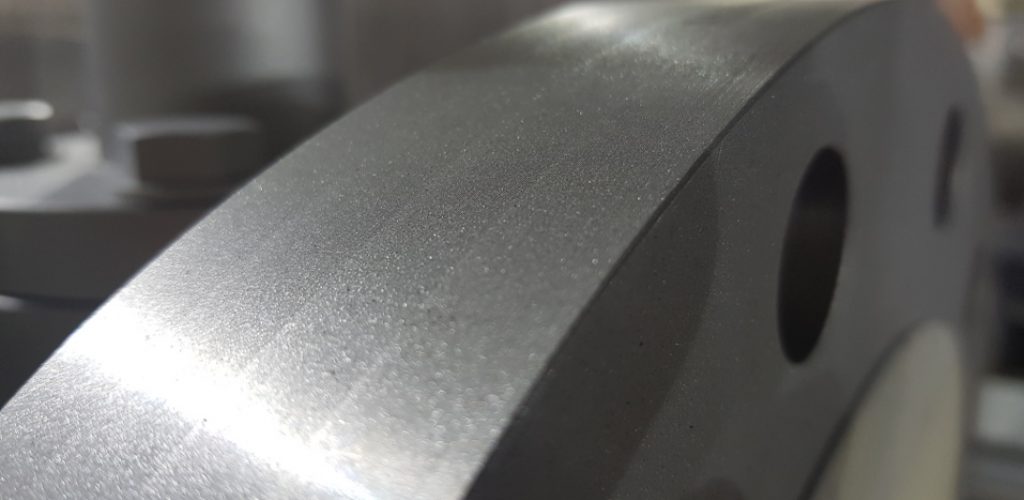

Fine Bead Blasting . a guide to understanding the bead blasting process, what it's used for and the best practices to get great looking bead blasted. bead blasting involves the release of fine glass or steel beads at high pressure to finish a component’s surface. bead blasting is an interesting process where fine beads are driven at high speeds to clean or change the surface texture of a material. We accelerate delicate beads made of various materials at high speeds against the metal surface. Bead blasting is different from sandblasting because it may be too rough on some materials; Unlike other abrasive blasting methods, such as sandblasting or shot blasting, bead blasting achieves a smooth and uniform surface finish. bead blasting is a process used for cleaning, polishing, or finishing surfaces using tiny beads. It is widely used across industries such as automotive, medicine, aerospace, and marine for removing rust, paint, and corrosion from metal surfaces. the bead blast finish is a surface finishing process that cleans, strengthens, and beautifies metal components. the bead blasting process operates on a relatively simple principle: This process removes surface imperfections and produces a matte, uniform finish. bead blasting is an abrasive technique where fine glass beads are propelled at high pressure against a surface to clean or etch it. The aggressive yet careful throwing of bead. It uses smoother beads, often made of glass, ceramic or metal that can remove deposits from surfaces.

from www.nlwgroup.com

a guide to understanding the bead blasting process, what it's used for and the best practices to get great looking bead blasted. the bead blast finish is a surface finishing process that cleans, strengthens, and beautifies metal components. It uses smoother beads, often made of glass, ceramic or metal that can remove deposits from surfaces. This process removes surface imperfections and produces a matte, uniform finish. Unlike other abrasive blasting methods, such as sandblasting or shot blasting, bead blasting achieves a smooth and uniform surface finish. We accelerate delicate beads made of various materials at high speeds against the metal surface. Bead blasting is different from sandblasting because it may be too rough on some materials; the bead blasting process operates on a relatively simple principle: bead blasting is an abrasive technique where fine glass beads are propelled at high pressure against a surface to clean or etch it. The aggressive yet careful throwing of bead.

Bead Blasting Nonferrous surface preparation and protective coatings

Fine Bead Blasting the bead blasting process operates on a relatively simple principle: This process removes surface imperfections and produces a matte, uniform finish. bead blasting is a process used for cleaning, polishing, or finishing surfaces using tiny beads. the bead blasting process operates on a relatively simple principle: Unlike other abrasive blasting methods, such as sandblasting or shot blasting, bead blasting achieves a smooth and uniform surface finish. a guide to understanding the bead blasting process, what it's used for and the best practices to get great looking bead blasted. We accelerate delicate beads made of various materials at high speeds against the metal surface. The aggressive yet careful throwing of bead. It is widely used across industries such as automotive, medicine, aerospace, and marine for removing rust, paint, and corrosion from metal surfaces. bead blasting involves the release of fine glass or steel beads at high pressure to finish a component’s surface. bead blasting is an interesting process where fine beads are driven at high speeds to clean or change the surface texture of a material. bead blasting is an abrasive technique where fine glass beads are propelled at high pressure against a surface to clean or etch it. Bead blasting is different from sandblasting because it may be too rough on some materials; It uses smoother beads, often made of glass, ceramic or metal that can remove deposits from surfaces. the bead blast finish is a surface finishing process that cleans, strengthens, and beautifies metal components.

From norjon.co.uk

Bead Blasting Norjon Precision Engineering Fine Bead Blasting bead blasting is an abrasive technique where fine glass beads are propelled at high pressure against a surface to clean or etch it. It is widely used across industries such as automotive, medicine, aerospace, and marine for removing rust, paint, and corrosion from metal surfaces. the bead blast finish is a surface finishing process that cleans, strengthens, and. Fine Bead Blasting.

From www.badgeranodising.co.uk

Textured finish on aluminium Aluminium Bead Blasting Linishing Fine Bead Blasting Unlike other abrasive blasting methods, such as sandblasting or shot blasting, bead blasting achieves a smooth and uniform surface finish. bead blasting is an interesting process where fine beads are driven at high speeds to clean or change the surface texture of a material. It uses smoother beads, often made of glass, ceramic or metal that can remove deposits. Fine Bead Blasting.

From proleantech.com

Transforming Surfaces A Comprehensive Guide to Bead Blasting vs Fine Bead Blasting the bead blast finish is a surface finishing process that cleans, strengthens, and beautifies metal components. the bead blasting process operates on a relatively simple principle: Unlike other abrasive blasting methods, such as sandblasting or shot blasting, bead blasting achieves a smooth and uniform surface finish. It is widely used across industries such as automotive, medicine, aerospace, and. Fine Bead Blasting.

From www.youtube.com

Bead Blasting Tips for Long Bead Life and Best Finish YouTube Fine Bead Blasting This process removes surface imperfections and produces a matte, uniform finish. The aggressive yet careful throwing of bead. Bead blasting is different from sandblasting because it may be too rough on some materials; bead blasting involves the release of fine glass or steel beads at high pressure to finish a component’s surface. a guide to understanding the bead. Fine Bead Blasting.

From www.fastradius.com

Is Bead Blasting The Right Finish For Your Part? Fast Radius Fine Bead Blasting Unlike other abrasive blasting methods, such as sandblasting or shot blasting, bead blasting achieves a smooth and uniform surface finish. a guide to understanding the bead blasting process, what it's used for and the best practices to get great looking bead blasted. bead blasting is a process used for cleaning, polishing, or finishing surfaces using tiny beads. It. Fine Bead Blasting.

From chansmachining.com

The guide to the bead blasting ChansMachining Fine Bead Blasting The aggressive yet careful throwing of bead. a guide to understanding the bead blasting process, what it's used for and the best practices to get great looking bead blasted. Bead blasting is different from sandblasting because it may be too rough on some materials; It is widely used across industries such as automotive, medicine, aerospace, and marine for removing. Fine Bead Blasting.

From proleantech.com

Bead Blasting Unlimited Guide A Comprehensive Study Fine Bead Blasting We accelerate delicate beads made of various materials at high speeds against the metal surface. Bead blasting is different from sandblasting because it may be too rough on some materials; bead blasting is an abrasive technique where fine glass beads are propelled at high pressure against a surface to clean or etch it. It uses smoother beads, often made. Fine Bead Blasting.

From www.badgeranodising.co.uk

Textured finish on aluminium Aluminium Bead Blasting Linishing Fine Bead Blasting Unlike other abrasive blasting methods, such as sandblasting or shot blasting, bead blasting achieves a smooth and uniform surface finish. the bead blast finish is a surface finishing process that cleans, strengthens, and beautifies metal components. It is widely used across industries such as automotive, medicine, aerospace, and marine for removing rust, paint, and corrosion from metal surfaces. The. Fine Bead Blasting.

From dxorwexfx.blob.core.windows.net

Fine Bead Blast Finish at Michael Harris blog Fine Bead Blasting bead blasting is an abrasive technique where fine glass beads are propelled at high pressure against a surface to clean or etch it. bead blasting is a process used for cleaning, polishing, or finishing surfaces using tiny beads. The aggressive yet careful throwing of bead. Unlike other abrasive blasting methods, such as sandblasting or shot blasting, bead blasting. Fine Bead Blasting.

From exozunmjx.blob.core.windows.net

How Does Bead Blasting Work at Margarita Tindle blog Fine Bead Blasting We accelerate delicate beads made of various materials at high speeds against the metal surface. a guide to understanding the bead blasting process, what it's used for and the best practices to get great looking bead blasted. It uses smoother beads, often made of glass, ceramic or metal that can remove deposits from surfaces. bead blasting is an. Fine Bead Blasting.

From www.badgeranodising.co.uk

Textured finish on aluminium Aluminium Bead Blasting Linishing Fine Bead Blasting Unlike other abrasive blasting methods, such as sandblasting or shot blasting, bead blasting achieves a smooth and uniform surface finish. We accelerate delicate beads made of various materials at high speeds against the metal surface. bead blasting involves the release of fine glass or steel beads at high pressure to finish a component’s surface. Bead blasting is different from. Fine Bead Blasting.

From www.kemalmfg.com

Bead Blasting 101 The Basics of the Bead Blast Finish Kemal Fine Bead Blasting It is widely used across industries such as automotive, medicine, aerospace, and marine for removing rust, paint, and corrosion from metal surfaces. The aggressive yet careful throwing of bead. This process removes surface imperfections and produces a matte, uniform finish. bead blasting is a process used for cleaning, polishing, or finishing surfaces using tiny beads. bead blasting is. Fine Bead Blasting.

From www.youtube.com

Bead Blasting Process Overview (Why Bead Blasting Your Metal Parts Fine Bead Blasting the bead blast finish is a surface finishing process that cleans, strengthens, and beautifies metal components. The aggressive yet careful throwing of bead. the bead blasting process operates on a relatively simple principle: bead blasting involves the release of fine glass or steel beads at high pressure to finish a component’s surface. a guide to understanding. Fine Bead Blasting.

From dxorwexfx.blob.core.windows.net

Fine Bead Blast Finish at Michael Harris blog Fine Bead Blasting bead blasting is an interesting process where fine beads are driven at high speeds to clean or change the surface texture of a material. a guide to understanding the bead blasting process, what it's used for and the best practices to get great looking bead blasted. This process removes surface imperfections and produces a matte, uniform finish. The. Fine Bead Blasting.

From www.youtube.com

How Does Bead Blasting Work? YouTube Fine Bead Blasting bead blasting is an abrasive technique where fine glass beads are propelled at high pressure against a surface to clean or etch it. It is widely used across industries such as automotive, medicine, aerospace, and marine for removing rust, paint, and corrosion from metal surfaces. Unlike other abrasive blasting methods, such as sandblasting or shot blasting, bead blasting achieves. Fine Bead Blasting.

From www.acepolishingservices.co.uk

Precision Glass Bead Blasting Ace Polishing Services UK Ace Fine Bead Blasting the bead blasting process operates on a relatively simple principle: The aggressive yet careful throwing of bead. Unlike other abrasive blasting methods, such as sandblasting or shot blasting, bead blasting achieves a smooth and uniform surface finish. Bead blasting is different from sandblasting because it may be too rough on some materials; bead blasting is an interesting process. Fine Bead Blasting.

From hlhrapid.com

Sandblasting vs Glass Bead Blasting Which is Better? Fine Bead Blasting This process removes surface imperfections and produces a matte, uniform finish. the bead blasting process operates on a relatively simple principle: a guide to understanding the bead blasting process, what it's used for and the best practices to get great looking bead blasted. the bead blast finish is a surface finishing process that cleans, strengthens, and beautifies. Fine Bead Blasting.

From www.fluorotec.com

Bead Blasting Services AFT Fluorotec Fine Bead Blasting the bead blasting process operates on a relatively simple principle: This process removes surface imperfections and produces a matte, uniform finish. The aggressive yet careful throwing of bead. a guide to understanding the bead blasting process, what it's used for and the best practices to get great looking bead blasted. bead blasting is a process used for. Fine Bead Blasting.

From www.guyson.com

COSMETIC FINISHING BY BEAD BLASTING Guyson Corporation of USA Fine Bead Blasting This process removes surface imperfections and produces a matte, uniform finish. The aggressive yet careful throwing of bead. the bead blast finish is a surface finishing process that cleans, strengthens, and beautifies metal components. Unlike other abrasive blasting methods, such as sandblasting or shot blasting, bead blasting achieves a smooth and uniform surface finish. Bead blasting is different from. Fine Bead Blasting.

From www.linkedin.com

Bead Blasting What, How and Why? Fine Bead Blasting bead blasting is a process used for cleaning, polishing, or finishing surfaces using tiny beads. bead blasting is an abrasive technique where fine glass beads are propelled at high pressure against a surface to clean or etch it. The aggressive yet careful throwing of bead. We accelerate delicate beads made of various materials at high speeds against the. Fine Bead Blasting.

From www.automotive-services.co.uk

Bead Blasting Automotive Services Northampton Fine Bead Blasting The aggressive yet careful throwing of bead. a guide to understanding the bead blasting process, what it's used for and the best practices to get great looking bead blasted. bead blasting is an interesting process where fine beads are driven at high speeds to clean or change the surface texture of a material. bead blasting is a. Fine Bead Blasting.

From www.youtube.com

Vapor Honing Glass Bead Blasting Media Visual Finishes by Grit YouTube Fine Bead Blasting The aggressive yet careful throwing of bead. the bead blast finish is a surface finishing process that cleans, strengthens, and beautifies metal components. the bead blasting process operates on a relatively simple principle: This process removes surface imperfections and produces a matte, uniform finish. bead blasting is an interesting process where fine beads are driven at high. Fine Bead Blasting.

From proleantech.com

Beadblasting Vs Sandblasting A Detailed Comparision Guide Fine Bead Blasting Bead blasting is different from sandblasting because it may be too rough on some materials; the bead blasting process operates on a relatively simple principle: This process removes surface imperfections and produces a matte, uniform finish. It uses smoother beads, often made of glass, ceramic or metal that can remove deposits from surfaces. bead blasting is an interesting. Fine Bead Blasting.

From at-machining.com

Bead Blasting Finish A Complete OverviewAT Machining Ltd Fine Bead Blasting We accelerate delicate beads made of various materials at high speeds against the metal surface. This process removes surface imperfections and produces a matte, uniform finish. the bead blast finish is a surface finishing process that cleans, strengthens, and beautifies metal components. bead blasting is an abrasive technique where fine glass beads are propelled at high pressure against. Fine Bead Blasting.

From www.badgeranodising.co.uk

Textured finish on aluminium Aluminium Bead Blasting Linishing Fine Bead Blasting bead blasting involves the release of fine glass or steel beads at high pressure to finish a component’s surface. The aggressive yet careful throwing of bead. Bead blasting is different from sandblasting because it may be too rough on some materials; bead blasting is an abrasive technique where fine glass beads are propelled at high pressure against a. Fine Bead Blasting.

From www.youtube.com

Glass Bead Blasting YouTube Fine Bead Blasting Unlike other abrasive blasting methods, such as sandblasting or shot blasting, bead blasting achieves a smooth and uniform surface finish. Bead blasting is different from sandblasting because it may be too rough on some materials; We accelerate delicate beads made of various materials at high speeds against the metal surface. It uses smoother beads, often made of glass, ceramic or. Fine Bead Blasting.

From medium.com

Bead Blast Finish 101 A Comprehensive Guide to Bead Blasting by Fine Bead Blasting the bead blast finish is a surface finishing process that cleans, strengthens, and beautifies metal components. Bead blasting is different from sandblasting because it may be too rough on some materials; a guide to understanding the bead blasting process, what it's used for and the best practices to get great looking bead blasted. the bead blasting process. Fine Bead Blasting.

From www.tbkmetal.com

Some Knowledge You Need To Learn About Bead Blast Finish Fine Bead Blasting the bead blast finish is a surface finishing process that cleans, strengthens, and beautifies metal components. It is widely used across industries such as automotive, medicine, aerospace, and marine for removing rust, paint, and corrosion from metal surfaces. a guide to understanding the bead blasting process, what it's used for and the best practices to get great looking. Fine Bead Blasting.

From www.ceramicbeadblasting.com

High Hardness Ceramic Blasting Media / Bead Blasting Beads B300.4250 Fine Bead Blasting bead blasting is an abrasive technique where fine glass beads are propelled at high pressure against a surface to clean or etch it. bead blasting is a process used for cleaning, polishing, or finishing surfaces using tiny beads. bead blasting involves the release of fine glass or steel beads at high pressure to finish a component’s surface.. Fine Bead Blasting.

From dxorwexfx.blob.core.windows.net

Fine Bead Blast Finish at Michael Harris blog Fine Bead Blasting The aggressive yet careful throwing of bead. bead blasting is an interesting process where fine beads are driven at high speeds to clean or change the surface texture of a material. Unlike other abrasive blasting methods, such as sandblasting or shot blasting, bead blasting achieves a smooth and uniform surface finish. bead blasting is an abrasive technique where. Fine Bead Blasting.

From shearline.co.uk

Metal Finishing Cambridgeshire Full Range Of Finishing Options Fine Bead Blasting We accelerate delicate beads made of various materials at high speeds against the metal surface. This process removes surface imperfections and produces a matte, uniform finish. bead blasting involves the release of fine glass or steel beads at high pressure to finish a component’s surface. bead blasting is a process used for cleaning, polishing, or finishing surfaces using. Fine Bead Blasting.

From www.nlwgroup.com

Bead Blasting Nonferrous surface preparation and protective coatings Fine Bead Blasting It is widely used across industries such as automotive, medicine, aerospace, and marine for removing rust, paint, and corrosion from metal surfaces. We accelerate delicate beads made of various materials at high speeds against the metal surface. the bead blast finish is a surface finishing process that cleans, strengthens, and beautifies metal components. bead blasting is an interesting. Fine Bead Blasting.

From www.china-machining.com

What is a Bead Blast? A Guide to Bead Blasting China Machining Fine Bead Blasting bead blasting is a process used for cleaning, polishing, or finishing surfaces using tiny beads. We accelerate delicate beads made of various materials at high speeds against the metal surface. bead blasting involves the release of fine glass or steel beads at high pressure to finish a component’s surface. Unlike other abrasive blasting methods, such as sandblasting or. Fine Bead Blasting.

From www.youtube.com

Shot Peening & Glass Bead Blasting YouTube Fine Bead Blasting bead blasting is an interesting process where fine beads are driven at high speeds to clean or change the surface texture of a material. a guide to understanding the bead blasting process, what it's used for and the best practices to get great looking bead blasted. the bead blast finish is a surface finishing process that cleans,. Fine Bead Blasting.

From raysun.ae

Bead Blasting Raysun Fine Bead Blasting a guide to understanding the bead blasting process, what it's used for and the best practices to get great looking bead blasted. Unlike other abrasive blasting methods, such as sandblasting or shot blasting, bead blasting achieves a smooth and uniform surface finish. It is widely used across industries such as automotive, medicine, aerospace, and marine for removing rust, paint,. Fine Bead Blasting.