Milling Insert Wear Chart . flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. Check your inserts every week to maintain optimal. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. detailed information on tool wear. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. Worn tips can diminish your scaling efficiency.

from www.winstarcutting.com

In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. Worn tips can diminish your scaling efficiency. detailed information on tool wear. Check your inserts every week to maintain optimal. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition.

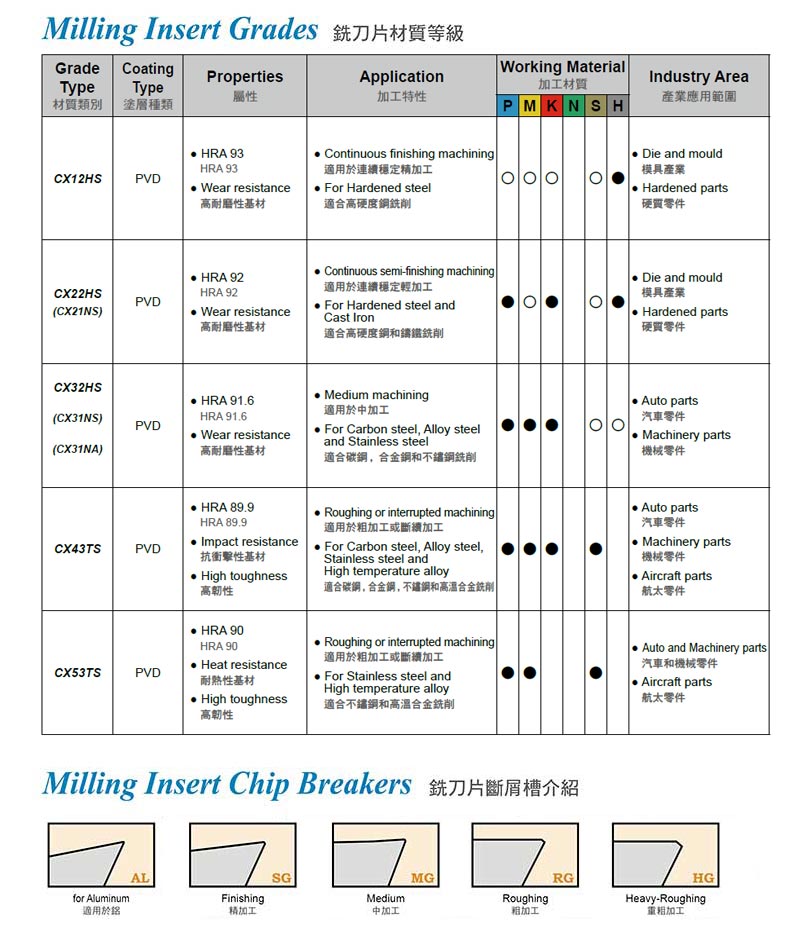

Insert Grades Winstar Cutting Technologies Corp

Milling Insert Wear Chart Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. detailed information on tool wear. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. Check your inserts every week to maintain optimal. Worn tips can diminish your scaling efficiency. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product.

From journals.sagepub.com

Effect of cutting speed on chip formation and wear mechanisms of coated Milling Insert Wear Chart flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. Worn tips. Milling Insert Wear Chart.

From mungfali.com

Insert Nomenclature Chart Milling Insert Wear Chart Worn tips can diminish your scaling efficiency. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. Check your inserts every week to maintain optimal. Normal flank. Milling Insert Wear Chart.

From www.hahn-kolb.com.tr

Indexable milling insert SNMXMM HAHN+KOLB Milling Insert Wear Chart Check your inserts every week to maintain optimal. Worn tips can diminish your scaling efficiency. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. detailed. Milling Insert Wear Chart.

From www.burraycarbide.com

SPMT060204SP Tungsten Carbide Milling Inserts CNC Machine Lathe Tool Milling Insert Wear Chart Check your inserts every week to maintain optimal. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. detailed information on tool wear. Worn tips can diminish your scaling efficiency.. Milling Insert Wear Chart.

From www.winstarcutting.com

Insert Grades Winstar Cutting Technologies Corp. 萬事達切削科技鎢鋼銑刀, 鎢鋼刀片, 鎢鋼鑽頭 Milling Insert Wear Chart Worn tips can diminish your scaling efficiency. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable. Milling Insert Wear Chart.

From www.kennametal.com

Milling Inserts Indexable Inserts • KSSM Milling Insert Wear Chart detailed information on tool wear. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Check your inserts every week to maintain optimal. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. flank face wear is caused by abrasion between the workpiece and the tool. Milling Insert Wear Chart.

From www.mscdirect.com

Milling Inserts Milling Insert Wear Chart Worn tips can diminish your scaling efficiency. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. Check your inserts every week to maintain optimal. detailed information on tool wear. In addition to. Milling Insert Wear Chart.

From www.mscdirect.com

Ceratizit Milling Inserts; Insert Size Code 1225 ; Insert Material Milling Insert Wear Chart flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. Check your inserts every week to maintain optimal. detailed information on tool wear. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. Worn tips can. Milling Insert Wear Chart.

From www.mscdirect.com

Turning Inserts MSC Industrial Supply Milling Insert Wear Chart Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. Worn tips can diminish your scaling efficiency. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert. Milling Insert Wear Chart.

From dxogukftg.blob.core.windows.net

Milling Speeds For Steel at Michael Reed blog Milling Insert Wear Chart In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. detailed information on tool wear. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition.. Milling Insert Wear Chart.

From www.youtube.com

2018 02 23 Online Training Series Insert wear YouTube Milling Insert Wear Chart Worn tips can diminish your scaling efficiency. detailed information on tool wear. Check your inserts every week to maintain optimal. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. Normal. Milling Insert Wear Chart.

From rozmierka.eu

incert vs insert Milling Insert Wear Chart utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Worn tips can diminish your scaling efficiency. flank face wear is caused by abrasion between the workpiece and the tool at. Milling Insert Wear Chart.

From www.mscdirect.com

Ceratizit Milling Inserts; Insert Size Code 04T3 ; Insert Material Milling Insert Wear Chart Check your inserts every week to maintain optimal. detailed information on tool wear. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. utilize the tungaloy insert wear chart. Milling Insert Wear Chart.

From www.swisscuttools.com

Milling Inserts SwissCut Milling Insert Wear Chart Worn tips can diminish your scaling efficiency. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. detailed information on tool wear. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. Check your inserts every week to maintain optimal. . Milling Insert Wear Chart.

From mungfali.com

Milling Speed Chart Milling Insert Wear Chart detailed information on tool wear. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert.. Milling Insert Wear Chart.

From www.toollink.co.th

Toollink Co., Ltd. Guide to select Milling Insert Toollink Co., Ltd. Milling Insert Wear Chart Worn tips can diminish your scaling efficiency. detailed information on tool wear. Check your inserts every week to maintain optimal. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert.. Milling Insert Wear Chart.

From zzyftools.en.alibaba.com

APGX160408 Carbide Milling Inserts For Aluminum Machining, View Carbide Milling Insert Wear Chart Check your inserts every week to maintain optimal. detailed information on tool wear. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. utilize the tungaloy insert wear chart. Milling Insert Wear Chart.

From huanatools.com

How to choose the right carbide turning insert Huana Tools Milling Insert Wear Chart flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up.. Milling Insert Wear Chart.

From rdbarrett.co.uk

How to Identify Carbide Inserts R.D. Barrett Milling Insert Wear Chart In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. Worn tips can diminish your scaling efficiency. Check your inserts every week to maintain optimal. Normal flank wear, since it is predictable. Milling Insert Wear Chart.

From www.mscdirect.com

Kennametal Milling Inserts; Insert Size Code None ; Insert Material Milling Insert Wear Chart Worn tips can diminish your scaling efficiency. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. Check your inserts every week to maintain optimal. utilize the tungaloy insert wear chart to. Milling Insert Wear Chart.

From www.yumpu.com

Milling Inserts korloy Milling Insert Wear Chart flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. Check your inserts every week to maintain optimal. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. Normal flank wear, since it is predictable and consistent,. Milling Insert Wear Chart.

From www.secotools.com

Seco Milling Insert Grades Seco Tools Milling Insert Wear Chart In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. Worn tips can diminish your scaling. Milling Insert Wear Chart.

From www.pinterest.co.uk

TNMG inserts Pesquisa Google Tableros de herramientas, Herramientas Milling Insert Wear Chart utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. Check your inserts every week to maintain optimal. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. flank face wear is caused by abrasion between the workpiece and the tool at the. Milling Insert Wear Chart.

From clinetool.com

Insert Wear Pattern Cause & Remedy Chart Cline Tool Milling Insert Wear Chart Check your inserts every week to maintain optimal. detailed information on tool wear. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Worn tips can diminish your scaling efficiency. utilize the tungaloy insert wear chart. Milling Insert Wear Chart.

From www.swisscuttools.com

Technical Information SwissCut Milling Insert Wear Chart flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Worn tips can diminish your scaling efficiency. Check your inserts every week to maintain optimal. detailed information on tool wear.. Milling Insert Wear Chart.

From morganwells.z19.web.core.windows.net

Kennametal Inserts Grades Chart Milling Insert Wear Chart Worn tips can diminish your scaling efficiency. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. Check your inserts every week to maintain optimal. detailed information on tool wear. utilize. Milling Insert Wear Chart.

From www.myxxgirl.com

Sandvik Milling Insert Grade Chart My XXX Hot Girl Milling Insert Wear Chart Worn tips can diminish your scaling efficiency. Check your inserts every week to maintain optimal. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. flank face wear is caused by. Milling Insert Wear Chart.

From huanatools.com

The Most Complete Introduction To Milling Inserts Huana Tools Milling Insert Wear Chart utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. detailed information on tool wear. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. Worn tips can diminish your scaling efficiency. Check your inserts every. Milling Insert Wear Chart.

From lucymcdonald.z13.web.core.windows.net

Sfm Chart For Milling Milling Insert Wear Chart Worn tips can diminish your scaling efficiency. detailed information on tool wear. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Check your inserts every week to maintain optimal. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. Normal. Milling Insert Wear Chart.

From www.kennametal.com

Selecting Carbide Inserts for Metalworking Kennametal Milling Insert Wear Chart detailed information on tool wear. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition.. Milling Insert Wear Chart.

From www.mscdirect.com

Ceratizit Milling Inserts; Insert Size Code 11T3 ; Insert Material Milling Insert Wear Chart Worn tips can diminish your scaling efficiency. Check your inserts every week to maintain optimal. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. In addition to an overview of cutting tools, safety. Milling Insert Wear Chart.

From www.tradeindia.com

Milling Inserts at Best Price in Ghaziabad, Uttar Pradesh Poshita Milling Insert Wear Chart Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. detailed information on tool wear. . Milling Insert Wear Chart.

From www.winstarcutting.com

Insert Grades Winstar Cutting Technologies Corp Milling Insert Wear Chart Check your inserts every week to maintain optimal. In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. utilize the tungaloy insert wear chart to quickly identify the root cause. Milling Insert Wear Chart.

From www.myxxgirl.com

Carbide Insert Wear Chart My XXX Hot Girl Milling Insert Wear Chart In addition to an overview of cutting tools, safety and precautions, information on calculation formulas, grades, product. Check your inserts every week to maintain optimal. Worn tips can diminish your scaling efficiency. detailed information on tool wear. utilize the tungaloy insert wear chart to quickly identify the root cause of carbide insert wear problems including built up. . Milling Insert Wear Chart.

From xmkktool.en.made-in-china.com

High Quality Roughing and Finishing Indexable Milling Inserts Milling Milling Insert Wear Chart Check your inserts every week to maintain optimal. Normal flank wear, since it is predictable and consistent, is the most desirable wear condition. flank face wear is caused by abrasion between the workpiece and the tool at the flank face of the indexable insert. Worn tips can diminish your scaling efficiency. detailed information on tool wear. In addition. Milling Insert Wear Chart.