Aluminium Anodizing Reaction . Students observe how anodising aluminium makes the oxide layer on its surface thicker, improving the metal’s resistance to corrosion. The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. In the process, students learn how the. The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. As we know, the surface consists of the pores with pigments as. There are three different anodizing processes: Anodising gives the aluminium surface a superior appearance. Anodizing aluminum reinforces naturally occurring features while providing additional properties suitable for mass production. It also makes the surface of the component easy to dye and paint due to the porous nature of the oxide layer. Anodizing is an electrolytic surface treatment most commonly used with aluminium components.

from aluconsult.com

Students observe how anodising aluminium makes the oxide layer on its surface thicker, improving the metal’s resistance to corrosion. Anodizing is an electrolytic surface treatment most commonly used with aluminium components. The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. As we know, the surface consists of the pores with pigments as. Anodising gives the aluminium surface a superior appearance. Anodizing aluminum reinforces naturally occurring features while providing additional properties suitable for mass production. In the process, students learn how the. The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. There are three different anodizing processes: It also makes the surface of the component easy to dye and paint due to the porous nature of the oxide layer.

How to Anodize Aluminum Type II Anodizing for Beginners AluConsult

Aluminium Anodizing Reaction There are three different anodizing processes: In the process, students learn how the. Students observe how anodising aluminium makes the oxide layer on its surface thicker, improving the metal’s resistance to corrosion. Anodizing is an electrolytic surface treatment most commonly used with aluminium components. Anodising gives the aluminium surface a superior appearance. The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. It also makes the surface of the component easy to dye and paint due to the porous nature of the oxide layer. As we know, the surface consists of the pores with pigments as. Anodizing aluminum reinforces naturally occurring features while providing additional properties suitable for mass production. There are three different anodizing processes:

From www.slideserve.com

PPT ANODIZING PowerPoint Presentation, free download ID581030 Aluminium Anodizing Reaction Anodising gives the aluminium surface a superior appearance. Anodizing aluminum reinforces naturally occurring features while providing additional properties suitable for mass production. Students observe how anodising aluminium makes the oxide layer on its surface thicker, improving the metal’s resistance to corrosion. It also makes the surface of the component easy to dye and paint due to the porous nature of. Aluminium Anodizing Reaction.

From www.iqsdirectory.com

Anodized Aluminum Types, Uses, Features and Benefits Aluminium Anodizing Reaction Students observe how anodising aluminium makes the oxide layer on its surface thicker, improving the metal’s resistance to corrosion. The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. Anodizing is an electrolytic surface treatment most commonly used with aluminium components. As we know, the surface consists of the pores with pigments as. There are. Aluminium Anodizing Reaction.

From dxogyyoub.blob.core.windows.net

Aluminum Anodizing Chemical Reaction at Carol Conner blog Aluminium Anodizing Reaction The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. There are three different anodizing processes: Anodising gives the aluminium surface a superior appearance. In the process, students learn how the. Anodizing is an electrolytic surface treatment most commonly used with aluminium components. It also makes the surface of the component easy to dye and. Aluminium Anodizing Reaction.

From www.valencesurfacetech.com

Anodizing Vs. Plating Key Differences And Similarities Aluminium Anodizing Reaction There are three different anodizing processes: It also makes the surface of the component easy to dye and paint due to the porous nature of the oxide layer. Anodising gives the aluminium surface a superior appearance. The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. Anodizing aluminum reinforces naturally occurring. Aluminium Anodizing Reaction.

From www.iqsdirectory.com

Anodized Aluminum Types, Uses, Features and Benefits Aluminium Anodizing Reaction There are three different anodizing processes: In the process, students learn how the. As we know, the surface consists of the pores with pigments as. Anodizing aluminum reinforces naturally occurring features while providing additional properties suitable for mass production. The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. The oxygen. Aluminium Anodizing Reaction.

From dxogyyoub.blob.core.windows.net

Aluminum Anodizing Chemical Reaction at Carol Conner blog Aluminium Anodizing Reaction Anodizing is an electrolytic surface treatment most commonly used with aluminium components. Anodising gives the aluminium surface a superior appearance. The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. In the process, students learn how the. It also makes the surface of the component easy to dye and paint due to the porous nature. Aluminium Anodizing Reaction.

From www.youtube.com

Small Scale Aluminium Anodising in the Home YouTube Aluminium Anodizing Reaction Anodizing is an electrolytic surface treatment most commonly used with aluminium components. The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. There are three different anodizing processes: As we know, the surface consists of the pores with pigments as. Students observe how anodising aluminium makes the oxide layer on its. Aluminium Anodizing Reaction.

From www.mdpi.com

Coatings Free FullText The Sealing Step in Aluminum Anodizing A Aluminium Anodizing Reaction Anodizing aluminum reinforces naturally occurring features while providing additional properties suitable for mass production. Anodizing is an electrolytic surface treatment most commonly used with aluminium components. Students observe how anodising aluminium makes the oxide layer on its surface thicker, improving the metal’s resistance to corrosion. There are three different anodizing processes: In the process, students learn how the. It also. Aluminium Anodizing Reaction.

From albionalumni.org

Glossary A Aluminium Anodizing Reaction The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. Students observe how anodising aluminium makes the oxide layer on its surface thicker, improving the metal’s resistance to corrosion. It also makes the surface of the component easy to dye and paint due to the porous nature of the oxide layer. In the process, students. Aluminium Anodizing Reaction.

From www.pa-international.com.au

Anodizing of aluminium Tag Aluminium Anodizing Reaction It also makes the surface of the component easy to dye and paint due to the porous nature of the oxide layer. The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. Anodizing is an electrolytic surface treatment most commonly used with aluminium components. Anodising gives the aluminium surface a superior. Aluminium Anodizing Reaction.

From achs-prod.acs.org

Anodic Aluminum Oxide Template Assisted Synthesis of Copper Nanowires Aluminium Anodizing Reaction Anodizing is an electrolytic surface treatment most commonly used with aluminium components. The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. There are three different anodizing processes: In the process, students learn how the. Anodising gives the aluminium surface a superior appearance. As we know, the surface consists of the. Aluminium Anodizing Reaction.

From www.researchgate.net

Types of anodic aluminum oxide and corresponding currenttime Aluminium Anodizing Reaction There are three different anodizing processes: The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. As we know, the surface consists of the pores with pigments as. It also makes the surface of the component easy to dye and paint due to the porous nature of the oxide layer. In. Aluminium Anodizing Reaction.

From www.researchgate.net

(a) Initial aluminum with a thin naturally formed oxide film. (b), (c Aluminium Anodizing Reaction There are three different anodizing processes: The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. Anodizing aluminum reinforces naturally occurring features while providing additional properties suitable for mass production. In the process, students learn how. Aluminium Anodizing Reaction.

From dxogyyoub.blob.core.windows.net

Aluminum Anodizing Chemical Reaction at Carol Conner blog Aluminium Anodizing Reaction Students observe how anodising aluminium makes the oxide layer on its surface thicker, improving the metal’s resistance to corrosion. There are three different anodizing processes: The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. As we know, the surface consists of the pores with pigments as. Anodizing is an electrolytic surface treatment most commonly. Aluminium Anodizing Reaction.

From www.mdpi.com

Coatings Free FullText A Review on Anodizing of Aerospace Aluminum Aluminium Anodizing Reaction Students observe how anodising aluminium makes the oxide layer on its surface thicker, improving the metal’s resistance to corrosion. The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. Anodising gives the aluminium surface a superior appearance. There are three different anodizing processes: It also makes the surface of the component. Aluminium Anodizing Reaction.

From www.numerade.com

SOLVEDSeveral reactions of aluminum are shown in the common reactions Aluminium Anodizing Reaction The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. Students observe how anodising aluminium makes the oxide layer on its surface thicker, improving the metal’s resistance to corrosion. Anodizing is an electrolytic surface treatment most commonly used with aluminium components. As we know, the surface consists of the pores with pigments as. Anodizing aluminum. Aluminium Anodizing Reaction.

From aluconsult.com

How to Anodize Aluminum Type II Anodizing for Beginners AluConsult Aluminium Anodizing Reaction In the process, students learn how the. The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. Students observe how anodising aluminium makes the oxide layer on its surface thicker, improving the metal’s resistance to corrosion. As we know, the surface consists of the pores with pigments as. Anodising gives the aluminium surface a superior. Aluminium Anodizing Reaction.

From www.madearia.com

The Basic Guide of Aluminum Anodizing Aria Manufacturing Limited Aluminium Anodizing Reaction Anodising gives the aluminium surface a superior appearance. The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. Anodizing aluminum reinforces naturally occurring features while providing additional properties suitable for mass production. There are three different anodizing processes: In the process, students learn how the. It also makes the surface of. Aluminium Anodizing Reaction.

From www.theengineeringprojects.com

Everything You Need To Know About Anodizing Aluminum Colors The Aluminium Anodizing Reaction Anodising gives the aluminium surface a superior appearance. Students observe how anodising aluminium makes the oxide layer on its surface thicker, improving the metal’s resistance to corrosion. The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. It also makes the surface of the component easy to dye and paint due. Aluminium Anodizing Reaction.

From www.slideserve.com

PPT ANODIZING PowerPoint Presentation, free download ID6742882 Aluminium Anodizing Reaction The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. Anodizing aluminum reinforces naturally occurring features while providing additional properties suitable for mass production. There are three different anodizing processes: Anodizing is an electrolytic surface treatment most commonly used with aluminium components. Students observe how anodising aluminium makes the oxide layer. Aluminium Anodizing Reaction.

From www.mdpi.com

Coatings Free FullText A Review on Anodizing of Aerospace Aluminum Aluminium Anodizing Reaction There are three different anodizing processes: As we know, the surface consists of the pores with pigments as. Anodising gives the aluminium surface a superior appearance. Anodizing aluminum reinforces naturally occurring features while providing additional properties suitable for mass production. Anodizing is an electrolytic surface treatment most commonly used with aluminium components. The oxygen anions react with aluminum cations to. Aluminium Anodizing Reaction.

From www.researchgate.net

Scheme of the reactions on anodized aluminum alloys in the Ni 2 /H 2 PO Aluminium Anodizing Reaction Anodizing aluminum reinforces naturally occurring features while providing additional properties suitable for mass production. There are three different anodizing processes: The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. Anodizing is an electrolytic surface treatment most commonly used with aluminium components. Students observe how anodising aluminium makes the oxide layer. Aluminium Anodizing Reaction.

From www.museoinclusivo.com

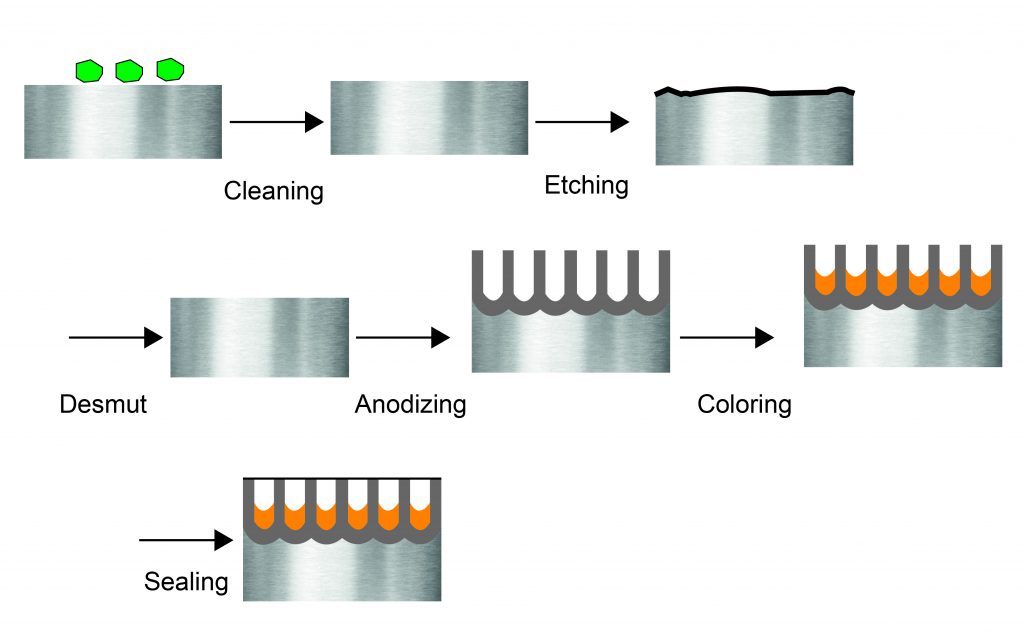

How to Anodize Aluminum A StepbyStep Guide Aluminum Profile Blog Aluminium Anodizing Reaction As we know, the surface consists of the pores with pigments as. There are three different anodizing processes: Anodising gives the aluminium surface a superior appearance. Anodizing is an electrolytic surface treatment most commonly used with aluminium components. In the process, students learn how the. The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics. Aluminium Anodizing Reaction.

From anodizing.eu

StepbyStep Process of Anodizing Aluminum Aluminium Anodizing Reaction The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. As we know, the surface consists of the pores with pigments as. In the process, students learn how the. Anodising gives the aluminium surface a superior. Aluminium Anodizing Reaction.

From www.iqsdirectory.com

Anodized Aluminum Types, Uses, Features and Benefits Aluminium Anodizing Reaction There are three different anodizing processes: Anodising gives the aluminium surface a superior appearance. The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. As we know, the surface consists of the pores with pigments as.. Aluminium Anodizing Reaction.

From www.museoinclusivo.com

How to Anodize Aluminum A StepbyStep Guide Aluminum Profile Blog Aluminium Anodizing Reaction There are three different anodizing processes: Anodizing is an electrolytic surface treatment most commonly used with aluminium components. The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. As we know, the surface consists of the pores with pigments as. Students observe how anodising aluminium makes the oxide layer on its. Aluminium Anodizing Reaction.

From recipepes.com

aluminum anodizing process basics Aluminium Anodizing Reaction Students observe how anodising aluminium makes the oxide layer on its surface thicker, improving the metal’s resistance to corrosion. The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. Anodizing is an electrolytic surface treatment most commonly used with aluminium components. The technique can help prepare parts for manufacturing and distribution, plus it can improve. Aluminium Anodizing Reaction.

From www.youtube.com

DSE07 (19) Anodization of aluminium YouTube Aluminium Anodizing Reaction As we know, the surface consists of the pores with pigments as. Anodizing is an electrolytic surface treatment most commonly used with aluminium components. Anodizing aluminum reinforces naturally occurring features while providing additional properties suitable for mass production. There are three different anodizing processes: Anodising gives the aluminium surface a superior appearance. The technique can help prepare parts for manufacturing. Aluminium Anodizing Reaction.

From dxogyyoub.blob.core.windows.net

Aluminum Anodizing Chemical Reaction at Carol Conner blog Aluminium Anodizing Reaction The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. There are three different anodizing processes: The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. Anodizing is an electrolytic surface treatment most commonly used with aluminium components. Anodizing aluminum reinforces naturally occurring features while providing. Aluminium Anodizing Reaction.

From fractory.com

Aluminium Anodising Process & Benefits Explained Fractory Aluminium Anodizing Reaction In the process, students learn how the. As we know, the surface consists of the pores with pigments as. It also makes the surface of the component easy to dye and paint due to the porous nature of the oxide layer. Anodizing aluminum reinforces naturally occurring features while providing additional properties suitable for mass production. There are three different anodizing. Aluminium Anodizing Reaction.

From www.researchgate.net

Scheme of the reactions on anodized aluminum alloys in the Ni 2 /H 2 PO Aluminium Anodizing Reaction As we know, the surface consists of the pores with pigments as. It also makes the surface of the component easy to dye and paint due to the porous nature of the oxide layer. Anodizing is an electrolytic surface treatment most commonly used with aluminium components. The technique can help prepare parts for manufacturing and distribution, plus it can improve. Aluminium Anodizing Reaction.

From www.researchgate.net

Schematic diagram showing the electrochemical reactions and ionic paths Aluminium Anodizing Reaction The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. Anodising gives the aluminium surface a superior appearance. Students observe how anodising aluminium makes the oxide layer on its surface thicker, improving the metal’s resistance to corrosion. It also makes the surface of the component easy to dye and paint due to the porous nature. Aluminium Anodizing Reaction.

From onlinelibrary.wiley.com

Anodizing AlSi Foundry Alloys A Critical Review Scampone 2022 Aluminium Anodizing Reaction Anodizing is an electrolytic surface treatment most commonly used with aluminium components. In the process, students learn how the. The technique can help prepare parts for manufacturing and distribution, plus it can improve aesthetics and reduce machining times. Anodising gives the aluminium surface a superior appearance. As we know, the surface consists of the pores with pigments as. Students observe. Aluminium Anodizing Reaction.

From finishingandcoating.com

Deoxidizing Aluminum and its Effectiveness as a PreTreatment for Aluminium Anodizing Reaction There are three different anodizing processes: As we know, the surface consists of the pores with pigments as. The oxygen anions react with aluminum cations to create a strongly adherent aluminum oxide layer. Anodizing aluminum reinforces naturally occurring features while providing additional properties suitable for mass production. Students observe how anodising aluminium makes the oxide layer on its surface thicker,. Aluminium Anodizing Reaction.