Composite Layup Hand Tools . Composite parts are formed in molds, also known as tools. Beckwith, fsampe sampe global technical director president,. The art of manual layup. The material type, shape and complexity depend upon the. Its a technique that has been tried and tested for. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. Tools can be made from virtually any material. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. From there it can be rolled out and left to cure, or vacuum bagged. Tooling 101 for composites manufacturing.

from www.loftingservices.co.uk

Tooling 101 for composites manufacturing. The art of manual layup. From there it can be rolled out and left to cure, or vacuum bagged. Composite parts are formed in molds, also known as tools. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. Its a technique that has been tried and tested for. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. The material type, shape and complexity depend upon the. Tools can be made from virtually any material. Beckwith, fsampe sampe global technical director president,.

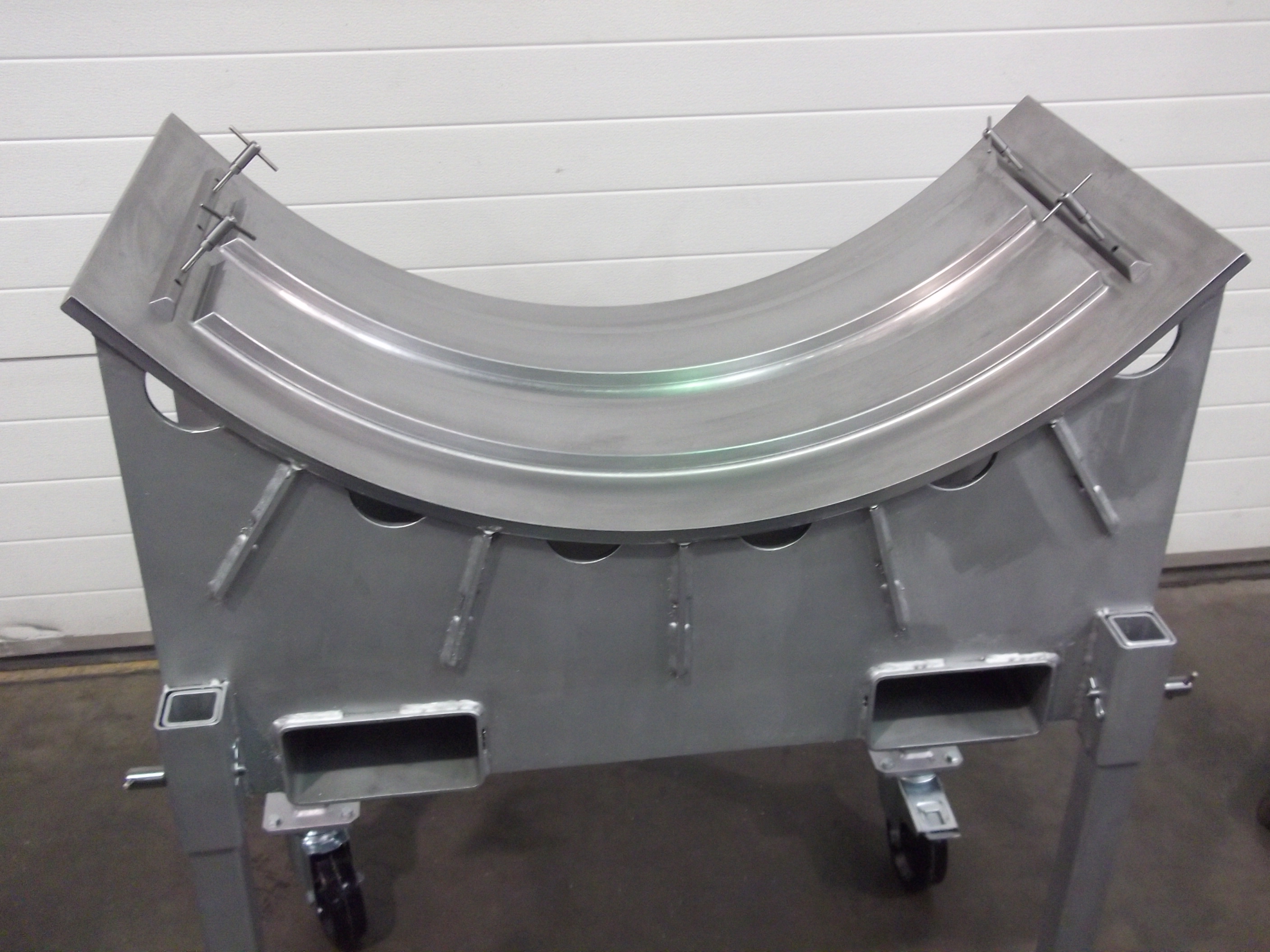

Steel Eggbox Type LayUp Tool Lofting Services

Composite Layup Hand Tools Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. Its a technique that has been tried and tested for. The material type, shape and complexity depend upon the. The art of manual layup. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. Beckwith, fsampe sampe global technical director president,. Composite parts are formed in molds, also known as tools. Tooling 101 for composites manufacturing. From there it can be rolled out and left to cure, or vacuum bagged.

From jloncomposite.en.made-in-china.com

FRP Tools Steel Fiberglass Roller for FRP Hand Lay up China Composite Layup Hand Tools From there it can be rolled out and left to cure, or vacuum bagged. Beckwith, fsampe sampe global technical director president,. The material type, shape and complexity depend upon the. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. Tools can be made from virtually any material. Its a technique that has. Composite Layup Hand Tools.

From www.youtube.com

how to layup a composite wing for a F18 1 YouTube Composite Layup Hand Tools Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. Composite parts are formed in molds, also known as tools. Beckwith, fsampe sampe global technical director president,. From there it can be rolled out and left to cure, or vacuum bagged. Tools can be made from virtually any material. Hand layup (or wet. Composite Layup Hand Tools.

From www.youtube.com

Automated prepreg composite layup onto a Fan blade Geometry YouTube Composite Layup Hand Tools From there it can be rolled out and left to cure, or vacuum bagged. Tooling 101 for composites manufacturing. The art of manual layup. Its a technique that has been tried and tested for. Tools can be made from virtually any material. The material type, shape and complexity depend upon the. Beckwith, fsampe sampe global technical director president,. Additional tools,. Composite Layup Hand Tools.

From catalysis3d.com

3D Printed Layup Tools For Composite Part Manufacturing Catalysis Composite Layup Hand Tools The material type, shape and complexity depend upon the. Tools can be made from virtually any material. Its a technique that has been tried and tested for. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and. Composite Layup Hand Tools.

From www.fassmer.de

Hand layup Method Fassmer Composite Layup Hand Tools Tools can be made from virtually any material. Tooling 101 for composites manufacturing. The art of manual layup. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. Its a technique that has been tried and tested for. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite. Composite Layup Hand Tools.

From explorecomposites.com

Favorite Composites Tools Explore Composites! Composite Layup Hand Tools Tooling 101 for composites manufacturing. The art of manual layup. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. Beckwith, fsampe sampe global technical director president,. The material type, shape and complexity depend upon the. From there it can be rolled out and left to cure, or vacuum bagged. Its a. Composite Layup Hand Tools.

From www.easycomposites.co.uk

XT135/S 250g 3k Tooling Prepreg Carbon 1.25m Easy Composites Composite Layup Hand Tools The art of manual layup. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. Tools can be made from virtually any material. Beckwith, fsampe sampe global technical director president,. The material type, shape and complexity depend upon the. From there it can be rolled out and left to cure, or vacuum bagged.. Composite Layup Hand Tools.

From www.dofrp.com

Composite layup process Composite Layup Hand Tools Tooling 101 for composites manufacturing. From there it can be rolled out and left to cure, or vacuum bagged. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. The art of manual layup. Tools can be made from virtually any material. Additional tools, such as molds, jigs, and mandrels, are used. Composite Layup Hand Tools.

From catalysis3d.com

3D Printed Layup Tools For Composite Part Manufacturing Catalysis Composite Layup Hand Tools The art of manual layup. From there it can be rolled out and left to cure, or vacuum bagged. Its a technique that has been tried and tested for. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. Additional tools, such as molds, jigs, and mandrels, are used to shape the. Composite Layup Hand Tools.

From www.addcomposites.com

What are the Fundamental Steps of Composites Manufacturing? Composite Layup Hand Tools Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. From there it can be rolled out and left to cure, or vacuum bagged. Tooling 101 for composites manufacturing. Composite parts are formed in molds, also known as tools. The material type, shape and complexity depend upon the. Its a technique that. Composite Layup Hand Tools.

From www.researchgate.net

Hand layup method employed for the preparation of composites Composite Layup Hand Tools Its a technique that has been tried and tested for. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. Tooling 101 for composites manufacturing. Tools can be made from virtually any material. From there. Composite Layup Hand Tools.

From www.tfcomposite.com

Hand Layup Resin Composite Layup Hand Tools Tools can be made from virtually any material. From there it can be rolled out and left to cure, or vacuum bagged. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. Its a technique that has been tried and tested for. Tooling 101 for composites manufacturing. Beckwith, fsampe sampe global technical. Composite Layup Hand Tools.

From www.loftingservices.co.uk

Steel Eggbox Type LayUp Tool Lofting Services Composite Layup Hand Tools Beckwith, fsampe sampe global technical director president,. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. Tools can be made from virtually any material. Composite parts are formed in molds, also known as tools. The art of manual layup. The material type, shape and complexity depend upon the. Its a technique that. Composite Layup Hand Tools.

From www.easycomposites.co.uk

Prepreg Laminating Dibber Tools Easy Composites Composite Layup Hand Tools Tools can be made from virtually any material. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. The art of manual layup. From there it can be rolled out and left to cure, or vacuum bagged. The material type, shape and complexity depend upon the. Its a technique that has been tried. Composite Layup Hand Tools.

From www.dofrp.com

Composite layup process Composite Layup Hand Tools The material type, shape and complexity depend upon the. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. Beckwith, fsampe sampe global technical director president,. Its a technique that has been tried and tested for. From there it can be rolled out and left to cure, or vacuum bagged. Tooling 101. Composite Layup Hand Tools.

From www.researchgate.net

Manufacturing techniques for NFRC. (a) Hand layup process, (b Composite Layup Hand Tools Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. From there it can be rolled out. Composite Layup Hand Tools.

From www.loftingservices.co.uk

Fabricated Steel Composite layUp Tool Lofting Services Composite Layup Hand Tools The material type, shape and complexity depend upon the. The art of manual layup. Beckwith, fsampe sampe global technical director president,. Its a technique that has been tried and tested for. Composite parts are formed in molds, also known as tools. From there it can be rolled out and left to cure, or vacuum bagged. Tools can be made from. Composite Layup Hand Tools.

From www.researchgate.net

3Shows typical depiction of hand layup process. Download Scientific Composite Layup Hand Tools The art of manual layup. Its a technique that has been tried and tested for. Tools can be made from virtually any material. Beckwith, fsampe sampe global technical director president,. From there it can be rolled out and left to cure, or vacuum bagged. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and. Composite Layup Hand Tools.

From www.researchgate.net

Fabrication of composites by hand layup method. Download Scientific Composite Layup Hand Tools Beckwith, fsampe sampe global technical director president,. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. The material type, shape and complexity depend upon the. Its a technique that has been tried and tested for. Tools can be made from virtually any material. Hand layup (or wet layup) is any process where. Composite Layup Hand Tools.

From www.nwaero.co.uk

Invar Layup Tools North West Aerotooling Composite Layup Hand Tools Beckwith, fsampe sampe global technical director president,. Its a technique that has been tried and tested for. The material type, shape and complexity depend upon the. The art of manual layup. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. From there it can be rolled out and left to cure,. Composite Layup Hand Tools.

From www.researchgate.net

Schematic diagram of Composite Hand Layup Method. Download Scientific Composite Layup Hand Tools The art of manual layup. From there it can be rolled out and left to cure, or vacuum bagged. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. Tools can be made from virtually any material. Tooling 101 for composites manufacturing. Composite parts are formed in molds, also known as tools.. Composite Layup Hand Tools.

From dq-daimu.en.made-in-china.com

High Density Tooling Board for Composite Layup Tools Pattern Making PU Composite Layup Hand Tools Its a technique that has been tried and tested for. Beckwith, fsampe sampe global technical director president,. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. From there it can be rolled out and left to cure, or vacuum bagged. Tooling 101 for composites manufacturing. Tools can be made from virtually any. Composite Layup Hand Tools.

From www.easycomposites.co.uk

How to Hand Laminate & Vacuum Bag a Simple Carbon Fibre Part Easy Composite Layup Hand Tools The material type, shape and complexity depend upon the. Its a technique that has been tried and tested for. From there it can be rolled out and left to cure, or vacuum bagged. Tools can be made from virtually any material. The art of manual layup. Beckwith, fsampe sampe global technical director president,. Tooling 101 for composites manufacturing. Additional tools,. Composite Layup Hand Tools.

From www.youtube.com

Processing of polymer composite Hand Lay Up Process YouTube Composite Layup Hand Tools Tools can be made from virtually any material. The art of manual layup. Its a technique that has been tried and tested for. Composite parts are formed in molds, also known as tools. Beckwith, fsampe sampe global technical director president,. From there it can be rolled out and left to cure, or vacuum bagged. Additional tools, such as molds, jigs,. Composite Layup Hand Tools.

From www.slideserve.com

PPT Composite Manufacturing Processes PowerPoint Presentation, free Composite Layup Hand Tools Tooling 101 for composites manufacturing. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. From there it can be rolled out and left to cure, or vacuum bagged. Tools can be made from virtually any material. Beckwith, fsampe sampe global technical director president,. Hand layup (or wet layup) is any process where. Composite Layup Hand Tools.

From www.easycomposites.eu

Complex Moulding Using Prepreg Carbon Fibre Video Tutorial Easy Composite Layup Hand Tools Tooling 101 for composites manufacturing. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. Tools can be made from virtually any material. From there it can be rolled out and left to cure, or vacuum bagged. Beckwith, fsampe sampe global technical director president,. The material type, shape and complexity depend upon the.. Composite Layup Hand Tools.

From jloncomposite.en.made-in-china.com

China FRP Tools Aluminum Head Fiberglass Bubble Bust Roller for FRP Composite Layup Hand Tools Composite parts are formed in molds, also known as tools. From there it can be rolled out and left to cure, or vacuum bagged. Tooling 101 for composites manufacturing. Beckwith, fsampe sampe global technical director president,. The material type, shape and complexity depend upon the. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as. Composite Layup Hand Tools.

From explorecomposites.com

Favorite Composites Tools Explore Composites! Composite Layup Hand Tools From there it can be rolled out and left to cure, or vacuum bagged. Beckwith, fsampe sampe global technical director president,. The material type, shape and complexity depend upon the. Tools can be made from virtually any material. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. Additional tools, such as. Composite Layup Hand Tools.

From www.compositestoday.com

Student Develops New Composite Laminating Tool Composite Layup Hand Tools The art of manual layup. Its a technique that has been tried and tested for. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. From there it can be rolled out and left to. Composite Layup Hand Tools.

From blog.bakerindustriesinc.com

Invar, Wire Additive Manufacturing Expand Tooling Options Composite Layup Hand Tools From there it can be rolled out and left to cure, or vacuum bagged. The material type, shape and complexity depend upon the. Tooling 101 for composites manufacturing. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. Composite parts are formed in molds, also known as tools. The art of manual. Composite Layup Hand Tools.

From explorecomposites.com

Favorite Composites Tools Explore Composites! Composite Layup Hand Tools Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. Tools can be made from virtually any material. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. Tooling 101 for composites manufacturing. The art of manual layup. Composite parts are formed in molds, also. Composite Layup Hand Tools.

From www.researchgate.net

TOOLING CONTROL CHECKLIST Download Table Composite Layup Hand Tools The art of manual layup. Beckwith, fsampe sampe global technical director president,. The material type, shape and complexity depend upon the. From there it can be rolled out and left to cure, or vacuum bagged. Its a technique that has been tried and tested for. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as. Composite Layup Hand Tools.

From www.resinlibrary.com

LayUp Methods For Fibreglass (GRP) Composites Resin Library Composite Layup Hand Tools Composite parts are formed in molds, also known as tools. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. Beckwith, fsampe sampe global technical director president,. Its a technique that has been tried and tested for. The art of manual layup. Additional tools, such as molds, jigs, and mandrels, are used. Composite Layup Hand Tools.

From www.swri.org

Robotic Prepreg Composite Layup Southwest Research Institute Composite Layup Hand Tools Tools can be made from virtually any material. Composite parts are formed in molds, also known as tools. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. The material type, shape and complexity depend upon the. Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as. Composite Layup Hand Tools.

From www.researchgate.net

The entire fabrication process of the composite (a and b) hand layup Composite Layup Hand Tools Additional tools, such as molds, jigs, and mandrels, are used to shape the composite as it cures. The art of manual layup. Tools can be made from virtually any material. Its a technique that has been tried and tested for. Hand layup (or wet layup) is any process where the laminator manually aplies the resin and the reinforcement. Composite parts. Composite Layup Hand Tools.