The Flux Commonly Used In Brazing Is . Brazing fluxes, which are mixtures of fluorides, borates, and boric acid, meet aws specification a5 31. A chemical flux is commonly used with many braze filler metals. The most common is class fb 3a, a white paste. Borax, either alone or in combination with other salts is commonly used in a flux. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. Function and performance requirements of brazing flux: 1) eliminate oxide films on metal surfaces, creating optimal conditions for wetting and spreading of the filler metal. Flux is a chemical compound applied to the joint surfaces before brazing. A flux is a chemical compound used in brazing operation to dissolve oxides which are formed on the surface of metal and filler rod. The advantages of joining metals by brazing are that dissimilar metals and parts having a thin section can be joined easily. Brazing is used for the fastening of pipe fittings, and tanks, credible tips on tools, radiators, heat exchangers, and the repair of castings. A flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when brazing.

from www.focusweld.com

1) eliminate oxide films on metal surfaces, creating optimal conditions for wetting and spreading of the filler metal. The advantages of joining metals by brazing are that dissimilar metals and parts having a thin section can be joined easily. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. The most common is class fb 3a, a white paste. A flux is a chemical compound used in brazing operation to dissolve oxides which are formed on the surface of metal and filler rod. A chemical flux is commonly used with many braze filler metals. Brazing is used for the fastening of pipe fittings, and tanks, credible tips on tools, radiators, heat exchangers, and the repair of castings. Function and performance requirements of brazing flux: Borax, either alone or in combination with other salts is commonly used in a flux. Brazing fluxes, which are mixtures of fluorides, borates, and boric acid, meet aws specification a5 31.

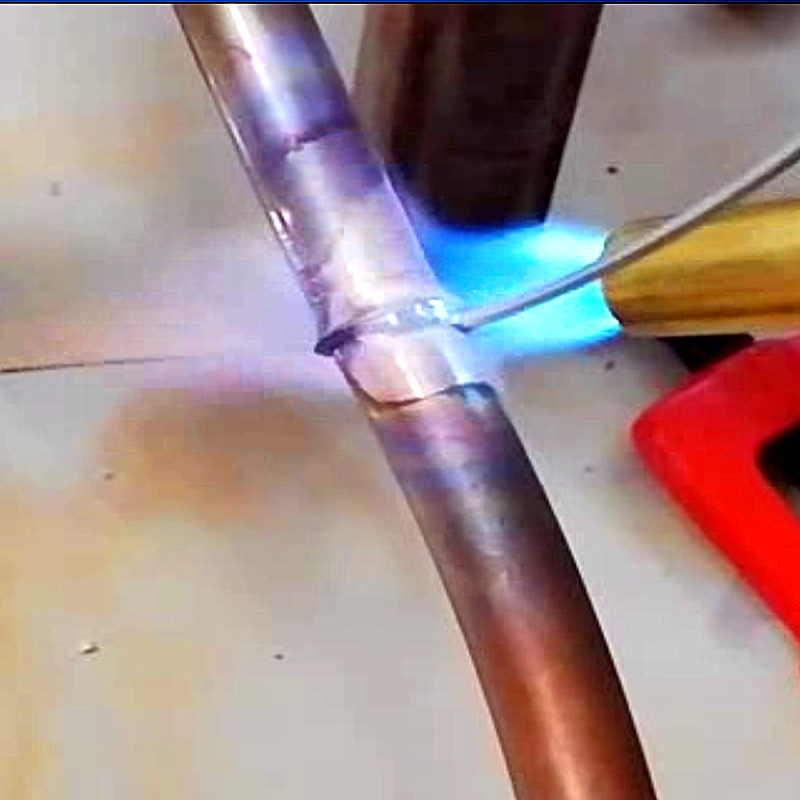

Brazing is a traditional metal joining process in which two or more

The Flux Commonly Used In Brazing Is 1) eliminate oxide films on metal surfaces, creating optimal conditions for wetting and spreading of the filler metal. 1) eliminate oxide films on metal surfaces, creating optimal conditions for wetting and spreading of the filler metal. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. A flux is a chemical compound used in brazing operation to dissolve oxides which are formed on the surface of metal and filler rod. The most common is class fb 3a, a white paste. The advantages of joining metals by brazing are that dissimilar metals and parts having a thin section can be joined easily. Flux is a chemical compound applied to the joint surfaces before brazing. Function and performance requirements of brazing flux: Brazing fluxes, which are mixtures of fluorides, borates, and boric acid, meet aws specification a5 31. A flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when brazing. Borax, either alone or in combination with other salts is commonly used in a flux. Brazing is used for the fastening of pipe fittings, and tanks, credible tips on tools, radiators, heat exchangers, and the repair of castings. A chemical flux is commonly used with many braze filler metals.

From www.slideshare.net

Brazing The Flux Commonly Used In Brazing Is The most common is class fb 3a, a white paste. Flux is a chemical compound applied to the joint surfaces before brazing. A flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when brazing. A chemical flux is commonly used with many braze filler metals. Brazing is. The Flux Commonly Used In Brazing Is.

From www.huaguangwelding.com

FluxCoated Brazing Alloys and Their Requirements The Flux Commonly Used In Brazing Is Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. Borax, either alone or in combination with other salts is commonly used in a flux. Function and performance requirements of brazing flux: Brazing fluxes, which are mixtures of fluorides, borates, and boric acid, meet aws specification a5 31. Flux is a chemical compound applied. The Flux Commonly Used In Brazing Is.

From www.indiamart.com

Braze Flux Copper Alloy Brazing Fluxes at Rs 950/kilogram Brazing The Flux Commonly Used In Brazing Is A chemical flux is commonly used with many braze filler metals. Brazing is used for the fastening of pipe fittings, and tanks, credible tips on tools, radiators, heat exchangers, and the repair of castings. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. Brazing fluxes, which are mixtures of fluorides, borates, and boric. The Flux Commonly Used In Brazing Is.

From slideplayer.com

Teknologi Dan Rekayasa ppt download The Flux Commonly Used In Brazing Is Flux is a chemical compound applied to the joint surfaces before brazing. A flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when brazing. The advantages of joining metals by brazing are that dissimilar metals and parts having a thin section can be joined easily. Brazing fluxes,. The Flux Commonly Used In Brazing Is.

From weldingpros.net

Brazing Filler Metals And Fluxes Explained In Detail The Flux Commonly Used In Brazing Is The most common is class fb 3a, a white paste. Flux is a chemical compound applied to the joint surfaces before brazing. 1) eliminate oxide films on metal surfaces, creating optimal conditions for wetting and spreading of the filler metal. The advantages of joining metals by brazing are that dissimilar metals and parts having a thin section can be joined. The Flux Commonly Used In Brazing Is.

From engineeringlearner.com

Types of Brazing Definition, Principle, Applications, Advantages The Flux Commonly Used In Brazing Is The most common is class fb 3a, a white paste. 1) eliminate oxide films on metal surfaces, creating optimal conditions for wetting and spreading of the filler metal. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. The advantages of joining metals by brazing are that dissimilar metals and parts having a thin. The Flux Commonly Used In Brazing Is.

From blog.thepipingmart.com

What is Brazing Fluxes? Uses and Working The Flux Commonly Used In Brazing Is Brazing is used for the fastening of pipe fittings, and tanks, credible tips on tools, radiators, heat exchangers, and the repair of castings. Borax, either alone or in combination with other salts is commonly used in a flux. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. 1) eliminate oxide films on metal. The Flux Commonly Used In Brazing Is.

From www.slideshare.net

Brazing The Flux Commonly Used In Brazing Is Brazing fluxes, which are mixtures of fluorides, borates, and boric acid, meet aws specification a5 31. A chemical flux is commonly used with many braze filler metals. Function and performance requirements of brazing flux: The most common is class fb 3a, a white paste. A flux is a chemical compound used in brazing operation to dissolve oxides which are formed. The Flux Commonly Used In Brazing Is.

From weldcote.com

brazing flux white anti borax fluxes Weldcote Welding For WellBeing The Flux Commonly Used In Brazing Is Borax, either alone or in combination with other salts is commonly used in a flux. The advantages of joining metals by brazing are that dissimilar metals and parts having a thin section can be joined easily. A flux is a chemical compound used in brazing operation to dissolve oxides which are formed on the surface of metal and filler rod.. The Flux Commonly Used In Brazing Is.

From blog.thepipingmart.com

Brazing Flux vs Soldering Flux What's the Difference The Flux Commonly Used In Brazing Is 1) eliminate oxide films on metal surfaces, creating optimal conditions for wetting and spreading of the filler metal. A flux is a chemical compound used in brazing operation to dissolve oxides which are formed on the surface of metal and filler rod. A chemical flux is commonly used with many braze filler metals. Flux is a chemical compound applied to. The Flux Commonly Used In Brazing Is.

From www.harrisweldingsupplies.com

Harris 600 Powder Flux General Purpose Brazing Flux 1 lb. Can The Flux Commonly Used In Brazing Is Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. Brazing fluxes, which are mixtures of fluorides, borates, and boric acid, meet aws specification a5 31. Borax, either alone or in combination with other salts is commonly used in a flux. A flux is a mix of chemicals, fluorides, and fluoroborates, and must be. The Flux Commonly Used In Brazing Is.

From dir.indiamart.com

Brass Brazing Fluxes at Best Price in India The Flux Commonly Used In Brazing Is Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. Borax, either alone or in combination with other salts is commonly used in a flux. The most common is class fb 3a, a white paste. Function and performance requirements of brazing flux: Brazing is used for the fastening of pipe fittings, and tanks, credible. The Flux Commonly Used In Brazing Is.

From bridgwaterweldingsupplies.co.uk

Brazing Flux The Flux Commonly Used In Brazing Is Borax, either alone or in combination with other salts is commonly used in a flux. Brazing is used for the fastening of pipe fittings, and tanks, credible tips on tools, radiators, heat exchangers, and the repair of castings. A flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable. The Flux Commonly Used In Brazing Is.

From www.takealot.com

MTS Brazing Flux 500g Shop Today. Get it Tomorrow! The Flux Commonly Used In Brazing Is Borax, either alone or in combination with other salts is commonly used in a flux. Function and performance requirements of brazing flux: The most common is class fb 3a, a white paste. Brazing fluxes, which are mixtures of fluorides, borates, and boric acid, meet aws specification a5 31. A flux is a mix of chemicals, fluorides, and fluoroborates, and must. The Flux Commonly Used In Brazing Is.

From www.aluminium-brazing.com

Sil Flux Brazing « to Aluminium Brazing Blog The Flux Commonly Used In Brazing Is 1) eliminate oxide films on metal surfaces, creating optimal conditions for wetting and spreading of the filler metal. Flux is a chemical compound applied to the joint surfaces before brazing. Brazing fluxes, which are mixtures of fluorides, borates, and boric acid, meet aws specification a5 31. Function and performance requirements of brazing flux: A chemical flux is commonly used with. The Flux Commonly Used In Brazing Is.

From www.hobbyistgeek.com

What Is Brazing Flux And How To Use It? The Flux Commonly Used In Brazing Is A flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when brazing. The most common is class fb 3a, a white paste. Borax, either alone or in combination with other salts is commonly used in a flux. A chemical flux is commonly used with many braze filler. The Flux Commonly Used In Brazing Is.

From giomqnucr.blob.core.windows.net

Brazing Flux Meaning at Beatrice Kinyon blog The Flux Commonly Used In Brazing Is Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. Brazing fluxes, which are mixtures of fluorides, borates, and boric acid, meet aws specification a5 31. A flux is a chemical compound used in brazing operation to dissolve oxides which are formed on the surface of metal and filler rod. 1) eliminate oxide films. The Flux Commonly Used In Brazing Is.

From www.slideserve.com

PPT SUPERIOR FLUX & MFG. CO. PowerPoint Presentation, free download The Flux Commonly Used In Brazing Is The most common is class fb 3a, a white paste. A flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when brazing. A flux is a chemical compound used in brazing operation to dissolve oxides which are formed on the surface of metal and filler rod. Brazing. The Flux Commonly Used In Brazing Is.

From blog.thepipingmart.com

Fusion Welding vs Brazing What's the Difference The Flux Commonly Used In Brazing Is A chemical flux is commonly used with many braze filler metals. Flux is a chemical compound applied to the joint surfaces before brazing. The advantages of joining metals by brazing are that dissimilar metals and parts having a thin section can be joined easily. A flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the. The Flux Commonly Used In Brazing Is.

From www.superradiatorcoils.com

Brazing Defects Flux Entrapment Overview and Causes The Super Blog The Flux Commonly Used In Brazing Is A flux is a chemical compound used in brazing operation to dissolve oxides which are formed on the surface of metal and filler rod. Brazing fluxes, which are mixtures of fluorides, borates, and boric acid, meet aws specification a5 31. The advantages of joining metals by brazing are that dissimilar metals and parts having a thin section can be joined. The Flux Commonly Used In Brazing Is.

From www.indiamart.com

Ewac Eutector Flux 1805 250 Gms Brazing Flux at best price in Indore The Flux Commonly Used In Brazing Is A chemical flux is commonly used with many braze filler metals. Brazing fluxes, which are mixtures of fluorides, borates, and boric acid, meet aws specification a5 31. 1) eliminate oxide films on metal surfaces, creating optimal conditions for wetting and spreading of the filler metal. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the. The Flux Commonly Used In Brazing Is.

From giomqnucr.blob.core.windows.net

Brazing Flux Meaning at Beatrice Kinyon blog The Flux Commonly Used In Brazing Is A flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when brazing. Brazing is used for the fastening of pipe fittings, and tanks, credible tips on tools, radiators, heat exchangers, and the repair of castings. 1) eliminate oxide films on metal surfaces, creating optimal conditions for wetting. The Flux Commonly Used In Brazing Is.

From giomqnucr.blob.core.windows.net

Brazing Flux Meaning at Beatrice Kinyon blog The Flux Commonly Used In Brazing Is The most common is class fb 3a, a white paste. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. 1) eliminate oxide films on metal surfaces, creating optimal conditions for wetting and spreading of the filler metal. A flux is a chemical compound used in brazing operation to dissolve oxides which are formed. The Flux Commonly Used In Brazing Is.

From www.mingledorffs.com

Soldering, Brazing, and Welding Mingledorff's The Flux Commonly Used In Brazing Is The advantages of joining metals by brazing are that dissimilar metals and parts having a thin section can be joined easily. Brazing is used for the fastening of pipe fittings, and tanks, credible tips on tools, radiators, heat exchangers, and the repair of castings. A chemical flux is commonly used with many braze filler metals. Flux is a chemical compound. The Flux Commonly Used In Brazing Is.

From www.hobbyistgeek.com

What Is Brazing Flux And How To Use It? The Flux Commonly Used In Brazing Is Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. The advantages of joining metals by brazing are that dissimilar metals and parts having a thin section can be joined easily. Brazing fluxes, which are mixtures of fluorides, borates, and boric acid, meet aws specification a5 31. A chemical flux is commonly used with. The Flux Commonly Used In Brazing Is.

From www.slideserve.com

PPT Brazing PowerPoint Presentation, free download ID5761358 The Flux Commonly Used In Brazing Is Brazing is used for the fastening of pipe fittings, and tanks, credible tips on tools, radiators, heat exchangers, and the repair of castings. The advantages of joining metals by brazing are that dissimilar metals and parts having a thin section can be joined easily. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow.. The Flux Commonly Used In Brazing Is.

From www.sarusilver.com

Brazing Flux Aluminium Brazing Flux, Brazing Flux Powder, Liquid Flux The Flux Commonly Used In Brazing Is A flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when brazing. Brazing is used for the fastening of pipe fittings, and tanks, credible tips on tools, radiators, heat exchangers, and the repair of castings. Function and performance requirements of brazing flux: Brazing fluxes, which are mixtures. The Flux Commonly Used In Brazing Is.

From giomqnucr.blob.core.windows.net

Brazing Flux Meaning at Beatrice Kinyon blog The Flux Commonly Used In Brazing Is Borax, either alone or in combination with other salts is commonly used in a flux. A flux is a chemical compound used in brazing operation to dissolve oxides which are formed on the surface of metal and filler rod. The most common is class fb 3a, a white paste. The advantages of joining metals by brazing are that dissimilar metals. The Flux Commonly Used In Brazing Is.

From weldingsuperstore.co.uk

Brazing Flux 100g Tub Welding Superstore The Flux Commonly Used In Brazing Is A flux is a chemical compound used in brazing operation to dissolve oxides which are formed on the surface of metal and filler rod. 1) eliminate oxide films on metal surfaces, creating optimal conditions for wetting and spreading of the filler metal. Function and performance requirements of brazing flux: Borax, either alone or in combination with other salts is commonly. The Flux Commonly Used In Brazing Is.

From www.seybusiness.com

Thermamax Brazing Flux SEYBUSINESS The Flux Commonly Used In Brazing Is Function and performance requirements of brazing flux: A chemical flux is commonly used with many braze filler metals. The most common is class fb 3a, a white paste. 1) eliminate oxide films on metal surfaces, creating optimal conditions for wetting and spreading of the filler metal. Flux is a chemical compound applied to the joint surfaces before brazing. Brazing fluxes,. The Flux Commonly Used In Brazing Is.

From www.indiamart.com

Brass Flux Brass Brazing Flux Powder at Rs 1200/kg Nanded Pune ID The Flux Commonly Used In Brazing Is Flux is a chemical compound applied to the joint surfaces before brazing. 1) eliminate oxide films on metal surfaces, creating optimal conditions for wetting and spreading of the filler metal. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. Brazing fluxes, which are mixtures of fluorides, borates, and boric acid, meet aws specification. The Flux Commonly Used In Brazing Is.

From www.cashbuildonline.co.za

Brazing Flux Cashbuild The Flux Commonly Used In Brazing Is Brazing fluxes, which are mixtures of fluorides, borates, and boric acid, meet aws specification a5 31. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. The advantages of joining metals by brazing are that dissimilar metals and parts having a thin section can be joined easily. A chemical flux is commonly used with. The Flux Commonly Used In Brazing Is.

From www.timesmojo.com

What flux is used for aluminum brazing? TimesMojo The Flux Commonly Used In Brazing Is Brazing fluxes, which are mixtures of fluorides, borates, and boric acid, meet aws specification a5 31. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. A flux is a chemical compound used in brazing operation to dissolve oxides which are formed on the surface of metal and filler rod. A chemical flux is. The Flux Commonly Used In Brazing Is.

From www.huaguangwelding.com

Fundamentals of Brazing Flux The Flux Commonly Used In Brazing Is Function and performance requirements of brazing flux: A flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when brazing. Proper fluxing is important because the flux absorbs oxides formed during heating and promotes the flow. 1) eliminate oxide films on metal surfaces, creating optimal conditions for wetting. The Flux Commonly Used In Brazing Is.

From www.focusweld.com

Brazing is a traditional metal joining process in which two or more The Flux Commonly Used In Brazing Is A flux is a chemical compound used in brazing operation to dissolve oxides which are formed on the surface of metal and filler rod. The most common is class fb 3a, a white paste. A flux is a mix of chemicals, fluorides, and fluoroborates, and must be used at the exact same temperature as the consumable alloy when brazing. Borax,. The Flux Commonly Used In Brazing Is.