Asme Flange Bolt Torque Calculator . Before using a given torque. Bolt torque is calculated for a flanged assembly using the following equation. \[ t = \frac{k \cdot f \cdot d}{12} \] where: Sealing for a safer and greener. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under. The torque tables are built on specific assumptions regarding bolt and nut factor. The formula for calculating flange bolt torque is given by: When performing the final tightening, the correct torque value must be used to ensure that all bolts are tightened to the. Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for.

from fixengineukusniju88.z22.web.core.windows.net

When performing the final tightening, the correct torque value must be used to ensure that all bolts are tightened to the. Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. The torque tables are built on specific assumptions regarding bolt and nut factor. Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. \[ t = \frac{k \cdot f \cdot d}{12} \] where: The formula for calculating flange bolt torque is given by: Before using a given torque. Sealing for a safer and greener. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under. Bolt torque is calculated for a flanged assembly using the following equation.

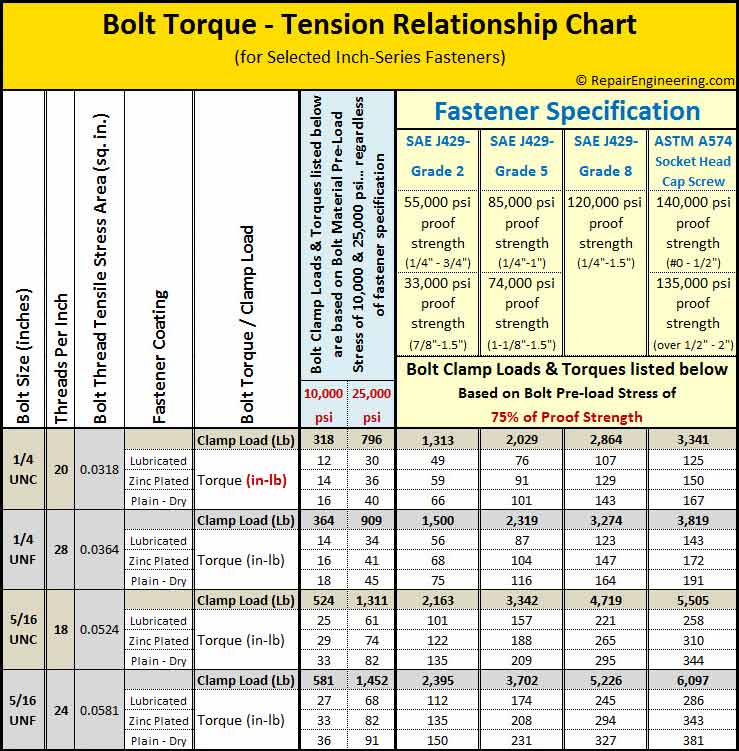

Torque Chart For Bolts Sizes

Asme Flange Bolt Torque Calculator Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. Sealing for a safer and greener. Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. Bolt torque is calculated for a flanged assembly using the following equation. The torque tables are built on specific assumptions regarding bolt and nut factor. The formula for calculating flange bolt torque is given by: Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under. Before using a given torque. \[ t = \frac{k \cdot f \cdot d}{12} \] where: When performing the final tightening, the correct torque value must be used to ensure that all bolts are tightened to the. Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for.

From www.htpipe.com

Bolt Dimension For ASME B16.5 flange Asme Flange Bolt Torque Calculator Before using a given torque. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under. \[ t = \frac{k \cdot f \cdot d}{12} \] where: Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. When performing the final tightening, the correct torque value. Asme Flange Bolt Torque Calculator.

From worksheetmediawinnifred.z21.web.core.windows.net

Flange Bolt Torque Chart Asme Flange Bolt Torque Calculator The torque tables are built on specific assumptions regarding bolt and nut factor. Before using a given torque. Sealing for a safer and greener. Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. Hytorc. Asme Flange Bolt Torque Calculator.

From repairfixmenyeid50.z4.web.core.windows.net

Stainless Bolt Torque Chart Asme Flange Bolt Torque Calculator Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. Before using a given torque. The formula for calculating flange bolt torque is given by: Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. The torque tables are built on specific assumptions regarding bolt. Asme Flange Bolt Torque Calculator.

From whatispiping.com

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart What Asme Flange Bolt Torque Calculator Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. When performing the final tightening, the correct torque value must be used to ensure that all bolts are tightened to the. The torque tables are. Asme Flange Bolt Torque Calculator.

From fixengineukusniju88.z22.web.core.windows.net

Torque Chart For Bolts Sizes Asme Flange Bolt Torque Calculator Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. Before using a given torque. Bolt torque is calculated for a flanged assembly using the following equation. \[ t = \frac{k \cdot f \cdot d}{12} \] where: The formula for calculating flange bolt torque is given. Asme Flange Bolt Torque Calculator.

From mungfali.com

ASME Flange Chart Asme Flange Bolt Torque Calculator Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under. Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. When performing the final tightening, the correct torque value must be used to ensure that all bolts are tightened to the. Sealing for a. Asme Flange Bolt Torque Calculator.

From mungfali.com

Pipe Flange Bolt Torque Chart Asme Flange Bolt Torque Calculator Sealing for a safer and greener. Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. When performing the final tightening, the correct torque value must be used to ensure that all bolts are tightened. Asme Flange Bolt Torque Calculator.

From mungfali.com

Pipe Flange Bolt Torque Chart Asme Flange Bolt Torque Calculator Before using a given torque. Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. \[ t = \frac{k \cdot f \cdot d}{12} \] where: The formula for calculating flange bolt torque is given by: Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges. Asme Flange Bolt Torque Calculator.

From repairfixmagdamams.z4.web.core.windows.net

Grade 8 Bolt Torque Spec Chart Asme Flange Bolt Torque Calculator Sealing for a safer and greener. \[ t = \frac{k \cdot f \cdot d}{12} \] where: Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. Before using a given torque. Bolt torque is calculated for a flanged assembly using the following equation. The torque tables. Asme Flange Bolt Torque Calculator.

From www.aiophotoz.com

Lug Bolt Tightening Sequence And Bolt Torque Chart Method Statement Hq Asme Flange Bolt Torque Calculator The torque tables are built on specific assumptions regarding bolt and nut factor. Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. Bolt torque is calculated for a flanged assembly using the following equation. When performing the final tightening, the correct torque value must be. Asme Flange Bolt Torque Calculator.

From materialschoollavonne.z21.web.core.windows.net

Asme Bolt Torque Chart Asme Flange Bolt Torque Calculator Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. Sealing for a safer and greener. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under. The formula for calculating flange bolt torque is given by: Before using a given torque. The torque tables. Asme Flange Bolt Torque Calculator.

From www.aiophotoz.com

Pipe Flange Bolt Torque Chart Images and Photos finder Asme Flange Bolt Torque Calculator Before using a given torque. The torque tables are built on specific assumptions regarding bolt and nut factor. Bolt torque is calculated for a flanged assembly using the following equation. \[ t = \frac{k \cdot f \cdot d}{12} \] where: Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and. Asme Flange Bolt Torque Calculator.

From mungfali.com

ASME Bolt Torque Chart Asme Flange Bolt Torque Calculator Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. Bolt torque is calculated for a flanged assembly using the following equation. When performing the final tightening, the correct torque value must be used to. Asme Flange Bolt Torque Calculator.

From exopzfqjk.blob.core.windows.net

Bolt Torque Tension Calculator at Charles Fairbanks blog Asme Flange Bolt Torque Calculator Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. Sealing for a safer and greener. The formula for calculating flange bolt torque is given by: Bolt torque is calculated for a flanged assembly using. Asme Flange Bolt Torque Calculator.

From mungfali.com

Pipe Flange Bolt Torque Chart Asme Flange Bolt Torque Calculator The formula for calculating flange bolt torque is given by: Bolt torque is calculated for a flanged assembly using the following equation. The torque tables are built on specific assumptions regarding bolt and nut factor. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under.. Asme Flange Bolt Torque Calculator.

From mavink.com

Pipe Flange Torque Chart Asme Flange Bolt Torque Calculator Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. The formula for calculating flange bolt torque is given by: Sealing for a safer and greener. Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. Before using a given torque. Hytorc flange bolting calculator. Asme Flange Bolt Torque Calculator.

From mavink.com

Pipe Flange Torque Chart Asme Flange Bolt Torque Calculator Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. The formula for calculating flange bolt torque is given by: Sealing for a safer and greener. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5. Asme Flange Bolt Torque Calculator.

From www.semanticscholar.org

Figure 1 from The New Interactive AWWA M11—Flange Bolt Torque Asme Flange Bolt Torque Calculator The torque tables are built on specific assumptions regarding bolt and nut factor. When performing the final tightening, the correct torque value must be used to ensure that all bolts are tightened to the. Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure. Asme Flange Bolt Torque Calculator.

From mungfali.com

Flange Bolt Torque Specification Chart Asme Flange Bolt Torque Calculator Sealing for a safer and greener. The torque tables are built on specific assumptions regarding bolt and nut factor. Before using a given torque. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under. Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps.. Asme Flange Bolt Torque Calculator.

From www.myxxgirl.com

Asme Flange Bolt Chart Sexiz Pix My XXX Hot Girl Asme Flange Bolt Torque Calculator When performing the final tightening, the correct torque value must be used to ensure that all bolts are tightened to the. Before using a given torque. \[ t = \frac{k \cdot f \cdot d}{12} \] where: Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges. Asme Flange Bolt Torque Calculator.

From mavink.com

Flange Bolt Torque Specification Chart Asme Flange Bolt Torque Calculator Bolt torque is calculated for a flanged assembly using the following equation. Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. When performing the final tightening, the correct torque value must be used to ensure that all bolts are tightened to the. The torque tables. Asme Flange Bolt Torque Calculator.

From mavink.com

Asme Flange Bolt Torque Chart Asme Flange Bolt Torque Calculator \[ t = \frac{k \cdot f \cdot d}{12} \] where: Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. Sealing for a safer and greener. The torque tables are built on specific assumptions regarding. Asme Flange Bolt Torque Calculator.

From www.scribd.com

Flange & Bolting Info ASME B16 5 & BS1560 Flanges 2 Metalworking Asme Flange Bolt Torque Calculator The formula for calculating flange bolt torque is given by: Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. \[ t = \frac{k \cdot f \cdot d}{12} \] where: Before using a given torque. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges. Asme Flange Bolt Torque Calculator.

From fixengineukusniju88.z22.web.core.windows.net

Bolt Torque Chart For Pipe Flanges Asme Flange Bolt Torque Calculator \[ t = \frac{k \cdot f \cdot d}{12} \] where: Before using a given torque. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under. Sealing for a safer and greener. Bolt torque is calculated for a flanged assembly using the following equation. Read api. Asme Flange Bolt Torque Calculator.

From davida.davivienda.com

Printable Flange Size Chart Printable Word Searches Asme Flange Bolt Torque Calculator When performing the final tightening, the correct torque value must be used to ensure that all bolts are tightened to the. Before using a given torque. \[ t = \frac{k \cdot f \cdot d}{12} \] where: Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges. Asme Flange Bolt Torque Calculator.

From whatispiping.com

Flange Bolt Torque Calculation and Pipe Flange Bolt Torque Chart What Asme Flange Bolt Torque Calculator \[ t = \frac{k \cdot f \cdot d}{12} \] where: Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under. Bolt torque is calculated for a flanged assembly using the following equation. The formula for calculating flange bolt torque is given by: Before using a. Asme Flange Bolt Torque Calculator.

From calculatorshub.net

Flange Bolt Torque Calculator Online Asme Flange Bolt Torque Calculator When performing the final tightening, the correct torque value must be used to ensure that all bolts are tightened to the. Before using a given torque. The torque tables are built on specific assumptions regarding bolt and nut factor. Bolt torque is calculated for a flanged assembly using the following equation. Sealing for a safer and greener. Read api 610. Asme Flange Bolt Torque Calculator.

From www.scribd.com

ASME Bolting Assembly Torque Values Asme Flange Bolt Torque Calculator Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. Sealing for a safer and greener. The formula for calculating flange bolt torque is given by: Bolt torque is calculated for a flanged assembly using the following equation. Before using a given torque. Read api 610. Asme Flange Bolt Torque Calculator.

From mungfali.com

Pipe Flange Bolt Torque Chart Asme Flange Bolt Torque Calculator The formula for calculating flange bolt torque is given by: Bolt torque is calculated for a flanged assembly using the following equation. Sealing for a safer and greener. Before using a given torque. The torque tables are built on specific assumptions regarding bolt and nut factor. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump. Asme Flange Bolt Torque Calculator.

From apkpure.com

FlangeMate, ASME flange info and torque calculator Latest Version 20.10 Asme Flange Bolt Torque Calculator The torque tables are built on specific assumptions regarding bolt and nut factor. Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. Bolt torque is calculated for a flanged assembly using the following equation. Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for.. Asme Flange Bolt Torque Calculator.

From mavink.com

Ansi Flange Bolting Charts Asme Flange Bolt Torque Calculator Bolt torque is calculated for a flanged assembly using the following equation. The torque tables are built on specific assumptions regarding bolt and nut factor. Before using a given torque. When performing the final tightening, the correct torque value must be used to ensure that all bolts are tightened to the. Welcome to this interactive flange bolting calculator from hytorc.the. Asme Flange Bolt Torque Calculator.

From www.uipintl.com

Flange Bolt Torque Sequence UIP International Premium Industrial Asme Flange Bolt Torque Calculator The formula for calculating flange bolt torque is given by: Sealing for a safer and greener. Read api 610 pumps vs ansi / asme b73.1 centrifugal pumps. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under. \[ t = \frac{k \cdot f \cdot d}{12}. Asme Flange Bolt Torque Calculator.

From mungfali.com

Pipe Flange Bolt Torque Chart Asme Flange Bolt Torque Calculator Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. Before using a given torque. The torque tables are built on specific assumptions regarding bolt and nut factor. Bolt torque is calculated for a flanged assembly using the following equation. When performing the final tightening, the. Asme Flange Bolt Torque Calculator.

From apkpure.com

FlangeMate, ASME flange info and torque calculator Latest Version 20.10 Asme Flange Bolt Torque Calculator Welcome to this interactive flange bolting calculator from hytorc.the program computes recommended torque values , bolting patterns, tool selection and pump pressure settings for. When performing the final tightening, the correct torque value must be used to ensure that all bolts are tightened to the. Bolt torque is calculated for a flanged assembly using the following equation. Hytorc flange bolting. Asme Flange Bolt Torque Calculator.

From mavink.com

Pipe Flange Torque Chart Asme Flange Bolt Torque Calculator When performing the final tightening, the correct torque value must be used to ensure that all bolts are tightened to the. Sealing for a safer and greener. Hytorc flange bolting calculator computes recommended torque values, bolting patterns, tool selection and pump pressure settings for standard asme b16.5 and api 6a flanges under. \[ t = \frac{k \cdot f \cdot d}{12}. Asme Flange Bolt Torque Calculator.