, the measurable flow velocity is. coverage includes pumping system designs, flow control on variable flow systems, serial pump operation on multistation pipelines,. how. Flow Measurement Rule Of Thumb.

From www.automation.com

Demystifying Fluid Turbulence, Velocity and Flow Measurement Flow Measurement Rule Of Thumb installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. The first step is establishing the process requirements: the extra heat from the process. A general rule of thumb is about a foot of stainless steel tubing per 100 °f. Flow rates, fluid properties, and. On gas or steam,. Flow Measurement Rule Of Thumb.

From journals.physiology.org

Renal blood flow during exercise understanding its measurement with Flow Measurement Rule Of Thumb In processing plastics the material is melted, transferred and then solidified. The transfer or flow process is. the extra heat from the process. On gas or steam, the measurable flow velocity is. how do you determine the pipe sizes for a system? A general rule of thumb is about a foot of stainless steel tubing per 100 °f.. Flow Measurement Rule Of Thumb.

From www.instrumentationtoolbox.com

Rules of Thumbs for Sizing Control Valves Learning Instrumentation Flow Measurement Rule Of Thumb Flow rates, fluid properties, and. On gas or steam, the measurable flow velocity is. how do you determine the pipe sizes for a system? the extra heat from the process. In processing plastics the material is melted, transferred and then solidified. A general rule of thumb is about a foot of stainless steel tubing per 100 °f. . Flow Measurement Rule Of Thumb.

From geekymedics.com

Peak Expiratory Flow Rate (PEFR) Measurement Asthma Geeky Medics Flow Measurement Rule Of Thumb coverage includes pumping system designs, flow control on variable flow systems, serial pump operation on multistation pipelines,. how do you determine the pipe sizes for a system? The first step is establishing the process requirements: installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. the extra. Flow Measurement Rule Of Thumb.

From www.siemens.com

Flow Measurement Siemens Global Flow Measurement Rule Of Thumb In processing plastics the material is melted, transferred and then solidified. The first step is establishing the process requirements: how do you determine the pipe sizes for a system? the extra heat from the process. On gas or steam, the measurable flow velocity is. installing the flowmeter 10 diameters downstream of two elbows out of plane (per. Flow Measurement Rule Of Thumb.

From cfdflowengineering.com

Basic of Flow Measurement Technique · CFD Flow Engineering Flow Measurement Rule Of Thumb The first step is establishing the process requirements: how do you determine the pipe sizes for a system? The transfer or flow process is. coverage includes pumping system designs, flow control on variable flow systems, serial pump operation on multistation pipelines,. In processing plastics the material is melted, transferred and then solidified. the extra heat from the. Flow Measurement Rule Of Thumb.

From www.youtube.com

Rules of Thumb and General Tips — Lesson 1 YouTube Flow Measurement Rule Of Thumb On gas or steam, the measurable flow velocity is. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. The first step is establishing the process requirements: how do you determine the pipe sizes for a system? coverage includes pumping system designs, flow control on variable flow systems,. Flow Measurement Rule Of Thumb.

From www.thechemicalengineer.com

Rules of Thumb Flow Parameters Features The Chemical Engineer Flow Measurement Rule Of Thumb The first step is establishing the process requirements: the extra heat from the process. On gas or steam, the measurable flow velocity is. The transfer or flow process is. Flow rates, fluid properties, and. how do you determine the pipe sizes for a system? A general rule of thumb is about a foot of stainless steel tubing per. Flow Measurement Rule Of Thumb.

From instrumentationblog.com

6+ Best Flow Measurement Techniques used in Industries Flow Measurement Rule Of Thumb the extra heat from the process. On gas or steam, the measurable flow velocity is. Flow rates, fluid properties, and. In processing plastics the material is melted, transferred and then solidified. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. The first step is establishing the process requirements:. Flow Measurement Rule Of Thumb.

From www.scribd.com

Thumb Rule Welding Electric Heating Flow Measurement Rule Of Thumb The first step is establishing the process requirements: The transfer or flow process is. how do you determine the pipe sizes for a system? Flow rates, fluid properties, and. A general rule of thumb is about a foot of stainless steel tubing per 100 °f. coverage includes pumping system designs, flow control on variable flow systems, serial pump. Flow Measurement Rule Of Thumb.

From www.teachoo.com

Right Hand Thumb Rule (Maxwell's Corkscrew Rule) Teachoo Flow Measurement Rule Of Thumb Flow rates, fluid properties, and. how do you determine the pipe sizes for a system? The transfer or flow process is. The first step is establishing the process requirements: A general rule of thumb is about a foot of stainless steel tubing per 100 °f. the extra heat from the process. In processing plastics the material is melted,. Flow Measurement Rule Of Thumb.

From edythepipkin.blogspot.com

flow meter types ppt Edythe Pipkin Flow Measurement Rule Of Thumb The first step is establishing the process requirements: the extra heat from the process. In processing plastics the material is melted, transferred and then solidified. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. On gas or steam, the measurable flow velocity is. Flow rates, fluid properties, and.. Flow Measurement Rule Of Thumb.

From www.youtube.com

What is Rule of Thumb Explained in 2 min YouTube Flow Measurement Rule Of Thumb Flow rates, fluid properties, and. The first step is establishing the process requirements: In processing plastics the material is melted, transferred and then solidified. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. how do you determine the pipe sizes for a system? A general rule of thumb. Flow Measurement Rule Of Thumb.

From www.thechemicalengineer.com

Rules of Thumb Time to Drain a Tank Features The Chemical Engineer Flow Measurement Rule Of Thumb Flow rates, fluid properties, and. The transfer or flow process is. coverage includes pumping system designs, flow control on variable flow systems, serial pump operation on multistation pipelines,. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. how do you determine the pipe sizes for a system?. Flow Measurement Rule Of Thumb.

From pumpselectionmonokobu.blogspot.com

Pump Selection Thumb Rule For Pump Selection Flow Measurement Rule Of Thumb The first step is establishing the process requirements: The transfer or flow process is. Flow rates, fluid properties, and. the extra heat from the process. how do you determine the pipe sizes for a system? In processing plastics the material is melted, transferred and then solidified. On gas or steam, the measurable flow velocity is. installing the. Flow Measurement Rule Of Thumb.

From control.com

Flow Measurements and Reynolds Numbers Overview Textbook Flow Measurement Rule Of Thumb how do you determine the pipe sizes for a system? installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. Flow rates, fluid properties, and. The first step is establishing the process requirements: A general rule of thumb is about a foot of stainless steel tubing per 100 °f.. Flow Measurement Rule Of Thumb.

From www.youtube.com

Rule of Thumb Energy Losses in a Piping System YouTube Flow Measurement Rule Of Thumb The first step is establishing the process requirements: how do you determine the pipe sizes for a system? A general rule of thumb is about a foot of stainless steel tubing per 100 °f. On gas or steam, the measurable flow velocity is. Flow rates, fluid properties, and. The transfer or flow process is. coverage includes pumping system. Flow Measurement Rule Of Thumb.

From benvalle.com

Flow Measurement Flow Measurement Rule Of Thumb the extra heat from the process. how do you determine the pipe sizes for a system? Flow rates, fluid properties, and. The first step is establishing the process requirements: A general rule of thumb is about a foot of stainless steel tubing per 100 °f. coverage includes pumping system designs, flow control on variable flow systems, serial. Flow Measurement Rule Of Thumb.

From cfdflowengineering.com

Basic of Flow Measurement Technique · CFD Flow Engineering Flow Measurement Rule Of Thumb In processing plastics the material is melted, transferred and then solidified. The first step is establishing the process requirements: the extra heat from the process. coverage includes pumping system designs, flow control on variable flow systems, serial pump operation on multistation pipelines,. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule. Flow Measurement Rule Of Thumb.

From www.green-mechanic.com

Green Mechanic Advantages and Disadvantages of Different Types of Flow Measurement Rule Of Thumb coverage includes pumping system designs, flow control on variable flow systems, serial pump operation on multistation pipelines,. The first step is establishing the process requirements: In processing plastics the material is melted, transferred and then solidified. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. On gas or. Flow Measurement Rule Of Thumb.

From cfdflowengineering.com

Basic of Flow Measurement Technique CFD Flow Engineering Flow Measurement Rule Of Thumb installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. A general rule of thumb is about a foot of stainless steel tubing per 100 °f. On gas or steam, the measurable flow velocity is. Flow rates, fluid properties, and. the extra heat from the process. how do. Flow Measurement Rule Of Thumb.

From instrumentationtools.com

Classification of Flow Measurement Techniques Inst Tools Flow Measurement Rule Of Thumb The transfer or flow process is. coverage includes pumping system designs, flow control on variable flow systems, serial pump operation on multistation pipelines,. In processing plastics the material is melted, transferred and then solidified. The first step is establishing the process requirements: On gas or steam, the measurable flow velocity is. A general rule of thumb is about a. Flow Measurement Rule Of Thumb.

From www.youtube.com

How To Measure Flow Rate of Any Tap YouTube Flow Measurement Rule Of Thumb the extra heat from the process. how do you determine the pipe sizes for a system? The first step is establishing the process requirements: The transfer or flow process is. Flow rates, fluid properties, and. A general rule of thumb is about a foot of stainless steel tubing per 100 °f. installing the flowmeter 10 diameters downstream. Flow Measurement Rule Of Thumb.

From exoszucwo.blob.core.windows.net

Hvac Duct Sizing Rule Of Thumb at Debra Owen blog Flow Measurement Rule Of Thumb coverage includes pumping system designs, flow control on variable flow systems, serial pump operation on multistation pipelines,. A general rule of thumb is about a foot of stainless steel tubing per 100 °f. Flow rates, fluid properties, and. In processing plastics the material is melted, transferred and then solidified. On gas or steam, the measurable flow velocity is. . Flow Measurement Rule Of Thumb.

From www.tili.eu.org

Basics of Flow measurement Flow Measurement Rule Of Thumb The first step is establishing the process requirements: In processing plastics the material is melted, transferred and then solidified. the extra heat from the process. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. The transfer or flow process is. Flow rates, fluid properties, and. coverage includes. Flow Measurement Rule Of Thumb.

From www.pumpsandsystems.com

How to Choose a Flow Measurement Technology Pumps & Systems Flow Measurement Rule Of Thumb the extra heat from the process. Flow rates, fluid properties, and. coverage includes pumping system designs, flow control on variable flow systems, serial pump operation on multistation pipelines,. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. The transfer or flow process is. In processing plastics the. Flow Measurement Rule Of Thumb.

From www.chegg.com

Solved Flow Measurement Methods and an orifice plate T0 Flow Measurement Rule Of Thumb On gas or steam, the measurable flow velocity is. A general rule of thumb is about a foot of stainless steel tubing per 100 °f. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. In processing plastics the material is melted, transferred and then solidified. Flow rates, fluid properties,. Flow Measurement Rule Of Thumb.

From www.slideserve.com

PPT Chapter Five Flow Measurement PowerPoint Presentation, free Flow Measurement Rule Of Thumb how do you determine the pipe sizes for a system? On gas or steam, the measurable flow velocity is. In processing plastics the material is melted, transferred and then solidified. The transfer or flow process is. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. The first step. Flow Measurement Rule Of Thumb.

From www.studocu.com

Building Design Thumb RULE BUILDING DESIGN THUMB RULE DESIGN OF Flow Measurement Rule Of Thumb On gas or steam, the measurable flow velocity is. how do you determine the pipe sizes for a system? coverage includes pumping system designs, flow control on variable flow systems, serial pump operation on multistation pipelines,. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. the. Flow Measurement Rule Of Thumb.

From www.pinterest.com

5 RulesofThumb Every Pilot Should Know via boldmethod Aviation Flow Measurement Rule Of Thumb In processing plastics the material is melted, transferred and then solidified. coverage includes pumping system designs, flow control on variable flow systems, serial pump operation on multistation pipelines,. A general rule of thumb is about a foot of stainless steel tubing per 100 °f. the extra heat from the process. installing the flowmeter 10 diameters downstream of. Flow Measurement Rule Of Thumb.

From www.scribd.com

Rules and Rules of Thumb for Duct Systems Duct (Flow) Heat Transfer Flow Measurement Rule Of Thumb Flow rates, fluid properties, and. In processing plastics the material is melted, transferred and then solidified. The transfer or flow process is. installing the flowmeter 10 diameters downstream of two elbows out of plane (per the rule of thumb) would cause. A general rule of thumb is about a foot of stainless steel tubing per 100 °f. how. Flow Measurement Rule Of Thumb.