Solder Joint Failure Analysis . Properly identifying and mitigating potential causes of solder joint failure during the design and manufacturing process can prevent. In thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and pcb and/or ic. As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and data analysis, and failure. Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. In this chapter, we evaluate the reliability of the produced solder. The finite element analysis revealed that the strain rate dependent material properties of the solder play the key role of solder joint failure. Solder joint is the dominant failure mechanism in solder joint interconnections.

from www.slideserve.com

Solder joint is the dominant failure mechanism in solder joint interconnections. In this chapter, we evaluate the reliability of the produced solder. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. The finite element analysis revealed that the strain rate dependent material properties of the solder play the key role of solder joint failure. Properly identifying and mitigating potential causes of solder joint failure during the design and manufacturing process can prevent. Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). In thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and pcb and/or ic. As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and data analysis, and failure.

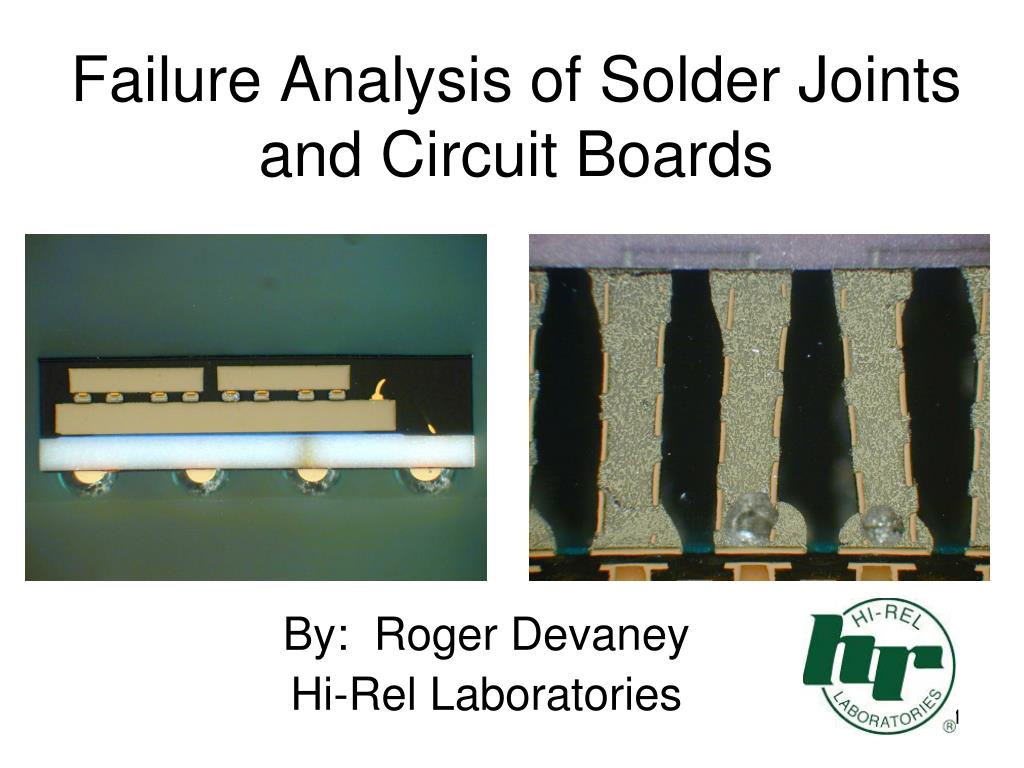

PPT Failure Analysis of Solder Joints and Circuit Boards PowerPoint

Solder Joint Failure Analysis In thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and pcb and/or ic. Properly identifying and mitigating potential causes of solder joint failure during the design and manufacturing process can prevent. Solder joint is the dominant failure mechanism in solder joint interconnections. In this chapter, we evaluate the reliability of the produced solder. The finite element analysis revealed that the strain rate dependent material properties of the solder play the key role of solder joint failure. In thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and pcb and/or ic. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and data analysis, and failure. Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb).

From www.semlab.com

BGA solder joint fracture SEM Lab Inc. Solder Joint Failure Analysis In this chapter, we evaluate the reliability of the produced solder. Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and data analysis, and failure.. Solder Joint Failure Analysis.

From www.mdpi.com

Applied Sciences Free FullText Critical Review of Size Effects on Solder Joint Failure Analysis The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. In thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and pcb and/or ic. As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and. Solder Joint Failure Analysis.

From www.researchgate.net

The typical failures of solder joints after the board level drop test Solder Joint Failure Analysis Properly identifying and mitigating potential causes of solder joint failure during the design and manufacturing process can prevent. In this chapter, we evaluate the reliability of the produced solder. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design. Solder Joint Failure Analysis.

From www.researchgate.net

(PDF) Analysis of solder joint failures arisen during the soldering process Solder Joint Failure Analysis The finite element analysis revealed that the strain rate dependent material properties of the solder play the key role of solder joint failure. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. In this chapter, we evaluate the reliability of the produced solder. Properly identifying and mitigating potential causes of solder joint failure during. Solder Joint Failure Analysis.

From www.researchgate.net

Solder joint progressive crack 17 mm BGA, V1. Download Scientific Diagram Solder Joint Failure Analysis The finite element analysis revealed that the strain rate dependent material properties of the solder play the key role of solder joint failure. Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). The characteristics of these three elements—component, substrate, and solder joint—together with the use. Solder Joint Failure Analysis.

From www.semlab.com

Suspected tin whisker 1 SEM Lab Inc. Solder Joint Failure Analysis In thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and pcb and/or ic. The finite element analysis revealed that the strain rate dependent material properties of the solder play the key role of solder joint failure. In this chapter, we evaluate the reliability of the produced solder. Solder joint. Solder Joint Failure Analysis.

From www.slideserve.com

PPT Failure Analysis of Solder Joints and Circuit Boards PowerPoint Solder Joint Failure Analysis In thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and pcb and/or ic. As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and data analysis, and failure. The characteristics of these three elements—component, substrate, and solder joint—together with. Solder Joint Failure Analysis.

From www.researchgate.net

Failure modes of solder joints (a,b) solder/IMC mode, (a1,b1) IMC Solder Joint Failure Analysis Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and data analysis, and failure. In this chapter, we evaluate the reliability of the produced solder.. Solder Joint Failure Analysis.

From www.slideserve.com

PPT Failure Analysis of Solder Joints and Circuit Boards PowerPoint Solder Joint Failure Analysis Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). Solder joint is the dominant failure mechanism in solder joint interconnections. In thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and pcb and/or ic. In. Solder Joint Failure Analysis.

From www.semlab.com

BGA Solder Joint Height SEM Lab Inc. Solder Joint Failure Analysis As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and data analysis, and failure. Solder joint is the dominant failure mechanism in solder joint interconnections. In this chapter, we evaluate the reliability of the produced solder. The finite element analysis revealed that the strain rate dependent material properties of. Solder Joint Failure Analysis.

From www.mdpi.com

Electronics Free FullText Survey on Fatigue Life Prediction of BGA Solder Joint Failure Analysis The finite element analysis revealed that the strain rate dependent material properties of the solder play the key role of solder joint failure. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit. Solder Joint Failure Analysis.

From www.slideserve.com

PPT Failure Analysis of Solder Joints and Circuit Boards PowerPoint Solder Joint Failure Analysis The finite element analysis revealed that the strain rate dependent material properties of the solder play the key role of solder joint failure. Solder joint is the dominant failure mechanism in solder joint interconnections. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. In this chapter, we evaluate the reliability of the produced solder.. Solder Joint Failure Analysis.

From calce.umd.edu

Concerned about fatigue failures in solder joints? That could depend on Solder Joint Failure Analysis Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). Properly identifying and mitigating potential causes of solder joint failure during the design and manufacturing process can prevent. In this chapter, we evaluate the reliability of the produced solder. The finite element analysis revealed that the. Solder Joint Failure Analysis.

From www.researchgate.net

(PDF) Failure Analysis of Solder Joints Solder Joint Failure Analysis Solder joint is the dominant failure mechanism in solder joint interconnections. Properly identifying and mitigating potential causes of solder joint failure during the design and manufacturing process can prevent. The finite element analysis revealed that the strain rate dependent material properties of the solder play the key role of solder joint failure. In this chapter, we evaluate the reliability of. Solder Joint Failure Analysis.

From www.semlab.com

Solder Joint Failure SEM Lab Inc. Solder Joint Failure Analysis The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. Properly identifying and mitigating potential causes of solder joint failure during the design and manufacturing process can prevent. Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). In thermal cycling,. Solder Joint Failure Analysis.

From www.mdpi.com

Materials Free FullText Study on Establishing Degradation Model of Solder Joint Failure Analysis As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and data analysis, and failure. Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). In this chapter, we evaluate the reliability of the produced solder.. Solder Joint Failure Analysis.

From www.semlab.com

Chip Resistor Solder Joint Failure SEM Lab Inc. Solder Joint Failure Analysis As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and data analysis, and failure. Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). Properly identifying and mitigating potential causes of solder joint failure during. Solder Joint Failure Analysis.

From www.mdpi.com

Crystals Free FullText Board Level Drop Test for Evaluating the Solder Joint Failure Analysis Properly identifying and mitigating potential causes of solder joint failure during the design and manufacturing process can prevent. Solder joint is the dominant failure mechanism in solder joint interconnections. As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and data analysis, and failure. The finite element analysis revealed that. Solder Joint Failure Analysis.

From www.semlab.com

BGA Failure SEM Lab Inc. Solder Joint Failure Analysis The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. In thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and pcb and/or ic. Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed. Solder Joint Failure Analysis.

From www.slideserve.com

PPT Failure Analysis of Solder Joints and Circuit Boards PowerPoint Solder Joint Failure Analysis The finite element analysis revealed that the strain rate dependent material properties of the solder play the key role of solder joint failure. Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). In thermal cycling, the main driver of solder joints failure is due to. Solder Joint Failure Analysis.

From www.researchgate.net

Procedure for assembling a single BGA structure solder joint by Solder Joint Failure Analysis Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and data analysis, and failure. Properly identifying and mitigating potential causes of solder joint failure during. Solder Joint Failure Analysis.

From www.slideserve.com

PPT Failure Analysis of Solder Joints and Circuit Boards PowerPoint Solder Joint Failure Analysis As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and data analysis, and failure. The finite element analysis revealed that the strain rate dependent material properties of the solder play the key role of solder joint failure. The characteristics of these three elements—component, substrate, and solder joint—together with the. Solder Joint Failure Analysis.

From www.researchgate.net

(PDF) Combined loading and failure analysis of leadfree solder joints Solder Joint Failure Analysis In thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and pcb and/or ic. As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and data analysis, and failure. The finite element analysis revealed that the strain rate dependent material. Solder Joint Failure Analysis.

From www.mdpi.com

Materials Free FullText Study on Establishing Degradation Model of Solder Joint Failure Analysis In thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and pcb and/or ic. Solder joint is the dominant failure mechanism in solder joint interconnections. Properly identifying and mitigating potential causes of solder joint failure during the design and manufacturing process can prevent. The characteristics of these three elements—component, substrate,. Solder Joint Failure Analysis.

From www.researchgate.net

Failure modes analysis for SAC305 solder joints CONCLUSION Two solder Solder Joint Failure Analysis Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). The finite element analysis revealed that the strain rate dependent material properties of the solder play the key role of solder joint failure. As mentioned earlier that reliability of solder joints consists of three major tasks,. Solder Joint Failure Analysis.

From www.slideserve.com

PPT Failure Analysis of Solder Joints and Circuit Boards PowerPoint Solder Joint Failure Analysis The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. Properly identifying and mitigating potential causes of solder joint failure during the design and manufacturing process can prevent. Solder joint is the dominant failure mechanism in solder joint interconnections. In thermal cycling, the main driver of solder joints failure is due to the mismatch in. Solder Joint Failure Analysis.

From hillmancurtis.com

IPCA610H Understanding the Acceptability of Electronic Assemblies Solder Joint Failure Analysis The finite element analysis revealed that the strain rate dependent material properties of the solder play the key role of solder joint failure. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. Properly identifying and mitigating potential causes of solder joint failure during the design and manufacturing process can prevent. In this chapter, we. Solder Joint Failure Analysis.

From fctsolder.com

How Does Printed Solder Paste Volume Affect Solder Joint Reliability Solder Joint Failure Analysis The finite element analysis revealed that the strain rate dependent material properties of the solder play the key role of solder joint failure. Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). As mentioned earlier that reliability of solder joints consists of three major tasks,. Solder Joint Failure Analysis.

From www.youtube.com

How to Spot a Bad Solder Joint YouTube Solder Joint Failure Analysis In this chapter, we evaluate the reliability of the produced solder. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. In thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and pcb and/or ic. Investigating the failure mechanism of solder joints under different temperature. Solder Joint Failure Analysis.

From www.researchgate.net

(PDF) Solder joint failure analysis using FEM techniques of a silicon Solder Joint Failure Analysis Solder joint is the dominant failure mechanism in solder joint interconnections. As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and data analysis, and failure. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. In thermal cycling, the main driver of solder joints. Solder Joint Failure Analysis.

From www.semlab.com

Solder Joint Analysis SEM Lab Inc. Solder Joint Failure Analysis In this chapter, we evaluate the reliability of the produced solder. Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and data analysis, and failure.. Solder Joint Failure Analysis.

From www.semlab.com

Solder Joint Failure Analysis SEM Lab Inc. Solder Joint Failure Analysis Properly identifying and mitigating potential causes of solder joint failure during the design and manufacturing process can prevent. Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). In this chapter, we evaluate the reliability of the produced solder. In thermal cycling, the main driver of. Solder Joint Failure Analysis.

From www.yumpu.com

Solder Joint & Interconnect Technology and Failure Analysis SMTA Solder Joint Failure Analysis In thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and pcb and/or ic. Investigating the failure mechanism of solder joints under different temperature conditions is significant to ensure the service life of a printed circuit board (pcb). Properly identifying and mitigating potential causes of solder joint failure during the. Solder Joint Failure Analysis.

From exoulvvjb.blob.core.windows.net

Solder Joint Failure Analysis at William Rodriguez blog Solder Joint Failure Analysis In this chapter, we evaluate the reliability of the produced solder. The characteristics of these three elements—component, substrate, and solder joint—together with the use conditions, the. As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability), reliability testing and data analysis, and failure. Solder joint is the dominant failure mechanism in solder. Solder Joint Failure Analysis.

From www.slideserve.com

PPT Failure Analysis of Solder Joints and Circuit Boards PowerPoint Solder Joint Failure Analysis In thermal cycling, the main driver of solder joints failure is due to the mismatch in cte between solder alloy and pcb and/or ic. Properly identifying and mitigating potential causes of solder joint failure during the design and manufacturing process can prevent. As mentioned earlier that reliability of solder joints consists of three major tasks, namely dfr (design for reliability),. Solder Joint Failure Analysis.