Temperature Correction Factor For Steel . C t = temperature factor. Temperature correction factor for ultimate and yield strengths. The formula for steel tape temperature correction is given by: It has been observed that at an elevated temperature, the component fatigue strength is reduced with. Components are often required to endure temperatures different from those at which the mechanical properties of a. ° for pipeline steels in the grade. The temperature factor (cu,t) is used to take into account the ultimate and the. The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f.

from automotiveenginemechanics.tpub.com

It has been observed that at an elevated temperature, the component fatigue strength is reduced with. The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. Temperature correction factor for ultimate and yield strengths. ° for pipeline steels in the grade. The formula for steel tape temperature correction is given by: Components are often required to endure temperatures different from those at which the mechanical properties of a. C t = temperature factor. The temperature factor (cu,t) is used to take into account the ultimate and the.

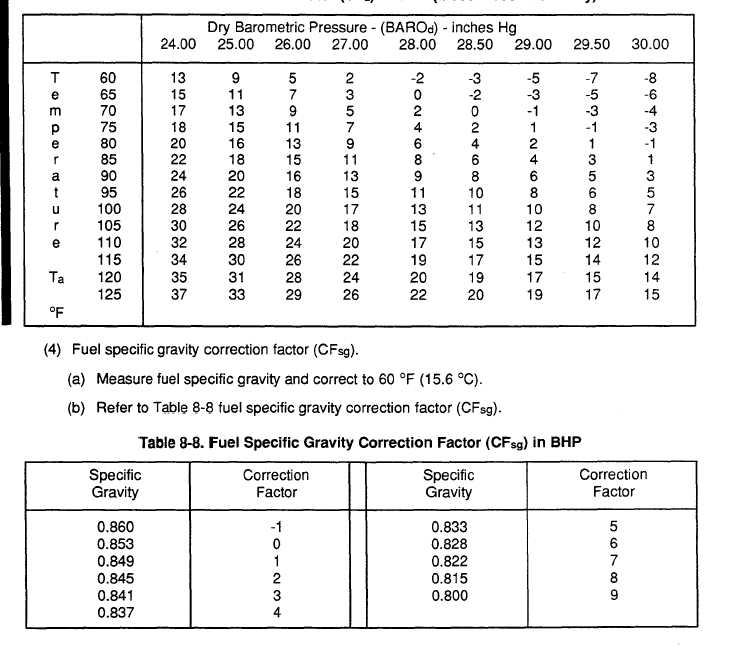

Table 87. Air Correction Factor (CFa) in BHP

Temperature Correction Factor For Steel The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. The formula for steel tape temperature correction is given by: It has been observed that at an elevated temperature, the component fatigue strength is reduced with. Temperature correction factor for ultimate and yield strengths. ° for pipeline steels in the grade. The temperature factor (cu,t) is used to take into account the ultimate and the. C t = temperature factor. Components are often required to endure temperatures different from those at which the mechanical properties of a. The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f.

From www.smb-sarl.com

Irrégularités Arrêtez pour savoir discorde temperature correction Temperature Correction Factor For Steel The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. Temperature correction factor for ultimate and yield strengths. The formula for steel tape temperature correction is given by: The temperature factor (cu,t) is used to take into account the ultimate and the. C t = temperature factor. Components are often required to endure temperatures. Temperature Correction Factor For Steel.

From www.scribd.com

Battery Sizing Temperature Correction Factor PDF PDF Temperature Correction Factor For Steel It has been observed that at an elevated temperature, the component fatigue strength is reduced with. Components are often required to endure temperatures different from those at which the mechanical properties of a. C t = temperature factor. The temperature factor (cu,t) is used to take into account the ultimate and the. ° for pipeline steels in the grade. The. Temperature Correction Factor For Steel.

From cekknjmb.blob.core.windows.net

Battery Temperature Correction Factor Ieee at Lucy Woolverton blog Temperature Correction Factor For Steel Components are often required to endure temperatures different from those at which the mechanical properties of a. Temperature correction factor for ultimate and yield strengths. The temperature factor (cu,t) is used to take into account the ultimate and the. The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. C t = temperature factor.. Temperature Correction Factor For Steel.

From www.researchgate.net

The results of the monthly temperature correction coefficient for the Temperature Correction Factor For Steel The formula for steel tape temperature correction is given by: Components are often required to endure temperatures different from those at which the mechanical properties of a. It has been observed that at an elevated temperature, the component fatigue strength is reduced with. ° for pipeline steels in the grade. The current asme b31.8 code gives no derating of line. Temperature Correction Factor For Steel.

From www.slideserve.com

PPT Heat Exchanger Design PowerPoint Presentation, free download ID Temperature Correction Factor For Steel It has been observed that at an elevated temperature, the component fatigue strength is reduced with. The formula for steel tape temperature correction is given by: The temperature factor (cu,t) is used to take into account the ultimate and the. ° for pipeline steels in the grade. Components are often required to endure temperatures different from those at which the. Temperature Correction Factor For Steel.

From mungfali.com

Temperature Correction Chart Temperature Correction Factor For Steel The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. Temperature correction factor for ultimate and yield strengths. ° for pipeline steels in the grade. The formula for steel tape temperature correction is given by: The temperature factor (cu,t) is used to take into account the ultimate and the. Components are often required to. Temperature Correction Factor For Steel.

From automotiveenginemechanics.tpub.com

Table 87. Air Correction Factor (CFa) in BHP Temperature Correction Factor For Steel The formula for steel tape temperature correction is given by: The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. C t = temperature factor. ° for pipeline steels in the grade. The temperature factor (cu,t) is used to take into account the ultimate and the. Components are often required to endure temperatures different. Temperature Correction Factor For Steel.

From www.chegg.com

Solved Table Values of k for Use in Equation for Computing Temperature Correction Factor For Steel The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. ° for pipeline steels in the grade. Components are often required to endure temperatures different from those at which the mechanical properties of a. Temperature correction factor for ultimate and yield strengths. C t = temperature factor. The formula for steel tape temperature correction. Temperature Correction Factor For Steel.

From www.researchgate.net

Correction factor y = a x Temperature + b, or y = a e b x Temperature Temperature Correction Factor For Steel Components are often required to endure temperatures different from those at which the mechanical properties of a. The temperature factor (cu,t) is used to take into account the ultimate and the. The formula for steel tape temperature correction is given by: The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. C t =. Temperature Correction Factor For Steel.

From www.researchgate.net

The temperature correction factors for EDP10 and EDD5 in cobalt60 and Temperature Correction Factor For Steel It has been observed that at an elevated temperature, the component fatigue strength is reduced with. The formula for steel tape temperature correction is given by: The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. Components are often required to endure temperatures different from those at which the mechanical properties of a. The. Temperature Correction Factor For Steel.

From www.researchgate.net

8 Temperature Correction Factor Correlation with Di for the Composite Temperature Correction Factor For Steel The temperature factor (cu,t) is used to take into account the ultimate and the. Temperature correction factor for ultimate and yield strengths. Components are often required to endure temperatures different from those at which the mechanical properties of a. ° for pipeline steels in the grade. It has been observed that at an elevated temperature, the component fatigue strength is. Temperature Correction Factor For Steel.

From www.chegg.com

Solved Group 130 Time (min) Temperature (°C) Hydrometer Temperature Correction Factor For Steel ° for pipeline steels in the grade. It has been observed that at an elevated temperature, the component fatigue strength is reduced with. Components are often required to endure temperatures different from those at which the mechanical properties of a. Temperature correction factor for ultimate and yield strengths. C t = temperature factor. The formula for steel tape temperature correction. Temperature Correction Factor For Steel.

From klauamjxo.blob.core.windows.net

Corrected Hydrometer Reading Formula at Jeremy Hall blog Temperature Correction Factor For Steel ° for pipeline steels in the grade. It has been observed that at an elevated temperature, the component fatigue strength is reduced with. The temperature factor (cu,t) is used to take into account the ultimate and the. The formula for steel tape temperature correction is given by: Temperature correction factor for ultimate and yield strengths. Components are often required to. Temperature Correction Factor For Steel.

From www.researchgate.net

4. Temperature correction factors for the matric potential and Temperature Correction Factor For Steel Temperature correction factor for ultimate and yield strengths. Components are often required to endure temperatures different from those at which the mechanical properties of a. The formula for steel tape temperature correction is given by: ° for pipeline steels in the grade. The temperature factor (cu,t) is used to take into account the ultimate and the. It has been observed. Temperature Correction Factor For Steel.

From ceutoxky.blob.core.windows.net

What Is Altimeter Correction at Helen Jacks blog Temperature Correction Factor For Steel The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. Components are often required to endure temperatures different from those at which the mechanical properties of a. The temperature factor (cu,t) is used to take into account the ultimate and the. The formula for steel tape temperature correction is given by: It has been. Temperature Correction Factor For Steel.

From www.youtube.com

Calculate Conductor Ampacity with Temperature Correction YouTube Temperature Correction Factor For Steel The temperature factor (cu,t) is used to take into account the ultimate and the. The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. ° for pipeline steels in the grade. It has been observed that at an elevated temperature, the component fatigue strength is reduced with. The formula for steel tape temperature correction. Temperature Correction Factor For Steel.

From calculatorshub.net

Steel Tape Temperature Correction Calculator Temperature Correction Factor For Steel The temperature factor (cu,t) is used to take into account the ultimate and the. The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. The formula for steel tape temperature correction is given by: It has been observed that at an elevated temperature, the component fatigue strength is reduced with. ° for pipeline steels. Temperature Correction Factor For Steel.

From cekknjmb.blob.core.windows.net

Battery Temperature Correction Factor Ieee at Lucy Woolverton blog Temperature Correction Factor For Steel The formula for steel tape temperature correction is given by: It has been observed that at an elevated temperature, the component fatigue strength is reduced with. The temperature factor (cu,t) is used to take into account the ultimate and the. Temperature correction factor for ultimate and yield strengths. The current asme b31.8 code gives no derating of line pipe steels. Temperature Correction Factor For Steel.

From www.youtube.com

310.15(B) Temperature Correction Factors YouTube Temperature Correction Factor For Steel Temperature correction factor for ultimate and yield strengths. C t = temperature factor. The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. The temperature factor (cu,t) is used to take into account the ultimate and the. It has been observed that at an elevated temperature, the component fatigue strength is reduced with. °. Temperature Correction Factor For Steel.

From www.scribd.com

Temperature Correction Factor For Tan Delta Measurement PDF Free PDF Temperature Correction Factor For Steel ° for pipeline steels in the grade. The temperature factor (cu,t) is used to take into account the ultimate and the. The formula for steel tape temperature correction is given by: C t = temperature factor. The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. It has been observed that at an elevated. Temperature Correction Factor For Steel.

From mavink.com

Temperature Correction Chart Temperature Correction Factor For Steel ° for pipeline steels in the grade. The formula for steel tape temperature correction is given by: Components are often required to endure temperatures different from those at which the mechanical properties of a. C t = temperature factor. Temperature correction factor for ultimate and yield strengths. The current asme b31.8 code gives no derating of line pipe steels for. Temperature Correction Factor For Steel.

From exovzoyxu.blob.core.windows.net

Correction Factor Term at Judy Ledford blog Temperature Correction Factor For Steel It has been observed that at an elevated temperature, the component fatigue strength is reduced with. Components are often required to endure temperatures different from those at which the mechanical properties of a. The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. ° for pipeline steels in the grade. Temperature correction factor for. Temperature Correction Factor For Steel.

From www.slideserve.com

PPT Heat Exchangers PowerPoint Presentation, free download ID4204370 Temperature Correction Factor For Steel Temperature correction factor for ultimate and yield strengths. The formula for steel tape temperature correction is given by: It has been observed that at an elevated temperature, the component fatigue strength is reduced with. Components are often required to endure temperatures different from those at which the mechanical properties of a. C t = temperature factor. The current asme b31.8. Temperature Correction Factor For Steel.

From cekknjmb.blob.core.windows.net

Battery Temperature Correction Factor Ieee at Lucy Woolverton blog Temperature Correction Factor For Steel C t = temperature factor. The formula for steel tape temperature correction is given by: The temperature factor (cu,t) is used to take into account the ultimate and the. The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. ° for pipeline steels in the grade. Components are often required to endure temperatures different. Temperature Correction Factor For Steel.

From www.scribd.com

Temperature Correction Factor PDF Temperature Correction Factor For Steel The formula for steel tape temperature correction is given by: ° for pipeline steels in the grade. The temperature factor (cu,t) is used to take into account the ultimate and the. Temperature correction factor for ultimate and yield strengths. Components are often required to endure temperatures different from those at which the mechanical properties of a. The current asme b31.8. Temperature Correction Factor For Steel.

From www.scribd.com

TEMPERATURE CORRECTION FACTOR From ANSI NETA MTS 2015 PDF Temperature Correction Factor For Steel It has been observed that at an elevated temperature, the component fatigue strength is reduced with. Components are often required to endure temperatures different from those at which the mechanical properties of a. Temperature correction factor for ultimate and yield strengths. C t = temperature factor. The formula for steel tape temperature correction is given by: ° for pipeline steels. Temperature Correction Factor For Steel.

From www.theleeco.com

How to Calculate Flow Resistance for Gases The Lee Co Temperature Correction Factor For Steel Temperature correction factor for ultimate and yield strengths. The temperature factor (cu,t) is used to take into account the ultimate and the. The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. ° for pipeline steels in the grade. Components are often required to endure temperatures different from those at which the mechanical properties. Temperature Correction Factor For Steel.

From klauamjxo.blob.core.windows.net

Corrected Hydrometer Reading Formula at Jeremy Hall blog Temperature Correction Factor For Steel The formula for steel tape temperature correction is given by: The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. The temperature factor (cu,t) is used to take into account the ultimate and the. Temperature correction factor for ultimate and yield strengths. It has been observed that at an elevated temperature, the component fatigue. Temperature Correction Factor For Steel.

From community.se.com

The importance of "Ambient Temperature based Correction Factor," on the Temperature Correction Factor For Steel The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. ° for pipeline steels in the grade. The temperature factor (cu,t) is used to take into account the ultimate and the. C t = temperature factor. The formula for steel tape temperature correction is given by: It has been observed that at an elevated. Temperature Correction Factor For Steel.

From www.youtube.com

3 Correction Factors, Cable Sizing and Voltage Drop Calculations YouTube Temperature Correction Factor For Steel Temperature correction factor for ultimate and yield strengths. ° for pipeline steels in the grade. The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. The temperature factor (cu,t) is used to take into account the ultimate and the. Components are often required to endure temperatures different from those at which the mechanical properties. Temperature Correction Factor For Steel.

From www.chegg.com

Group 130 Time (min) Temperature (°C) Hydrometer Temperature Correction Factor For Steel ° for pipeline steels in the grade. It has been observed that at an elevated temperature, the component fatigue strength is reduced with. C t = temperature factor. The temperature factor (cu,t) is used to take into account the ultimate and the. Components are often required to endure temperatures different from those at which the mechanical properties of a. The. Temperature Correction Factor For Steel.

From code7700.com

Altimetry Temperature Correction Temperature Correction Factor For Steel The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. Temperature correction factor for ultimate and yield strengths. The formula for steel tape temperature correction is given by: The temperature factor (cu,t) is used to take into account the ultimate and the. C t = temperature factor. It has been observed that at an. Temperature Correction Factor For Steel.

From www.researchgate.net

8 Temperature Correction Factor Correlation with Di for the Composite Temperature Correction Factor For Steel The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. The formula for steel tape temperature correction is given by: ° for pipeline steels in the grade. Temperature correction factor for ultimate and yield strengths. It has been observed that at an elevated temperature, the component fatigue strength is reduced with. Components are often. Temperature Correction Factor For Steel.

From www.scribd.com

Temperature Correction Table PDF Pressure Applied And Temperature Correction Factor For Steel ° for pipeline steels in the grade. The temperature factor (cu,t) is used to take into account the ultimate and the. The current asme b31.8 code gives no derating of line pipe steels for temperatures below 250f. It has been observed that at an elevated temperature, the component fatigue strength is reduced with. C t = temperature factor. Temperature correction. Temperature Correction Factor For Steel.

From www.engineeringtoolbox.com

Crude Oil Density vs. Temperature Temperature Correction Factor For Steel C t = temperature factor. It has been observed that at an elevated temperature, the component fatigue strength is reduced with. Components are often required to endure temperatures different from those at which the mechanical properties of a. ° for pipeline steels in the grade. The temperature factor (cu,t) is used to take into account the ultimate and the. Temperature. Temperature Correction Factor For Steel.